Cars admin26.02.2020

Release date: March 21, 2021

Criticism of a car owner named Thaddeus: *****

Category: Auto repair instructions

Vehicle characteristics: The vehicle dimensions are as follows: body length - 3307, width - 1100, height - 1639 mm. The wheelbase is 2104 mm. Ground clearance 138 mm. The car is equipped with a hybrid power unit. The 4-cylinder engine is equipped with a system that provides engine power output. There are 4 valves per cylinder. The diameter of one cylinder is 71 mm, the piston stroke is 78 mm. The engine crankshaft accelerates to 4000 rpm. Maximum torque is maintained up to 4000 rpm.

Posted by admin: at the request of Rahman

Quality: HD 720

Laughter on the topic: - Grandfather, grandfather, do you remember that first girl you kissed? - My dear grandson, I don’t even remember the last one!

The domestic car of the especially small class VAZ with the index 1111 (11113) is the only AvtoVAZ model from the entire family that was equipped with a two-cylinder engine. At the same time, during the creation of this motor, the designers tried to unify this motor as much as possible with other types, in particular from VAZ-2108-21099 cars. The result of this work was that the principle of operation of the units and many elements of these installations are the same and interchangeable (for example, CPG), the only difference is in quantity.

VAZ 11113

We measure and adjust the thermal clearances of the valve mechanism on a cold VAZ 11113 engine.

- Remove the air filter housing (see "Removing the air filter housing"). Remove the front timing belt cover (see "Adjusting the tension of the timing belt").

- Use a Phillips screwdriver to loosen the clamp securing the crankcase ventilation supply hose.

- Remove the hose

- Using a 10mm wrench, unscrew the two nuts securing the cylinder head cover (valve cover).

- Remove the washers and rubber sealing bushings installed in the holes of the valve cover.

- After disconnecting the crankcase ventilation outlet hose from the carburetor fitting, remove the valve cover.

- Remove the valve cover gasket.

The procedure for checking and adjusting the clearances in the valve drive mechanism is as follows.

- Turn the crankshaft clockwise until the timing marks on the camshaft timing belt and rear timing belt cover align (see “Replacing the timing belt”).

- Then we turn the crankshaft another 40-50° (2.5-3 teeth on the camshaft pulley).

- In this position of the shafts, use a feeler gauge to check the gap at the first camshaft cam. The clearance between the camshaft cams and shims should be 0.20 mm for intake valves and 0.35 mm for exhaust valves. The clearance tolerance for all jaws is +0.05 mm.

- If the gap differs from the norm, then install a device for adjusting the valves on the studs of the camshaft bearing housing. We introduce the “fang” of the device between the cam and the pusher. We rotate the pusher so that the slot in its upper part faces forward (along the direction of the car).

- By pressing down on the lever of the device, we recess the pusher with the “fang” (Fig. 1) and install a clamp (Fig. 2) between the edge of the pusher and the camshaft, which holds the pusher in the lower position.

Rice. 1. Recessing the valve pusher when replacing the adjusting washer: 1 – device; 2 – pusher.

Rice. 2. Fixing the valve pusher when replacing the adjusting washer: 1 – clamp; 2 – adjusting washer.

26. Calculate the thickness of the new shim using the formula:

(all values in mm)

where H is the thickness of the new washerB is the thickness of the old washerA is the value of the measured gapC is the nominal gap

For example (for intake valve): A = 0.26 mm, B = 3.75 mm, C = 0.2 mm, then H = 3.75 + 0.26 – 0.2 = 3.81 mm. Within the tolerance of the gap (±0.05 mm), we select the closest washer in thickness - 3.8 mm.

27. Install a new washer into the pusher with the thickness calculated according to the formula with the inscription facing down (toward the pusher). Press the pusher with the tool and remove the lock. Check the clearance again and repeat the adjustment if necessary.

28. Turn the crankshaft one revolution (360°) and adjust the valve clearances of the other cylinder in the same order. Then fill the top of the cylinder head with oil if it has been removed.

26. Calculate the thickness of the new shim using the formula:

(all values in mm)

where H is the thickness of the new washer B is the thickness of the old washer A is the value of the measured gap C is the nominal gap

For example (for intake valve): A = 0.26 mm, B = 3.75 mm, C = 0.2 mm, then H = 3.75 + 0.26 – 0.2 = 3.81 mm. Within the tolerance of the gap (±0.05 mm), we select the closest washer in thickness - 3.8 mm.

