07/18/2021 6,483 VAZ 2109

Author: Ivan Baranov

Many owners of Russian-made cars are faced with the problem of the inability to start the car, and the reasons may be different. And quite often it happens that the VAZ 2109 does not start due to the fact that the car’s starter does not turn. You can learn more about this malfunction, as well as options for solving the problem, from this material.

[Hide]

Popular causes of malfunction

The most common reasons account for about 95% of all cases where the starter does not turn. That’s why we pay attention to them first.

The starter does not turn differently in different situations. It is important to take this into account and clearly monitor all associated symptoms. So, even without the help of specialists, you will be able to return the unit to operation and resume normal operation of the ignition system

| Situation | Probable Causes |

| There is one click, after which the starter goes silent. |

|

| Multiple clicks occur in succession |

|

| Clicks are completely absent, as are other signs of starter life. |

|

Bendix

Often, simply disassembling and cleaning the internal components of the starter can eliminate problems with its functionality. Therefore, after removing the device and not finding damaged elements inside it, try to thoroughly clean everything, assemble it and put it back in place. It is likely that the starter will start turning.

Bushings

Bushings (aka bearings) are located in front and behind the starter. They are responsible for rotating the device shaft. If these elements are worn out, the starter will start clicking, but will not turn. Problems with bushings can also be caused by the fact that the starter is installed incorrectly, that is, it does not occupy the desired position along the axis. Or the winding could short-circuit. In this case, see the previous paragraph.

Healthy! Also, problems with the bushings will be indicated by “heavy” cranking of the starter, even if the engine is well warmed up.

Although many do not consider bearing failure to be a serious failure, they need to be replaced. Otherwise, the starter shaft will jam, which in turn can cause a fire.

The starter does not turn over, what should I do?

In the life of owners of the VAZ-2114, and other cars close to this line (see above), sometimes such an unpleasant moment arises when you need to go somewhere, but it is not possible to start the power plant due to the fact that the starter does not turn the flywheel engine.

That is, when you turn the ignition key to the “start” position, nothing happens.

And if in the summer you can calmly look for the cause of the malfunction, then in the winter, in severe frost, you won’t spend much time searching for the malfunction. And in order to quickly fix a breakdown, you need to know where to look for it.

How to quickly start your car in cold weather, see below.

The starter clicks but does not turn in VAZ 21099

VAZ (Lada) 2108/2109 1984 - 2006

VAZ 21099. I drove up to the store and turned off the engine, after 5 minutes I left the store and the starter did not turn, just one click and that’s it. I sat in the car for about 10 minutes and turned the ignition key to the starter with the hope that the starter would still work, but it never did. As a result, I reached under the hood and directly closed the starter with a screwdriver. The starter worked the first time and the engine started. Why then was there only one click in response from the ignition switch and that was it?

- Loss of VAZ starter power – 5 answers

- Solenoid relay click and long reaction in 2108 – 5 answers

- How to determine whether the bendix or retractor on a VAZ 2108 is failing? – 5 answers

- VAZ 2109 does not start, the starter does not turn - 4 answers

- Problems with the supply of electricity to the starter - 4 answers

If every time you turn the key in the ignition switch with the ignition on in the starter cranking mode, a click is heard from under the hood and the starter does not start rotating, then the solenoid relay itself is to blame, inside of which the contacts of the moving or fixed group have burnt out. There are two options: replacing the relay, or disassembling it - cleaning the contacts, and possibly replacing them with new ones if they are worn out (burned out). How to do this, watch the video

In the video, the contact bolts are made of iron with copper soldering - this is frankly the rarest piece of junk. It is better to replace them with solid ones made of copper, since copper has better current conductivity and oxidation resistance. And on such contact bolts as in the video, the copper soldering may fall off due to heating when an electric current passes through them and the relay stops functioning. Or it may even create a short circuit inside the solenoid relay and the starter will turn even with the ignition key removed and can only be turned off by disconnecting the battery. + In addition, the appearance of rust on such bolts worsens the quality of contact, which in no way facilitates the passage of electric current through it.

Why is there no sound from the starter when I turn the key?

The design of the starter of any vehicle is a powerful electric motor, the power source of which is a car battery. Such an element is characterized by both mechanical damage caused by improper operation and natural wear of its component parts, as well as malfunctions associated with its electrical part. When no changes occur in the starting system of the power unit after turning the ignition key, the starter is silent, and its retractor relay does not make characteristic clicks, the following diagnostic measures must be carried out:

- Measure the power supply voltage

- Check the condition of the contacts in the ignition switch

- Perform a performance test on the solenoid relay

- Carry out diagnostics of the starter and its bendix

The condition of the lock contacts is checked by turning on the ignition using the key. The lighting of the indicators on the instrument panel is evidence of the working condition of the ignition switch, but if this does not happen, it is necessary to begin troubleshooting.

