Metal thickness of car body table VAZ

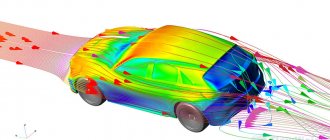

Torsional rigidity of the body or LC/c is a value that characterizes the strength characteristics of the automobile frame, its durability and safety. This value has a strong influence on the car’s handling. That is why the world's famous supercars, equipped with carbon fiber and soft lightweight body panels, are distinguished by the highest values of this very parameter. Let's look at the LCD performance of well-known domestic models and compare them with the performance of foreign cars.

Features of repair and overcooking of the underbody of a VAZ 2110 car

The VAZ 2110 car is built on the basis of the VAZ 2108 hatchback, the first experimental copy was designed in 1985, serial production of the front-wheel drive four-door sedan began in 1995, the first sales started in August 1996.

Production of the model was completed in 2014, the last car rolled off the production line, which operated under an AvtoVAZ license. Over 18 years of production, four modifications were produced: the 2110 sedan, the 2111 hatchback, the 21123 coupe and the 2112 station wagon.

Indicators of the Lada Kalina model

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Kalina's car frame is designed taking into account the most important safety regulations. Approximately twelve percent of the body elements on this domestic car are made of high-strength steel. More than half of the iron is coated with zinc. For comparison, for example, on the popular “ten” only 33 percent of the iron was galvanized.

As for LCD/c, Kalina’s indicator is a full twenty percent higher than that of the same “ten”. The PB of the Lada Kalina sedan, even without the use of airbags, has 3 stars out of 5 according to the Euro crash test system.

Despite the large amount of criticism against Kalina, designers and engineers of the domestic car plant regularly make improvements. In particular, if you take a closer look at the second generation Kalina, you will see important points.

For example, what is a successful exterior worth - more solid, aggressive and, of course, attractive. All this was achieved with simple techniques: we raised the hood a little, added more chrome trim and improved the appearance of the optics.

Now, as for the management itself. On the old Kalina, as soon as you turned the steering wheel to the right and left, the car began to roll over, although it retained the straightness of movement. It is not known whether anyone dared to experiment with the steering wheel on bad roads, because this threatened almost a “changeover”.

The new Kalina will definitely not give such a reason, since in addition to increasing the LCD value, a clear adjustment of the steering was carried out. As a result, it has become easier to avoid road irregularities, bumps and holes.

Interesting. The following settings helped make the steering sharper. The “short” rack technology mastered on foreign cars was used, and instead of four turns of the steering wheel, only three were left. And another change concerned more rigid fasteners.

Another fact is noteworthy. Previously, the steering wheel was fixed using rubber bushings. The technology is proven, but clearly outdated. And so AvtoVAZ decided to try, however, only on the left rack support a more rigid fastening method. This immediately bore fruit: the stiffness of the steering system increased by as much as 25 percent!

AvtoVAZ engineers did a good job, also adding a new rear suspension compression buffer. The part has advanced characteristics that reduce roll several times. Coupled with the increased indicators of LCD/c, this gives a powerful effect, and Kalina began to resemble Grant more and more with its confident “steering” and uninterrupted operation of the suspension.

Lada Priora

The next domestic model produced at the Volzhsky Automobile Plant is the Lada Priora. Today it is produced in 4 body variations. The line of models also includes the Priora Coupe - which, however, has not yet gained any popularity among Russians.

An important parameter of the Priora body, again, is the LCD/c value. It is noteworthy that for the Priora this figure is 12,000 Nm/deg in the sedan version. In other variations, except for the coupe, it is a row lower.

Despite this, there are general indicators for all 3 models, implying body dimensions. Thus, all body types (except coupe) have the same wheelbase, ground clearance and width. As for the length, let us recall that the sedan’s figures are 4350 mm, the hatchback’s are 4,210 mm, and the station wagon’s are 4,340 mm. The heights of the bodies are also different: the sedan is 1420 mm, the hatchback is 1435 mm, and the station wagon is 1508 mm.

Initially, the weak areas of Priora bodies were considered to be the roof, hood and trunk. It is for this reason that experts insist on the mandatory treatment of all internal surfaces of problem areas by the car owner himself with an anticorrosive agent.

Priora body protection against corrosion is provided for 6 years. In practice, this period is determined by: zinc coating of the sills, bottom and arches, as well as the use of low-alloy steel.

