07/18/2021 10,534 VAZ 2109

Author: Ivan Baranov

Each car engine is equipped with a device for measuring the temperature of the power unit. This component allows the driver to detect overheating in time and eliminate this problem. What is the fan switch on sensor on a VAZ 2109 with a carburetor engine, what is its structure and how to replace it - read on.

[Hide]

Sensors VAZ 2109 injector

Although VAZ 2109 cars stopped being produced at the end of 2014, there are a huge number of them traveling on the roads of the country. The latest nine models were produced with an injection-powered engine power system. Compared to the original carburetor models, the injector contains a large number of additional sensors. A carburetor car had only one single sensor that affected engine operation - a Hall sensor. The remaining sensors of the carburetor model - oil pressure sensor, coolant temperature sensor, fan switch sensor, reverse sensor - do not affect engine operation in any way. The temperature sensor and oil pressure sensor are installed on the instrument panel and serve to inform the driver about the temperature and presence of oil pressure in the engine lubrication system. A machine with an injector contains an electronic control unit - ECU, which can also be called a controller. This controller is the brains that control the operation of the engine. The controller is an electronic device that controls the operation of the engine by sending signals to the injectors based on the state of various sensors installed on the car.

Sensors VAZ 2109 with injector

The following sensors are installed on a VAZ 2109 with an injector: 1) Mass air flow sensor (MAF) 2) Throttle position sensor (TPS) 3) Coolant temperature sensor (DTOZH) 4) Knock sensor 5) Oxygen sensor 6) Crankshaft position sensor (DPKV) 7) Speed sensor Phase sensor To understand why each of the sensors listed above is needed, let's look at the block diagram of engine operation control: 1) In order to regulate the air/gasoline ratio, the injection engine control system has a mass air flow sensor (MAF). ).

Phase sensor To understand why each of the sensors listed above is needed, let's look at the block diagram of engine operation control: 1) In order to regulate the air/gasoline ratio, the injection engine control system has a mass air flow sensor (MAF). ). Based on the signal from this sensor, the controller regulates the duration of the pulse supplied to the injector, that is, the amount of fuel. The mass fuel flow sensor is installed in the air filter housing. Depending on the modification of the controller, the mass air flow sensor has two different types of output signal: a) Depending on the amount of air flow, the voltage from the sensor changes; b) Depending on the amount of air flow, the frequency of the sensor output voltage changes. In general, the task of the mass air flow sensor is to send a signal to the controller about the amount of intake air. 2) Throttle position sensor. The throttle valve is mechanically connected to the TPS. The throttle valve opens when you press the gas pedal; when the pedal is released, the throttle valve is closed. TPS is a regular rheostat, the slider of which is driven by the throttle valve. When the gas pedal is released and the throttle valve is closed, the signal from the TPS to the controller lies within 0.4..0.7V. As soon as the driver presses the gas pedal and the throttle valve opens slightly, the voltage at the TPS output begins to rise. When the throttle valve is fully open, the voltage at the sensor output is more than 4V. Receiving a signal to open the throttle valve, the controller increases the duration of pulses to the injectors, thereby increasing engine speed. 3) The VAZ 2109 coolant temperature sensor is designed to transmit information about the engine temperature to the electronic control unit, also known as the ECU, also known as the controller. If this sensor is faulty, it will be difficult or impossible to start the VAZ 2109 engine in cold weather. Receiving a signal from the DTOZH indicating that the engine is cold, the controller forms an enriched combustible mixture to start the engine. As it warms up and the temperature increases, the controller reduces the amount of gasoline in the mixture to its normal value. The principle of operation of the sensor is that the resistance of the sensor changes depending on the temperature. When the engine is cold, the resistance of the sensor is high; as it heats up, it decreases and on a warm engine it is 170 Ohms. 4) The knock sensor is designed to eliminate detonation in the engine. If the ignition timing calculated by the controller is correct, then the car engine runs smoothly, without shaking. However, if the engine begins to knock, then the ignition timing must be changed. This is what the knock sensor is used for. The sensor is installed on the engine cylinder head. Inside the knock sensor there is a piezoelectric element that generates voltage when the engine detonates. The stronger the detonation, the higher the signal level from the sensor. The controller processes the signal from the knock sensor and adjusts the ignition timing to prevent further detonation. 5) Oxygen sensor - feedback on the quality of combustion of the mixture in the engine. If the sensor shows a low oxygen content in the engine exhaust gas, it means that the mixture is being prepared over-enriched, it is necessary to reduce the pulse duration to the injectors. If, on the contrary, the amount of oxygen is large, the fuel mixture is lean, and it is necessary to increase the fuel supply for normal engine operation. The use of an oxygen sensor allows you to control the chemical composition of exhaust gases and reduce emissions into the atmosphere. 6) The crankshaft position sensor is a kind of analogue of the ignition distributor with a Hall sensor on a carburetor VAZ. The crankshaft position sensor counts the teeth of a special disk mounted on the engine crankshaft. The toothed disk has a special place where there are no teeth - this place corresponds to the top dead center of the first cylinder of the engine. Thanks to the engine crankshaft position sensor, the controller knows which cylinder and at what point in time fuel and spark supply is required. 7) The speed sensor is installed in the gearbox and is designed to determine the speed of the vehicle. The principle of operation of the speed sensor is as follows: while driving, the speed sensor generates impulses to the controller, the frequency of which depends on the speed of the vehicle. Pulses come rarely, which means the car is moving slowly. Impulses come often - moves quickly. Each pulse means moving a certain distance, which is recorded in the controller’s memory. The phase sensor is installed only on cars with a 16-valve engine. The phase sensor is designed to determine the angular position of the engine camshaft. That is, the phase sensor allows the control system to determine which engine cylinder now needs to be supplied with fuel and a spark.