To check the battery, simply disconnect the negative terminal and measure the voltage of the power source using a voltmeter. If it is within 9V, the battery needs to be recharged, since its capacity is not enough to start the engine.

Clearly audible characteristic clicks in the area where the starter is located when starting the engine are produced by its traction relay. Note that the relay can click either when there is a fault in it or the starter itself, or when the power source is discharged, while the indicators on the instrument panel glow dimly or go out completely.

Causes of clicking noises when starting the engine, checking and solving the problem

Solenoid relay malfunctions

Thus, it is not difficult to think of reasons why the click of the retractor relay may not be accompanied by activation of the starter. The simplest of them is power problems: dead battery, oxidized terminals. At the moment when the solenoid relay turns on the starter winding, a sharp drop in voltage occurs, and with it, in strict accordance with Ohm’s law, the current in the holding winding. The energy of the magnetic field is no longer enough to counteract the retractor return spring, and the core moves outward, breaking the starter circuit. Depending on the condition of the car and the battery, this results in either a single click from the starter or a “machine-gun burst” of clicks from under the hood.

Therefore, the first thing you should check is the battery charge, inspect the terminals on the battery and, if necessary, clean them. Having already guaranteed the supply of electricity “as intended,” we proceed to further verification.

A few clicks

The VAZ 2109 starter does not work when you hear several clicks after you insert the key into the ignition and turn it. However, these few clicks immediately notify the driver of the cause of the breakdown:

- The holding winding began to weakly fix the core;

- Your battery is dead;

- The terminals are loose.

{banner_content}

To start

charge the battery

, because it very often leads to the car not starting. If this does not help, then check the winding and terminals. Both parts can be replaced very easily if you have the slightest understanding of your car's design and mechanics. However, every driver must know such basic things, otherwise you will often get stuck in the middle of the road.

Repair of a collapsible solenoid relay

The manufacturer equips starters with a non-separable or collapsible retractor device. If a non-separable relay breaks down, it must be replaced, but a dismountable relay can be repaired. The described method allows you to check the solenoid relay of all VAZ models: 2101, 2102, 2103, 2104, 2105, 2106, 2107, 2108, 2109, 21099, 2110, 2111, 2112, 2113, 2114, Niva, Lada Priora, Kalina, Granta, Vesta and most foreign cars. Disassembly and repair of the relay is carried out in the following order:

- Unscrew the nuts securing the housing cover.

- If necessary, the ends of the windings are additionally soldered.

- After removing the cover, inspect the power contacts:

- If they burn, the damaged part is cleaned with sandpaper;

- When worn out, replace.

- The device is assembled in the reverse order and tested for functionality.

- The repaired relay is installed back on the starter.

Every driver wants to drive a car that behaves predictably from the moment the key is turned in the ignition. But sometimes it is at this moment that troubles happen with the car. One of the culprits for this event may be the relay in the starter.

Before checking the starter solenoid relay, it is advisable to make sure that the diagnosis is unambiguous. To do this, a superficial check of the participating elements in the vehicle starting system is carried out.

Diagnosis of engine starting problems

The driver must make sure that the problem is solely a relay malfunction. To do this, you can conduct a visual inspection of the electrical wiring and measure the battery charge. If this circuit and all parameters are normal, then with a high degree of probability the breakdown lies in the starter relay.

The absence of clicking sounds from the starter indicates that the solenoid relay is not working. If switching on/off is heard, then the fault is outside the relay.

First you need to try again by turning the key in the ignition. Silence of the motor in response to these actions will lead to disassembly of the starter. But, before disassembling the starter solenoid relay, it must be removed from the engine compartment.

How to fix starter malfunctions with your own hands

The electrical component of the starter consists of the following structural elements:

- winding;

- brush assembly;

- solenoid relay.

When checking the solenoid relay, skip the starter operation, bypassing its switching. The relay has 3 terminals at once, one of which is the control terminal. The remaining 2 large terminals, located at the input to the battery and at the output of the starter, are closed using a screwdriver or wrench. Closing for a short period of time is enough, the main thing is that the tool you are using does not touch the metal body directly under the hood.

Observe the changes in the starter during the process of closing the terminals - if the device rotates, perhaps with a clearly audible crackling sound, then the fault is caused by the solenoid relay.

Remember that starting the engine in this way is prohibited, because the main gear of the device does not engage.