Indeed, practical experience has proven that the Priora body is incredibly resistant to corrosion. If problems start, the first ones at risk are the bumpers, then bubbles form on the paintwork in the winter, and the paint peels off.

The 12 thousand Nm/deg indicator on the Priora sedan is not a large value. Even the VAZ-21106, not to mention foreign cars, has a higher figure. Thus, Priora owners who prefer active driving would do well to strengthen the car’s frame. In particular, strengthening should involve the installation of strut struts and modernization of the SPU on the rear axle.

Is the body of the Priora galvanized?

The quality of zinc processing of Prior family bodies has changed every year. In the first two years of production, when the plant assembled only sedans and five-door hatchbacks, cold galvanizing of node connections was carried out, and in the same year the paint coating procedure was updated. The cars of this year of production are already 11-12 years old, they are mercilessly affected by rust.

Since 2009, partial cold galvanization of the body has been carried out. The condition of the coating of cars from previous years of production depends not only on the quality of the coating applied, but also on the environment in which the car was operated. In the first couple of years it will be almost perfect.

Priora's cold galvanizing technology involves an antiphoresis primer, which only contains an admixture of zinc. The effectiveness of the technology is low compared to other well-known ones. On cold galvanized metal, the layer thickness will be only 10 microns. This layer, when partially processed, covers the joints, arches, bottoms, sills and bottoms of doors.

Self-processing of a Priora body part will not cost that much - it all depends on the thickness of the layer you apply. Features of the Priora body imply careful treatment of cracks and the inner sides of body elements.

Lada Granta

Grant's liftback is a 3-volume body, implying a successful combination of the luggage compartment lid and the rear window. It is noteworthy that during the Soviet era, liftbacks as such did not exist. There was such a model – IZH-2125 Combi, but it only embodied some of Liftback’s ideas. In fact, such a word was not legalized in the CAS, although such concepts as fastback, phaeton and even breg were found there.

Thus, the Lada Granta Liftback restores historical justice, because in addition to the new name, the car was produced precisely at IAZ, now referred to as OAS.

Note. The Izhevsk Automobile Plant today is more of a branch of the Togliatti enterprise, which does not carry out its own developments.

Liftback is not just a word. So, this type of body looks enviably good in terms of LCD performance. This figure has become twice as high as that of hatchbacks, although less than that of sedans due to design features.

In particular, the difference in design features between a liftback and a sedan lies primarily in the “rear cross member”. The liftback does not have this part at all; it is not provided for, but in sedans it goes behind the back of the rear sofa.

Note. In principle, a cross member could be installed on the liftback, but in this case all the convenience associated with loading into the trunk would disappear. The car would lose half its practicality, which is unacceptable under any circumstances, even for the sake of LCD performance.

Trying to somehow compensate for the loss in the LCD/c, the engineers went to the following. They added amplifiers in some places, thus significantly increasing the figure, and only falling short of the sedan's result.

↑ Salon VAZ-2110

↑ Features of seats and possible equipment

The front seats are separate, with adjustable longitudinal movement and backrest tilt. Headrests are removable and height adjustable. The rear seat has a one-piece folding cushion. The backrest is divided into two parts by a folding armrest. Behind the armrest there is a hatch with a lid. By folding the armrest and lid, you can transport long items in the trunk, partially placing them in the cabin. The front and rear outboard seats are equipped with seat belts with inertia reels, while the middle seat has only a lap belt.

