07/17/2021 2,878 Cooling system

Author: Victor

The cooling system is one of the important components in any car. Vehicles today are equipped with a variety of regulators and measuring instruments designed to ensure the correct operation of the internal combustion engine. We will describe below where the coolant temperature sensor is located, why it is used and how to change it.

[Hide]

Purpose of the device

DTOZH should not be confused with an antifreeze level controller. If the first is intended to detect the temperature of the power unit, then the second is used to control the volume of consumables - refrigerant. Based on the DTOZH readings, the control unit detects temperature changes and transmits data to the on-board computer about the state in which the engine is operating. Using the controller, engine warm-up, overheating, and the optimal temperature of the operating internal combustion engine are determined. Pulses transmitted to the control module determine the functionality of the internal combustion engine control system as a whole.

The engine temperature determines the following nuances:

- fuel consumption per 100 km;

- volume and quality of gases;

- ignition of the air-fuel mixture;

- optimal operation of the gearbox.

All these factors are controlled by a control device, which, based on the information received, determines the optimal operating mode of the engine. Therefore, the performance of the temperature sensor is important for the vehicle. If the device is faulty and sends incorrect pulses to the control module, this can lead to problems.

How does DTOZh affect the operation of the internal combustion engine?

Based on the parameters supplied to the control device, the module performs the following functions:

- Enrichment of the air-fuel mixture or its depletion. If the controller detects that the temperature is too low, it will begin to increase the duration of the signal sent to the injectors, which helps to enrich the fuel mixture. In accordance with the normalization of the temperature regime, the fuel is gradually depleted, which prevents possible excessive consumption of gasoline and reduces the volume of exhaust gases. If the sensor breaks down, it can regularly lower the temperature in the engine, which will lead to fuel contamination and increased consumption.

- The control unit sets the ignition. It can be early or late. If the temperature increases, the control module adjusts the ignition timing to reduce exhaust toxicity.

- Thanks to DTOZH, proper recirculation of gases is performed during warming up. The recirculation valve closes tightly when the power unit warms up. If the car’s engine is still cold, then recirculation will cause fluctuations in idle speed and random engine stops.

- With the help of DTOZH, the control unit purges the filtration system, which traps fuel vapors. To achieve better machine controllability, the carbon filter element is not purged until the engine is completely warmed up.

- Locking of the gearbox torque converter when the internal combustion engine warms up. The control module should not limit the operation of the device until the machine warms up.

- The ECU controls the operation of the unit's cooling fan. Based on the temperature controller readings, the module activates and deactivates the ventilation device to correctly select the temperature of the unit. If the DTOZ gives incorrect impulses, there is a possibility of the motor overheating.

How engine sensors work and how to check them

The parameters of such physical phenomena as:

- Temperature of various liquids, gases and aggregates

- Pressure in various media and systems

- Speed, direction and number of gross revolutions

- Concentration of substances in all kinds of mixtures (liquids and gases)

- Quantitative and volumetric parameters of air flow

- Relative spatial position of moving parts

- Vibration vibrations and other factors

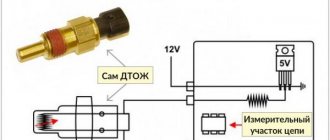

Let's say you need to test some sensor. From the ECU it receives a voltage of 5V. By connecting diagnostic equipment (car scanners and motor testers) to the wires connecting the sensor to the unit, you can see the “picture” of the transmitted signal. Scanners allow you to evaluate the quality of signals in general terms; moreover, they are not applicable to older car models. A motor tester, on the other hand, gives an accurate idea of the smallest details, although it requires more work to use.

Overview of types of DTOZH: design and principle of operation

Let's take a closer look at the operating principle and types of controllers.

Magnetic

Such controllers consist of coils located on the sides of a steel armature. The arrow of the controller located on the instrument panel in the cabin is connected to the latter. The first coil is connected to the vehicle's on-board network, and the second to a cable with varying resistance. This parameter changes according to the temperature values in the engine. The voltage passing through the coils creates a magnetic field that controls the armature. The element displacement parameter is determined by the field difference depending on the current value.

User Irimiya Evgeniy showed in his video how unstable the DTOZh is.

Bimetallic

The operating principle of bimetallic controllers is based on the expansion of elements during heating. The device is equipped with a rod that changes size as the temperature of the internal combustion engine increases. The stripes in the coil rotate the arrow on the control panel in the car's interior in accordance with the current value.