Most likely, the contact planes on the inner plane simply burned out, and therefore a dielectric layer of metal oxides formed on top. To burn the contacts, there is no need to make great efforts; just one start of the VAZ-2109 engine is enough.

There are 2 ways to repair the VAZ-2109 solenoid relay:

- Dismantle the device and disassemble it into components, clean the contacts.

- If it is financially possible, it is better to replace the relay completely. Practice shows that if a relay fails, the contacts will have to be cleaned more and more often to restore its operation. If you want the repaired relay to last a long time, give preference to this option for repairing the starter if the device does not spin or click.

Special cases

- Charge the battery.

- Clean and compress the contacts on the battery and starter.

- check the battery - close the contacts with a wire, a spark should appear that will melt it;

- pass the plus from the battery directly to the solenoid relay.

In the morning the starter turned, after 15 minutes I warmed up the car, then started it, but it didn’t move, the starter closed just a spark and silence, what should I do?

I installed a new relay. If the devices go off when you start them, then look at the wiring near the battery, if not, then look at the retractor, try tapping it well, if It’s just stuck, but sometimes it helps. And charge the battery well.

VAZ 2110 injector, started it on autostart, worked for 10 minutes and stalled. Now I can’t start, the starter doesn’t turn, can you tell me what’s the reason?

When you start it, the starter only makes a click, but if you connect it directly, it just turns.

Exal everything was normal and suddenly the car stalled, the panel went dark, then after 10 seconds everything turned on again, released the clutch, started. Everything is fine, I arrived, installed it, then started it, turned the key - the starter doesn’t turn, but turns straight.

The car was working normally, I came to put it in the garage, start it, but there was only a click and no movement, there was no current on the positive wire. What reasons could there be?

There may be no mass from the engine to the passenger compartment, the pigtail has broken

The starter stopped turning, everything else works. Start from the pusher, what could happen?

If it turns straight, there may be a problem with the mounting block or ignition switch. Check the voltage on the retractor, although it may be there, but the current strength is not enough to operate the relay.

The starter doesn't turn. You close the bolts - it turns, and starts with half a turn. He doesn’t want to use the key, the relay clicks once and there’s silence. What could be the matter?

Look, this thing is about the retractor :)

VAZ 2109 injector, this is the problem, started it half a turn, drove 30 km and the car stalled, all the devices went out, checked the wires on the generator, on the battery, but it didn’t help , a day later I started it at idle, it works, but when you give it gas it starts to burn! It worked for a little bit and stalled and all the devices went out again, no signs of life, tell me what could be the reason?

I started the car (2109i), drove for 1-2 km, and heard the sound of a tick-tick-tick. etc. almost at the same frequency, the speed was all right, after 500m I stopped, opened the hood (I didn’t turn off the car), there was a sound, then I turned off the car, tried to start it - no noise Lo, one click, the instrument panel lights up, no trills from the starter side, one click and silence, the towbar did not start (it was in 3rd gear, released the clutch - silence). The battery is normal, I cleaned the terminals, nothing, changed the battery - nothing. The idle speed sensor began to crackle every time I turned the key. I connected the starter directly to the battery - silence, changed the ignition relay - silence. The car has an immobilizer installed - it works now differently than before - When you turn the key so that the dashboard lights up, it should flash - it requires the key - now it just doesn’t flash, you take it out the key or in the “off” position the immobilizer diode lights up steadily. I blame him for now, maybe he blocked everything for me. There are no other explanations yet.

Why is it needed, its price, how much will the auto service charge for replacement, what malfunctions can arise, what the danger is, how to fix it, etc.

The door on the six closes with noise, and for this you need to make an effort? This article will tell you how you can get rid of the problem. This article talks about silent locks on the BAZ 2106. You will find out how much they cost and how to install them.

Where is it located (depending on the year of manufacture); when should it be changed and how to do it? And also get advice that will protect you from making a serious mistake.

Source: automanyak.com

Starter device, principle of its operation

The starter of the VAZ-2114 car (factory index - 5712.3708) is a DC power electric motor, additionally equipped with an overrunning clutch with a gear (Bendix) and a retractor relay.

The principle of its operation is very simple: when the ignition is turned on, voltage is supplied to the solenoid relay. Due to the creation of a magnetic field in it, the armature connected to the plug is retracted.

This fork moves the bendix along the rotor shaft of the electric motor and engages the gear with the flywheel ring gear.

In this case, the armature, fully entering the relay, closes the contacts, and voltage is already supplied to the electric motor itself, which is switched on.

The task of the overrunning clutch is also to protect the electric motor. After starting the power plant, the rotation speed of the flywheel significantly exceeds the speed of the gear. It turns out the opposite effect - the flywheel turns the gear.