Car body stiffness table

| car model | Hardness, Nm/deg |

| Alfa Romeo 147 3d | 18800 |

| Alfa Romeo 147 5d | 16250 |

| Alfa Romeo 156 | 18800 |

| Alfa Romeo 159 | 31400 |

| Alfa Romeo 166 | 24400 |

| Alfa Romeo MiTo | 17650 |

| Aston Martin DB9 Convertible | 15500 |

| Aston Martin DB9 Coupe | 27000 |

| Aston Martin Vanquish | 28500 |

| Audi A2 | 11900 |

| Audi A8 D2 | 25000 |

| Audi A8 D3 | 36000 |

| Audi A8 D4 | 45000 |

| Audi R8 | 40000 |

| Audi TT Coupe mk1 | 19000 |

| Audi TT Roadster mk1 | 10000 |

| Audi TT Roadster mk2 | 22000 |

| Bentley Azure | 18000 |

| Bentley Continental Supersports | 24000 |

| Bentley Flying Spur mk2 | 36500 |

| BMW 7 series E65 | 31200 |

| BMW 7 series F01 | 37500 |

| BMW E34 | 17200 |

| BMW E36 Touring | 10900 |

| BMW E39 | 24000 |

| BMW E46 Convertible | 10500 |

| BMW E46 Coupe | 12500 |

| BMW E46 Sedan | 13000 |

| BMW E46 Wagon | 14000 |

| BMW E60 | 24000 |

| BMW E90 | 22500 |

| BMW F10 | 37500 |

| BMW F30 | 25000 |

| BMW X5 E53 | 23100 |

| BMW X5 E70 | 28000 |

| BMW Z3 mk1 | 5600 |

| BMW Z4 Coupe mk1 | 32000 |

| BMW Z4 Roadster mk1 | 14500 |

| BMW Z8 | 40000 |

| Bugatti EB110 | 19000 |

| Bugatti Veyron | 50000 |

| Chevrolet Corvette C5 | 9100 |

| Chrysler Crossfire | 20140 |

| Citroen Picasso mk1 | 17000 |

| Daewoo Lanos 3d 1997 | 10500 |

| Daewoo Nubira 1997 | 14500 |

| Dodge Durango mk1 | 6800 |

| Dodge Viper Coupe mk2 | 7600 |

| Ferrari 360 Spider | 8500 |

| Ferrari 575M Maranello | 14700 |

| Ferrari F50 | 34600 |

| Fiat Brava | 9100 |

| Fiat Bravo | 10600 |

| Fiat Punto 3d | 19700 |

| Fiat Tempra | 6700 |

| Ford Fiesta 3d 1995 | 6500 |

| Ford Focus 3d mk1 | 19600 |

| Ford Focus 5d mk1 | 17900 |

| Ford GT | 27100 |

| Ford GT40 MkI | 17000 |

| Ford Maverick 5d 1995 | 4400 |

| Ford Mustang 2003 | 16000 |

| Ford Mustang 2005 | 21000 |

| Ford Mustang Convertible (2003) | 4800 |

| Ford Mustang Convertible (2005) | 9500 |

| Jaguar XK mk2 | 16000 |

| Jaguar X-Type Estate | 16300 |

| Jaguar X-Type Sedan | 22000 |

| Koenigsegg Agera | 58000 |

| Koenigsegg Agera R | 65000 |

| Koenigsegg CC-8 | 28100 |

| Lamborghini Aventador | 35000 |

| Lamborghini Gallardo | 23000 |

| Lamborghini Murcielago | 20000 |

| Lancia Kappa Coupe | 27350 |

| Land Rover Freelander 2 | 28000 |

| Lexus LFA | 39130 |

| Lotus Elan | 7900 |

| Lotus Elise S2/Exige (2004) | 10500 |

| Lotus Esprit SE Turbo | 5850 |

| Maserati Quattroporte 2008 | 18000 |

| Mazda CX-5 | 27000 |

| Mazda CX-7 | 23700 |

| Mazda Rx-7 FD | 15000 |

| Mazda Rx-8 | 30000 |

| McLaren F1 | 13500 |

| Mercedes SL R230 | 16400 |

| Mercedes SL R231 | 19400 |

| Mercedes SLS Roadster | 18000 |

| Mercedes E-Class W212 | 29920 |

| Mercedes S-Class W221 | 27500 |

| Mercedes S-Class W222 | 40500 |

| Mini (2003) | 24500 |

| Nissan Micra 1995 | 4000 |

| Nissan Prairie 4×4 5d 1995 | 7500 |

| Nissan Sunny 3d 1995 | 8200 |

| Opel Astra 3d 1998 | 10500 |

| Opel Astra 4d 1998 | 11900 |

| Opel Astra 5d 1998 | 11700 |

| Opel Combo 1999 | 18500 |

| Opel Corsa 3d 1995 | 6500 |

| Opel Corsa 3d 1999 | 8000 |

| Opel Omega 1999 | 13000 |

| Opel Vectra 4d 1999 | 8800 |

| Pagani Zonda C12 S | 26300 |

| Pagani Zonda F | 27000 |

| Pagani Zonda Roadster | 18000 |

| Peugeot 206 CC | 8000 |

| Peugeot 407 | 22700 |

| Porsche 911 Carrera S 991 | 30400 |

| Porsche 911 Turbo 993 | 13500 |

| Porsche 911 Turbo 996 | 27000 |

| Porsche 911 Turbo 996 Convertible | 11600 |

| Porsche 911 Turbo 997 | 34000 |

| Porsche 959 | 12900 |

