Causes of malfunction of injection nozzles

Modern fuel injectors in gasoline engines come in two types: electromagnetic and mechanical. The first is a solenoid valve that is controlled by the vehicle's ECU system. When the appropriate signals are given, the valve opens to a certain angle, regulating the amount of fuel supplied to the cylinder. The second only supplies fuel to the channel. Its design includes a needle with a step. When there is enough pressure, the fuel overcomes the resistance of the spring and the needle rises. Accordingly, the nozzle opens and fuel is supplied to the chamber. Currently, electromagnetic injectors have gained wide popularity as they are more technologically advanced. Therefore, we will further consider checking and cleaning using their example.

There can be only a few malfunctions of the electromagnetic injector:

As practice shows, it is the latter option that is the most common cause of complete or partial failure of the nozzle.

How can you tell if something is wrong with the injectors? Signs of injector failure

Common signs indicating problems with the fuel injection system:

- The engine idles unstably, or even stalls at idle;

- Increased vibration at idle, increased noise;

- The engine does not start well;

- The “Check Engine” light comes on on the dashboard;

- Increased fuel consumption;

- A characteristic smell of fuel in the engine compartment, possible leakage;

- Deterioration in dynamics and drop in power.

Of course, most of the above symptoms can have more than one possible cause, and do not always indicate a faulty fuel injection system. Similar symptoms are typical for other breakdowns, for example, faulty spark plugs can cause most of the above problems.

Connecting the computer to the “brains”

A universal code system is used to clarify a specific problem that is associated with a particular part or system. This allows you to speed up the process of diagnosing and finding the causes of a car malfunction. So, for example, a faulty fuel injector is indicated by codes in the range from P0000 to P0299 (air-fuel mixture control). The last digit between P0300 - P0308, for example - 8, indicates a problem cylinder in which there is a malfunction. Therefore, the P0308 code indicates that the No. 8 cylinder has an injector problem. You can read the error code in the ECU memory by visiting a service station or purchasing an OBD scanner.

How to check fuel injectors on a fuel injection engine

There are several methods for checking the performance of an injector. Let us list them in order with a detailed indication of the algorithm of actions.

Check using resistance measurement

You can check the injectors without removing them using a multimeter. First, check which injectors are installed on your car - high or low impedance (electrical resistance). This data will be necessary to perform an accurate diagnosis. In order to check the injectors with a tester without removing them from the engine, you must adhere to the following plan:

Measuring the resistance of the injector winding

High impedance injectors have an insulation resistance of 11.17 ohms, and low impedance injectors have an insulation resistance of 2.5 ohms.

If the measured insulation resistance value differs significantly from the specified value, this indicates that the injector is faulty. Accordingly, the injector must be dismantled and detailed diagnostics performed.

It is important to know that the voltage to the injectors from the ECU is supplied in pulsed and not constant form. Therefore, it is recommended to measure resistance not only with an ohmmeter, but also with an oscilloscope, so you can see what peak values the resistance and voltage take. And the tester shows the average value.

How to check power to injectors

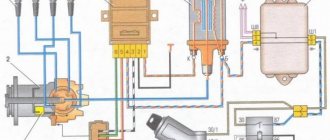

Checking the power supply to the fuel rail of VAZ 2110-2112

Let's look at checking the availability of power to the ramp using the example of VAZ 2110, 2111, 2112 cars, as some of the most popular. But first, let us recall that in the block with contacts, four of them supply power to the injectors, and one (pink wire with a black stripe) is the common ground. You need to act according to the following algorithm:

The resistance value should be within 11.5. 15.5 ohms . Remember that this way you will only measure the power supply on the ramp to each injector.

You can check the injector simply for vibration. When the engine is running, a working injector should vibrate slightly . If there is no shaking, it means it is out of order.

Checking the power supply from the car's electrical circuit is quite simple, you just need:

If the injector starts spraying fuel, then the problem must be looked for in the wiring.

How to check the starting injector

First, let's say a few words about the monoinjector. Today, such units are becoming less and less common, since the system is outdated. Its essence lies in installing only one injector - in front of the throttle valve. They can be found on old models of foreign cars from VW, Audi, Skoda, Seat and others.

Checking diesel injectors for overflow (drain to return)

As diesel injectors wear out over time, a problem arises due to the fact that the fuel from them gets back into the system, due to which the pump cannot generate the required operating pressure. The consequence of this may be problems with starting and operating the diesel engine.