And so that the force is not transmitted back, after exceeding the speed of rotation of the electric motor, the gear begins to rotate freely on the shaft until the driver turns off the power to the retractor relay, after which the spring returns the bendix to its original position, disengaging the gear.

Read more: Car starter design.

Checking with the starter removed using a multimeter

This test of the solenoid relay allows you to very accurately perform internal diagnostics and determine the condition of the windings and contacts. Dismantling the starter, depending on the make of the car, is carried out in various ways. For VAZ 2110, this procedure is carried out from below from the pit. Before unscrewing the fasteners, remove the wires (it is better to mark the terminals so as not to confuse them during assembly); you may need to remove the crankcase protection.

To begin with, voltage is applied from the battery to the body and terminals of the relay; operation is accompanied by a characteristic click and visible movement of the rod. Further checks are carried out using a multimeter, which is switched to resistance measurement mode and the range of 200 Ohms is selected.

Video: Checking the starter removed from the car

First, check the serviceability of the retractor and retention coils. To do this, one of the probes is connected to ground, the second touches the contacts in succession. The device readings are 2 ohms. Deviation of the device readings from the specified value is a sign of a break or short circuit. To check the power contacts, remove the core from the relay body and remove the return spring, after which the core is inserted back. The core rod is pressed against the table with a certain force and the resistance between the contacts is replaced. The resistance is approximately 1.5 ohms.

VAZ 21099 carburetor does not start List of popular reasons and repair methods

- There is no voltage from the battery to the starter;

- Check the indicator on the battery; it should light green.

- If it is black or red, it means the charge is very low and you need to recharge the battery. 20-25 minutes are enough to start the engine;

- The degree of wear of the graphite rod on the distributor of the trampler has exceeded the permissible standards, as a result of which current does not flow to the first cylinder and the mixture cannot ignite;

- We unscrew the cover of the distributor and look at the rod, it is centered inside. The minimum length should be 1.0 cm or more, if less, replace the tamper cover. Due to the fact that the graphite rod does not reach the distributor, the current is not transmitted to the spark plugs and, accordingly, there is no ignition.

- The throttle valve is closed and air does not enter the working chambers of the carburetor;

- Check the tension of the choke cable. The air damper rod must be strictly vertical; all other positions may overlap it and become a barrier to air. Press out the bolt and straighten the rod.

- The fine filter of the fuel system is very dirty and does not allow gasoline to pass into the combustion chamber in the required quantity;

- Look at the filter color. If it is a rough orange color, it needs to be changed because it is clogged. The optimal color is light yellow.

- The coil on the ignition coil is damaged, causing the spark plugs to not receive the spark that is the source of ignition. See the article “How to test the ignition coil with a multimeter”;

- Proceed as follows: disconnect the positive cable on the battery, unscrew the top part of the ceramic block on the coil and you will see a metal spiral. If there is damage, the entire ceramic module must be replaced. There are no other options. It is strictly forbidden to use soldering, it will not help.

- The fuel and/or air jets are clogged and cannot transfer the mixture to the combustion chamber;

- You can only check by unscrewing the air filter cover and removing it along with the top carburetor cover. After unscrewing both types of jets, blow them with a stream of compressed air and screw them back in. There is no need to change.

- The line of the electrical cable that transmits current through the circuit is damaged;

- If you are not an electrician, then it will be difficult for you to determine which wire is damaged. Try only with the tester, starting from the ignition switch;

- There is no gasoline in the gas tank (for example, it was drained);

- The diaphragm in the fuel pump does not work or is damaged (see signs of a faulty fuel pump);

- Only by removing the top cover of the fuel pump can you understand the degree of integrity of the diaphragm. Replace if damaged.

- The cam on the fuel pump rod is damaged or severely worn, as a result of which the rocker rod does not touch it and fuel is not pumped into the system;

- In this case, it is necessary to change only the entire fuel pump as a whole. Once a cam wears out, it cannot be repaired.

- The air filter is clogged;

- The cylinder head is broken, and as a result, the compression level has dropped sharply and is not enough to ignite the mixture.

