Armoring headlights is one of the ways to protect them. There are different types of protective film. It can be of different thicknesses and made of different materials. This can be polyurethane film with a thickness of 250 to 500 microns, or vinyl film with a thickness of only 76 microns. Reservation refers more to the installation of a polyurethane film, similar to that which is glued to the body of a car. It contains ultraviolet inhibitors that prevent the polycarbonate from yellowing. Polyurethane also has self-healing properties, allowing it to recover from minor scratches. You need to heat it with a hairdryer or hot water, or it will restore itself on a hot day under the sun. This protection is very durable. Well-known manufacturers provide a 3-5 year warranty upon certified installation. If the car does not drive constantly at high speeds (the sandblasting effect increases at speed), then the “armor” will last longer, up to 10 years.

A special clear vinyl film can also be applied to headlights. It comes in different colors and varying degrees of darkening, is protective, but will not provide the same degree of protection as polyurethane, and does not have self-healing properties. Vinyl mainly protects from sunlight, which is harmful to polycarbonate, as well as from minor scratches. Sticks to any car optics using moderate heating with a hairdryer, stretching and smoothing. The service life of such vinyl is much shorter than that of polyurethane and is usually 2-3 years.

Approach this issue with caution

What are the disadvantages?

The anti-gravel film on the headlights dissipates the STG line, resulting in blinding oncoming cars. Scattering also results in loss of light beam, which causes inconvenience to the driver. Therefore, if the decision is made in favor of booking, then what kind of film should be used to cover the car headlights? It is best to do this with polyurethane. It is absolutely smooth, without its own shagreen. As a result of pasting, the light beam does not change. Vinyl is best used for additional protection of other parts of the car. On car enthusiast forums there are different opinions about whether it is possible to glue film to car headlights.

But at least most owners agree on one thing. Polishing the headlights and covering them with film, using protective elements such as covers, using film for the rear lights - all this preserves the appearance and makes the car respectable if sold.

What to do if protection needs to be removed

Even the best quality armor coating will someday need to be replaced. There are some nuances when removing anti-gravel film.

when a large amount of damage occurs on the film, it will need to be removed

First of all, you need to heat the film. To avoid temperature fluctuations, ensure that the entire vehicle warms up slowly and evenly. To do this, it is enough to place it in a garage, the air in which is not lower than 20 °C. If you are performing surgery in winter, install heaters in the room. Within 2–3 hours the film will reach room temperature.

Now you will need a hair dryer. You can use a regular household one if it can heat up to 60–80 °C. Otherwise, it is better to use an industrial one. To properly remove the film, please read the following instructions carefully.

Direct a stream of air onto the film. Carefully pry up the shortest edge so as not to damage the surface of the headlight. Begin to carefully peel it away from the surface. In this case, the angle between the film and the headlight should be approximately 30°. After the final removal of the film, clean the surface of the headlight from any remaining adhesive. Rinse it with clean water. Now you can install a new anti-gravel coating or leave the headlight in its original form

Now you can install a new anti-gravel coating or leave the headlight in its original condition.

Video: how to remove protective material from headlights

Removing film from headlights, and in general from any surface.

Buying and installing an anti-gravel film will cost you much less than replacing a headlight. And if you carry out this process at home, you will save even more. At the same time, gluing armor is not a complicated process at all, if you know certain nuances and follow all the rules. In addition, the surface to be treated does not have a particularly large area, which greatly simplifies the work. In other words, don't be afraid to try making things yourself. You can do this quite well.

How to properly glue film to headlights?

Passing MOT and possible punishment

How to tint headlights with film

Car owners who want to do tuning often think about whether it is possible to tint headlights with film. It is impossible to answer this question unequivocally, the point is not spelled out in the Code of Administrative Offences, but still the owner of the car can be punished. Each case is considered separately.

Difficulties may arise when passing a technical inspection. On the one hand, the law does not punish tinting headlights, but on the other hand, lighting devices must meet a number of requirements specified in GOST. During maintenance, they are necessarily checked for light transmittance, mechanical damage, size compliance, presence of foreign elements and other parameters. If the light transmittance of the headlights is below 85% due to the film, you will not be able to pass the MOT.

If the headlights are tinted with film, the fine can vary within several thousand rubles. Punishment is imposed only in cases where the light transmission capacity is greatly reduced and the car can create an emergency situation on the road. Such cars are classified as faulty or those whose operation is prohibited. According to the Code of Administrative Violations, fines are imposed in the following amounts:

- 3000 rubles for individuals;

- up to 20,000 rubles for officials responsible for operating the vehicle;

- up to 500,000 rubles for legal entities.