27. Install a new washer into the pusher with the thickness calculated according to the formula with the inscription facing down (toward the pusher). Press the pusher with the tool and remove the lock. Check the clearance again and repeat the adjustment if necessary.

28. Turn the crankshaft one revolution (360°) and adjust the valve clearances of the other cylinder in the same order. Then fill the top of the cylinder head with oil if it has been removed.

The domestic car of the especially small class VAZ with the index 1111 (11113) is the only AvtoVAZ model from the entire family that was equipped with a two-cylinder engine. At the same time, during the creation of this motor, the designers tried to unify this motor as much as possible with other types, in particular from VAZ-2108-21099 cars. The result of this work was that the principle of operation of the units and many elements of these installations are the same and interchangeable (for example, CPG), the only difference is in quantity.

Oka carburetor design

Cars under the Oka brand were produced from 1987 until 2008, at first the VAZ-1111 was modified (with a 0.65-liter two-cylinder engine). The updated VAZ-11113 model was launched into production in 1995, and it received a 749 cm³ engine. Initially, for 0.65-liter engines, the Dimitrovgrad Automobile Unit Plant developed the DAAZ carburetor series 1111, which combined elements of the Ozone and Solex type HRVs. Later, the DAAZ-11113 model began to be produced for the 0.75-liter internal combustion engine (ICE), which later underwent a slight modernization.

Carburetor 11113 is a device for creating an air-fuel mixture in a certain proportion, which sets the stable operation of a car engine in all modes. The body of this unit consists of 3 parts: the top cover, the middle (main) part where the float chamber is located, and the bottom part with throttles (flaps), the carburetor device itself is a 2-chamber one, with sequential opening of the throttles.

The carburetor assembly includes:

- the main dosing system (abbreviated as GDS), operating in all modes, which includes diffusers, fuel/air supply jets for both chambers;

- idle speed system (abbreviated as XX), which allows the engine to operate stably at minimum speed and consume fuel economically; economizer, which enriches the fuel mixture at high speeds and heavy loads;

- accelerator pump, its main function is to ensure uniform operation without failures with any, even the most sharp, pressing of the accelerator (gas) pedal; a starting device that allows you to smoothly start a cold engine at low air temperatures;

- float chamber, due to which a constant level of gasoline in the carburetor is maintained, required for stable operation of the internal combustion engine.

- a transition system that makes it possible to achieve a smooth increase in speed, without jerking, during the opening of the secondary chamber.

Each of the systems in this unit performs its own specific task, and configuration and adjustment are carried out using adjusting screws, selection of jets, setting the angles of the throttle and air damper.

Features of the timing device

The same applies to the gas distribution mechanism. The essence of the work is identical, as well as the design, but the VAZ Oka has 11113 distributors. the shaft has only 4 cams. Therefore, the maintenance of the power plant of a small car is no different from the VAZ-2108.

The Oka uses a gas distribution mechanism with an overhead camshaft, which is installed in the engine cylinder head. This made it possible to abandon a number of components (bars, rocker arms). In this design, the camshafts. shafts act on the valves through pushers. In this case, it is necessary to have a thermal gap between the component elements (cam-pushrod-valve heel), which compensates for the change in geometric parameters occurring due to expansion of the metal as a result of heating.

But during engine operation, wear occurs on the surfaces of the cams, pushers and heels as a result of friction, which causes the thermal gap to change. Moreover, it is not necessary that it will increase; it also happens that the gap decreases. This often happens due to low-quality oil, which leads to the appearance of deposits on the working surfaces of the timing belt.

As a result of a change in the thermal gap, a violation of the valve timing occurs, which is why the power plant loses power (which the Oka already has “sparsely”), fuel consumption increases, and dynamics decrease. And all because the valves either open insufficiently (increased clearance) or do not fit tightly to the seats (reduced clearance).

To compensate for changes in the thermal gap, the VAZ-1111 uses special adjusting washers, which are placed in a special seat in the pusher. That is, the contact of the camshaft cam occurs not with the pusher, but with the installed washer.

In order for the thermal gap to meet the standard, periodic adjustment of the valves on the Oka is required. Due to the design features of the timing belt, the entire process boils down to installing washers of the required thickness.