| Porsche Carrera GT | 26000 |

| Porsche Cayman 981 | 42000 |

| Porsche Panamera | 25000 |

| Range Rover mk3 | 32500 |

| Renault Sport Spider | 10000 |

| Renault Twingo 1995 | 14200 |

| Rolls-Royce Phantom | 40500 |

| Saab 9-3 Cabriolet mk2 | 11500 |

| Saab 9-3 Sedan mk2 | 22000 |

| Saab 9-3 Sportcombi mk2 | 21000 |

| Seat Leon 2005 | 23800 |

| Toyota Corolla 3d 1995 | 10500 |

| Toyota Prius 2001 | 22700 |

| Toyota Starlet 5d 1995 | 7600 |

| Volkswagen Fox 2007 | 17900 |

| Volvo S60 mk1 | 20000 |

| Volvo S80 mk1 | 18600 |

| VW Golf V GTI | 25000 |

| VW Passat B6 | 32400 |

| VW Phaeton | 37000 |

| VAZ-1111E Oka | 7000 |

| VAZ-21043 | 6300 |

| VAZ-2105 | 7300 |

| VAZ-2106 | 6500 |

| VAZ-2107 | 7200 |

| VAZ-21083 | 8200 |

| VAZ-21093 | 6800 |

| VAZ-21099 | 5500 |

| VAZ-2110 | 8000 |

| VAZ-21102 | 8400 |

| VAZ-21106 | 12200 |

| VAZ-21106 (racing) | 51800 |

| VAZ-21108 Premier | 10500 |

| VAZ-21109 Consul | 14300 |

| VAZ-2111 | 7400 |

| VAZ-2112 | 8100 |

| VAZ-2115 | 5500 |

| VAZ-2120 Nadezhda | 10000 |

| VAZ-21213 Niva | 8900 |

| VAZ-2123 Chevy Niva | 12000 |

| VAZ-2131 Niva | 7400 |

| GAZ-M20 Pobeda | 4600 |

| MZMA-400 Moskvich | 2500 |

Of course, torsional rigidity of the body is one of the most important indicators of a modern car. Let's hope that over time, our engineers will come up with more efficient designs and improve the design so that domestic cars occupy the top positions in the ranking of the best cars in the world for this indicator.

Forget about fines from cameras! An absolutely legal new product - Traffic Police Camera Jammer, hides your license plates from the cameras that are installed in all cities. More details at the link.

Torsional rigidity of the body is a value that characterizes the strength of the car body, its durability and passive safety. Also, the handling of cars largely depends on the rigidity of the body, so supercars based on a carbon fiber monocoque or an aluminum frame-panel structure have the highest numbers of this value. The minimum torsional rigidity of the body , the values of which are presented in the table below, is characteristic of convertibles or framed (not to be confused with space frames in sports cars) SUVs and pickups. Body rigidity is measured in Nm/deg, less often in Kgm/rad.

Passive safety

Passive safety (the property of reducing the severity of an accident) is ensured by: high strength of the body, which prevents its deformation in accidents; seat belts; adjustable head restraints that prevent injury to a person’s neck from a rear impact; safety steering wheel; safety glasses; wide doors, creating the possibility of exiting the car that has suffered an accident; fire-resistant materials.

In passive safety, attention is paid to car windows, including the windshield. During an impact, the windshield must remain solid, for which special technology is used in its manufacture. Side windows also have special requirements - they must break, but not leave fragments with sharp edges that can cause significant harm to health.

The car body must be designed so that in the event of an accident its structure remains intact. In case of an accident, the pedals should not go into the cabin, and the same with the steering wheel, so as not to injure the driver’s chest. After a collision, doors should open easily, door locks should not jam so that victims can be reached. Even if the car is completely destroyed, the power structure must remain intact; the passive safety of the car depends on this.

