VAZ 11113

Adjusting the carburetor drive

Performed when replacing the carburetor

, as well as when drive parts are worn or replaced.

- When the gas pedal is fully pressed, the throttle valves should be fully open, and when released, they should be closed.

- If this is not the case, by unscrewing or tightening the adjusting nuts on the front end of the drive cable (carburetor side), we achieve the correct position of the throttle valves.

- The tension of the cable with the pedal fully released is checked as follows: we pull the cable in the middle of the branch near the carburetor by about 10 mm, while the throttle valves should not open. If you pull the branch back a large amount (about 15 mm), they should begin to open slightly.

Adjusting the fuel level in the float chamber

Performed when replacing a needle valve or float (see also “Diagnostics of engine malfunctions”).

- We remove the carburetor cover (see “Disassembling the carburetor”) and measure the protrusion of the needle valve above the cover, which should be 10 mm. If this is not the case, replace the gasket or valve with gasket.

- Having placed the float with its lower part on a flat surface, measure the distance from it to the center of the float axis. It should be 23.1 mm. We adjust the size by bending the lever.

- We measure the distance from the tongue to the top plane of the float, which should be 2.0 mm.

- A drill can be used as a gauge.

- We adjust the distance by bending the tongue. In this case, its supporting surface must be perpendicular to the axis of the needle valve.

Adjusting the starter

Performed on a removed carburetor.

- When turning the choke control lever counterclockwise all the way, the choke should close completely. If it does not close, eliminate the cause of the jam (or straighten the deformed valve).

- With the air damper completely closed, the throttle valve of the first chamber must be slightly open to the starting gap C (see figure).

- This gap is adjusted by turning the screw on the throttle drive lever with a thin slotted screwdriver.

- With the air damper completely closed, press manually (you can use a screwdriver, stick, etc.) on the trigger rod until it stops. In this case, the air damper should open slightly to the starting gap (see table above). We use a drill as a gauge.

- To adjust the gap, use an “8” wrench to loosen the lock nut of the screw located on the starter cover. Inserting a thin slotted screwdriver into the slot, unscrew (to increase the gap) or tighten (to decrease the gap) the screw, and then tighten the locknut.

Starting device: 1 - starting device lever; 2 — throttle valve; 3 - thrust screw for opening the throttle valve; 4 — lever on the axis of the throttle valve of the first chamber; 5 — starter control cable: 6 — lower edge of the cam groove; 7 — upper edge of the cam groove: 8 — air damper spring; 9 - air damper: 10-lever on the air damper axis; 11 — trigger diaphragm rod: 12 — trigger diaphragm: 13 — diaphragm thrust (adjusting) screw; 14 — screw for fastening the trigger lever; B - starting gap of the air damper; C - starting gap of the throttle valve.

Adjusting the idle system

Performed during maintenance or engine malfunctions (see “Diagnostics of faults”).

- The adjustment is performed on a warm engine. At the factory, the engine is adjusted to a minimum crankshaft speed of 820-900 rpm and a carbon monoxide (CO) content of 0.5-1.2%, after which a restrictive plastic sleeve is pressed onto the screw head. If by turning the bushings it is not possible to restore the factory adjustment parameters, we unscrew the screw, breaking the bushing, then by rotating the quantity screw we set the crankshaft speed, and by turning the quality screw we set the content of carbon monoxide in the exhaust gases.

- When you press the gas pedal, the engine should increase the crankshaft speed without interruption, and when you release the pedal, it should not stall.

- When turning the quantity screw clockwise, the crankshaft speed increases.

- When turning the quality screw clockwise, the CO content in the exhaust gases increases.

How to set a carburetor without a strobe for efficiency

The carburetor is responsible for creating and supplying the internal combustion engine with an air-gasoline mixture corresponding to the speed limit, as well as for its reliable starting at any temperature. Despite the widespread introduction of fuel injection systems, carburetors will be in demand for a long time on the VAZ 2107, -2106, -2109 and their more modern counterparts. Their popularity is due to their relatively low price and the ability to customize the engine operating mode to best suit the owner’s driving style.

The carburetor is responsible for reliable engine starting at any air temperature

How to set up a carburetor

The carburetor is one of the most complex components of a modern car, allowing the use of a particular engine with maximum efficiency. It is the correctness of its adjustment that determines fuel consumption and the content of toxic substances in exhaust gases. Regardless of the specific model of carburetor and car, it is possible to correctly adjust the parameters of the air-gasoline mixture only using a gas analyzer and professional measuring equipment. It is advisable to adjust the carburetor for efficiency after any work on the engine.

