VAZ 2108, 2109, 21099 cars have a dial gauge for the coolant temperature in the instrument panel.

Connection diagram for the coolant temperature indicator sensor in the cooling system of VAZ 2108, 2109, 21099 cars up to 1998. with mounting block 17.3722 and “low” instrument panel

Connection diagram for the coolant temperature indicator sensor in the cooling system of VAZ 2108, 2109, 21099 cars after 1998. with mounting block 2114 and “high” instrument panel

Notes and additions

— The cooling system of carburetor engines of VAZ 2108, 2109, 21099 cars is equipped with another temperature sensor - the cooling system fan switch sensor (TM-108). It is installed in the radiator tank and its signal turns on the radiator fan.

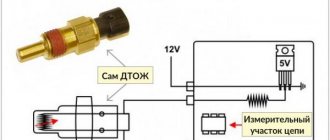

— The cooling system of an injection engine also has a coolant temperature indicator sensor. The control function of turning on the fan is carried out by the control unit (ECU) based on a signal from the coolant temperature sensor (DTOZH), installed in the pipe near the thermostat.

More articles on the engine cooling system of VAZ 2108, 2109, 21099 cars

Generator connection diagram: 1 – battery; 2 – generator; 3 – voltage regulator; 4 – ignition switch (lock); 5 – fuse block; 6 – battery charge indicator lamp; 7 – battery charge warning lamp relay

Starter connection diagram: 1 – starter; 2 – battery; 3 – generator; 4 – ignition switch (lock); P1 – relay pull-in coil; P2 – relay holding coil

Diagram of the contact ignition system: 1 – spark plugs; 2 – ignition distributor; 3 – ignition coil; 4 – ignition switch (lock); 5 – generator; 6 – battery

Diagram of a contactless ignition system: 1 – battery; 2 – generator; 3 – ignition switch (lock); 4 – ignition coil; 5 – switch; 6 – ignition distributor sensor; 7 – spark plugs

Connection diagram of the carburetor solenoid valve control system 21053-1107010: 1 – carburetor limit switch; 2 – solenoid valve; 3 – control unit; 4 – ignition coil; 5 – switch; 6 – ignition switch (lock)

Diagram of the alarm system and direction indicators: 1 – direction indicator lamps in the front lights; 2 – battery; 3 – generator; 4 – side direction indicators; 5 – main fuse block; 6 – additional fuse block; 7 – ignition switch (lock); 8 – alarm switch; 9 – direction indicator switch; 10 – relay-interrupter for direction indicators and hazard warning lights; 11 – speedometer with indicator lamp for turning on the direction indicators; 12 – direction indicator lamps in the rear lights

Scheme for switching on sound signals: 1 – sound signals; 2 – relay for turning on sound signals; 3 – sound signal switch; 4 – fuse block; 5 – generator; 6 – battery

What is a temperature sensor used for?

The main function of the “six” temperature sensor is to control the heating of antifreeze in the engine and display information on the car’s dashboard. However, the functions of such sensors are not limited to this.

In addition, the sensor is connected to the vehicle control unit. Engine temperature data is also transmitted there. And the block, in turn, makes corrections when supplying the fuel mixture to the engine, depending on the temperature obtained. For example, if the engine is cold, then the control unit, based on previously received data, will set a rich fuel mixture. This will make it easier for the driver to start the car. And when the engine warms up, the control unit will make the mixture leaner so that the car does not suddenly stall. That is, not only the driver’s awareness of the condition of the engine, but also fuel consumption depends on the correct operation of the antifreeze sensor.

How does a temperature sensor work on a VAZ 2106

The main element of the sensor is a thermistor. Depending on the temperature, the resistance of the thermistor may change. The thermistor is installed in a sealed brass housing. The resistor contacts are located on the outside of the housing. In addition, the body has a thread that allows you to screw the sensor into a standard socket. There are two contacts on the sensor. The first one connects to the car's electronic unit. The second is to the so-called mass.

For the thermistor in the sensor to operate, a voltage of five volts must be applied to it. It is supplied from the electronic unit. And voltage stability is ensured by a separate resistor in the electronic unit. This resistor has a constant resistance. As soon as the temperature of the antifreeze in the engine increases, the resistance of the thermistor begins to drop.

The voltage supplied to the thermistor also drops sharply. Having detected a decrease in voltage, the control unit calculates the temperature of the motor and displays the resulting figure on the dashboard.

Where is the temperature sensor located?

On the VAZ 2106, temperature sensors are almost always installed in sockets on the cylinder blocks.

In later models of “sixes” there are sensors installed in thermostat housings, but this is very rare.

This sensor on almost all cars is located next to the pipe through which hot antifreeze goes into the radiator. This arrangement allows you to take the most accurate temperature readings.

Pointer functions and operation

The purpose of the device, built into the dashboard to the left of the tachometer, is to display the engine oil pressure level, guided by the sensor. The principle of operation of the pointer resembles the operation of a conventional ammeter, which responds to changes in current strength in the circuit. When the mechanical rheostat inside the measuring element changes resistance, the current increases or decreases, deflecting the needle. The scale is graduated in pressure units corresponding to 1 Bar (1 kgf/cm2).

The pointer indicator reacts to changes in the resistance of the electrical circuit created by the sensor

The device consists of the following main elements:

- round body;

- pointer mechanism with permanent magnet and windings;

- a control light connected to the corresponding sensor by a separate line;

- scale with backlight;

- compensation resistor;

- connecting wires with connector.