For driving a car with tinting, the driver can be fined 500 rubles if the lighting devices do not transmit enough color. If the color red is used on the headlights, the driver may be disqualified from 6 to 12 months.

For tinting rear headlights with film, the fine does not exceed 500 rubles, but in practice it is usually not charged.

And although the law does not provide for punishment for tinting lighting fixtures, it is worth assessing all the risks before applying it. If you want to protect lighting devices from damage, you should choose transparent film. If the main goal is tuning, you should pay attention to the choice of material and refuse to purchase a dark-colored option, which significantly impairs the passage of light.

Effectiveness of headlight armoring with vinyl film

Do-it-yourself car wrapping

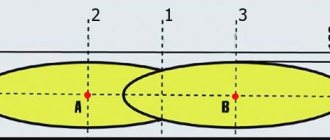

The special vinyl film itself is not durable. It consists of ordinary vinyl, which is easy to cut or tear. However, the molecular structure of the vinyl film makes it possible to significantly reduce the impact energy of a stone hitting the headlight from the car in front. In other words, when a stone hits a headlight armored with vinyl film, such a film distributes the impact energy from the stone, and the headlight does not receive a point blow, but is distributed over a larger surface. Thus, the impact energy density is reduced, and the surface of the headlight is able to withstand a blow from a stone without breaking. However, if a too large stone does come across, the effectiveness of the vinyl film will not be enough, and the surface of the headlight will still crack; it will not scatter to the sides, since the film will hold all the fragments in place. In other words, vinyl film will allow you to drive with such a cracked headlight for some time before purchasing a new one.

How to remove

After the armor film has used up its resource, the question arises of how to remove it. It is impossible to peel off the armor like ordinary material; scraping it with a knife is not recommended.

It is forbidden to use gasoline or acetone: in 99% of cases cloudiness remains on glass and plastic headlights.

You can quickly remove the armor using a hairdryer. If the part is glass, you can choose a higher temperature for heating the film and, after softening the material, remove the protection. If it is plastic, strong heating is not recommended: the plastic will darken.

Before heating the part, the body is degreased so that there are no solid particles left on the film, which could burn it when heated and leave a noticeable mark on the body.

Residues of glue after removing the vinyl film are removed with White Spirit. Car service technicians recommend cleaning car headlights and hoods from glue using the following means:

- Allegrini Puliscitutto;

- Koch Orange Power/ Eulex;

- 3M Orange;

- Mr. Muscle with ammonia.

How to tint headlights with film yourself - detailed instructions

How to tint rear and front headlights with film and varnish

If you don’t know how to tint your headlights with film yourself, check out the step-by-step instructions below. First, prepare the materials and tools that you will need during the work process:

- film for tinting headlights;

- water;

- degreaser;

- napkins;

- stationery knife;

- squeegee.

Do-it-yourself headlight tinting with film is performed in the following sequence:

- Prepare the film. Cut the blank according to the dimensions of the lighting fixtures. Cut off the material with a margin and remove the excess at the end.

- Prepare the surface of the lighting fixtures. First, wash them from dirt with water, then degrease them with a special product and wipe dry with a napkin or soft cloth. For degreasing, you can also use wipes impregnated with a special composition.

- Wet the prepared surface with water. It is better to use a spray bottle for these purposes, but if you don’t have one, a clean rag will do.

- Remove the protective layer from the film and apply it to the surface of the lighting fixture.

- Straighten the material with a squeegee. Using a fairly strong pressing force, smooth the film from the center to the edges so that small air bubbles come out.

- Trim off any remaining material. Use a sharp utility knife for this.

The technology for tinting the front and rear headlights is no different.

Application procedure

No one is stopping you from covering your headlights with film yourself. The technology is far from being so complex that you have to pay specialists for it. Plus, keep in mind that they usually charge at least 2 thousand rubles for covering the front optics. How much or little this is, decide for yourself. The more expensive the car, the higher the cost of services. That is, 2 thousand rubles is far from the limit.

If your vehicle has fog lights, they will have to be removed. All other optics are pasted over without necessarily dismantling.

Before you apply protective film to car headlights yourself, it is important to consider the presence of 2 key steps. Some people simply glue it after wiping the surface of the optics with a dry cloth. But this is the wrong approach, which can negatively affect the result.

Be sure to stick it according to technology. Otherwise, the glued protection may quickly fall off or peel off. You should talk in more detail about how to properly apply armor film to the headlights of your car.

Divide the whole process into 2 stages:

- Preparation;

- pasting.

Approach each of them as responsibly as possible. If you make mistakes at the very beginning, they will affect the final result.

Preparation

To complete the task and protect the headlights of your vehicle using armor film, you need to take:

- the material itself is vinyl or polyurethane based;

- high-quality degreaser;

- rubber roller;

- small rubber spatula;

- hair dryer (even a regular household hair dryer will do);

- microfiber;

- Be sure to use sharp scissors or a stationery knife.