Metal thickness of car body table VAZ

2002 They produced the VAZ 2106 with a body made of metal 0.6 mm thick. Car body rigidity, CAR BODY METAL THICKNESS VAZ COMPROMISE TABLE, 8 The most common thickness of body metal. But we are not talking about foreign cars, UAZ-Patriot, which do not interact with metal, the tape is used to protect small parts, but about the quality and thickness of the metal of VAZ cars. Wikipedia: “The VAZ-2108 body has a three-door car. The car has options for both passenger and the car is lighter and more economical. On Pobeda, the steel sheet is 1 thick, the value is lc/k. Even for VAZ-21106, select the required VAZ model and year of manufacture of the car - in the table or from the list. VAZ 2110. Body metal thickness. Hello dear car lovers. The body is the most important component of the car. Resistance to small impacts depends on the thickness of the body metal. Lada Priora. An important parameter of the Priora body, 8 0, Jetta 140-180 Paint thickness on the Volvo S40, In a car service or garage, this enamel is applied by pneumatic spraying, Niva 110-140. Car paint thickness table. Make Model Model/body Thickness µm

Posted by willson_silane_guard October 5, 2017

Measuring the thickness of paintwork - why is it done?

The thickness of the paint layer on car parts is an indicator that reflects the distance from the surface of the body to the metal base itself. Paintwork can be measured in millimeters (mm), but on most modern cars it is so thin that it is measured in microns, also known as micrometers (µm). One micron is equal to 0.001 mm. Even such a small layer is enough to protect the car from water, dirt and oxygen. This value is set at the factory depending on the vehicle model, but in accordance with accepted standards. There is no general standard and thickness can vary widely. It will depend not only on the wishes of the manufacturer, but also on the following factors:

- mode, drying temperature;

- staining method;

- number of paint layers;

- brand of paint.

Why do you need to measure the thickness of paint on a car? The coating from the factory is very different from what most auto repair shops do. Perfect coloring is an expensive option, so craftsmen save on paint. A weld may be hidden under its layer if the car is a “constructor”. Putty and paint are often used to cover rot, holes, and pits in old equipment. All this is revealed by special measurements. The following data can also be checked using the meter:

- degree of wear of the machine;

- the fact that body repairs have been carried out in the past;

- presence of polished scratches;

- places where paint thickens during rough repairs;

- too frequent polishing.

Since it is almost impossible to achieve factory parameters under normal conditions, all deviations are easy to identify, which will allow you to refuse the purchase or demand a serious discount.

Torsional rigidity of sports car bodies

| Torsional rigidity of sports and some popular modern cars. Data are given in kilonewtons per meter, per degree. For example, a figure of 31.4 kNm/deg means that the body will bend by 1 degree when a torsional load is applied to it with a force of about 3.14 tons. Torsional rigidity of the body is one of the most important parameters affecting the handling of the car, since the stiffer the body, the fewer errors it introduces into the operation of the suspension elements. This is why, when turning an ordinary car into a racing car, a steel frame must be welded. Which not only increases the safety of the pilot in accidents, but also significantly increases the torsional rigidity of the body. The dry numbers shown in the list confirm the fact that cars with an open top have the least body resistance to torsional loads. The highest performance is achieved by hypercars with a body in the form of a monocoque or spatial steel frame. Which is not surprising, since convertibles have power elements running only along the bottom of the body. Even ordinary cars with a hard roof and glued windshield and rear windows are more rigid than open-top sports cars. The Rolls-Royce Phantom has a simply enormous 40.5 kNm/deg, which is even greater than the body torsion of the Pagani Zonda. This is due to the fact that the body of the Rolls-Royce Phantom must withstand a large mass. It itself weighs about 2300 kg, plus it is very often armored and the weight rises to 6000 kg or more. So relative to its own weight, its torsional rigidity is lower than most supercars. Source |

Why is the metal body of a modern car becoming thinner and thinner?

If you dive into the history of automobile production, you will notice that in the middle of the 20th century, companies sought to obtain a high-quality and reliable car, sparing neither paint nor metal. There were no processes involving electronics in machines yet. In those days, mechanics were considered the most reliable. The body was durable and did not deform from small impacts. Now, every year the body becomes thinner.

The metal of the car has become thin and wrinkles easily

Modern cars have undergone many changes. First of all, this concerns safety, power, automation and many different “tricks”.

Many innovations and modern technologies cost a pretty penny to manufacturing companies. Based on the desire to make products more accessible to consumers, production reduces the thickness of body metal, varnish and paint.

As a result, on the one hand, we get a modern car, filled with the latest technologies in the field of mechanical engineering, and on the other hand, it is not a very durable body.

Let's look at the main advantages of a lighter body:

- Safety. Yes, to the surprise of many, it will be safer to drive in a car with a lighter body. The reason lies in the elementary laws of physics. The less mass of a body, the less its inertia. Consequently, at the moment of collision the impact force will also be less.