The pointer is connected to the sensors, ignition switch and dimensions to illuminate the scale

Zero readings of the device correspond to a circuit resistance of 320 Ohms. When it drops to 100-130 Ohms, the needle stays at 4 Bar, 60-80 Ohms - 6 Bar.

If the arrow does not show pressure at idle, it is worth checking the functionality of the device

The Zhiguli engine lubrication pressure indicator is a fairly reliable element that breaks very rarely. If the arrow does not want to leave the zero mark, then the culprit is usually the sensor. When you doubt the functionality of the indicating device, check it using a simple method: measure the voltage at the connection contacts of the MM393A oil sensor with the engine running. If voltage is present and the needle is at zero, the device should be changed.

The VAZ 2106 oil pressure monitoring system with two sensors and a mechanical indicator is simple and reliable in operation. Despite the outdated design, car enthusiasts often buy and install these meters on other, more modern cars, equipped from the factory with only a control indicator. Examples are the updated VAZ Seven, Chevrolet Aveo and Niva.

For normal operation of the VAZ-2106 cooling temperature sensor, a voltage of 5 V is required. Since the thermistor has a negative temperature coefficient, as the antifreeze heats up, the resistance on the sensor will drop. Accordingly, the tension will decrease. The instrument panel determines the temperature based on the level of voltage drop.

In different VAZ models, the sensor can be located in different places - in the cylinder head, in the thermostat housing or on its body. The element must be placed in the area of the outlet hose, which is needed for the passage of fluid into the radiator. In the VAZ-2106, DTOZH can be found in the cylinder head.

Signs of sensor failure

It is generally accepted that the temperature sensor on the VAZ 2106 is a reliable device, since its design is very simple. However, problems may occur. As a rule, all problems are associated with changes in the resistance of the thermistor. Due to the changed resistance, the operation of the electronic unit is disrupted, which receives erroneous data and cannot correctly influence the preparation of the fuel mixture. You can understand that the sensor is faulty by the following signs:

- severe oxidation of the sensor housing. As mentioned above, sensor housings are usually made of brass. This is a copper based alloy. If the driver, having unscrewed the sensor from its socket, found a green coating on it, then the cause of the breakdown has been found;

With all of the above problems, the driver will have to change the temperature sensor. It cannot be repaired, so going to an auto parts store and replacing the device is the only rational option. The price of sensors for a VAZ 2106 starts from 200 rubles.

Temperature sensor of VAZ 2107 does not work

Sensor (counter, then controller) indicating water-cooled engine (DTO)

To prevent the car's engine from boiling, VAZ 2107 sensors are built into its cooling system. The first indicates heating of the water, the second includes a fan for additional purging of the engine. If the temperature regulator gives incorrect readings, the VAZ 2107 cooling water temperature sensor is replaced. Change. this is such a normal procedure that you don't even have to think about passing 100. Checking and changing hands will take 5-7 minutes and will save you a lot of time and money.

Diagnosis of errors

The indicator on the panel reports engine overheating (boiling), but external signs of engine heating are absolutely normal, and there is nothing that suggests boiling, perhaps the sensor is just lying there (DOTJ). The situation is even worse, when the engine "boils", the indicator on the control panel indicates normal temperature, the reason is the same, you just need to wait until the engine cools down and add fluid (great if there is a supply). So:

- If you suspect that the controller (DOTH) on your AvtoVAZ 2107 is giving false evidence of heating water in the cooling system, then you need to check its operation on a heated engine.

- Turn on the ignition, remove the end of the wire from the water temperature meter and close it to the motor housing.

- At the same time, if the heat indicator needle on the instrument panel is deflected to the right into the reddish area, the cooling water temperature (abbreviated as DOT) meter is faulty.

- If the arrow does not move, it means an open circuit

The water temperature (heating) indicator in the water cooling system on the unit panel (photo below) is located at the bottom left.

At the bottom left you see the water heating indicator in the cooling system

- White sector. cool engine;

- Greenish sector. this is the normal temperature of a running engine;

- Reddened sector. The engine began to boil (overheat).

tools

- A 21mm socket wrench or the deepest 21mm socket also fits the spark plug wrench

- Tank for draining water from the cooling system

- New meter

How to replace the coolant temperature sensor on a VAZ 2107

- The heat meter is located on the engine head behind the fourth cylinder on the left.

- Disconnect the negative cable from the battery terminal.

- Drain the coolant from the cylinder block (so that its level is below the heat meter level).

- After removing the protective cap, disconnect the wire from the water temperature sensor in the cooling system.

- Using a 21mm wrench (deep or spark plug), we unscrew the coolant temperature (DOT) sensor from the cylinder head.

After removing the protective cap, disconnect the wire and unscrew the water heater meter.

Methods for checking temperature sensors

If the driver wants to make sure that the cause of problems with the car is the antifreeze sensor, then he will have to carry out a simple checking procedure. But before you start, you need to make sure the integrity of the car wiring. As mentioned above, for the sensor to work normally, it must be continuously supplied with a voltage of 5 volts. To make sure that the supplied voltage does not deviate from this value, you should start the car, and then remove the wires from the sensor and connect them to a multimeter. If the device clearly shows 5 volts, then there are no problems with the wiring and you can begin to examine the sensor itself. There are two verification methods. Let's list them.

Hot water test

The sequence of actions in this option is simple.

- The sensor is placed in a pan of cold water. An electronic thermometer is also placed there (it is much more convenient than a regular one, because the measured temperatures will be quite high).