Modern antifreeze temperature sensors can use two types of sensors:

- semiconductor;

- bimetallic.

The latter are practically not used today. The strip in such controllers moves to the coil and opens the contacts, helping to change the amount of current flowing to the dashboard. And semiconductors are used everywhere. The control unit supplies a signal to the device thermistor with a negative coefficient through a resistive element with constant resistance. As the temperature increases, the resistance in this circuit drops. Accordingly, the voltage level decreases. The control module detects a decrease in this parameter and determines the temperature of the consumable material, displaying it on the control panel with an indicator.

Capillary

It is considered the oldest and irrelevant type of sensor for use today. The arrow on the device is directly connected to the device. The controller is made in a housing in the form of a container with consumables, which has a low boiling point. The reservoir is connected to a pointer as well as a steel tube. When the power unit warms up, the refrigerant in the container begins to boil and evaporate, resulting in an increase in pressure in the flask. This parameter is sent to the pointer where the Bourdon tube is located. This element begins to straighten as a result of pressure and moves the arrow on the control panel.

This type of controller is almost never used for several reasons:

- the measuring element itself runs through the entire engine compartment, connecting to the tube on one side and to the control panel on the other;

- The capillary tube is quite thin and is quickly damaged during operation.

Photo gallery “Varieties of DTOZH”

Diagrams of different types of sensors are shown in the photo.

Magnetic type DTOZH

Bimetallic sensor

Capillary sensor circuit

The principle of operation of an injection engine

So, after we have figured out the main components of an injection engine, let's see how it works. After the starter cranks the crankshaft, the DPKV tells the control unit which cylinder is in which position. In turn, the phase sensor reported the clock cycles. The control unit took this information into account and opened the injector in the cylinder in which the intake stroke begins. But he opened it for a reason, but for a strictly defined period of time, which, according to the tables, corresponds to the readings of the mass air flow sensor or DBP. This is how the working mixture was formed.

Video: how a gasoline injection internal combustion engine works

After the intake stroke has ended here, compression begins, at which time intake occurs in the other cylinder. Here the piston reaches top dead center, as indicated by the DPKV and DF, respectively, it is time to apply voltage to the ignition module, to the desired cylinder. To do this, the control unit contains two transistors, which take over two cylinders each.

Engine warm-up and engine temperature sensor

This point is worth considering separately; let’s just say this is a small clarification. So, the engine warm-up mode is in no way connected with the readings of some sensors, that is, nothing depends on them. In particular, these are mass air flow sensor and air pressure sensor, as well as a knock sensor. The block, as already mentioned, contains certain tables, there are a lot of them, millions. So, during the warm-up mode, the ECU works strictly according to these tables and nothing else. This means that if the air to fuel ratio is written into it as 14.1:1, then it will be so. This figure is the generally accepted standard for operating temperature. So, until the engine temperature reaches the one specified in the firmware of the control unit, the warm-up mode will not turn off. Afterwards the ECU starts working based on the sensors.

Where is the sensor located?

Before checking and changing the device, you need to know about its location. Where the sensors are installed depends on the car manufacturer.

The device location can be like this:

- in the cylinder head;

- on the upper line of the radiator device;

- in the thermostat housing.

Regardless of where the controller is installed, the device is fixed next to the outlet hose through which the coolant enters the radiator. This is important because it is this mounting location that allows you to accurately determine the temperature of the consumable.

Symptoms of a problem

The AndRamons channel provided a video about the controller verification process.

The main symptom of a controller malfunction is the inoperability of the ventilation device when the power unit warms up. But the machine can also be equipped with a fan activation sensor that performs the switching function. Then the reason should be sought in damage to the electrical circuit or failure of the controller.

What other symptoms can be used to determine the inoperability of the DTOZH:

- increased fuel consumption;

- difficult engine start when the unit is warmed up;

- increased idle speed;

- engine detonation;

- unit overheating.

Many modern cars have an electronic fault detection system. Errors may appear on a special screen on the dashboard when the DTOZ breaks down. But usually fault codes indicate both a possible breakdown of the sensor and damage to the wiring or controller connector.

Checking the DTO on a car

Correspondence table for temperature, resistance and voltage parameters for checking DTOZH

The essence of diagnosing the controller on the car and outside the car is to check the resistance and voltage values.