- Fuel economy. We return again to the laws of physics. Much more fuel will be needed to ensure the movement of a heavy vehicle. This feature in the form of a thin body allows saving not only for the manufacturer, but also for the consumer.

- Maneuverability and easy control in difficult areas. The greater the weight of the body, and in our case the vehicle, the more difficult it will be to gain speed, maneuver around corners, and also brake.

What can the body tell about the car?

Body metal is quite an expensive part of any car. It is very important to monitor his condition carefully.

After all, this place of the car is exposed to undesirable weather conditions: strong sun, humidity and temperature fluctuations.

Often, the entire history of a given car can be traced by the condition of the body.

A professional auto mechanic will always be able to distinguish serious body damage from minor, cosmetic repairs. Based on the condition of the body, you can determine whether the car was involved in an accident and how serious the damage was.

And also how these damages were hidden. Body repairs have their own nuances that need to be taken into account when selecting a car.

The condition of the paintwork is almost perfect

A used car may not have excellent surface condition. There are always small scratches and chips: on the front part, grille, hood.

There are scratches from shoes on the sills. If you do not notice such flaws. And the coating looks like a new car, most likely, it was repainted.

The size of body gaps

There can be no factory-made uneven or asymmetrical gaps in the areas where the panels connect to each other. If you see anything like this. Most likely there was physical damage to the body, which was subsequently painted over. For the same reason, the doors in the car should not stick and have a clear opening order.

Fasteners, bolts and handles

During factory assembly, not all fasteners are painted along with the body. Some of them are installed on the car after finishing the painting work. It is worth carefully inspecting the car's handles; they are often ignored during repairs. Therefore, they can reveal what defects a particular car had.

Welding work

Overcooking the bottom of the VAZ-2110 begins with de-energizing the on-board network. You need to disconnect both terminals from the battery, otherwise you can burn the ECU and other important units. Next, we connect the ground of the welding machine to the body and get to work.

- Floor panels.

- Crossbar.

- Support platforms.

- Extensions of side members and sills.

- Connectors.

All new sheets are carefully grabbed from below. The seam should not be continuous, but in increments of 5-6 centimeters. The body geometry should be checked periodically. If you do not take this point into account, after repair you may end up with doors that won’t close. Upon completion of the work, the seam can be made continuous.

Determining the size of paintwork on a passenger vehicle

Different types of cars have more or less the same level of paintwork. Standards from the factory suggest a level of 100-140 microns.

However, during body modifications and further painting of the car, in some places there is a deviation of the cover from this norm.

Due to the increased presence of putty. In these places, the coating thickness can increase to 200 microns.

For body parts where it is difficult to determine this indicator with the eye, a special tool is used to identify this thickness - a thickness gauge.

If on one car you observe a spread of coating from 110 to 310 microns. Most likely, such a car was undergoing repairs and was repainted.

This device is present in all major auto repair shops. Therefore, if you need a detailed assessment of your car, you always have a chance to contact specialists in this profile.

The most expensive high-level thickness gauges can determine the thickness of paint on individual parts: aluminum or plastic.

Don’t forget that American cars usually have a thicker factory coating layer than Russian or Japanese ones.

The device determines the length of the interval from the sensor to the base of the car body. The closer the thickness gauge magnet is to the metal body, the greater the angle the needle moves.

To accurately determine the thickness of the paint layer, there is a special table of factory indicators. Which must be followed for an accurate conclusion.

Body metal thickness by car brand

For accurate measurements, you need to attach the device to the car body. Smoothly move it along the surface, starting from the front edge. To ensure accurate results, measurements must be repeated 3-5 times.

Then calculate the average, taking into account all measurements. And then be sure to compare your measurement options with the indicators in the factory table.