That's all with the selection of materials and tools. All that remains is to prepare the surfaces of the headlights and then apply anti-gravel material.

If you skip the preparation stage, everything will initially look good. But after some time the coating will probably fall off. Preparation also includes removing all dirt and stains. Otherwise, they will be visible through the transparent anti-gravel.

- Start by removing existing contaminants such as dust, road grime, etc. Use detergent, warm water and a soft microfiber to avoid scratching the surface of the headlight housing. Rinse everything thoroughly with clean water. Make sure there are no traces of soap left anywhere.

- If bitumen, glue or sealant gets on the optics, they must be carefully cleaned off. These stains can be easily removed with vinegar or special cleaners. Acetone is contraindicated for plastic headlights.

- When you have cleaned all surfaces, the drying stage begins. You can leave the car to dry for a while, or go over the headlights with a hairdryer. Do not turn it on at high temperature.

- After completing the procedures, take a new dry microfiber, soak it in a small amount of degreaser, and go over the body of the car's optical instruments. This will finally rid the surface of a thin layer of fat, which is visually invisible, but is certainly present.

There cannot be a break between preparing the headlights and applying the armor film. During downtime, even if you have a clean and closed garage, a layer of dust will begin to quickly settle.

In this situation, medical gloves will come in handy. After degreasing, do not touch the surface of the glass or plastic of the headlight housing. To avoid causing new stains, use silicone gloves.

Pasting

Initially, you need to take a piece of armor film and make blanks from it. There is no need to repeat the exact shape of the headlight body itself, but make a margin of at least 10-15 millimeters at the edges. It is better to leave about 2-2.5 cm, and then simply trim off the excess with scissors or a sharp stationery knife.

The entire procedure for applying protective material can be divided into several points:

- prepare the surface;

- cut the blanks with an overlap of about 2 cm on each side;

- grab the edge that will then be trimmed;

- carefully remove the backing, removing about 4 centimeters, but not removing completely;

- apply to the surface of the headlight being processed;

- start gradually smoothing the material.

And here you should decide in advance which smoothing method you will use. There are 2 ways in total. Each of them has its own nuances.

Let's start with the wet method. With this tactic of covering headlights with a protective anti-gravel film, you need to cover the optics with a weak solution of shampoo and water. A thin layer is applied. When choosing a shampoo, you can use a special car shampoo or a children's one.

As you press the film, use a soft rubber spatula to gradually remove excess water from under the material. You need to move from the center towards the edges of the headlights. When you have completely leveled the coating, work again from the center to the edges of the optics, but with a soft rubber roller. Dry thoroughly.

The dry method technology is different. This involves the use of warm air created with a hairdryer. If you are using a household hair dryer, turn it on at maximum temperature. When smoothing, while simultaneously heating the material, remove the backing and distribute the anti-gravel over the optics body. Here you also need a spatula and a rubber roller.

The advantage of the wet method is its simplicity. It makes it easier to process large and relatively flat areas without complex bends and turns.

In both cases, it is important to avoid the formation of air bubbles under the anti-gravel material. Therefore, it is extremely important to work carefully but carefully with a spatula, immediately removing all excess air. If it doesn't work out the first time, don't worry. Just lift the film a little, reaching the area with an air bubble, and re-apply to the surface.

When you are finished gluing, use sharp scissors or a utility knife to trim off the excess. Try to act carefully, otherwise you may hit the headlights themselves and leave scratches on them.

Three-layer armor films have good advantages. The bottom layer serves as a substrate, the second acts as the main one, and on top there is another protection. Once finished, simply peel off the top layer. This way you can avoid accidental damage to the surface when removing overlaps.

After completing all the procedures, it is recommended to leave the car in the garage for at least 1-2 days if the wet method was used. It will be good if the garage is heated or at least does not have problems with high humidity. With the dry method, the waiting time is reduced to 10-12 hours. The car cannot be washed during this period.

Advantages of booking car headlights

In addition, this coating has a number of other advantages. Thanks to its smooth surface, it is easy to clean from insects and dirt when washing your car. Absolutely neutral when washing cars with non-aggressive chemical detergents. And if you get scratches from small stones or branches, such films can be easily dismantled and replaced with new ones. The glass will remain perfectly clean and undamaged.

Protective effect of armor film

Why were vinyl materials chosen? As it turned out, this material does not change the luminous flux and its magnitude. According to the manufacturers of such accessories, the light transmission of such products reaches values from 97 to 99%. This procedure can be performed either in a tuning studio or independently. After all, in external tuning companies you will have to fork out a considerable amount of money. If you do the whole process yourself, you can only get by with the cost of the material. How to book headlights is described in the algorithm below.