Based on the signal from this sensor, the controller regulates the duration of the pulse supplied to the injector, that is, the amount of fuel. The mass fuel flow sensor is installed in the air filter housing. Depending on the modification of the controller, the mass air flow sensor has two different types of output signal: a) Depending on the amount of air flow, the voltage from the sensor changes; b) Depending on the amount of air flow, the frequency of the sensor output voltage changes. In general, the task of the mass air flow sensor is to send a signal to the controller about the amount of intake air. 2) Throttle position sensor. The throttle valve is mechanically connected to the TPS. The throttle valve opens when you press the gas pedal; when the pedal is released, the throttle valve is closed. TPS is a regular rheostat, the slider of which is driven by the throttle valve. When the gas pedal is released and the throttle valve is closed, the signal from the TPS to the controller lies within 0.4..0.7V. As soon as the driver presses the gas pedal and the throttle valve opens slightly, the voltage at the TPS output begins to rise. When the throttle valve is fully open, the voltage at the sensor output is more than 4V. Receiving a signal to open the throttle valve, the controller increases the duration of pulses to the injectors, thereby increasing engine speed. 3) The VAZ 2109 coolant temperature sensor is designed to transmit information about the engine temperature to the electronic control unit, also known as the ECU, also known as the controller. If this sensor is faulty, it will be difficult or impossible to start the VAZ 2109 engine in cold weather. Receiving a signal from the DTOZH indicating that the engine is cold, the controller forms an enriched combustible mixture to start the engine. As it warms up and the temperature increases, the controller reduces the amount of gasoline in the mixture to its normal value. The principle of operation of the sensor is that the resistance of the sensor changes depending on the temperature. When the engine is cold, the resistance of the sensor is high; as it heats up, it decreases and on a warm engine it is 170 Ohms. 4) The knock sensor is designed to eliminate detonation in the engine. If the ignition timing calculated by the controller is correct, then the car engine runs smoothly, without shaking. However, if the engine begins to knock, then the ignition timing must be changed. This is what the knock sensor is used for. The sensor is installed on the engine cylinder head. Inside the knock sensor there is a piezoelectric element that generates voltage when the engine detonates. The stronger the detonation, the higher the signal level from the sensor. The controller processes the signal from the knock sensor and adjusts the ignition timing to prevent further detonation. 5) Oxygen sensor - feedback on the quality of combustion of the mixture in the engine. If the sensor shows a low oxygen content in the engine exhaust gas, it means that the mixture is being prepared over-enriched, it is necessary to reduce the pulse duration to the injectors. If, on the contrary, the amount of oxygen is large, the fuel mixture is lean, and it is necessary to increase the fuel supply for normal engine operation. The use of an oxygen sensor allows you to control the chemical composition of exhaust gases and reduce emissions into the atmosphere. 6) The crankshaft position sensor is a kind of analogue of the ignition distributor with a Hall sensor on a carburetor VAZ. The crankshaft position sensor counts the teeth of a special disk mounted on the engine crankshaft. The toothed disk has a special place where there are no teeth - this place corresponds to the top dead center of the first cylinder of the engine. Thanks to the engine crankshaft position sensor, the controller knows which cylinder and at what point in time fuel and spark supply is required. 7) The speed sensor is installed in the gearbox and is designed to determine the speed of the vehicle. The principle of operation of the speed sensor is as follows: while driving, the speed sensor generates impulses to the controller, the frequency of which depends on the speed of the vehicle. Pulses come rarely, which means the car is moving slowly. Impulses come often - moves quickly. Each pulse means moving a certain distance, which is recorded in the controller’s memory. The phase sensor is installed only on cars with a 16-valve engine. The phase sensor is designed to determine the angular position of the engine camshaft. That is, the phase sensor allows the control system to determine which engine cylinder now needs to be supplied with fuel and a spark.