However, you can adjust it to your driving style yourself.

Video tutorial on how to clean and adjust a VAZ carburetor

In this case, you should follow the basic rules:

- The carburetor can be adjusted only after the engine reaches operating temperature;

- You should check and clean all high-voltage wires, as well as battery terminals;

- It is necessary to make sure that the fuel supply system is working properly and that the ignition is set correctly. You can start adjusting only after making sure that all other systems are working properly. Often the cause of dips and poor response to the pedal is simple contamination of the mesh filter;

- During adjustment, it is advisable to turn on all powerful consumers of electricity: high beams, stove, heated windows, etc.;

- Before disassembling and cleaning the carburetor, it is advisable to purchase a repair kit for a specific model. It contains jets, sealing gaskets, diaphragms of the accelerator pump, starting device and other auxiliary elements;

- It is unacceptable to use rags, brushes or metal wire to clean internal surfaces. The best option is to use compressed air.

SOLEX is a popular manufacturer of carburetors for domestic cars

The main manufacturers of carburetors for domestic cars are Ozon, Weber, PeKAR (K151) and Solex (SOLEX). There are no fundamental differences in their adjustment. However, it must be taken into account that all modifications of the Solex 2108 carburetor have different calibration data, which is caused by their widespread use on VAZ, ZAZ and AZLK vehicles.

Design features

Despite the fact that the Solex from the Eight was taken as the basis for its creation, the Oka carburetor has some design features:

- The float and shut-off needle are separated. The first element is installed in the float chamber, the second is located in the lid. Because of this, the technology for adjusting the fuel level differs from the usual Solex;

- There is only one float chamber, and it is located on the side of the main dosing system (and not on the sides, like the Solex);

- The float is fixed in the chamber in such a way that a constant normal supply of gasoline is ensured during acceleration and upward movements;

- The calibration (hole cross-section) of the jets is smaller than that of the DAAZ from 2108.

As for the differences between the carburetors of the Oka models 1111 and 11113, they only come down to different calibrations of the jets.

Model 1111 uses fuel jets with a calibration of 95 (on the 1st and 2nd chambers) and air jets with a calibration of 190 (1st chamber) and 95 (2nd).

Version 11113 has 95 fuel jets (on both chambers) and 170 (1st), 85 (2nd chamber).

Since the dimensional parameters of Solex jets are identical and only the sections differ, it is possible to upgrade the Oka carburetor to increase power by installing jets of larger sections (but at the same time, gasoline consumption will also increase).

Do-it-yourself adjustments without disassembling the carburetor

Most carburetors are available for adjustment without disassembly:

- A screw that allows you to adjust the idle speed;

- A screw that allows you to adjust the enrichment of the gasoline-air mixture at idle;

- Throttle valve locking screw of the first chamber;

- Idle jet holder.

In most cases, experimentally, using only these elements, it is possible to significantly improve engine performance. It is advisable to set the idle speed to 800÷900 in the summer, and 900÷1000 in winter.

The carburetor can be adjusted optimally for efficiency at the service station.

Very often, the quality of the mixture entering the engine can be judged by the deposit on the spark plugs:

- Slight gray-brown soot indicates good quality of the mixture;

- Black color indicates a significant excess of fuel;

- White - about excess air.

The use of the IKS-2 indicator, installed instead of a standard spark plug and allowing you to see the color of the flame, is often recommended for adjusting the quality of carburetor operation. However, practice has shown that using it to achieve a minimum level of exhaust toxicity is very difficult.

Using your car's tachometer, you can adjust the idle speed without a strobe light. However, it is advisable to optimally configure the carburetor for efficiency and absence of harmful emissions at a service station. Despite well-described methods for tuning all models of carburetors, it is always difficult to get to the stand of a qualified carburetor technician.

Installation of Solex on Oka

It is often possible to achieve fuel economy and more stable engine operation by repairing the carburetor, replacing the repair kit, and making proper adjustments. But not all owners of small cars are satisfied with the dynamics of the engine and its throttle response, so some drivers perform tuning - install a Solex control unit from cars 2108-09. The price of this unit is relatively low, and many can afford this installation, but it will require some additional parts and minor modifications. Spare parts needed:

- thick spacer for the carburetor;

- 2 thin gaskets;

- clamps;

- fuel pipes (if necessary).