AutoFlit.ru

Improvement of the starter blocking relay and contact protection in VAZ 2110, 2111, 2112

Based on the operating experience of VAZ (first the classic 21011, then 2111), it has long been noticed that very often the ignition switch contacts (ISC) that control the starter solenoid relay burn out and become unusable. The current through these contacts reaches 20A. We have to replace the entire contact group. So I decided to fix this problem immediately on a new machine, without waiting for it to appear. A common option is to install an additional relay in the power circuit and control it with 3Z contacts. Everything is simple, but as it turned out, this is not at all necessary, because... you can use an existing starter interlock relay, retaining its original functions completely. As analysis of the circuit showed, the starter lock relay is powered from +12V from the main relay of the ECU, and the minus is supplied from pin 50 of the ECU (January 7.2), and is controlled by an “open collector” key in the ECU. When the ignition is turned on, the ECU sets the “low level” (shorts to ground) on contact 86 of the locking relay. The relay is activated, completing the circuit between the ignition switch and the starter solenoid relay. When you turn the key ZZ from pin “50”, 12V is supplied to the starter solenoid relay. As soon as the engine starts, the ECU removes the signal from pin 86 of the relay, it is de-energized, breaking the circuit, and thereby blocking the starter. The blocking works! Fig. 1 shows a fragment of the circuit in the basic version, and Fig. 2 - after modification. As you can see, the changes are minimal: 1. The pink-black wire is disconnected from the pin. "85" and isolated; 2. The power wire from the ignition switch is connected to pin. “85” relay 3. Added a power wire (30 cm) from the connector from which the CB is powered (2-pin connector to the front harness) - with a cross-section of at least 4 mm2, connected to the pin. 87 relays. Now the power circuit is controlled through a relay, and the current through the 3Z contacts does not exceed 0.2A. The modification was completed in 2009. Pros: minimal alterations, no need for another relay, saving space in the control unit Cons: not found in 6 years.

Below is a fragment of the diagram.

Well, the final option. Starter relay and additional relay for “unloading” the ignition switch contacts

Similar articles

Lada Kalina fuel pump relay where is the photo

The final diagram with unloading of the lock contacts along the ignition circuit

But that's not all! The next weak point: the power contacts of the starter solenoid relay. Due to high currents, they receive an even greater electrical load, and as a result, erosion. You can protect them from sparking, especially when opening, by connecting one powerful diode in parallel with the starter and the control winding of the solenoid relay. The essence of the modification is to suppress the “self-induced emf” - the main cause of contact burnout. I used fairly common diodes, KD2998 - high pulsed and direct current, and they had sufficient quantities on hand. You can use rectifier diodes from computer power supplies rated for a forward current of at least 30A. The diodes are placed in 2 layers of heat shrink and connected directly to the starter on short wires. The connection diagram is shown.

Elimination of voltage drop in VAZ 2110, 2111, 2112

Much has been written about the rather unsuccessful and dim rear lights of the VAZ-2111. This problem becomes especially relevant

Connection diagram

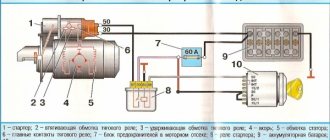

Now let's talk about how to connect the starter to the car's electrical network. Let's look at the connection diagram somewhat simplified.

Since the electric starter motor of the VAZ 2114 and other cars is a power motor, a significant amount of energy is consumed, which is supplied from the battery. Essentially, the device is the main consumer.

And to ensure maximum energy output, the battery and starter are connected directly to each other by a “positive” wire of a large cross-section.

This wire goes from the battery terminal to one of the solenoid relay terminals.

The second terminal of this relay is connected to the electric motor. To ensure that the electric motor runs only when needed, there is an open circuit between these terminals.

There is also another “positive” wire in the circuit, which goes from the battery to the ignition switch and is intended to power the auxiliary relay itself. Additionally, the circuit includes a mounting block and fuses.

Knowing the connection diagram, you can understand how everything works. By turning the key to the “start” position, the driver closes the relay power circuit and voltage is applied to its winding, resulting in the formation of a magnetic field that acts on the armature.

That, in turn, after moving, eliminates the circuit break between the relay contacts, and the energy is supplied to the electric motor.

Rare situations

They happen noticeably less frequently than those we described above. But under no circumstances should we exclude them.

After reviewing the situations below, compare them with the behavior of your starter and a car that has stopped turning or clicks but does not turn.

- With an injection engine at a frosty temperature of about -20 degrees Celsius, all devices function. This indicates that the battery is fully charged. At the same time, for some reason the starter refuses to turn. Your actions:

- If there are no clicks when you try to start the engine, check the condition of the fuse, wiring and solenoid relay;

- If there is a clicking noise, the most likely source of the problem is the solenoid relay. It must be replaced.