Checking the second parameter is done using a voltmeter:

- Connect the probes of the device to grounding, as well as to the signal contact of the controller.

- The engine must be cold. Turn on the ignition.

- Measure the voltage parameter and compare the data obtained in accordance with the table.

To diagnose the temperature parameter you will need a thermometer:

- measure the temperature of the consumable;

- start the engine and let it warm up, while heating the internal combustion engine, measure the voltage value taking into account the temperature change;

- If the obtained parameters do not correspond to the table ones, then the device has failed.

User Yakovlev Dmitry showed in the video how to check the controller.

Using an ohmmeter, perform a resistance test:

- Diagnostics are carried out at different temperatures of the machine motor. The parameters are compared with the table ones.

- If the resistance value on a cold engine is in the correct range, then the temperature of the consumable may deviate to the side by several degrees.

Check outside the car

For diagnostics outside the car:

- Place the device in a tank of water and check the temperature.

- Measure the DTOZ resistance parameter. Check the results obtained with those indicated in the table.

- The container with water gradually heats up. During warm-up, periodically check the resistance level and temperature.

What symptoms indicate problems with the sensor?

During long-term operation of the car, obvious and indirect signs may be observed indicating problems with the temperature sensor or its electrical circuit. The first ones directly indicate the need to check the functionality of the device:

- The engine heating indicator on the dashboard stopped working;

- the cooling fan stopped turning on, although the engine water jacket had already warmed up to 100 °C;

- antifreeze leakage from under the part body;

- The fan starts at random, including when the engine is cold.

We recommend: Brake caliper: types, principle of operation, malfunctions, repairs

If your car exhibits the listed signs of a malfunction of the coolant temperature sensor, then feel free to proceed to diagnosing it and fixing the problem, which will be discussed below. Indirect symptoms may indicate a breakdown of the meter or other elements of the cooling system or power unit. Here are the most common ones:

- Cold starting of the engine is difficult. The car starts, but immediately stalls, you need to make several repeated attempts. The cause may be a thermocouple, throttle position sensor, insufficient compression or ignition problems.

- Unstable operation at idle. In addition to the temperature meter, it is affected by the serviceability of the spark plugs, mass flow sensor, injectors and many other factors.

- The temperature is within normal limits, but the coolant begins to boil. If the thermostat fails or the level of antifreeze in the jacket decreases, then the readings of the device may differ from the real state of affairs.

The serviceability of an electronic temperature meter can be checked at home. If indirect symptoms of a malfunction are observed, the test will help to identify them or exclude them from a number of parts that are “under suspicion.” If you successfully check the problem, you will have to look elsewhere or contact the nearest auto repair shop.

Replacing the coolant temperature sensor

You can only replace a failed DTOZ with a similar device.

Required Tools

To complete the task you will need:

- container for collecting waste liquid;

- wrench 19;

- sealant.

Step-by-step instruction

Dismantling and installing the controller is performed as follows:

- Some of the coolant must be drained from the radiator; this will be required to dismantle the sensor.

- Disconnect the connected wires from the device.

- The controller itself is disabled using a 19mm wrench.

- Run device diagnostics if necessary. If you are changing the device, then before installation it is necessary to treat its threads with sealant.

- Screw the new controller into place and connect the wiring to it.

- Fill the cooling system with previously drained antifreeze. Make sure that there is no refrigerant leaking through the unit.

Video “How to change the controller correctly”

A visual guide to replacing an antifreeze temperature sensor is described in a video filmed by user Vasily Kalugin.

Do you have any questions? Specialists and readers of the AUTODVIG website will help you ask a question

Was this article helpful?

Thank you for your opinion!

The article was useful. Please share the information with your friends.

Yes (100.00%)

No

X

Please write what is wrong and leave recommendations on the article

Cancel reply

Rate this article: ( 5 votes, average: 5.00 out of 5)

Discuss the article:

Sensors for an injection engine. Let's look at the VAZ as an example

Well, friends, after the article, carburetor or injector , I mentioned that the second one is controlled by a bunch of various sensors and, in fact, its operation is not possible without them. Some of my viewers and readers began to ask questions - how many are there, what do they control and what do they influence? I think this information is really necessary (for general development), so I decided to write an article. So read it, it will be useful...

THE CONTENT OF THE ARTICLE

It is worth noting that the injector on almost all cars is the same, and therefore its sensors are almost the same. But it is worth noting that for some manufacturers they may differ slightly.