Lada 2109 › Logbook › First problems. Coolant temperature sensor

The entry will be without photos, since I didn’t take any photos and didn’t think it could be useful. I’ll say right away: yes, in my particular case the whole problem was in the DTOZH. Neither the mass air flow sensor, nor the DPKV and TPS and cleaning the throttle valve also did not help

The car stalls while driving, kicks, increased speed

After I bought a nine, I discovered that it had high idle speeds, about 1500-1700, sometimes under 2000. At that time, I couldn’t check anything on the go, since I was still studying at a driving school, I didn’t have a license. As my good friend (also the previous owner of the car) told me, most likely the whole issue was in the mass air flow sensor, which consistently showed 1.035v, with the norm being 1-1.01v

Until I started driving it, I was also convinced of this. But on the second day of operation, interesting things began to happen: while the car was moving, when I pressed the gas pedal, it began to go crazy... It was shaking all over, the engine refused to turn, the speed dropped, and eventually the car stalled. It started up in about 30-40 seconds, with great difficulty. If, nevertheless, it started, then the revolutions were approximately at 1900 at idle, on a warm engine

In general, the problem was intermittent, and sometimes I could drive for half a day normally, but for other half days it started all over again

As I wrote earlier, I was sure that the mass air flow sensor was to blame for everything. I have no experience, so, to be sure, I asked several people, they all agreed on one thing

Okay, I called the dealership, found out about availability and price, and the next day I was about to go, when suddenly I had the urge to question the theory with the mass air flow sensor. I read a lot of forums and realized that a voltage of 1.035V is quite tolerable, people change the sensor with a voltage of 1.1V, and up to its value they do not experience any problems other than increased consumption

Okay, let's say we exclude the mass air flow sensor, then what do we have left? Injection machines are rich in various sensors, so I went deeper... I read about the possibility of poor contact of the crankshaft position sensor. I go out, open the hood, remove the chip from the sensor, and inspect it. Dirty, but looks healthy. I put it back, start it, the car turns at 1700, as it was. I fiddle with the sensor, it doesn’t stall, everything is fine. Okay, let's rule it out, read on

Sensors VAZ 2109

The Nine managed to make a lot of noise among the people, in the 90s “bandits” drove it, and in the 2000s it was used by young people, but even today there are more than enough of these cars. Initially, in 1993, the VAZ 2109 was equipped with a carburetor engine, but progress did not stand still and in the late 90s the nine received an injection engine, which had a positive effect on its technical characteristics.

As you know, for proper and reliable operation, an injection engine requires a large number of sensors and a “brain” that will manage it all. There are a lot of sensors on the VAZ 2109 and they are all interconnected in their own way.

This article will focus specifically on the sensors of the injector system on the VAZ 2109, namely, their purpose, location and signs of malfunction.

Hall sensor VAZ 2109 (carburetor)

Its malfunction can cause problems in the carburetor. And it is very difficult to determine that this tiny detail is to blame. Perhaps, by the method of elimination. Sometimes they suggest checking its operation using a special device.