Before the test, you will need to buy a 20 ml medical syringe and an IV system (to connect the syringe you will need a 45 cm long tube). To find an injector that throws more fuel into the return line than it should, you need to use the following algorithm:

- remove the plunger from the syringe;

- with the engine running, use the system to connect the syringe to the “return” of the injector (insert the tube into the neck of the syringe);

- hold the syringe for two minutes so that fuel is drawn into it (provided that it will be filled);

- repeat the procedure one by one for all nozzles or build a system for all of them at once.

Based on information about the amount of fuel in the syringe, the following conclusions can be drawn:

Checking the return flow

- if the syringe is empty, it means the nozzle is fully operational;

- the amount of fuel in a syringe with a volume of 2 to 4 ml is also within normal limits;

- if the volume of fuel in the syringe exceeds 10...15 ml, this means that the injector is partially or completely out of order and needs to be replaced/repaired (if it pours 20 ml, then it is useless to repair, since this indicates wear on the injector valve seat ), since it does not maintain fuel pressure.

However, such a simple check without a hydraulic stand and plan test does not give a complete picture. Indeed, in fact, when the engine is running, the amount of fuel discharged depends on many factors; it can be clogged and needs to be cleaned, or it freezes and needs to be repaired or replaced. Therefore, this method of checking diesel injectors at home allows you to only judge their throughput capabilities. Ideally, the amount of fuel volume they pass through should be the same and range up to 4 ml in 2 minutes.

You can find the exact amount of fuel that can be supplied to the return line in the manual of your car or engine.

To ensure that the injectors last as long as possible, refuel with high-quality diesel fuel. After all, it directly depends on the operation of the entire system. In addition, install original fuel filters and do not forget to change them on time.

Basic malfunctions and diagnostics of injectors on GAZelles

If the vehicle was operated using high-quality fuel, filled at the same gas stations, the engines and injectors will last a long time. You can drive tens of thousands of kilometers without problems by regularly changing the original fuel filters (every 10–15 thousand km) and cleaning the injectors of toxins. If there is a malfunction inside the fuel system, it has certain symptoms:

This is interesting: Which engine is better: gasoline or diesel?

Injectors are the most susceptible to malfunction. Despite the fact that the fuel passes through a mesh filter and then through two fine filters, over time the nozzles become dirty. Cleaning can be done independently or at a service center. In addition, injectors have a service life during which parts wear out. If washing and cleaning the injectors does not bring results, it is better to replace them with new ones.

How to identify a faulty diesel injector

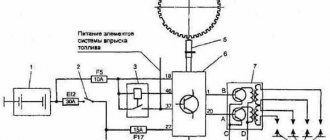

On Cummins 2.8 ICF power plants, you can determine the faulty injector yourself. To do this, you need to find out which of the sprayers sends the most diesel fuel into the return system:

The clamps are removed, the backflow from the injectors is removed. Syringes are inserted into the upper holes of the nozzles

Video: diagnostics of faulty injectors in Cummins engines

Watching the video, you can see that injectors 1 and 4 are working properly. Injectors 2 and 3 will have to be replaced.

Diagnostics of gasoline engine injectors

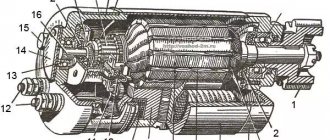

A non-working gasoline engine injector (ZMZ 406, 405) can be determined without removing it from its seat. To do this you need to perform several simple operations:

The fuel block is disconnected from the injectors The connectors are removed from the injector sockets The tester probes are connected to the pins of the control socket to measure the resistance of the injector winding The control electromagnetic winding should have a resistance of 15–16 Ohms

How to clean injectors

Most often, the problem with the operation of injectors is their banal contamination. Therefore, to restore their functionality and return the injector to its nominal performance, it is enough to clean it. This can be done in two ways - without removing it from the engine (by adding a special cleaner to the fuel) and in the removed state (passing the cleaner through a separate nozzle or using ultrasound). The following methods are used for cleaning:

In this article we will talk about only a few, since cleaning injectors often requires additional professional equipment. You will find detailed information about self-cleaning in another material. Here we will briefly touch on these methods.

Cleaning the nozzle at home

A separate nozzle can be cleaned using special chemical compounds. For example, the same additives that are added to fuel to clean the system or the so-called “Carburetor Cleaner”. In this case, it is necessary to act according to the following algorithm:

If the nozzle is working properly, detergent should come out from its reverse side under pressure. The purging procedure must be repeated several times to achieve the required degree of cleanliness.