Table: temperatures and corresponding resistances, characteristic of serviceable VAZ 2106 sensors

| Temperature, °C | Resistance, Ohm |

| +5 | 7280 |

| +10 | 5670 |

| +15 | 4450 |

| +20 | 3520 |

| +25 | 2796 |

| +30 | 2238 |

| +40 | 1459 |

| +45 | 1188 |

| +50 | 973 |

| +60 | 667 |

| +70 | 467 |

| +80 | 332 |

| +90 | 241 |

| +100 | 177 |

Checking without an electronic thermometer

This method of checking the sensor is simpler than the previous one, but less accurate. It is based on the fact that the temperature of boiling water reaches one hundred degrees and does not rise higher. Therefore, this temperature can be used as a reference point and find out what the sensor resistance will be at one hundred degrees. The sensor is connected to a multimeter switched to resistance measurement mode, and then immersed in boiling water. However, you should not expect the multimeter to show a resistance of 177 ohms, which corresponds to a temperature of one hundred degrees. The fact is that the temperature of water constantly decreases during the boiling process and averages 94–96 °C. Therefore, the resistance on the multimeter will vary from 195 to 210 ohms. And if the numbers produced by the multimeter differ from the above by more than 10%, the sensor is faulty and it’s time to change it.

How to check?

Since the VAZ-2106 coolant temperature sensor is extremely simple, the methods for diagnosing it are extremely simple. But before diagnosing the element, you should inspect the wiring and its integrity. You can also check whether voltage is coming to the sensor.

The most accurate way to check functionality is to measure the resistance using a multimeter. But during the measurement process, the element will have to be boiled in water. As the temperature changes, the resistance of the sensor will change. But since in the VAZ-2106 the DTOZH does not affect anything, it is easier to simply replace the faulty element. Moreover, its price is not higher than two hundred rubles.

To replace the VAZ-2106 engine temperature sensor, it is enough to cool the engine if it was previously heated. In the process, you will have to unscrew the element from the cylinder head cooling jacket, and you can get burned by the hot liquid. The sensor has an M14 thread. In order to unscrew it, you will need a 19mm wrench. The faulty element is unscrewed, and a new one is screwed in its place. In some cars, it is recommended to drain the coolant a little before replacing it.

You can replace the sensor with any one that is sold in the store and fits the thread in the cylinder head. The main thing is that the contacts on the element are similar to the plug in the car wiring. Then everything will connect and work without any problems.

During long-term operation, the internal parts of the sensor wear out and periodically fail. The malfunction manifests itself in the form of false readings on the indicator scale or a constantly burning emergency lamp. Before drawing conclusions about power unit failures, it is highly advisable to check the functionality of the sensor.

If the indicator lights up when the engine is running and the arrow shows zero, it must be turned off immediately.

When the light comes on and goes out in a timely manner, and the needle does not deviate, you should check the serviceability of the oil sensor - the MM393A pressure meter. You will need a 19 mm open-end wrench and a pressure gauge with a scale of up to 10 Bar (1 MPa). A flexible pipe with a threaded tip M14 x 1.5 must be screwed to the pressure gauge.

Test pressure gauges are equipped with adapters for testing various engines

The verification procedure is as follows:

- Turn off the engine and let it cool to 50-60 °C so you don’t have to burn your hands while working.

- Disconnect the wires from the sensors and unscrew them with a 19 mm wrench along with the tee.

Please note that during disassembly a small amount of oil may leak out of the unit. The assembly assembly can be easily unscrewed with a regular open-end wrench - Screw the threaded part of the pipe into the hole and carefully tighten it. Start the engine and observe the pressure gauge readings.

To check, the pressure gauge is screwed into place of the sensor. - Oil pressure at idle is from 1 to 2 Bar; on worn engines it can drop to 0.5 Bar. The maximum reading at high speeds is 7 bar. If the sensor produces different values or is at zero, you need to buy and install a new spare part.

When measuring, it is advisable to compare the readings of the pressure gauge and the indicator on the dashboard

On the road, it is more difficult to check the VAZ 2106 oil sensor, since there is no pressure gauge at hand. To make sure there is lubricant in the engine channels, unscrew the element, disconnect the main ignition wire and rotate the crankshaft with the starter. If the pump is working properly, oil will splash out of the hole.

When the light signal does not light up at all, consider 3 options:

- the light bulb burned out;

- broken wiring;

- The small sensor in the form of a hexagon has become unusable.

The first 2 versions can be easily checked by testing them with a tester or multimeter. The serviceability of the membrane element is tested as follows: turn on the ignition, remove the wire from the terminal and short it to vehicle ground. If the lamp lights up, feel free to change the sensor.

To remove the meter, you need to unscrew the fitting nut that presses the tee to the block

Replacement is done by unscrewing the large or small sensor with a wrench. It is important not to lose the bronze sealing washers, since they may not be included with the new part. Remove any leaks of engine lubricant from the hole with a rag.

Both meters cannot be repaired, only replaced. Their metal cases, capable of withstanding the oil pressure of a running engine, are hermetically sealed and cannot be disassembled. The second reason is the low price of VAZ 2106 spare parts, which makes such repairs pointless.

Replacing the antifreeze temperature sensor on a VAZ 2106

Before replacing the antifreeze sensor on a VAZ 2106, you should consider several important nuances:

- The car engine must be cold. After unscrewing the sensor, antifreeze begins to flow out of its socket. And if the engine is hot, then the antifreeze does not flow out of it, but is thrown out in a powerful jet, since the pressure in a hot engine is very high. As a result, you can get severe burns;

- Before buying a new sensor in a store, you should carefully examine the labeling of the old one. Almost all VAZ classics use the same sensor labeled TM-106. You should purchase this one, since the correct operation of other sensors is not guaranteed by the manufacturer;

- Before replacing the sensor, remove both terminals from the battery. This will avoid a short circuit, which is possible when antifreeze leaks out and this liquid gets on the wires.