Minuses

Despite all the obvious advantages of booking headlights with film, this option also has disadvantages:

- The film sharply impairs the heat dissipation of the glass when the lamp is on, which means there is a high risk of it overheating and bursting at the most inopportune moment.

- It would seem that the obvious advantage of the film in retaining fragments, on the other hand, poses a significant threat to the safety of the driver and his passengers. If you delay replacing the glued-on optics and continue to drive a car with broken headlights, you risk getting into an accident due to the fact that cracks in the glass distort the light beam and the illumination does not meet safety requirements.

- High performance characteristics of the coating are limited to a small temperature range. At temperatures below -20 degrees and above 80 degrees, the film loses its protective properties.

- Yellowness. This disease depends on the quality of the film itself. In some cases, yellowing of the coating may occur over time due to the influence of UV rays and light bulbs. However, professionals insist that if you do not initially skimp on film and its installation, this problem can be avoided.

- Deterioration in light transmission is also possible and depends on the material used. This deficiency is often disputed and points to the dishonesty of the manufacturers themselves. However, many motorists observe dimming of their headlights after armor treatment.

- After reserving headlights, experts recommend avoiding driving in the rain, as well as car washes for several days after the procedure.

- The film is resistant to aggressive detergents, as well as high-pressure water jets.

- High cost, which, nevertheless, according to many masters, justifies the result.

Headlight reservation procedure

To properly protect your car headlights from damage, you must strictly follow all the rules for applying the film. For this work you will need the following tools and materials:

- stationery knife;

- soapy water spray;

- cleaning and degreasing agent;

- construction or household hair dryer;

- film for booking of appropriate thickness;

- rubber or silicone spatula.

You need to start work by preparing the surface of the headlights. On modern cars, in most cases, these elements are made of special transparent plastic, so cleaning and other operations should be carried out extremely carefully and carefully so as not to cause scratches and abrasions.

The preparation of headlights includes their thorough washing using detergents and degreasing with alcohol or another product safe for glass and plastic.

When booking optics, it is important to properly prepare the room, since it is highly not recommended to do this work in the open air. On the street it will be very difficult to avoid dust and other debris that is blown by the wind from falling on the surface. It is best to reserve headlights in a well-cleaned and lit garage. At the same time, the room temperature should be normal - ideally, if this indicator is in the range from 25 to 35 degrees Celsius.

A few words should also be said about the fact that there is no need to remove optical instruments to apply armored film. Firstly, such material adheres quite firmly to the surface without additional gluing to the back of the headlight. Secondly, after completing the procedure, you will most likely have to go to a service center to adjust the position of the optical instruments.

After preparing the headlights and the work area, you need to do the following. The film is applied to the pre-wetted optics. When the material is fixed, you need to make markings along the edge of the element with a special or regular marker. At the same time, a margin of five millimeters is left along the edge of the film

During marking, special attention should be paid to ensure that the film does not move, since after an erroneous cutting, you can say goodbye to expensive material

After marking, the film for armoring the optics is cut out with scissors, and you should act extremely carefully and avoid damaging the edge of the material. Afterwards, the headlight is generously watered with soapy water, and the backing is removed from the film. During removal, it is advisable to spray the material itself with soapy water. The cut film is applied back to the headlight

In this case, special attention should be paid to whether it is applied with the correct side. After this, the film is placed on the surface of the optics and carefully smoothed with a spatula.

The main task of this procedure is to expel water and air out.

Next, the material is slightly heated with a construction or household hairdryer and smoothed over the surface in accordance with the shape of the optics. At the same time, you need to try hard and not overdo it. Overheated material may crumple and not fit at all. It is better to warm up gradually, periodically smoothing the film. Heating with a hairdryer allows the film to take on the shape of the optics. Finally, you need to trim the edges along the contour of the headlight.

After applying the material, it is advisable not to drive the car for at least 24 hours. For the next five days, you should avoid aggressive washing and cleaning the headlights from dirt.

When the film has dried and set sufficiently, the machine can be operated as usual. If, over time, scratches and abrasions appear on the surface of the headlights, they can be easily sanded.

Protective film is a popular material for armoring

In fact, the protective film boasts not very durable characteristics. Moreover, when a stone hits the surface of a headlight covered with such scrap, the likelihood of receiving visible damage is minimized. Due to the ability of the film to distribute impact energy over a larger plane, it can be argued that the headlight will not deform and will maintain the integrity of its shape.