- The engine started normally throughout the day, but in the evening it suddenly stopped working normally. When you turn the key in the ignition switch, there is only a click, but the starter does not turn. When you try to start the engine several times in a row, several clicks are heard. Your actions: Charge the battery;

- Crimp, strip and tighten the contacts on the starter and battery;

- If the first two points do not produce results, check the battery itself. To do this, the wire closes its contacts. If the battery is working properly, a spark will appear that melts the wire;

- Connect the plus from the battery directly to the solenoid relay. If the starter is silent, replace the starter.

car battery

- During the day the car started without problems. But after being idle for several minutes, attempts to start the car fail. When you turn the key, the relay is activated, but the starter stubbornly refuses to turn. By closing the two bolts of the solenoid relay, everything started. We reached our destination, stopped, and turned off the engine. When I try to start again, the same situation occurs. Just locking the bolts no longer works. Your actions:

- Disassemble the starter housing;

- Check the condition of the brushes. There is a high probability that they have been completely erased. Hence this effect;

- Replace the brushes with new ones. This is cheaper than completely replacing the unit.

- The starter doesn't turn over. When you try to close it, only noise arises, like when a drill is working. The engine shows no signs of life. But it was possible to start it from the pushrod without any problems. Your actions:

- Make sure your starter is working properly;

- If everything is fine with it, go to the mounting block and check the fuses;

- Also examine the condition of the ignition switch. It is possible that the problem is with him;

- Do not forget to check the wiring for breaks and short circuits;

- Check the status of the contacts. It’s not uncommon that minus does not reach the starter relay only for the banal reason of oxidation or burnt wire.

Having understood the reasons for the failure of the starter, you can bring the device back to life on your own. Don't rush to throw away your old starter and buy a new one. The practice of VAZ 2109 owners shows that partial repairs, and sometimes even simple cleaning of the device, make it possible to restore the functionality of one of the main elements of the ignition system for a long time.

Source: luxvaz.ru

Device

- retaining ring

- restrictor ring

- overrunning clutch drive

- lever axis

- front cover

- drive lever

- armature relay

- traction relay

- back cover

- protective cover

- lock washer

- pinch bolt

- shim

- brush spring

- brush

- frame

- anchor

The starter on the “Nine” does not turn: we are looking for the cause and a way to eliminate it

Many owners of Russian-made cars are faced with the problem of the inability to start the car, and the reasons may be different. And quite often it happens that the VAZ 2109 does not start due to the fact that the car’s starter does not turn. You can learn more about this malfunction, as well as options for solving the problem, from this material.

The main relay of the VAZ 2110 does not turn on

Three reasons why the car's main relay does not turn on.

In this material we are talking about a car with an injection engine. Let's say the following happens: you turn on the ignition, as a result, electric current begins to flow to the controller output connected to it. At the same time, the main relay should turn on, after which power will begin to flow according to the electrical circuit to other objects consuming it. But the main relay does not turn on... The consequences of this malfunction are always noticeable. The engine simply won’t start in such a situation because there is no power supplied to either its injectors, the ignition system, or the relay that ensures the operation of the fuel pump, and so on.

Typically, for most modifications of VAZ cars, the main relay is located approximately in the same place where the fuses and relays for the radiator cooling fan and fuel pump are located, that is, in the cabin, on a shelf located on the right under the control panel, closer to the passenger seat. To find the main relay in a GAZ car, you will have to open the hood and look down at the front stack of the cabin opposite the passenger seat.

So, let's consider a situation in which you turned on the ignition, but did not hear the sound that accompanies the relay turning on. This means that the first thing you need to do is make sure that electric current is present at the contacts corresponding to this relay - Nos. 85 - 86. To do this, you need to use a test lamp that consumes no more than 0.25A, connected to the negative which should light up when the ignition is turned on. If, as a result of testing, you find that there is no light in the control lamp, this means that no electric current is supplied to the main relay.

The causes of the malfunction may be the following: Firstly, the contact between the main relay and its well is broken. Secondly, the integrity of the wiring in the area between the controller and the relay or between the “minus” and the motor housing is broken. If the wiring is in order, then look for the third reason. Thirdly, the controller failed. For GAZ cars, this is a very typical malfunction when, as a result of moisture or a break in the negative wire, the controller stops working. Now let's consider another situation in which you turned on the ignition and heard a characteristic sound that accompanies the activation of the relay, but this in fact does not happen. In this case, check for power supply at pins No. 30 and No. 87.

The causes of the malfunction may be the following: Firstly, if after testing with a test lamp, one terminal of which is connected to the minus, and the second touches connector No. 87, the light in the lamp does not light up, then the cause of the failure may be an outdated fuse or leaky wiring . Secondly, if the contact of the lamp terminal with connector No. 87 lights the light bulb, but with connector No. 30 it does not, then the cause of the malfunction is in the relay itself. Perhaps its contacts have already burned out and it needs to be replaced. In various modifications of the VAZ, the old relay can be replaced with any other one available on the mounting block, be it a turn signal relay or other light signals.