Now about the tools. We will need only two things:

- open-end wrench 21;

- new antifreeze sensor for VAZ 2106.

Sequencing

Replacing the sensor consists of two simple steps:

- Carefully remove the protective plastic cap with wires from the sensor. After this, the sensor is unscrewed several turns using a 21 key.

The VAZ 2106 operating instructions instructs to completely drain the coolant from the car before replacing the sensor. The vast majority of drivers do not do this, rightly believing that it is not worth changing all the antifreeze because of such a trifle as a sensor. It's easier to change the sensor without any drains. And if a lot of antifreeze leaks out, you can always add it to the expansion tank.

Video: changing the antifreeze sensor on a “classic”

So, replacing the antifreeze temperature sensor is a task that even a novice car enthusiast can do. The main thing is not to forget to cool the car engine well, and then act as quickly as possible. And everything will work out.

Source

Oil pressure

On “sixes” and other classic models, a VAZ 2106 oil pressure sensor of type Mm393A is installed. The pressure indicator works on the principle of converting this parameter, which is created in the lubrication system, into resistance. The oil pressure sensor is installed in the engine cylinder block. A regulator is also installed here, which turns on the oil pressure light.

This element is triggered as a result of the closing and opening of contacts at a particular level of pressure in the system. The corresponding indicator on the control panel may light up if the characteristics are violated, namely, if there is little liquid in the system.

Designation of part elements

How to check the controller? You can check the engine fluid pressure sensor by removing the regulator from its installation location. After removal, you should turn the starter; you do not need to start the power unit. If everything is fine with the supply of consumables, then you need to change the regulator. You can tell about the oil supply by the splashing of liquid from the controller seat.

VAZ-2106 diagram

The VAZ-2106 car was produced from 1976 to 2008. This guide provides color-coded wiring diagrams (for the injector and carburetor) with a description of all elements for various modifications. The information is intended for self-repair of the six. Electrical circuits are divided into several blocks for ease of viewing via a computer or phone; there are also circuits in the form of a single picture with a description of each element - for printing on a printer. All electrical equipment of a car can be divided into the following components:

- engine starting system;

- battery charge elements;

- fuel mixture ignition system;

- elements of external and interior lighting;

- sensor system on the instrument panel;

- sound notification elements;

- fuse block.

Typical malfunctions of the blowing system

Now let's look at the breakdowns that you may encounter during the operation of the car, as well as methods for eliminating them. Moreover, it should be noted that our site is dedicated to how to make repairs with your own hands, without resorting to the help of specialists at a service station. Why spend a lot of money if you can do everything yourself and very quickly? And you will receive a small “bonus” - because you will know how this or that car system works and what condition its components are in. Let's now make a rating of the most popular fan sensor failures.

A breakdown of the most sensitive element leads to the fact that the electric fan does not turn on even when the temperature has reached a critical level of 100 degrees, or even more. Of course, the antifreeze begins to boil and splashes out through the expansion tank cap. Therefore, many motorists install “emergency” buttons, which are used to start the fan. And for some, such a system is even the main one; you just need to not miss the moment when you should turn on the airflow. You can check whether the sensor (and not another element) has really failed - remove one wire from it and connect it to the second. If the impeller starts to rotate, the fan switch sensor is faulty.

Diagram for switching on the VAZ 2106 radiator blower

Of course, sometimes the fan itself fails, in which case even if directly connected to a power source it will not work. Please note that the wires may break or burn out, so you need to check the presence of voltage at the electric fan connector. Another nuance - as a rule, the entire electrical circuit is powered from the ignition switch. Consequently, if you turn off the engine while the electric fan is running, the latter will stop cooling the system. And this is fraught with consequences, since it is even possible to destroy the engine block - the appearance of cracks in it and the cylinder head. It is for this reason that you should either not turn off the engine until the fan stops, or connect the entire circuit to the battery.

And, of course, it is worth mentioning the electromagnetic relay. If it is used in your car, then you need to diagnose it. The contacts move and sometimes burn, which leads to failure of the relay.

Electrical diagram of VAZ-2106 (old)

General diagram of the electrical equipment of VAZ 2106 / 21061 / 21063 / 21065 produced in 1976 - 1987.

1 – front lights; 2 – side direction indicators; 3 – battery; 4 – battery charge indicator relay; 5 – relay for turning on low beam headlights; 6 – relay for turning on the high beam headlights; 7 – starter; 8 – generator; 9 – external headlights; 10 – internal headlights; 11 – sound signals; 12 – electric motor of the engine cooling system fan; 13 – fan motor activation sensor; 14 – ignition coil; 15 – ignition distributor; 16 – spark plugs; 17 – carburetor solenoid valve; 18 – coolant temperature indicator sensor; 19 – engine compartment lamp; 20 – reverse light switch; 21 – oil pressure indicator sensor; 22 – sensor for low oil pressure indicator; 23 – indicator sensor for insufficient brake fluid level; 24 – windshield wiper gearmotor; 25 – windshield washer electric motor; 26 – relay for turning on sound signals; 27 – relay for turning on the fan motor; 28 – voltage regulator; 29 – windshield wiper relay; 30 – additional fuse block; 31 – main fuse block; 32 – relay-breaker for alarm and direction indicators; 33 – brake signal switch; 34 – plug socket for a portable lamp; 35 – heater electric motor; 36 – additional resistor of the heater electric motor; 37 – hours; 38 – heater motor switch; 39 – glove box lighting lamp; 40 – cigarette lighter; 41 – alarm switch; 42 – instrument lighting switch; 43 – warning lamp for insufficient brake fluid level; 44 – three-lever switch; 45 – ignition switch; 46 – rear fog lamp switch*; 47 – external lighting switch; 48 – lamp switches located in the front door pillars; 49 – switches for warning lights of open front doors; 50 – alarm lights for open front doors; 51 – lamp switches located in the rear door pillars; 52 – parking brake warning switch; 53 – interior lamps; 54 – fuel level indicator with reserve indicator; 55 – coolant temperature indicator; 56 – oil pressure gauge with low pressure indicator; 57 – tachometer; 58 – parking brake warning lamp; 59 – battery charge indicator lamp; 60 – carburetor air damper indicator lamp; 61 – side light indicator lamp; 62 – turn signal lamp; 63 – headlight high beam indicator lamp; 64 – speedometer; 65 – carburetor air damper warning switch; 66 – parking brake warning relay; 67 – rear lights; 68 – license plate lights; 69 – sensor for level indicator and fuel reserve; 70 – trunk lighting lamp; 71 – rear fog lamp*.