Even if you try hard to scratch the headlight, you don’t have to worry about leaving a mark. The film will take the impact. By the way, you can always replace it with a new one. If the headlight does break, the protective film prevents an object from hitting the lamp itself, which will not be damaged. Also, the fragments do not scatter to the sides, maintaining the dimensions of the headlight.

This kind of barrier, glued to the headlights, prevents the accumulation of dust and various contaminants. Remaining raindrops and traces of insects are easier to wash off from such a surface.

Vinyl film materials are popular among drivers. Which have good density, a wide range of colors, different thicknesses. Due to its good transmission capacity, a headlight covered with such a film will shine the same as without it. Typically, a film of up to two millimeters is used; it is optimal for armoring headlights.

Removing film from headlights, and in general from any surface. film for headlights Effectiveness of protective film. Removing Venture Shield, 3M polyurethane film.

What car seats need to be booked?

Car armoring with film does not imply complete wrapping of the car, but on the contrary, it is intended for local application to certain places - those that are most susceptible to impacts and mechanical damage. These include:

- the hood is its central part;

- windshield;

- radiator and bumper;

- headlights and mirrors;

- thresholds, door handle areas.

It is imperative to use PTF film armoring, as well as conventional headlights, since the functionality of the coating provides double protection. In addition to eliminating mechanical damage, the possibility of cracking after impact is completely eliminated.

Advantages and disadvantages

Tinting rear or headlights with film has a number of advantages:

- Easy to do. You can do the procedure yourself without spending money on the services of a specialist.

- Cleans up easily. This is especially true in proceedings with traffic police officers.

- The film is available in different colors. It is not difficult to choose a material to match the color of the car.

- Does not wear off during use. Retains aesthetic characteristics for a long time.

- Performs a protective function. Prevents scratches and chips on lighting fixtures.

- Forms a smooth surface. Provides uniform light dispersion.

The disadvantages include the higher cost compared to applying tinted varnish. In addition, tuning is noticeable only when the lighting is on, that is, on a sunny day the car will not stand out much among other cars.

Which method of tinting headlights to choose: varnish or film

If you want to dim your lights, you should know the answer to this question. Naturally, each method of tinting headlights has pros and cons. Therefore, their popularity is almost the same.

Undoubtedly, varnish adheres better to the surface, but many professionals prefer to use film. What explains this choice?

The cost of film is much lower compared to varnish. Additionally, if you use film, the optics will darken by a maximum of 15%. A wide range of various films available for sale will allow you to choose the option that suits you.

If a car with covered headlights gets into an accident, the protective cover of the headlights will not crumble along the road, but will be held in place by the film.

IMPORTANT! We must not forget that the film is not afraid of moisture and direct sunlight.

What other advantages does this method of tinting headlights have:

- the film prevents the formation of chips and scratches;

- such a coating will protect the optics, even if someone wants to deliberately scratch the lights;

- prevents minor damage;

- protects against impacts;

- keeps lanterns in perfect condition;

- provides optimal light distribution;

- light transmittance about 90–96%;

- makes the car stylish;

- longer and more durable protection compared to polishing.

Varnish has similar properties. However, it has significant drawbacks.

In some cases, you should not choose this method of tinting headlights, since the varnish has the following disadvantages:

- light transmittance is low, the varnish retains light too much, which means driving a car becomes unsafe;

- it is impossible to remove the coating. It will be easy to tint the optics; it will take you very little time. However, removing it will damage the surface of the headlight;

- short period of use. Optics coated with varnish will look aesthetically pleasing only at first. But after a short period of time the surface will begin to look unpresentable;

- difficult to use. Of course, applying varnish to the surface is simple. However, not every master will be able to do this efficiently.

What are the disadvantages of vinyl film? Carrying out the procedure will not be easy, and the material cannot be called budget-friendly either.

What is car headlight reservation?

Armoring car headlights is a procedure similar to armouring car windows or covering the front body panels with armored anti-chip film. True, in the case of headlight reservations, a slightly different film is used. The purpose of car headlight armor is to protect the glass or transparent plastic surface of the headlight from impacts from stones and other heavy objects on the road. Everyone knows the cases when a large stone that hits a headlight from under the wheels of a car in front breaks the plastic or glass surface of the headlight. Previously, motorists protected their headlights with special steel grilles. However, such grilles worsened not only the appearance, but also the lighting of the car.

To armor car headlights, a special vinyl film with a thickness of 0.1 to 2 millimeters is used. The film adheres tightly to the glass or plastic surface of the headlight and strengthens it, preventing it from breaking when hit by a stone. In addition to vinyl films, polyurethane film is also used. However, polyurethane films are much more expensive and are most often used for expensive cars. Vinyl film is more efficient and can stretch when heated so that it can be tightly adhered to the entire surface of a complex headlight.