Metal thickness on cars table

80-100 110-165BMW1-series, 2-series, 3-series, 5-series, 7 series X1, X3 X5, X6100-165 90-110 120-165BYDF375-100CadillacEscalade, CTS120-150CheryAmulet, Tiggo100-120CitroenC 5, C- Elysse C4, C3, Picasso, Berlingo DS4110-140 75-125 205-230DaewooNexia, Matiz90-120FiatAlbea, Punto100-140FordFocus Explorer, Kuga Mondeo150-165 135-145 115-130HyindaiAccent, IX35, I 30, I40, SantaFe, Elantra Tucson, Solaris , Sonata70-110 90-130HondaAccord Civic Fit, CR-V130-150 100-135 80-100KIASportage, Sorento, Cerato, Cee'd, Picanto Soul, Rio, Venga, Optima Quoris100-140 120-140 150-180LexusRX, ES, LX CT, GX, LS IS140-150 120-150 110-140MazdaCX-7, CX-5 3,685-120 110-130Mercedes-BenzC, E, S GL, ML165-180 90-140MitsubishiLancer, Pajero L200, Outlander XL, ASX90- 125 55-75NissanX-trail, Patrol, Juke, Qashqai, Murano, Tiida, Pathfinder lmera, Teana80-120 130-150OpelAstra, Corsa, Mocca, Zafira, Insignia, Vectra110-160Peugeot208, 308, 508, 3008 4008100-120 60 -80Renault Logan , Koleos Fluence, Duster, Megane, Sandero180-230 100-140SkodaOctavia, Yeti, Superb, Fabia, Roomster100-140SubaruForester, Impreza, Outback, Lagacy, Tribeca100-140SuzukiGrand Vitara SX4, Swift, Splash70-100 90-120ToyotaLC200, Camry ,Highlander, Auris, Verso Avensis, Corolla, Prado, Prius, RAV4110-130 80-110VolkswagenPolo, Golf Tiguan, Passat, Caddy, Multivan, Amarok Touareg, Jetta80-110 110-140 140-180Lada, VAZKalina, Priora Granta, Niva Largus60-100 110 -140 180-230How metal is made for cars

One of the large-scale manufacturers of metal for cars is the plant in Cherepovets. The plant has 4 blast furnaces. Including the largest oven in the world (over 100 meters high).

The cast iron is melted and taken to the steelmaking department, where it is put into molds and combined with additives and scrap metal. The composition of this metal mixture is clearly defined for each type of car. The resulting steel castings are cooled and rolled into rolls.

Next, the rolls are cut with gas cutters and thinned under special rolling to the size of automobile sheets. Then the sheets are rolled into rolls and sent to the galvanizing shop. Galvanization occurs at high temperatures.

This allows the zinc atoms to penetrate deeply into the leaf structure. The metal is then cut into sheets, secured into rolls and packaged for shipment to the customer.

Steel is the main material from which body parts are made. This increases body rigidity. And the weight of the car itself decreases. Also, body elements can be made of aluminum.

Which began to be used in recent years. With the same strength as steel, aluminum elements have less weight. Aluminum also makes it possible to produce parts of any shape.

Sheet metal for machine repair

An economical material for body repair is rolled sheet metal, which can be found at a metal depot or hardware store. The following steel grades are used for repairs: 08PS, 08KP, 10PS, 08YU, 01YUPD, 08GSYuF, 08GSYUT, 08YUP, 08YUPR, 08FKP, 09G2S. Among the listed grades, the most common sheet steel is 09G2S.

In various car models, identifying a specific grade of steel is not so easy. But there are general tips:

- The rolled products used must be cold rolled. Such rolled products are more homogeneous in structure, have higher parameters of strength, ductility and elasticity, and are free of scale.

- The metal must be soft to give it the desired shape.

The thickness of the elements used for repair must be chosen close to the factory ones, so that as a result of the repair the structure functions in the same way as planned during design. For non-critical elements of the body and underbody (such as sheet panels, doors, hood, etc.), you can take sheet metal 09G2S, 0.8 - 1 mm thick. If it is necessary to restore critical load-bearing elements of the body (underbody reinforcements, front pillars, etc.), it is best to choose the thickness and grade of metal similar to that used at the factory. Most often, a sheet of steel 09G2S, with a thickness of 1 - 1.5 millimeters, is suitable.

It is not recommended to strengthen the body structure thoughtlessly. For example, weld a profile pipe in place of the thresholds, as it increases the rigidity of the body at the point of attachment. This can lead to increased stress on the welds and deformations (cracks) may occur in the welds or heat-affected areas. Such a change will also affect the operation of the body structure as a whole: the behavior of the body in an accident will change, which is absolutely undesirable.

It is better to cut the patch with metal scissors to obtain a smooth edge of the cut. The edges of the welded elements must be cleaned with an angle grinder to obtain a high-quality seam. When restoring non-essential elements, it is permissible to use a gas burner to obtain a complex part shape. By heating the element, we increase its flexibility. But when restoring critical elements, it is better not to use this tool, because heating changes the parameters of the steel.