The order of conditional numbering of plugs in blocks:

a – windshield wiper and windshield wiper breaker relay; b – hazard warning and direction indicator breaker relay; c – three-lever switch.

Tachometer sensor

Separately, it is worth considering such an element of the tachometer circuit as its sensor, or rather, the crankshaft position sensor (CPS). This device serves not only to count crankshaft revolutions, but also to determine its position at a certain moment, which is necessary for the electronic control unit to ensure proper operation of the power unit.

What is a crankshaft position sensor?

DPKV is an electromagnetic device whose operating principle is based on the phenomenon of induction. When a metal object passes near the sensor core, an electrical impulse is generated in it, which is transmitted to the electronic engine control unit. The role of such an object in the power unit of the “six” is played by the crankshaft gear. It is to its teeth that the sensor reacts.

The operating principle of the sensor is based on the phenomenon of induction

Where is the crankshaft position sensor located?

The DPKV on the VAZ 2106 is fixed in a hole on a special boss of the camshaft drive cover in the lower part of the engine next to the crankshaft gear. The wiring harness going to it can help determine its location. The sensor itself is enclosed in a black plastic case. It is attached to the timing cover with one screw.

The hole for mounting the sensor is marked with a blue arrow

How to check DPKV for performance

In order to determine whether the sensor is working, there are two methods. For this we need:

- wrench 10;

- screwdriver with Phillips bit;

- multimeter

The verification process consists of the following steps:

- Using a 10mm wrench, loosen the negative terminal on the battery. Let's take it off.

- Raise the hood and find the crankshaft position sensor.

- Disconnect the connector from it.

- Using a screwdriver, unscrew the screw securing the device.

- We remove the sensor.

- Turn on the multimeter in voltmeter mode with a measurement limit of 0–10 V.

- We connect its probes to the sensor terminals.

- With an energetic movement, we bring the blade of a screwdriver near the end end of the device. At this moment, a voltage jump of up to 0.5 V should be observed on the device screen.

- Switch the multimeter to ohmmeter mode with a measurement limit of 0–2 KOhm.

- We connect the probes of the device to the sensor terminals.

- The resistance of the sensor winding should be in the range of 500–750 Ohms.

If the device readings differ from those indicated, the sensor is faulty and must be replaced. The device is replaced in accordance with paragraphs. 1–5 of the above instructions, only in reverse order.

Replacing the tachometer VAZ 2106

If a malfunction is detected in the tachometer itself, it is hardly worth trying to repair it yourself. Even if he earns money, it is not a fact that his testimony will be correct. It is much easier to buy and install a new device. To replace the VAZ 2106 tachometer you will need:

- flat blade screwdriver;

- pliers;

- pencil, felt-tip pen or marker.

To replace the tachometer, you must:

- Remove the instrument panel trim by prying it off with a screwdriver.

- Move the panel to the side.

- Disconnect the wiring harness block from the device, as well as the connectors of additional wires, having previously marked their location with a marker or pencil.

- Using your hands or using pliers, unscrew the nuts securing the tachometer to the panel.

- Remove the device from the cover.

- Install a new tachometer and secure it with nuts.

- Connect and install the panel in reverse order.

As you can see, the tachometer is not such a sophisticated device. There is nothing complicated either in its design or in the connection diagram. So, if problems arise with it, you can easily deal with them without outside help.

Electrical diagram of VAZ-2106 (new)

General diagram of the electrical equipment of VAZ 2106 / 21061 / 21063 / 21065, produced 1988 - 2001.