A simple way to check the performance of the Hall sensor of a VAZ 2109 (carburetor)

Take a sample with a light bulb. Its plus and minus (these are the extreme contacts) on the plug are connected to the distributor. There should be a gap between the center wire and ground. After this, you need to close the “minus” and the center. terminal. A spark will appear on the wire or spark plug. If it appears, the Hall sensor needs to be changed. If not, check further.

However, it also happens that the sensor works, but incorrectly. Here you can find out only by replacing.

If you do not know where the Hall sensor is located on a VAZ 2109 (carburetor), the photo below will help you.

"Hall sensor" number 8 in this photo

The price for a VAZ 2109 Hall sensor (carburetor) is usually low - about 120 rubles.

This photo shows a VAZ 2108 breaker plate with a Hall sensor:

Fan switch on VAZ 2109 (carburetor)

If you are interested in replacing the VAZ 2109 carburetor fan switch sensor, many are interested in whether it is possible to change it without draining all the coolant?

The answer is yes. But you will lose some coolant during the replacement process. This sensor is essentially an ordinary thermostat. There are special toggle switches on sale that can be used to turn it on forcibly.

Fan switch on VAZ 2109 (carburetor)

Sometimes you just need to take everything apart and clean it. Dirt and scale may get on the sensor. In any of these cases, even if you need to change the sensor, there is nothing wrong with that. The part itself is very cheap; it can be replaced either by the driver himself or by car workshop workers.

You can also read on this topic:

Manual transmission (manual transmission) and its purpose

Toyota Land Cruiser - an indestructible off-road conqueror

When and how to change brake pads on a car

New car up to 750,000 rubles: how to make a choice

Choosing car varnish from a huge assortment

Share on social networks

Alex S January 9, 2014

Published in: Useful tips and car devices

Tags: Advice for motorists

Electronic engine control unit

The engine control unit is responsible for the operation of almost the entire car. In this part, hundreds of processes are calculated, all readings from sensors installed on the car are processed. Many people call the ECU a “computer” and it’s impossible to disagree with this. The unit, receiving readings from the sensors, processes them and controls the engine, adjusting the supply of fuel and air to the combustion chamber.

Location

The engine control unit on the VAZ 2109 is located under the glove compartment at the feet of the front passenger. You can see it by looking under the panel; the block is closed with a special plastic cover.

Signs of malfunction:

Problems with the operation of the sensor are most often associated with damage to the microcircuit, for example, burnout of a track or damage to one of the radio components, due to which one of the cylinders may fail, etc. It is quite difficult to judge the failure of the ECU based on its symptoms, since they are all similar to the failure of one of the sensors, so the malfunction of the unit can only be determined by diagnosing, disassembling, or replacing it with a known good one.

Speed sensor

With the transition of the nine to an injector, the measurement of vehicle speed began to be carried out not mechanically, using a special sensor that reads readings from the rotation of the gearbox gears, transmitting the readings to the computer. The block processes the readings from the sensor and sends signals to the speedometer.

Location

The VAZ 2109 speed sensor is located on the gearbox housing, you can see it by looking under the thermostat and you can find this sensor next to the gearbox dipstick.

Signs of malfunction:

Knock sensor

The knock sensor on the nine is used to detect detonations in the engine that occur due to low-quality fuel. These detonations can cause serious damage to the engine if they are not corrected in time, which is exactly what the knock sensor does. It detects detonation, then sends a signal to the ECU, which adjusts the ignition timing, thereby reducing detonation in the engine.

Location

The knock sensor is located on the block in the middle, it can be seen between the 2nd and 3rd cylinders.

Signs of malfunction:

Engine cooling system VAZ-21083

1 – expansion tank; 2 – expansion tank plug; 3 – steam removal hose; 4 – hose from the expansion tank to the thermostat; 5 – radiator supply hose; 6 – radiator outlet hose; 7 – left radiator tank; 8 – aluminum radiator tubes; 9 – sensor for turning on the electric fan; 10 – right radiator tank; 11 – drain plug; 12 – radiator core; 13 – electric fan casing; 14 – electric fan impeller; 15 – electric motor; 16 – pump gear pulley; 17 – pump impeller; 18 – camshaft drive toothed belt; 19 – heater radiator outlet pipe; 20 – pump supply pipe; 21 – tap; 22 – heater radiator; 23 – hose for draining fluid from the heating of the inlet pipe to the carburetor heating block; 24 – carburetor heating block; 25 – exhaust pipe; 26 – heater supply pipe; 27 – hose for draining fluid from the heating of the inlet pipe and the carburetor heating unit; 28 – coolant temperature indicator sensor; 29 – thermostat.