There is another reason why the main relay may not work when the ignition is turned on, but this has nothing to do with the breakdown. The point, in this case, lies in the connection diagram of the anti-theft system, which provides for blocking the electrical circuit in many situations that are suspicious, according to the security program installed. Perhaps there was a malfunction in the system, or perhaps during your absence, someone disturbed the system and it turned on the lock, so the main relay did not work.

2011-2016 - Information agency pokatim.ru - car news, car market news, car accessories, foreign and Russian cars, photos and videos of cars, car tuning. Reproduction of materials from the news agency’s website is permitted only with the condition of installing an active hyperlink to pokatim.ru

How to charge the battery in a VAZ-2109

If the starter malfunction is due to lack of battery charge, start charging the device. To properly charge the battery, carry out the procedure in a ventilated room. It is not necessary to remove the unit from the car; the process can take place directly in the VAZ-2109. When charging the battery, follow these requirements:

- Disconnect all electrical cables.

- Immediately before charging, carefully clean the terminals from adhering dirt and dust, paying special attention to oxidized areas.

- It is advisable to completely discharge the battery before charging - to do this, turn on all electrically powered devices.

- Observe the movements of the ammeter needle; it should approach the zero mark.

- Monitor the temperature of the electrolyte - it will increase during charging. For example, the temperature of the electrolyte has increased to 40 degrees, then the current should be halved. If within 2 hours the density of the electrolyte and the battery voltage in the VAZ-2109 remain unchanged, it means that the battery is fully charged.

Typically, 10-12 hours are enough to charge the battery. Please note that in the summer the electrolyte in the VAZ-2109 heats up at an accelerated pace, so the car owner’s task is to regularly check the density and level of the material.

Check and replacement

If the car shows signs of malfunction, there are signs of breakdown of elements of the ignition system, do not rush to immediately blame the starter or module for everything. Often the culprit may be an element that is insignificant in size and cost - the relay.

Dismantling works

To check the relay you need:

- Arm yourself with an ohmmeter or a multimeter more suitable for a motorist, which has all the necessary modes;

- Check resistance indicators;

- We check the holding coil by connecting one terminal of the tester to the relay connection terminal, and the second to ground, that is, the housing;

- Next, the pull-in winding is checked. Here the terminals are connected to the starter motor field winding connection bolt and the control wire connection bolt;

- If there is no resistance, there is only one output - failure.

Checking with a multimeter

Repairing the ignition switch does not make any sense. The element can only be replaced. Plus, it costs pennies.

To replace, you will need to perform a few simple steps. You don't have to be a car repairman here.

- Disconnect the battery by removing the negative terminal.

- Using a slotted screwdriver, unscrew the four screws on the steering column housing. This will allow you to easily remove the element.

- Using a Phillips screwdriver, unscrew another screw that holds the bottom of the casing in place.

- Remove the steering column protective cover.

- At the bottom there is a block of the harness with wires where the ignition relay is connected.

- To replace the relay, you simply need to disconnect the device from the block and install a new element in its place.

- Check the performance of the car with a new transmission.

As you can see, there is nothing difficult about checking and replacing the device. It does not fail very often, but it is worth monitoring the condition of the ignition relay.

Loading …

Forced starting of the starter by closing the contacts

In order to put knowledge into practice, you will need the help of a partner (preferably) and a long screwdriver or wrench. The idea is that the metal base of the tool needs to close the power contacts of the starter and apply voltage to its winding directly.

Before starting work, it is extremely important to check the gear shift lever. It should be in a neutral position. The handbrake lever should be raised and locked as much as possible.

A spark may occur

Alternative methods (if there is no key)

In addition to this method, there are several more. One of them involves starting the starter from the passenger compartment. To do this, you will need to remove the plastic panel located under the steering wheel of the car. Separate the bundle of wires going to the ignition switch from it.

Disassembling the steering column mechanism

First of all, we are interested in the wire going to ground (black or green, sometimes yellow with a black stripe). You can correctly determine whether it is correct or not using a multimeter. To do this, the tip is connected to the one we are interested in, the second to the body of the machine. A zero on the device screen will confirm that this is the correct wire. Its stripped end is isolated and moved to the side.

Power on the VAZ-2114 car is supplied by a red or yellow wire, but it is best to check this with a multimeter.

The one responsible for the starter is determined as follows: the power wire is closed with the remaining ones. The one from which the mechanism will work and will be its supply wire.

The remaining beam is connected to the positive one, after which it is struck with the “starter” one. If determined correctly, the engine should start. It is extremely important when starting in this way, not to short-circuit the wires for a long time, as this will discharge very quickly.