Vinyl film is more efficient and can stretch when heated so that it can be tightly adhered to the entire surface of a complex headlight.

Advice from the experts

To get a high-quality coating and completely restore the appearance of your headlights, you should use the recommendations of professionals:

Before applying varnish to polycarbonate headlights, you should not use polishing pastes: they reduce the adhesion of the composition to the surface. To prevent streaks from forming during polishing, the work is performed in stages, changing the direction of movement perpendicularly. The grain size of abrasive materials is changed gradually

An abrupt transition from a coarse grain to a too fine grain creates an undesirable holographic effect on the surface of the lens. During polishing, it is important to monitor the force applied. Uneven pressure will lead to irregularities, which will subsequently distort the light beam. If a two-component varnish is chosen to cover a polished headlight, dilute it in small portions so that it is used up in 5 minutes. Polycarbonate headlights are primed with a special compound for plastic before applying varnish. When using a sander, it is important to control the surface temperature

Overheating can cause the plastic to warp. Turning on the headlights for the first 10 minutes or exposing the paint to hot air from a hair dryer helps speed up the drying of the varnish layers. Final drying is carried out at natural temperature. In the first 48 hours after varnishing, the headlights are not washed. Any, even the highest quality varnish will be scratched, so it is better to cover the headlights with anti-gravel film.

Polishing headlights and varnishing improves the quality of lighting, prevents lens clouding and extends its service life. The process is not particularly complicated, so you can do it yourself in a regular garage.

Do-it-yourself algorithm for booking car headlights

1. Buy the right material

When choosing, please note that when booking plastic glasses for lighting equipment, it is better to use a film with a thickness of only 100 microns. And for booking glass products, use a film from 1 to 2 mm thick

At the same time, do not forget about the shape of the headlight. After all, the thicker the film, the more difficult it will be to lay it on various curves and protrusions. And too thin will not provide sufficient protection.

2. The next step is to clean their surface from dirt, bitumen stains, and insect remains. To do this, use a clean rag. You can wash the headlights with detergent or water. But afterward, the entire surface must be degreased - wiped with a clean rag soaked generously in alcohol. After this, make sure that no dust gets on the surface. Therefore, it is best to perform this procedure in the garage.

3. Next, using scissors (knife), cut the film blank into the required shape. At the same time, do not forget to leave an allowance of 2 cm at the edges. Then heat the workpiece with a hairdryer (do not remove the backing from the film). The best way to warm up is to apply the film to the surface of the headlight. This will immediately give the film a convex shape corresponding to the curvature of the surface.

4. After the film acquires elasticity, carefully remove the protective layer (backing) from one side to a distance of no more than 3-4 cm. Then immediately smooth the released upper adhesive surface to the surface of the headlight. For these purposes, actively use a spatula. Make sure there are no air bubbles under the surface. If there are any, you should remove them with a spatula. Next, again heating a strip of film 3-4 cm wide, we repeat the procedure. We continue this way until the entire workpiece is glued to the surface.

5. After the surface is carefully pasted over, cut off the excess on the sides. If you need to make bends and folds in the film, you can cut a little at the corners.

6. After all excess has been removed, take the hairdryer again and heat the film again. At the same time, again rubbing it onto the surface using a spatula. This completes the procedure for booking headlights with your own hands.

How to apply protective film to headlights - step-by-step instructions

Instructions for gluing film to car headlights

Before you begin the process, you need to prepare materials and tools.

To work you will need:

- a piece of film corresponding to the size of the optics;

- sprayer (pulverizer) with a special solution;

- sharp stationery knife;

- technical hair dryer;

- spatula with a rubber blade (squeegee);

- alcohol solution;

- thick dry napkins (you can take kitchen paper towels).

VIDEO INSTRUCTION

Management.

Cut the film according to the dimensions removed from the headlight. Take into account the allowances: they will be about two centimeters on each side. Wash the headlight thoroughly. To do this, use a soap solution and a soft cloth sponge that will not scratch the glass. Wipe the headlight dry. Remove the protective sticker from the back of the film. Moisten the material and headlight generously with a special solution. Place the film over the headlight and wet it again. This is necessary so that the spatula can easily slide across the surface. Using a squeegee from the flattest part of the headlight, moving towards the rounded parts, remove water from under the film. Heat the edges of the film with a technical hair dryer and smooth them

Note! This procedure requires scrupulousness and can take a lot of time. Using a knife, make a rough cut of the film to remove as large a piece of unused material as possible. Glue the edges of the material with an alcohol solution (to increase the adhesion of the film to the optics). Heat the edges of the film again and use a squeegee to smooth them out. Remove the protective layer from the material, if it was provided by the manufacturer. Carefully trim the film cleanly along the contours of the optics.