How to adjust engine valves yourself

Adjusting the valves involves setting the required thermal clearance and is a mandatory procedure on engines without hydraulic compensators. If the specified gap is not adjusted, then as the mileage increases the valves begin to knock. Valve knocking can occur either due to increased clearance or as a result of pinched valves (for example, after incorrect adjustment). In both cases, if the clearance is damaged, the life of the valve mechanism is significantly reduced, the engine starts to run noisily, etc.

At first glance, it may seem that the use of hydraulic compensators on modern engines should completely solve this problem, since the design ensures automatic maintenance of the required clearance.

Unfortunately, the increasing complexity of the system and increased requirements for the quality of engine oil do not allow us to talk about high timing reliability on units with hydraulic valve supports compared to analogues that do not have such supports, that is, they require adjustment. In other words, hydraulic compensators make operation more comfortable, but the reliability of the mechanism is reduced.

For this reason, many automakers (both domestic and foreign) have not used compensators on their engines for a long time. Next, we will look at how to adjust the valves yourself, since today there are still a lot of cars on the roads without hydraulic compensators.

When to adjust valves

If your engine does not have devices to maintain the required clearance automatically, then you need to be prepared for the fact that every 30-35 thousand km. the indicated gaps must be checked.

When should adjustment be made?

The valve clearance on the Oka, according to the manufacturer’s recommendations, should be adjusted every 30 thousand km. But this is far from an accurate indicator, since much depends on operating conditions. Thus, lubricants, fuel, climatic conditions, features and intensity of use of the car can significantly affect the operation of the timing belt, and work on adjusting the thermal gap will have to be carried out earlier.

There are a number of signs indicating a change in the thermal gap:

- Increased engine noise (the sound of the unit is similar to a diesel unit);

- Power drop;

- Poor launch;

Some note that fuel consumption also increases. This is true, but the Oka uses a carburetor power system (except for the latest models equipped with a Chinese 3-cylinder unit), so it is simply unrealistic to determine the amount of fuel consumed, and such a sign of a change in the thermal gap can be ignored.

Valve clearances (Oka)

Sukhoi Log city

February 21, 2011, 09:23 #1

Good day everyone! Guys of Okavoda, help me out. The question is, what are the optimal valve clearances for an Oka? The thing is, the car ran up to 150 km/h, then it accidentally overheated and the piston partitions fell out. I've rebuilt the engine, but I can't find the optimal clearances. I set the intake to 0.20, exhaust to 0.35, it runs fine. But it eats like a steam locomotive, I set it to 0.15 and 0.30, the power increases, consumption is more economical, and the speed is maximum 110 and the engine works like it’s wearing out at crazy speeds that is about to fly out from under the hood. In general, we want to return the old regime and speed and economy. Thank you in advance for your response!

February 21, 2011, 09:35 #2

Set the intake to 0.15 and exhaust to 0.25! this is a better option!

February 21, 2011, 10:53 #3

and are you sure that the problem is not in the marks on the timing belt, according to the description you missed the mark.

Sukhoi Log city

February 21, 2011, 14:40 #4

Eugene! Good afternoon. I couldn't fly by a tooth. The marks looked the same, the only thing is that before the engine was overhauled, the distributor was completely unscrewed to +. By the way, after I overhauled it, detonation appeared, if I put small gaps, the detonation disappears. But there is a possibility of valve burnout.

February 21, 2011, 15:26 #5

180xot, 21 February 2011, 14:40

Eugene! Good afternoon. I couldn't fly by a tooth. The marks looked the same, the only thing is that before the engine was overhauled, the distributor was completely unscrewed to +. By the way, after I overhauled it, detonation appeared, if I put small gaps, the detonation disappears. But there is a possibility of valve burnout.

completely plus is bad, it should be 2/3 or a little less, but as for the marks, there may be a mistake, try transferring it to a tooth, it’s not a tricky thing and doesn’t last long, it helped me on the 9, also after replacing the timing belt I couldn’t get it right Direct the engine channel.

Lada Kalina 11176-luxLada Kalina 11176-lux

February 21, 2011, 15:50 #6 + 1

180xot If the clearance in the valves is greater than the norm, then the engine becomes more high-torque but slow to accelerate, and vice versa, in both cases there will be increased fuel consumption, look in the literature or on the Internet to see what the norm is and adjust correctly, but the distributor with normally set timing marks. should rotate proportionally in both directions, i.e., be adjustable both earlier and later; in the normal position, the marks on the tramler body should, when seated in the socket, be located approximately in the middle relative to the ebb marks of the block; in principle, the guys above described everything correctly.