In addition to the check methods listed above, you can also mention checking the toxicity of gases and smoke - a low level of CO during gas release is a sign of poor injector performance. This method is practiced at some service stations as a way to monitor engine operation. Since both certain knowledge and equipment are needed, we will not consider it as one of the options for self-diagnosis.

How to prevent clogging and damage to injectors on a Nissan Note

Despite the reliability of Nissan Note cars, during their use, owners are faced with problems with wear of parts, due to time, or poor-quality chemicals. One of these problems is the breakdown or clogging of the injectors or its components. Let's focus specifically on the injectors. This is an important element of a diesel engine, so it is necessary to approach the issue of its selection and repair very responsibly. Even with minor malfunctions, you need to go to service. Use the services of official Nissan showrooms and service centers. If you try to carry out repair procedures yourself, you may do something wrong. The same applies to budget auto repair shops - it’s better not to take risks, but to contact an official dealer.

Some of the most common types of injector malfunctions:

The injectors become dirty, as noted: https://www.spbparts.ru/remont/remont_forsunok_nissan.htm due to being in an area with elevated temperatures. This leads to their coking with flammable resins present in the fuel. This is how persistent deposits accumulate on the nozzles, blocking all or part of the spray holes and violating the tightness of the needle valve. Corrosive changes appear as a result of using low-quality fuel, which contains water and a large amount of sulfur.

You can also identify problems on your own. This is determined by the following signs: difficult starting of the car, excessive smoke, excessive consumption of fuel, jerking when driving. If the injectors wear too much, the car hardly moves, and the excessive consumption of fuel is very large. This indicates that the injectors need to be changed urgently. Tapping noises while driving, smoke and difficult starting generally indicate faulty pump injector nozzles, which are the main elements of the injectors.

If one or more of the above signs of problems with the injectors appear, you should immediately go to an official Nissan service center. And if the injectors are too worn, they will be carefully removed and replaced with new ones; if the main elements are significantly dirty, they will be removed and cleaned; in the presence of corrosive contaminants, the rusted areas will be thoroughly cleaned and covered with protective compounds. All these manipulations will be carried out on specialized equipment, and after completion of the work they will test the functioning of the injectors using a professional stand. And at the end, they will give detailed recommendations on the regularity of these events.

Cleaning the nozzle without removing it

In this case, cleaning can be carried out using several methods:

conclusions

Problems with the operation of the injectors are not a critical failure, but if they occur, we recommend that you do not delay checking and eliminating the malfunction. In most cases, repair work can be carried out independently using the methods described above. Timely checking and diagnostics of injectors will allow you to avoid problems with the operation of the machine. Prevention will cost you less than repair work on injectors or other engine components. We recommend that you clean the injectors every 30.35 thousand kilometers of your car, regardless of their condition.

Welcome to ChipTuner Forum.

Theme Options

mel2004

voltage is checked with a multimeter, oscilloscope

remove the connector from the injector, find the power wire, connect the device and measure

brownie Kuzma

Bugulma

voltage is checked with a multimeter, oscilloscope

remove the connector from the injector, find the power wire, connect the device and measure

It’s better to do this with the connector on and the engine running; a load won’t hurt either.

Is a 12 volt LED suitable for checking the signal on the injectors? If not, how long is the LED needed?

How to clean injectors without removing them from the engine

If a malfunction of the engine injectors is diagnosed, it is possible that they are dirty. To correct the situation without removing the injector from the engine, you can:

Use specialized engine cleaning additives that are poured into the fuel tank;- To keep engine injectors clean, experienced drivers recommend cleaning them monthly using pressure. To do this, you need to accelerate the car on a flat road to a speed of 120 kilometers per hour. In this mode, you need to cover 10-15 kilometers, after which you can slow down;

- If you do not have the opportunity to drive the car at high speeds, you can use another method of cleaning the injectors without removing them from the engine. It is necessary to maintain the vehicle idle speed at 4-5 thousand for 3 minutes. This method of cleaning injectors is less effective than the options listed above.

Experts recommend cleaning engine injectors every 30-35 thousand kilometers, even if there are no problems with the engine.

( 428 votes, average: 4.60 out of 5)

How to check a car thermostat in two ways

How to properly bleed the clutch