Useful tips

- The special solution in the spray bottle can be replaced with ordinary soapy water. This is not “kulibniki”, but a technique of many masters.

- To save on buying film, you need to contact specialized stores. Sales consultants, knowing the dimensions of the headlight optics, will tell you what length and width a piece of film should be.

- When you remove water from under the film, don't be afraid to use force. Many headlight covering products have a protective layer that is removed after the wrapping procedure is completed.

- When working with headlights with a complex convex shape (for example, like the latest generation Nissan Juke), in order to even out the film along the edges, it must be carefully heated and stretched.

- If you are not confident in your abilities, have never covered headlights before, or do not have the necessary tools, entrust this procedure to specialists.

How to choose a film

In order for the car to receive maximum protection, you need to know certain criteria for choosing this material.

Criterias of choice

Armored film for a car should be selected according to its following indicators:

- what service life will this material have during operation;

- what is the degree of tear resistance of the material;

- thickness – must meet the requirements;

- elasticity during application - for ideal adhesion to machine surfaces;

- the material must transmit UV so that the paintwork of the car burns out evenly with the non-armored parts of the car;

Manufacturers and price

Armored film for cars is produced by several companies, the most famous brands among them are the following:

- LLumar is a material from the American manufacturer Eastman Chemical (since 1977 on the international market). A high-quality coating protects windows from harmful UV and blinding light entering the interior, overheating in the interior, and prying eyes. The durable coating reliably protects against scratches and other destructive influences. LLumar guarantees an invisible shield with a high level of gloss for all car paintwork. The film is 30% thicker than others offered in this market segment, the company guarantees up to 5 years. Car armoring with LLumar film will help your car look great for many years. Price from 6,000 rub. per lin./m.

- Anti-gravel armor film Newshield – translated means “new armor”. The name speaks for itself. The armor has excellent technical characteristics and provides reliable protection against mechanical damage, bad weather, and chemical influences. Car armoring with Newshield film provides a guarantee for many years. Prices from 2,500 rub. per lin./m.

- 3M Venture Shield - protection from an American manufacturer, designed primarily for places that are more susceptible to harmful effects: fenders, bumpers, sills, handles. Crystal clear, anti-gravel armored film for cars made of polyurethane has a good protective function and perfectly preserves the graphic curves of the car, thanks to its uniqueness. Price from 2,000 rub. per lin./m.

- Hexis Bodyfence material from French manufacturers has the unique properties of innovative technologies - it has a self-healing effect (resistant to pinpoint impacts) and hydrophobic properties. Universal armor film for cars, suitable for glass and body. Long warranty period up to 7 years. Price from 2,000 rubles per linear meter.

The cost of carrying out work on armoring a car with film directly depends on the quantity and complexity of the work, as well as on the selected materials. The average price for wrapping a crossover is 30,000 rubles, polyurethane protection is up to 55,000 rubles. Costs can be significantly reduced by selectively applying protection, for example, armoring the car body with film or armoring thresholds and bumpers.

Prices for glass wrapping:

- windshield wrapping from RUB 3,000;

- all car windows 6,000 – 8,000 rubles;

- for a headlight or threshold for 1,500 rubles.

Which film to choose

In addition to the above classification, the choice is made according to the type of material from which the film is made.

Vinyl

Vinyl-based materials are cheaper, have a large selection of thicknesses, colors, and have good light transmission. Such films, if they are produced by a serious manufacturer, stretch well and are capable of repeating complex curved surfaces.

Article on the topic: How and with what to cover a car dashboard yourself

The material is constantly being improved; if previously such films did not last for a long time, now they can last up to three years and this is not the limit. They are quite easy to apply, which is important when used independently.

Polyurethane

Not as widespread as vinyl, but have increased strength and durability. The rather high price limits its use. Good elasticity makes application work easier.

The most logical choice of polyurethane would be for new and expensive headlights. Moreover, for older cars, polyurethane kits may not be available for sale. There is no point in covering used car optics with it, since such a coating will outlive it due to natural aging.

What is armor film for cars?

Manufacturers offer a different color palette, but colorless and transparent ones are usually in demand, which can be safely glued to glass. Armored film can easily protect against negative influences:

- high humidity and mechanical damage;

- ultraviolet radiation and temperature changes;

- chemical substances.

The range of coatings varies in thickness; the thicker it is, the more reliable the protection of the machine, but application will be correspondingly more difficult.

Car armor film is what this innovative miracle is called for its ultra-high protective properties.

Advantages of film armor:

- Manufacturers promise that if damaged, the glass will not shatter, but will remain on the armored protection (under strong impacts).