Sukhoi Log city

February 21, 2011, 16:13 #7

THANK YOU GUYS for the good advice. I'm pretty good with electrical stuff, but I've only had trouble dealing with valves on a motorcycle, URAL

Renault Megane Extreme

21 February 2011, 17:24 #8

Detonates from ignition too early. It is necessary to set the recommended ignition timing according to the marks and set the valve clearances to the norm. In general, it’s a nasty car, it reacted exclusively to the spark plugs, nothing else was able to bring gasoline consumption back to normal.

21 February 2011, 18:06 #9

BERKUT, February 21, 2011, 15:50

180xot If the clearance in the valves is greater than the norm, then the engine becomes more high-torque but slow to accelerate, and vice versa, in both cases there will be increased fuel consumption, look in the literature or on the Internet to see what the norm is and adjust correctly, but the distributor with normally set timing marks. should rotate proportionally in both directions, i.e., be adjustable both earlier and later; in the normal position, the marks on the tramler body should, when seated in the socket, be located approximately in the middle relative to the ebb marks of the block; in principle, the guys above described everything correctly.

Since when does a large gap affect torque? This gap means that the valve does not open completely and naturally the cylinder is not completely filled with the combustible mixture. This results in a drop in power and excessive fuel consumption. Another thing that is added is the rumble in the increased gaps. And if the gaps are less than normal, there is a possibility that in the near future the valves or valve seats will get damaged as a result of their burnout. It is advisable to do everything according to the manual.

Lada Niva 2131МNissan Patrol

February 21, 2011, 18:26 #10

Garik 2 is one hundred percent right. It's all about setting the ignition correctly. And playing with the valves is fraught - they will either burn out with a small gap, or the rocker arms and valve heads will grind, and in this case there will be no proper power take-off.

Source

What will you need?

The only problem with timing belt adjustment is the shims. The fact is that a professional set of them is quite expensive, since it includes washers with a thickness of 3.0 to 4.5 mm (in increments of only 0.05 mm).

But many auto stores sell these washers separately, so the price of one washer is low. Only in the process of carrying out the work will you have to make all the necessary calculations, go to the auto store, purchase the required sized elements and download the assembly.

In addition, you will also need special devices - a tool for squeezing the valve and retainer. Since this specialized tool is practically not found on Oka, you can buy a regular one - for the VAZ-2108, and modify it a little.

The squeeze tool consists of a tube with holes for attaching to the valve cover studs, and a handle with a curved lever (pointed at the end) connected through an axle, allowing the lever to move freely.

The tool works simply: a handle with a lever is put on the tube. It is then secured to the valve cover studs. The handle moves freely along the tube, allowing it to be positioned exactly opposite the cam. The lever is installed between the cam and the pusher; when you press the handle, it compresses the valve spring, and all that remains is to install a clamp to hold the pusher in the depressed position. You can see how everything happens in the photo below.

As for modifying the tool from the VAZ-2108 to work with the VAZ-11113, you just need to drill two through holes in the tube, the distance between which corresponds to the position of the valve cover studs of the Oka engine (it is 17.8 cm).

In general, to make the adjustment you will need:

- Set of keys (open-end, socket);

- Screwdrivers;

- Punch and tweezers;

- Tool for squeezing pushers;

- Retainer;

- Set of probes;

- A tool for accurately measuring thickness (at least a caliper);

- Washers;

- Rags;

- New valve cover gasket;

Gearbox

Owners of Oka walk-behind tractors, like any other equipment, sometimes encounter operational problems. Including the operation of the gearbox.

Next, we will look at the most common difficulties, their probable causes and ways to solve the problem:

- There is oil leaking on the output shaft: the axle shaft cuff may be worn out (replacing the cuff will help);

- the gearbox is jammed (one of the reasons is a broken chain; it needs to be replaced);

- it is not possible to change gears (you need to disassemble the gearbox and replace broken parts);

- the mechanism for disengaging the axle shafts is broken (adjusting the tension of the axle shaft control cable will help).