1 — front lights; 2 — side direction indicators; 3 - battery; 4 — battery charge indicator lamp relay; 5 – relay for turning on low beam headlights; 6 — relay for turning on the high beam headlights; 7 – starter; 8 – generator; 9 – external headlights; 10 – internal headlights; 11 – fan motor activation sensor; 12 — electric motor of the engine cooling system fan; 13 – sound signal; 14 – ignition coil; 15 – ignition distributor; 16 – spark plugs; 17 — carburetor solenoid valve; 18 – coolant temperature indicator sensor; 19 – engine compartment lamp; 20 – reverse light switch; 21 – oil pressure indicator sensor; 22 – low oil pressure indicator sensor; 23 – indicator sensor for insufficient brake fluid level; 24 — windshield wiper gearmotor; 25 – switch*; 26 — windshield washer electric motor; 27 – fan motor activation relay**; 28 – voltage regulator; 29 – windshield wiper relay; 30 – additional fuse block; 31 – main fuse block; 32 – relay-interrupter for alarm and direction indicators; 33 – relay for turning on the heated rear window***; 34 – brake light switch; 35 – plug socket for a portable lamp****; 36 – additional resistor of the heater electric motor; 37 – heater electric motor; 38 – heater motor switch; 39 – hours; 40 – glove box lighting lamp; 41 – cigarette lighter; 42 – alarm switch; 43 – instrument lighting regulator; 44 – brake fluid level indicator lamp; 45 – three-lever switch; 46 – ignition switch; 47 – rear window heating switch***; 48 – rear fog lamp switch; 49 – external lighting switch; 50 – lamp switches located in the front door pillars; 51 – gearmotors for electric windows of the front doors***; 52 – lamp switches located in the rear door pillars; 53 – parking brake warning lamp switch; 54 – interior lamps; 55 – fuel level indicator with reserve indicator; 56 – coolant temperature indicator; 57 – oil pressure indicator with low pressure indicator; 58 – tachometer; 59 – parking brake warning lamp; 60 – battery charge indicator lamp; 61 – carburetor air damper indicator lamp; 62 – side light indicator lamp; 63 – turn signal lamp; 64 – headlight high beam indicator lamp; 65 – speedometer VAZ-2106; 66 – carburetor air damper warning switch; 67 – power window switch for the left front door***; 68 – relay for turning on the electric windows of the front doors***; 69 – power window switch for the right front door***; 70 – rear lights; 71 – license plate lights; 72 – sensor for level indicator and fuel reserve; 73 – pads connected to the rear window heating element***; 74 – trunk lighting lamp; 75 – rear fog lamp.

The order of conditional numbering of plugs in blocks:

a – switch; b – ignition distributor sensor; c – windshield wiper and windshield wiper breaker relay; d – hazard warning and direction indicator breaker relay; d – three-lever switch.

* Installed if a vehicle uses a contactless ignition system. In this case, an ignition distributor sensor of type 38.3706 and an ignition coil of type 27.3705 or 027.3705 must be installed. ** Since 2000, it has not been installed and electric motor 12 is switched on directly by sensor-switch 11. In this case, instead of the previously used temperature sensor 11 of type TM-108, sensor-switch 661.3710 is used. *** Installed on car parts. **** Not installed since 2000.

Wiring diagram VAZ-2106 carburetor - full view:

Control circuit modernization

The cooling fan on the top ten turns on at a temperature of 100-105°C, while the normal operating temperature of the engine is 85-90°C, so the fan turns on when the engine overheats, which naturally has a negative effect.

This problem can be solved in two ways: adjust the switch-on temperature in the “brains” or make a button. We'll focus on the second one. Turning on the fan from the button is very convenient: if you get into a traffic jam, turn it on, drive out, turn it off, and no overheating occurs.

A button for selecting the fan operating mode was installed in the cabin (always off, constantly on, automatically turned on via a sensor) - this “tuning” is not mandatory, but will be a very useful addition.

There will be a large current at relay contacts 87, 30, on the wire from the battery to the fuse and the fan ground, and therefore we must use wires there with a cross-section of at least 2 mm, otherwise the thinner wire will not withstand it and will burn out.

Wiring diagram VAZ 2106 (injector)

1 controller 2 electric fan of the cooling system 3 ignition system harness connector to the left mudguard harness 4 ignition system harness connector to the right mudguard harness 5 fuel level indicator 6 fuel level harness connector to the fuel level sensor harness 7 oxygen sensor 8 fuel level sensor harness connector to the system harness ignition 9 electric fuel pump 10 speed sensor 11 idle speed control 12 throttle position sensor 13 coolant temperature sensor 14 mass air flow sensor 15 diagnostic block 16 crankshaft position sensor 17 canister purge solenoid valve 18 ignition coil 19 spark plugs 20 VAZ-2106 injectors 21 ignition system harness block to instrument panel harness 22 electric fan relay 23 controller power supply circuit fuse 24 ignition relay 25 ignition relay fuse 26 electric fuel pump power circuit fuse 27 electric fuel pump relay 28 ignition system harness block to injector harness 29 injector harness block to ignition system harness 30 block g guta instrument panel to the ignition system harness 31 ignition switch 32 instrument cluster 33 engine anti-toxic system display

What indicates a faulty coolant temperature sensor

The easiest way to diagnose a problem with the coolant temperature sensor is by its appearance. In most cases, it fails due to damage, which can be mechanical or corrosive. If the sensor housing is cracked, you can forget about its stable operation. In this case, the thermistor itself located in the housing may also fail, and a malfunction of the coolant temperature sensor in this case will be indicated by:

- Warning lamp signaling the driver about engine overheating;

- Noticeable increase in gasoline consumption;

- Problems with the engine: difficulty starting, spontaneous stopping, unstable idle speed and other malfunctions;

- Errors on the dashboard determined by the electronic control unit (their numbers vary depending on the model and manufacturer of the car).

If there are symptoms indicating a malfunction of the coolant temperature sensor, you can immediately replace it. The price of such a device is low, especially for common car models. If desired, you can diagnose it to make sure that the sensor is the source of the problems.