In any case, you will need to do something with the air filter housing: either upgrade an existing part, or purchase it from the VAZ-2108 (09) model. It's all about price, and if you want to save money, then it is better, of course, to modernize. Replacing a standard carburetor unit with a Solex is done as follows:

- remove the old HRSG (dismantle the air filter assembly, disconnect the fuel hoses, gas draft, choke cable, unscrew the four fastening nuts);

- We install thin gaskets on the collector platform, and a spacer between them;

- fasten the Solex with four nuts;

- we attach the gas rod, there should be no problems, adjustments are usually not required here;

- connect the EMG wire;

- we secure the fuel pipes with clamps; if there is no return line on the machine, we install a plug on the corresponding fitting;

- the choke cable will need to be “thrown over”, otherwise it will not be long enough;

- Having connected and installed everything except the “air”, we pump fuel into the float chamber with a gas pump, and try to start the engine.

Idle speed adjustment should be carried out only after the internal combustion engine has completely warmed up; idle speed is adjusted by tightening and unscrewing the quality and quantity screws. First, by using “quantity,” we raise the speed a little (to about 1000), then we tighten the quality screw until the engine runs quieter and small interruptions appear. We “add quality” a little, turning the screw a little, and using “quantity” we achieve speed within the standard range of 850-900 rpm.

Finally, we install the “air” in place and conduct tests on the road. If fuel consumption seems high, or the idle speed is not satisfactory, idle speed can always be adjusted on site, without removing the air filter housing.

Source

Adjusting the carburetor float mechanism

Adjusting the float mechanism is a very important and at the same time simple operation when servicing a carburetor. Due to the design of the float mechanism, errors made here are most often the cause of its unsatisfactory operation.

The adjustment is performed with the cover removed and includes two operations:

— checking the degree of protrusion of the needle ball;

— adjusting the position of the float bracket tongue.

The first operation is performed to determine the condition of the needle damping ball and the resulting ability to make subsequent adjustments. At the same time, on the cover removed from the carburetor, measure the distance from the plane of the gasket to the ball protruding from the needle. A distance of 10 mm is considered normal. With a smaller size, you can install an additional gasket under the needle seat.

Before checking the fuel level, first unscrew the carburetor cover mounting screws, leaving the two middle screws tightened. Also, loosen the screw securing the clamp on the fuel hose. Then manually pump up the fuel with a fuel pump until the float chamber is completely filled; As quickly as possible, to prevent “excess” fuel from penetrating into the float chamber, remove the hose from the fuel supply fitting.

If the measured value does not correspond to the tabulated data, bend the float tongue; To lower the level, bend the tongue up, to raise it, bend it down. Before checking the level again with a rubber bulb or syringe, remove at least a third of the fuel from the float chamber.

Once correctly adjusted, the float mechanism remains for a very long time, being disrupted most often due to careless handling of the removed cover, as well as due to the natural wear of the rubbing parts of the mechanism: the needle locking cone, its seat, the tongue and the axis of the bracket.

In operation, there is usually no need to specially disassemble a properly functioning carburetor to check the adjustment; it is enough to combine its control with regular cleaning of the float chamber and air jets.

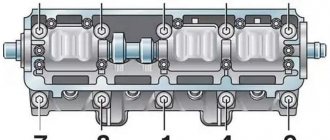

Dismantling the carburetor OKA 11113

Before proceeding with dismantling the carburetor, you should decide on the necessary tools.

Tools and materials

- set of open-end wrenches;

- flat screwdriver, medium size;

- set of spanners.

Sequence of operations

- The hood of the car is opened and the negative terminal is removed from the battery.

- The air damper is attached to the rod using a 12mm bolt. This bolt is slightly loosened with an open-end wrench.

The carburetor choke bolt of an OKA car is loosened using an open-end wrench.

The bolt on the OKA carburetor bracket is loosened with an open-end wrench

The choke rod of the carburetor of the OKA car is removed manually

The intermediate rod of the OKA carburetor is removed using a flat screwdriver

The ventilation hose from the carburetor of an OKA car is removed manually

The wires of the OKA car idle economizer are disconnected manually

Manually removing the vacuum regulator hose on the OKA carburetor

Using a screwdriver to loosen the clamp of the main fuel hose of the carburetor on an OKA car

The OKA car air filter bracket is removed manually

After unscrewing the fastening nuts, the carburetor is removed from the OKA car manually