The figure below shows a cross-sectional diagram of the walk-behind tractor gearbox

- Adjusting valves VAZ 2109, 2108

If the normal operation of the oil seals is disrupted, namely when oil leaks, the oil seals should be removed and inspected for cracks and wear. Replace if necessary.

Sequencing

All work is performed on a cold engine. The whole process is done like this:

- Remove the air filter housing from the car. Cover the carburetor with a rag;

- We disconnect the pipes from the valve cover and move them to the side;

- Unscrew the nuts securing the valve cover and remove it;

- We set the TDC. To do this, rotate the crankshaft until the marks on the generator drive pulley and the timing belt cover align (since there are two marks on the cover, you need to install it on the long one);

- The order of adjustment of the cylinders on the Oka is not important, since in the engine of this car they run synchronously. That is, start adjusting on any cylinder. It is only important to remember that the outer valves are exhaust, and the inner ones are inlet (exhaust-inlet-inlet-exhaust). This is necessary in order not to confuse the thermal gaps. For example, we will consider a cylinder located closer to the camshaft gear;

- We measure the gaps on the valves of the selected cylinder using feeler gauges and write them down;

- The pushers have special slots for removing the washer. Use a screwdriver to turn the pusher to turn one of the slots towards you;

- We install a squeezing tool on the valve cover studs and secure it with nuts;

- We place the handle opposite the first valve, place the lever between the camshaft. shaft and pusher, press the handle, overcoming the force of the spring;

- Install the retainer between the distributors. using the pusher shaft, remove the lever and move it to the side;

- Use a punch to pry up the washer, and then remove it with tweezers;

- The size is marked on the washer (if it is worn out, change its thickness with a caliper);

- We calculate the required thickness of the new washer. To do this, take the thickness of the removed washer, add the measured thermal gap to the value and subtract the nominal value. Let's take the intake valve as an example. The measured gap was 0.28 mm. We removed the washer, measured it and got a value of 3.80 mm. We combine these indicators - 4.08 mm. We subtract the nominal gap (0.2 mm) from it and it turns out that you need to install a washer 3.88 mm thick. Since there is no element with this value in the set, we select the closest one to it (for this we need an error of 0.05 mm). As a result, to restore the thermal gap, a washer with a thickness of 3.90 mm is needed.

- We install the selected washer and move on to the next cylinder valve. We calculate the thickness in the same way, but taking into account the fact that the exhaust valve has a nominal gap of 0.35 mm;

- After making adjustments on one cylinder, move on to the other. But to do this, it is tedious to rotate the crankshaft 360 degrees. And then all work is performed in the same way as indicated above;

- After adjustment, we install the removed elements from the engine, and the valve cover gasket must be replaced;

Finally, we note that this operation is also carried out in the case of work related to the removal of the camshaft, for example, when replacing valve seals.

“>

- Moving the lever of the device to the upper position, use tweezers to pry the adjusting washer through the slot and remove it.

- If there is no device for adjusting the valves, you can use two screwdrivers.

- Using a powerful screwdriver, leaning on the cam, press the pusher down. By inserting the edge of another screwdriver (with a blade at least 10 mm wide) between the edge of the pusher and the camshaft, we fix the pusher.

- Use tweezers to remove the adjusting washer.

The gap is adjusted by selecting the thickness of the adjusting washers. To do this, measure the thickness of the washer with a micrometer. The thickness H of the new adjusting washer is determined by the formula:

where A is the measured gap; B – thickness of the removed washer; C – nominal gap.

The thickness of the washer is marked on its surface with an electrograph.

We install the new washer in the pusher with the marking down and remove the lock.

Check the gap again. When adjusted correctly, a 0.20 or 0.35 mm feeler gauge should fit into the gap with slight pinching.

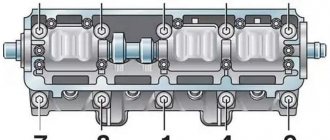

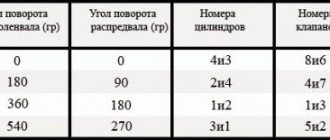

Consistently turning the crankshaft half a turn, we adjust the clearances of the remaining valves in the sequence shown in the table:

Angle of rotation of the crankshaft from the alignment of the marks, degrees.