Air flow sensor

The mass air flow sensor, also known as MAF, is probably the most famous and most recognizable sensor of all the sensors in a car. Its purpose is to count the air entering the engine. Air counting is necessary to create the air-fuel mixture in the correct proportions.

Location

The VAZ 2109 air flow sensor is located on the intake corrugation between the throttle valve and the air filter housing.

Signs of malfunction:

Throttle position sensor

This sensor is necessary to determine the opening angle of the throttle valve. These readings are necessary to correctly determine the air supply to the engine. TPS works in tandem with IAC and mass air flow sensor. Since the sensor is made of a rheostatic type, that is, it changes its resistance with each opening of the throttle, it quite often fails.

Location

The TPS is located on the throttle valve of the VAZ 2109.

Signs of malfunction:

Crankshaft position sensor

The crankshaft sensor (CPS) is one of the main sensors in the car system; if it breaks down, the engine will not even start. It takes readings from the position of the crankshaft, namely, it determines the top dead center of the piston. This is necessary so that the ECU understands when to send a signal to send a spark to the combustion chamber of a certain cylinder.

Location

The DPKV on the VAZ 2109 is located near the generator drive pulley; you can find the sensor by looking behind the oil filter; next to it there is a crankshaft sensor.

Signs of malfunction:

Replacement instructions

Replacing the DTOZH on a VAZ-2109 (injector) is quite simple, you can do everything yourself, you need to follow the following algorithm of actions:

- First you should check the fuses. If they burn out, then it is because of them that the DTOZH shows incorrect values. If the fuses are not blown, you need to move on to the next step.

- You must wait until the engine cools down. Then you need to drain the liquid from the cooling system.

- Next, you need to disconnect all the wires going to the DTOZH.

- Using a socket, unscrew the thermostat and remove it from the hole located in the pipe.

- Using a rag and cleaner, you need to treat the hole where the DTOZH is attached. If treatment is not carried out, temperature changes may occur again.

- Next, you need to install a new sensor and connect a conductor to it.

- Fill the radiator with antifreeze.

- Check engine operation.

The temperature regulator on the VAZ-2109 can be changed independently, without the help of specialists. Mostly, problems occur due to a broken wire or poor contact. The first sign of a breakdown is the random turning on of the fan.

Coolant temperature sensor

To measure the coolant temperature in the VAZ 2109, a special sensor is used, which serves to determine the fluid temperature and adjust the fuel mixture. The sensor changes its resistance depending on the temperature of the liquid and transmits the readings to the ECU, and the unit sends signals to the injectors to supply the required amount of fuel to warm up the car.

Location

The DTOZH on the VAZ 2109 is located in the thermostat housing; you can find it by removing the air filter box.

Signs of malfunction:

Replacing the coolant temperature sensor on a VAZ 2108, VAZ 2109, VAZ 21099

Location

Located in the exhaust pipe of the cylinder head, look at the photo below:

Note! There is a sensor directly in the person’s hand, and a red arrow indicates the hole where it is installed.

When to change the sensor?

• The presence of a sensor malfunction leads to engine malfunction - starting is difficult in cold weather.

• In hot weather, the car engine heats up to high temperatures. A broken sensor will cause a loss of engine power and increase fuel consumption.

Coolant temperature sensor VAZ 21083, 21093, 21099, injector

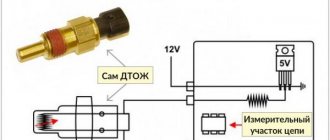

The coolant temperature sensor (DTOZH) is an element of the electronic injection engine control system (ECM) of VAZ 21083, 21093, 21099 vehicles.

Based on its readings, the control unit (ECU) determines the thermal state of the engine and calculates the required amount of fuel mixture for injection and ensuring normal operation engine in different modes.

Coolant temperature sensor (DTOZH) VAZ 21083, 21093, 21099, injector

— Temperature sensor location

On VAZ 21083, 21093, 21099 vehicles with injection engines, the sensor is installed in the coolant outlet pipe between the thermostat and the block head.