Important! When starting the starter, the car must be in neutral and have the handbrake applied.

Push launch (classic)

The starter spins for a long time before starting

The starter clicks but does not turn, what is the reason?

Good afternoon. Many car enthusiasts are familiar with the situation when the starter clicks but does not turn. As luck would have it, such situations happen at the most inconvenient moments, for example, at gas stations or when leaving for work.

In today's article, we will tell you how to determine the malfunction and, if possible, start the car to get to the repair site.

Before telling the troubleshooting algorithm, let's look at the starter device. For clarity, watch this video:

As you can see, the starter is a regular DC motor and relay. When you turn the key in the ignition and hear a click, it is the solenoid relay that clicks (the coil and contacts at the top of the screen in the video). If the starter does not rotate, but clicks, the following options are possible:

- The battery is dead.

- starter relay failed

- The contact coins in the solenoid relay are burnt.

- The starter brushes are worn.

- the starter armature is jammed.

- power plus is not supplied to the starter (because if there is no mass there will not even be retractor clicks)

Below we will analyze each of these faults in detail, and tell you which faults will allow you to start the car on the spot, using the existing starter, in order to get to the service station.

A severely discharged battery is the most common cause of clicking noises when turning the ignition key.

The error looks like this:

In our video you can see that when starting, at first, the starter barely turns the engine, and then it just crackles…. If the battery is severely discharged, the starter will not even try to crank the engine but will immediately make nasty clicking noises.

The fact is that the battery voltage is not enough even to operate the solenoid relay!

Options to solve the problem:

- light a cigarette from another car (we have a separate article about this on our website).

- start the car from a pusher/tug (if it has a manual transmission).

- remove and charge the battery.

Your starter is working!

Starter relay failure.

Relay failure manifests itself as a quiet click when turning the key.

In this case, you can start the car using a simple screwdriver. This is done like this:

Attention! If you are not confident in your abilities, you should not do this. It is better to contact specialists or call a tow truck. If you make a mistake when starting this way, the vehicle may move unintentionally or catch fire due to a short circuit.

Vehicle with manual transmission:

- set the parking brake.

- turn on neutral gear.

- open the hood and prepare a flathead screwdriver.

- turn the key in the ignition switch to the ignition on position.

- Using a screwdriver, we close two contacts on the solenoid relay (as in the video).

- After starting the engine, remove the screwdriver and drive to the repair site.

Car with automatic (+variator and robot) gearbox:

- install a car parking brake (for robot and variator).

- open the hood and prepare a screwdriver (possibly two).

- turn the ignition to the on position, press the brake, move the gear selector to the parking position (P).

- Using a screwdriver, we close two contacts on the solenoid relay (as in the video).

- After starting the engine, remove the screwdriver and drive to the repair site.

The contact coins in the solenoid relay are burnt.

This malfunction manifests itself in the form of loud clicks when the key is turned to the start position and the key is released. In some cases, the starter may trip.

Here is a video example of such a malfunction:

How to quickly diagnose contact patches?

Everything is extremely simple - open the hood, take a screwdriver, and bridge these two terminals:

Starter bushings

Another reason could be worn copper-graphite bushings on which the rotor rests. One of them is pressed into the rear housing cover, where the brushes of the electric motor itself are located, and the front end of the rotor rests on a bushing, which is pressed into a hole in the clutch housing or in the starter housing itself, if the structure is closed.

The first option has almost gone out of use, because the bushing located in the clutch housing quickly breaks, the rotor begins to rotate misaligned and quickly becomes unusable. The second option is widespread almost everywhere, and bushings in this version are much more durable.

However, they also wear out over time and play appears, which eventually leads to jamming.

General reasons why the VAZ 2109 starter does not turn

- There is only one click, and then silence.

- You hear several clicks in succession.

- There are no clicks or other signs of life.

- The power bolts on the retractor relay - they were burnt. Because of this, a voltage of less than the required 12 volts reaches it.

- The fork pushing out the Bendix – it could have broken or been somehow deformed. Because of this, the Bendix does not fully reach the flywheel, the cores only partially enter the coil, and the contacts open.

- In the Bendix - the teeth on it were worn out. Therefore, there is no voltage from the solenoid relay at the starter.

- Armature brushes or bushings - they are worn out.

- Winding short circuit.

- The battery is dead.

- Its terminals - they have become sour or weakened.

- Holding winding - it poorly fixes the core, which is retracted by the retracting winding.

- Short circuit of the winding - in this case you should smell a burning smell and see smoke.

- The ring located in the starter reducer - it has collapsed.

- The key is to try to replace it.