Installation of Solex on Oka

It is often possible to achieve fuel economy and more stable engine operation by repairing the carburetor, replacing the repair kit, and making proper adjustments. But not all owners of small cars are satisfied with the dynamics of the engine and its throttle response, so some drivers perform tuning - install a Solex control unit from cars 2108-09. The price of this unit is relatively low, and many can afford this installation, but it will require some additional parts and minor modifications. Spare parts needed:

- thick spacer for the carburetor;

- 2 thin gaskets;

- clamps;

- fuel pipes (if necessary).

In any case, you will need to do something with the air filter housing: either upgrade an existing part, or purchase it from the VAZ-2108 (09) model. It's all about price, and if you want to save money, then it is better, of course, to modernize. Replacing a standard carburetor unit with a Solex is done as follows:

- remove the old HRSG (dismantle the air filter assembly, disconnect the fuel hoses, gas draft, choke cable, unscrew the four fastening nuts);

- We install thin gaskets on the collector platform, and a spacer between them;

- fasten the Solex with four nuts;

- we attach the gas rod, there should be no problems, adjustments are usually not required here;

- connect the EMG wire;

- we secure the fuel pipes with clamps; if there is no return line on the machine, we install a plug on the corresponding fitting;

- the choke cable will need to be “thrown over”, otherwise it will not be long enough;

- Having connected and installed everything except the “air”, we pump fuel into the float chamber with a gas pump, and try to start the engine.

Idle speed adjustment should be carried out only after the internal combustion engine has completely warmed up; idle speed is adjusted by tightening and unscrewing the quality and quantity screws. First, by using “quantity,” we raise the speed a little (to about 1000), then we tighten the quality screw until the engine runs quieter and small interruptions appear. We “add quality” a little, turning the screw a little, and using “quantity” we achieve speed within the standard range of 850-900 rpm.

Finally, we install the “air” in place and conduct tests on the road. If fuel consumption seems high, or the idle speed is not satisfactory, idle speed can always be adjusted on site, without removing the air filter housing.

Setting the STARTING CLEARANCES of the Oka Carburetor!!!

Adjusting the clearances in the valve drive of the VAZ 1111 OKA

Adjusting the clearances in the valve drive

- Repair manuals

- Repair manual for VAZ 1111 (Oka) 1988-2003.

- Adjusting the clearances in the valve drive

| Valve location (counting from the camshaft drive belt): 1 and 4 – exhaust valves 2 and 3 – intake valves |

|

Before starting work

Remove the air filter (see subsection 10.10.1.).

To compensate for the thermal expansion of the valve, a gap is structurally specified between the end of the valve stem and the camshaft cam. With an increased gap, the valve will not open completely, and with a decreased gap, it will not close completely. The gap is measured with a feeler gauge on a cold engine (at a temperature of +20 ° C) between the camshaft cam (the cam should be directed upward from the pusher) and the valve pusher adjusting washer. The nominal clearance for the intake valve is (0.2±0.05) mm, and for the exhaust valve - (0.35±0.05) mm. The gaps are adjusted by selecting the thickness of the shims. Spare parts are supplied with washers with a thickness of 3 to 4.5 mm (every 0.05 mm).

Device for adjusting clearances in valve drives:

1 – device for compressing valve springs2 – tube for VAZ (4-cylinder engine)3 – tube for Oka (2-cylinder engine)4 – retainer

If there is no special tool for the Oka, you can use the tool for front-wheel drive VAZ models. In this case, instead of the tube supplied with the device, select a tube of the same diameter and length of at least 21 mm. Drill two holes in it with a diameter of about 10 mm at a distance of 17.8 mm or drill an additional hole in tube 2 supplied with the device according to the specified dimensions (in this case the device can only be used to adjust the Oka gaps).

| EXECUTION ORDER |

1. Close the carburetor with a plug or a clean rag.

2. Remove the washers from both head cover mounting studs.

3. Unscrew the two nuts securing the cylinder head cover.

4. After loosening the clamps, remove the hose of the small branch of the crankcase ventilation from the fitting of the cylinder head cover.

5. . ventilation hose from the cylinder head cover pipe and.

6. . hose of the large ventilation branch from the fitting of the cylinder head cover.