— DTOZH device

It is a thermistor - a resistor with a negative temperature coefficient, the resistance of which changes with increasing or decreasing temperature. When heated, the resistance decreases, when cooled it increases. For example, at plus 100 gr. – resistance 180 Ohms, at minus 40 – resistance 100700 Ohms. On one side of the sensor there are two contacts; on the other (located in the coolant flow) there is a sensitive element.

— Operating principle of DTOZH VAZ 21083i, 21093i, 21099i

After turning the key in the ignition switch, the control unit supplies voltage to the DTOZH through a resistor with a constant resistance located inside the unit. Since the temperature sensor is a thermistor, the voltage supplied from the ECU will immediately change depending on the coolant temperature. Based on the voltage drop, the control unit calculates the engine temperature and, accordingly, the volume of fuel for injection. The voltage drop will be high when the engine is cold (more fuel is injected) and low when the engine is warm (less fuel is injected). As the engine warms up, the volume of fuel entering the engine cylinders decreases.

In addition to starting, based on the temperature sensor readings, the control unit adjusts engine idle speed, decides to enrich the fuel mixture at medium and high load modes, changes the ignition timing in one direction or another, and turns the cooling system fan on and off.

— DTOZh malfunctions

If the temperature sensor goes out of order, it does not allow the ECU to correctly calculate the amount of fuel required by the engine at the moment, and this in turn leads to the inability to start the engine, especially in cold weather, interruptions in its operation at idle and while driving, and increased fuel consumption. In addition, a malfunction of the DTOZH may be one of the reasons for engine overheating (untimely switching on of the cooling system fan) or, conversely, its prolonged warming up.

In some cases, if a temperature sensor malfunctions, the engine control system switches to backup mode. In this case, at startup, the ECU considers the engine temperature to be zero, the calculation of the dependence of the volume of injected fuel on engine warming up will be carried out based on the time it is running, and not on the readings of the temperature sensor, the cooling system fan will be constantly on. The Check Engine light on the instrument panel lights up, and the self-diagnosis system will write an error code into the memory of the control unit.

You should not immediately replace the sensor with a new one; you must first check the sensor connection connector and the wires leading to it. If a malfunction occurs on the way, you can remove the connector from the sensor and drive to the repair site in the ECM backup mode. Also, if the car engine does not start well, or does not start at all at low temperatures, you can remove the chip from the sensor and the engine will start.

— Applicability of DTOZH

VAZ 21083, 21093, 21099 with injection engine 2111 – DTOZH 2112-3851010 (23.3828).

Notes and additions

— A resistor is an element of an electrical circuit that has resistance. They allow you to control and regulate the voltage and strength of the electric current passing through them. The unit of resistance is Ohm.

— In addition to the coolant temperature sensor, the injection engines of VAZ 21083, 21093, 21099 cars have a coolant temperature indicator sensor, which is designed to display information on the instrument panel about the engine temperature. These are two completely different sensors with different functions.

Coolant temperature sensor for VAZ 2109 and 21099 cars

Location of the coolant sensor in the VAZ 2109

First, it is advisable to know where the engine temperature sensor is located. On models 2108, 21099 and VAZ 2109, the coolant temperature sensor is installed between the cylinder head and the thermostat, in the exhaust pipe.

Device and principle of operation

The engine temperature controller itself is a thermistor-resistor device characterized by a negative temperature coefficient. The resistance parameter itself can be measured only when the temperature decreases or increases.

When the power unit heats up as a result of operation, the resistance indicator decreases; if the engine cools down, this parameter increases. For example, at the operating temperature of the engine on a VAZ 2109, the resistance is equal to 180 Ohms, and if it is 40 degrees cold outside, then the resistance will be equal to 100,700 Ohms. On one side of the DTOZH VAZ 2109 injector there are two contacts, and on the other there is a sensitive component, which is located directly in the flow of consumables.

As for the principle of operation, when the driver turns on the ignition, the control unit transmits voltage to the regulator via a resistor. Since the DTOZH itself is a thermistor, the voltage supplied from the control unit changes immediately taking into account the temperature of the consumable. When the parameter decreases, the unit analyzes the temperature and, in accordance with these data, determines the required volume of gasoline for injection. As the power unit warms up, the volume of gasoline that is transferred to the cylinders will decrease.