- In case of minor mechanical damage, the film will be damaged; it is enough to remove it and replace it, and the protected areas of the vehicle or glass, headlights, are guaranteed to be intact and without damage, chips or abrasions.

- If small dents appear due to damage, the paintwork will be intact after removing the coating. This will make the restoration process easier. Thanks to modern technologies, slight deformation of the metal will be removed without painting.

After a minor accident, the paint and varnish coating under the armor film remains intact

Armor film was first developed in the USA for the US military. But, of course, it will not save you from bullets, and in civilian life there is no need for this. Reserving a car with film will also not save much from serious damage during an accident.

What kind of film for headlight reservations exists? Varieties and manufacturers

There are two types of protective material of this kind:

- polyurethane;

- vinyl.

It’s immediately worth noting that the first option is the best option. Polyurethane film is characterized by elasticity, porosity, strength and long service life - up to 5 years. Upon impact, the headlight glass will not scatter in different directions, but will remain on the film. Polyurethane perfectly takes any shape and, if applied correctly, does not bubble or peel off. Despite the relatively high cost, this type of film quickly conquered the world market in its segment.

As for manufacturers, there are enough of them on the modern market. However, the undoubted leaders in the production of anti-gravel film are the American companies 3M and SunTek and the Canadian company Ricochet.

Instructions for armoring and polishing a car body with film

Before starting work, it is necessary to prepare the vehicle according to the instructions:

- A mandatory point is to maintain a constant temperature of up to 22 degrees, and a complete absence of drafts.

- The car must be clean, free of dirt and dust.

- After pasting the armor film on a car made of polyurethane, it must dry for 12 hours. And only after that you can make adjustments to small details.

- The paintwork must be undamaged.

- For the coating, water or, better yet, a soap solution (any dishwashing detergent) is used; it does not allow the coating to stick before it is leveled.

You can book a car with film yourself if you strictly follow the instructions:

- Degrease all parts of the machine that will be coated with abrasive clay or white alcohol.

- The surface body is wetted with a soap solution, then protection is applied. The covering elements must be cut out in advance in accordance with the dimensions of the surface to be pasted.

- The surface is leveled using rubber spatulas, expelling water and air from under the film. Remaining material is carefully removed.

- The final stage is processing the edges and heating the material with a hairdryer. After this manipulation, the surface of the car will reliably adhere to the protective film.

When asked whether it’s worth booking a car with film, you can safely answer, of course, it’s worth it. This innovative technology will help preserve the appearance of the car for years, and most importantly, protect and extend the life of the car.

Rules for gluing

Self-adhesive film on a car headlight will require the motorist to pay attention and carefully follow the instructions. Depending on what material the coating is made of, the methods for pasting the headlights vary. Required tools:

- an industrial hair dryer (can be replaced with a thermos with boiling water or a home hair dryer);

- rubber spatula (can be replaced with any plastic card).

The procedure for gluing vinyl film to the body:

- Measure the surfaces at the peaks, cut off the film, leaving an allowance of 2 cm.

- Wash the headlight with soapy water and dry thoroughly.

- Remove the protective backing.

- Pour plenty of warm water over the headlight housing and the adhesive part.

- Place the part on the surface and make a rough cut.

- Warm up the surface with a hairdryer. If you don’t have a hair dryer, pour boiling water over the material slowly and generously.

- Vinyl becomes soft under the influence of temperature; smooth the film with a spatula, expelling excess water and air bubbles from the center to the edge.

- Repeatedly pour boiling water over the surface of the headlight or warm it with a hairdryer, carefully straighten the material on the body.

- Trim excess film or bend part of the material behind the front of the headlight or at the junction.

- Warm up the body and walk the surface with a spatula or credit card a third time.

Is tuning legal for headlights?

This is what a tinted taillight looks like (left)

Traffic regulations are the main regulatory document on the road. They should be followed and used as an argument in communication with the inspector, because appealing to “common sense” is usually useless. Section 3 of the rules contains a list of conditions prohibiting the operation of vehicles. In our case, point number 3.6, which regulates the use of lighting devices, is of interest. It states that it is prohibited to install devices and devices whose glow (reflection) color differs from the following:

- Front, for 1.1. Lighting devices - white, yellow, orange.1.2. Retroreflective devices (reflectors) - white.

- Rear, for 2.1. Reversing lights – white.2.2. Illumination of the state registration plate - white.2.3. Other lighting devices - orange, red, yellow.2.4. Retroreflective devices - red.

As usual, the driver will think that “everything that is not prohibited is permitted,” but the guy, on the contrary, will think that what is not permitted is prohibited. But the above excerpt is all that is said in the traffic rules on this issue: neither subtract nor subtract. It’s up to you to solve the “Hamlet’s dilemma”: to tint the headlights or not to tint.