Injection engine control unit diagram

Electrical connection diagram for the injection engine control system:

1. — Controller connector. 2. — Mass air flow sensor. 3. — Coolant temperature sensor. 4. — Crankshaft position sensor. 5. — Throttle position sensor. 6. — Oxygen concentration sensor. 7. — Speed sensor. 8. — Ignition module. 9. — Electromagnetic valve for purge of the adsorber. 10. — Electric fan relay. 11. — Electric fuel pump relay. 12. — Main relay. 13. — Fuse protecting the power circuit of the electric fuel pump relay. 14. — Fuse protecting the power circuits of the main relay. 15. — Fuse link. 16 - Fuse protecting the constant power supply circuit of the controller. 17. — Diode. 18. — Idle speed regulator. 19. — Injectors. X1. — Diagnostic block. X2. — Connection block to the vehicle electrical system.

Where is the coolant temperature sensor located?

The DTOZH is a small plastic device with a metal thread. With its help, it is attached to the exhaust pipe of the cylinder head, screwing into it. The sensor must be located so as to have direct contact with the coolant, based on which it can be concluded that its readings are inaccurate when its level is low.

Important: Some car models may have two coolant temperature sensors. In this case, one of them records the temperature at the engine outlet, and the second at the radiator outlet.

Schemes of individual six units

Generator connection diagram

1 — battery VAZ-2106; 2 — “six” generator set; 3 - regulatory device designed to control the operating voltage parameter; 4 - lock; 5 — plastic module with safety elements; 6 - control light indicator that determines the battery charge; 7 - relay that protects the power line of the battery charge indicator light.

How are the main wiring elements of the VAZ-2106 car protected?

The electrical wiring of the machine is protected by fuses, which are mainly installed in the central and additional units, located at the bottom of the instrument panel on the left side next to the steering column. The circuit from the battery to the terminals and connections is closed when the car ignition is turned on.

If one of the circuit elements is damaged, the fuse trips. If a malfunction occurs in the main set of fuses, the backup fuses are switched on, which are additionally installed next to the ignition unit. If a blown fuse is detected, it is not enough to just replace it - you need to study the wiring in detail and find out the reason for the combustion of this spare part in the VAZ-2106.

The electrical equipment and wiring diagram should help you quickly find and eliminate faults in the headlights, dashboard indicators and other systems of your VAZ-2106.

VAZ2107 fuse and relay diagram

The electrical wiring of the machine is protected by fuses, which are mainly installed in the central and additional units, located at the bottom of the instrument panel on the left side next to the steering column. The circuit from the battery to the terminals and connections is closed when the car ignition is turned on.

F1(16A) Klaxon, lamp socket, cigarette lighter, brake lamps, clock and interior lights (plafonds) F2(8A) Windshield wiper relay, heater and wiper motors, windshield washer F3(8A) Left headlight high beam and warning lamp on high beam F4(8A) High beam of the right headlight F5(8A) Low beam fuse of the left headlight F6(8A) Low beam of the right headlight and rear fog lamp F7(8A) This fuse in the VAZ 2106 block is responsible for the side light (left sidelight, right rear light), trunk light, license plate light right light bulb, instrument lighting lamps and cigarette lighter light F8(8A) Side light (right sidelight, left rear light), license plate light left light bulb, engine compartment lamp and side light warning light F9(8A) Oil pressure gauge with warning lamp, coolant temperature and fuel level indicator, battery charge warning lamp, direction indicators, carburetor choke indicator, rear window heating F10(8A) Voltage regulator and generator excitation winding F11(8A) Reserve F12(8 ) Reserve F13(8A) Reserve F14(16A) rear window heating F15(16A) Cooling system fan electric motor F16(8A) Turn indicators in hazard warning mode

Owners of 2106 should be aware that the old design of fuses has long become obsolete, since each time they operate they overheat, which affects the density of the cells. Lack of tight contact between the fuse and the connectors leads to their burning. Therefore, replacement of the fuse blocks is necessary. To avoid unnecessary problems with the electrical wiring, you should inspect the safety devices every six months. If the contact part burns, it is necessary to replace the fuses and clean the sockets. Today, many VAZ 2106 owners are modernizing classic blocks, replacing them with modern blade fuses.

Malfunctions of the VAZ 2105 generator and their elimination

The VAZ-2106 temperature sensor is a practically fail-safe device. Its design is very simple. Hence such reliability. But even with it, motorists may have problems. The reliability of modern spare parts leaves much to be desired.

Problems with the sensor boil down to violation of readings, violation of calibration and resistance. But the only trouble is the risk of engine overheating, since the driver does not see the real temperature. On injection cars, the damage from a broken sensor will be much greater - there the sensor is also connected to the ECU, and the proportions of mixture formation depend on the engine temperature.

Read more: Kia Soul 2021: configurations, price, photos, release date in Russia || New Kia Soul - start of sales in Russia

If we talk about another VAZ-2106 temperature sensor, which is responsible for turning on the fan, then its malfunction can lead to disastrous consequences. Due to the exceeded temperature of its activation, the fan will not work on time. In order for the cylinder head to overheat and begin to deform, the temperature needs to rise only a couple of degrees above normal. The second malfunction that can lead to no readings on the dashboard is a break in the wiring to the sensor.

The generator set ensures uninterrupted operation of the vehicle's electrical equipment while driving and charges the battery by converting mechanical energy into electrical energy. It is important to monitor its condition so that problems do not arise along the way. You can diagnose and fix generator problems yourself, without involving specialists, by following step-by-step instructions.

The VAZ 2105 was equipped from the factory with generators G-222 and 37.3701.

They differ from each other in rotor and stator coils and some components. The generator unit is a three-phase alternating current device, the voltage in which arises due to the excitation of the rectifier and magnets

Modern cars are equipped with powerful lighting devices, various electrical appliances and other equipment that require large amounts of electricity. Standard generators installed on the VAZ2105 sometimes cannot cope with such a load. As a more powerful source, you can set the following options to “five”:

- generator set 9412.3701–03, installed on VAZ 212114, produces a current of 110A;

- generator G-2107–370101, produces a current of 80 A;

- The unit is from a VAZ 2110 and can produce a current of 80 A and higher.