Two antifreeze temperature sensors for VAZ

In addition to starting, according to the readings of the regulator, the ECU adjusts the operation of the power unit at idle speed. As a result, he independently makes decisions on enriching the combustible mixture at high and medium loads on the internal combustion engine. This indicator can be changed depending on the ignition timing.

There are two temperature sensors on a carburetor car. One turns on the fan, the other is responsible for indicating the temperature on the dashboard.

Possible faults

There are several reasons why the regulator on the VAZ 21099 refuses to work.

So, why DTOZH does not work:

- An electrical contact is located inside the device structure. Over time, this contact may simply break or cracks may form on it. If a break occurs inside the structure, this may cause complete failure. That is, the DTOZH will simply burn out. If there are cracks on the contact, the DTOZH, in principle, can work, but as a result of the lack of normal contact, the regulator will transmit incorrect data about antifreeze.

- Poor device insulation. If the insulation is broken, short circuits may occur in the operation of the device. Accordingly, ultimately, these short circuits can lead to the DTOZH, again, burning out and having to be replaced.

- There was a broken wire near the regulator. As a result of the break, the regulator will not be able to activate the fan designed to cool the power unit. Accordingly, this will lead to the engine overheating and may even boil (the author of the video is a Mechanical Technician).

How can a car owner understand that the DTOZh is out of order and it’s time to replace it?

To do this, it is enough to know about the main signs of problems, which we will discuss below:

- The fan designed to cool the engine can turn on randomly at any time. In particular, the driver should be wary that the fan turns on when the engine is not completely warmed up. Remember that the fan should always function when the internal combustion engine is overheated.

- The driver has difficulty starting a warmed-up internal combustion engine. The cooling system should automatically adjust the temperature, but because the unit is faulty, it cannot receive the correct signal.

- If you carefully monitor the operation of the car, you will notice that gasoline consumption has increased. The increase in consumption is due to the fact that the car is simply overloaded when running on a hot internal combustion engine.

- If the device fails completely, the gauge on the dashboard will show an incorrect temperature signal. A ten-minute drive is enough to warm up the engine. If after 10 minutes the temperature has not risen to the optimal temperature or when starting the internal combustion engine, the dashboard shows overheating, this indicates a malfunction.

Malfunctions

There are several main malfunctions that lead to failure of the coolant temperature sensor. Namely:

In the summer, a failure in the operation of the diesel engine is rarely noticed, but in winter it becomes much more difficult to start the engine.

Signs of breakdown

How can you determine that the coolant temperature sensor has stopped working normally or has completely burned out?

Before making final conclusions regarding the breakdown or malfunction of the DTOZH on the VAZ 21099, be sure to carry out verification activities.

Reasons for sensor failure

The specialist told me about such common causes of failure as:

- Sudden actions when the car is moving.

- Much higher fuel consumption.

- Much higher number of revolutions (idling).

- Poor starting on hot and cold liquid.

- Device overheating.

- DTOZH VAZ 21099 injector provides incorrect temperature values for cold liquid.

- A break inside the DTOZH VAZ 21099 injector or wires.

Someone will ask about the location of the temperature sensor on the VAZ 21099 carburetor injector? It is located between the engine cylinder block and the thermostat or on the hose. And to connect it, you can use car diagrams, which can be found in large quantities on the Internet.

By the way, the temperature sensor may produce incorrect values if it malfunctions. The main reason is a breakdown of the light bulb indicating t°, a malfunction of the t° sensor specifically, or a malfunction of the electrical circuit.

Examination

Today, VAZ 2109 car owners use two methods to check the condition of the coolant temperature sensor. Let's say right away that the second one is more reliable, but the first one is easier. Decide for yourself which of the methods presented below to use.

Verification method

Your actions

According to the table, check whether the resistance corresponds to that required at a particular temperature of coolant or boiling water.

Temperature (in degrees Celsius)

Resistance (Ohm)

If there are deviations from the norm, we conclude that the sensor no longer performs its functions properly and therefore requires mandatory replacement.

Sensor check

VAZ 21093 coolant temperature sensor

There are two ways to check. To check the temperature sensor in the first way, you should:

- Connect the negative end of the voltmeter to the engine.