7. Remove the washers from both head cover mounting studs.

Now on sale

Nizhnekamsk

Citroen C1

2012 | 60,000 km360,000 rub. Naberezhnye Chelny

KIA Picanto

2011 | 93,000 km TTS Chelny 430,100 rub. Naberezhnye Chelny

KIA Picanto

2013 onwards | 46,811 kmTTS Chelny429,100 rub. Kazan

KIA Picanto

2015 | 19,964 kmTTS Kazan, st. Decembrists549,000 rub. Kazan

Daewoo Matiz

2013 onwards | 60.688 kmTTS Kazan, st. Decembrists199,000 rub. Naberezhnye Chelny

Daewoo Matiz

2013 onwards | 27,575 km TTS Chelny 155,200 rub. Kazan

Peugeot 107

2008 | 102.929 kmTTS Kazan, st. Decembrists240,000 rub. Kazan

KIA Picanto

2010 | 77.461 kmTTS Kazan, st. Decembrists330,000 rub. Naberezhnye Chelny

Daewoo Matiz

2013 onwards | 37,749 kmTTS Chelny164,900 rub. Naberezhnye Chelny

KIA Picanto

2013 onwards | 89,200 kmTTS Chelny359,000 rub.

VAZ 1111 | Adjusting the clearances in the valve drive

1. Close the carburetor with a plug or a clean rag.

2. Remove the washers from both head cover mounting studs.

3. Unscrew the two nuts securing the cylinder head cover.

4. After loosening the clamps, remove the hose of the small branch of the crankcase ventilation from the fitting of the cylinder head cover.

5. . ventilation hose from the cylinder head cover pipe and.

6. . hose of the large ventilation branch from the fitting of the cylinder head cover.

7. Remove the washers from both head cover mounting studs.

8. Move the carburetor choke drive rod aside.

9. Remove the rubber bushings from both studs securing the cylinder head cover (replace bushings that have lost elasticity, deformed and torn ones).

10. Remove the cylinder head cover.

11. Use a wheel wrench to turn the crankshaft by the bolt securing the generator drive pulley through the hole in the right wheel niche (to make it easier to turn the shaft, you can unscrew the spark plugs) so that.

12. . The marks on the generator drive pulley and on the front camshaft drive cover coincide. In this case, you can adjust the clearances in the drive of either the 1st and 2nd, or the 3rd and 4th valves. The order in which the valves are adjusted does not matter. Note that.

Disassembly and assembly of the front door

Remove the front door trim (see section “Removing and installing the front door trim”), the outside rear view mirror adjustment knob and the mirror by unscrewing the fastening screws. Using the window lifter handle, lower the glass all the way down and remove the lower sliding glass seals from the door. Unscrew the fastening screws and remove down the guide grooves of the sliding glass and remove it through the top. Unscrew the seven nuts securing the window regulator to the door panel, remove the washers from the studs and remove the window regulator.

Unscrew button 1 (see Fig. 170) of the lock, remove bracket 3 securing the external lock drive and the drive itself. Remove two screws securing bracket 16 of the internal handle and three screws 3 (Fig. 182) securing the lock, disconnect the lock switch rod and remove the lock assembly with rod 2 and lock button rod 1. If necessary, unscrew the fastening screws and remove the door opening limiter.

Reassembling the door is done in the reverse order. Before assembly, lubricate the moving parts of the window regulator and door lock with CIATIM-201 lubricant. After assembly, check the operation of the locks and window regulator.

Features of installing carburetors

It is better to install two new carburetors. Their parameters must be identical. The position of the mixture quality and quantity screws should be checked. If necessary, adjustments are made

It is important that the adjustment screws are turned out the same amount

All hoses must be securely secured with clamps.

To ensure reliable and durable operation, it is important to install an air filter. Since there is only one filter in the standard production, modification is required

How to make a filter depends on the ingenuity of the car enthusiast, but the main thing is to avoid allowing the engine to operate directly. An option for making a filter is to cut out a sheet steel housing to the size of the filter element.

The final adjustment is carried out on a warm engine using vacuum gauges designed for multi-carburetor bikes. You can also use for these purposes:

- calibrated econometers;

- mixture quality sensors inserted into the spark plug hole.

VAZ 2106 - 2 sport carburetors - a brief history

Having installed two carburetors on a VAZ, during operation you should monitor the condition of the spark plugs of each pair of cylinders. A different color from the normal electrodes will indicate that the mixture feeding the engine is excessively rich or lean. Having decided which carburetor requires adjustment, it is necessary to achieve the optimal mixture composition

It is important that the engine operates stably at any speed.