To install alternative devices, additional fasteners and minor changes to the electrical circuits are required.

The generator consists of the following elements:

- An armature (rotor) that creates a magnetic field due to the rotation of the coils.

- Stator. An alternating current appears in its windings and flows to the diode bridge.

- Aluminum housing consisting of two covers. It has specially made holes for heat removal.

- The brushes serve to supply voltage to the rotor slip rings. They are mounted in a special brush holder.

- Voltage regulator - a relay that does not allow the output voltage to exceed 14.2–14.6 V.

- The diode bridge (rectifier) performs the function of converting the alternating current coming from the rotor into direct current. Consists of 6 silicon diodes.

- Two bearings on which the stator rotates.

The generator is located in the engine compartment to the right of the power unit. It works thanks to the crankshaft through a belt drive.

Although the VAZ generator is a reliable unit, over time the parts wear out, which leads to interruptions in the operation of the installation. The following signs indicate a generator malfunction:

- The indicator on the instrument panel does not go out or blinks, indicating that the battery is charging.

- Low voltage current is generated.

- The electrolyte in the battery boils away.

- Extraneous sounds when the generator unit is operating.

- The generator set wires are melting.

Diagnostics can be performed in several ways:

- Using a multimeter. We set up a voltage measuring device. We take measurements of the incoming voltage. The value should be in the range of 13.8–14.5 V. Next, we check the voltage at the battery contacts, which must correspond to the passport data. Next, we check the armature winding, positive and negative diodes and capacitor.

- It is possible to carry out diagnostics at the stand at home if you have the necessary equipment, but most often it is carried out at a car service center.

- An oscilloscope. The device allows you to determine the malfunction of the unit based on the signal shape.

In the first diagram, the generator is working, in the second one of the diodes has failed, in the third there is an open circuit in the diode circuit.

If there are problems with the windings, you should change the wires. Most often, a break occurs near the slip rings, so you need to check the soldering at the ends of the winding. To fix the problem, unwind the winding turn, remove the broken end and unwind the wire to the slip ring.

If the incoming voltage is too high or low, the cause is a faulty regulator and must be replaced. If the generator unit is working properly and the warning light is on, this indicates a faulty light bulb power diode. The problem is solved by replacing the diode.

If extraneous noise is heard during operation of the generator unit, the cause is worn bearings. It is necessary to disassemble the assembly and replace worn parts.

Work begins with removing the generator. To do this, you need to prepare the following tools:

- set of heads;

- a set of keys;

- knob;

- ratchet;

- hammer;

- extension.

After long use, the fasteners stick, so it is better to lubricate the fastening points with WD-40 before disassembling.

Dismantling the unit on a VAZ 2105 is carried out in stages:

- We de-energize the car by removing the negative terminal from the battery. We disconnect the wires from the generator unit, having previously remembered how they were connected.

- Unscrew the fastening nut on the bracket, loosen the tension on the belt drive and remove the belt.

- Having descended under the car, unscrew the lower nut using a ratchet.

- Using a hammer, knock out the bolt through a wooden extension and remove it from the assembly.

- Now we take the generator to the side and remove it. It is more convenient to do this from below.

We move on to repairing the dismantled unit.

In addition to a set of keys, you need to prepare a Phillips screwdriver and a special puller for bearings.

The disassembly procedure is a sequence of steps:

- First, we clean the generator from dirt, oil and dust, and lubricate the mountings with WD-40.

- Use a screwdriver to unscrew the bolt that secures the voltage regulator to the housing.

- We take out the relay and brushes. If the corners look worn, replace them during assembly.

- Using a screwdriver, secure the rotor from turning, and unscrew the fastening nut on the generator set pulley.

- We fix the axle so that it does not rotate, and dismantle the necessary elements: washers, impeller and pulley.

- Next, knock the key off the armature axis and remove the washer.

- We unscrew the nut that holds the terminal on the air conditioner and disconnect the contact. We unscrew the fastenings of the capacitor and dismantle it.

- In order not to make a mistake with the location of the parts during assembly, we put the appropriate marks on them.

- To separate the housing parts, unscrew the fasteners and remove them.

- Remove the front part of the assembly.

- If play is detected during rotation, change the bearings. They are located in the front cover and are held in place by a plate. Unscrew the fasteners and remove the plate. We squeeze the worn bearing out of the seat and press in a new part using a piece of metal pipe of suitable diameter.

- Having removed the thrust ring from the rotor, we fix the shaft in a vice and pull off the rear part with the stator coils.

- Disconnect the armature from the stator.

- We remove the second bearing using a puller and press in a new one using a suitable spacer.

- We unscrew the fasteners of the contacts of the coil and the rectifier block. Using a screwdriver, remove the stator rings.

- We dismantle the diode bridge. If it is discovered that one of the diodes is faulty, we replace the plate with diodes.

- We remove the bolt from the diode bridge that relieves voltage on the battery.

- On the back of the case, unscrew the bolts securing the rectifier and coil terminals.

- We change the necessary parts and reassemble.

Read more: Repair and tuning of vases What's new

On the VAZ 2105, problems with the generator rarely occur. Basically, maintenance work consists of replacing and tightening the belt, as well as replacing failed brushes or a voltage regulator relay in case of problems with battery charging.

Repair of a generator on a classic VAZ model.