- Turn on the ignition.

- Using a voltmeter, determine what voltage is generated while driving a car.

- It is important that this voltage is at least 12 V (with a charged battery).

Note: otherwise you will have to either repair or replace the sensor with a new one.

VAZ 21093 coolant sensor

The second verification method is more reliable. To implement it you need:

- Set the multimeter to voltmeter mode. The voltage should be measured in the range from 100 Ohms to 10 kOhms.

- Take a thermometer that can change the temperature up to 100 degrees and above.

- Place the sensor in a container with coolant.

- Warm it up. In this case, you should constantly monitor the temperature, which a thermometer will help with.

- Measure the resistance of the sensor at different temperatures.

Note: This method can be slightly modified. Pour boiling water into the container and immerse only the working part of the sensor in it. Monitor the resistance of the sensor as the water cools.

Coolant temperature indicator sensor VAZ 2108, 2109, 21099

The coolant temperature indicator in the instrument panel of VAZ 2108, 2109, 21099 cars and their modifications receives information about the coolant temperature in the cooling system from a sensor installed in the engine cylinder block.

This is the coolant temperature indicator sensor TM 106.

Installation location of the coolant temperature indicator sensor

On VAZ 2108, 2109, 21099 cars with carburetor or injection engines, it is screwed into the end of the cylinder block, above the gearbox housing. There is only one wire going to it (“negative”).

Coolant temperature gauge sensor device

The coolant temperature indicator sensor TM 106 has a brass body with a turnkey nut set to “21”. The threaded part of the housing is made in the form of a cone to seal and seal the sensor in the mounting hole. At the bottom of the sensor housing (washed by coolant) there is a “tablet” of a semiconductor thermistor. It is pressed by a current-carrying spring. One end of the spring rests against the semiconductor and the other against the contact part of the sensor with a wire outlet. The spring is isolated from the walls of the sensor.

Operating principle of the temperature indicator sensor

The operating principle of the temperature indicator sensor is based on the operation of a semiconductor thermistor installed in it. When the coolant temperature is low - the thermistor resistance is high - the current flowing through the sensor is small - the temperature indicator arrow in the instrument panel is deflected to the left. As the liquid warms up, the resistance of the thermistor drops - the current increases - the arrow on the temperature indicator rises.

Applicability of the coolant temperature gauge sensor

VAZ 2108, 2109, 21099 cars with carburetor and injection engines, cars of the 10th family, Samara-2 (2113, 2114, 2115), etc.

Temperature gauge sensor malfunctions

If problems arise with the temperature indicator sensor, the indicator itself in the instrument panel begins to show incorrect information. It is necessary to determine the specific reason: the sensor or pointer is faulty. To do this, turn on the ignition, remove the wire from the sensor and touch it to ground. If the sensor is faulty, the pointer will move to the left to the beginning of the scale. If the arrow does not move, you must first check the electrical circuit of the coolant temperature indicator or replace it with a working one.

Characteristics of the TM 106 sensor

Temperature measurement range: 45-140º

Rated voltage: 12V

Sensing element: thermistor

Connection diagram for TM 106 sensor

Notes and additions

— On VAZ 21083, 21093, 21099 cars with a 2111 injection engine there is another coolant temperature sensor (DTOZH). It is installed in the pipe leading from the thermostat to the engine. Based on its readings, the ECM control unit determines the coolant temperature in the cooling system. This is one of the parameters by which the control unit calculates the injection amount, ignition timing, and voltage in the ignition system.

— In the cooling system of carburetor engines of VAZ 2108, 2109, 21099 cars there is another temperature sensor - the sensor for turning on the engine cooling system fan. It is located on the right radiator tank; its signal turns on the radiator fan. There is no such sensor in the cooling system of an injection engine. There, turning on the fan is controlled by the control unit based on a signal from the DTOZH.

Source

VAZ 2109: coolant temperature sensor and its malfunctions

Coolant temperature sensor

In a VAZ 2109 car, the coolant temperature sensor plays a very important role. Without it, the system will not function properly, which can lead to overheating or hypothermia of the machine. Therefore, if any problems are observed with the sensor, they need to be diagnosed in advance so that later it is not too late. On a VAZ 2109, you can easily check the coolant temperature sensor on your own.