Compression measurement in cylinders of a carburetor car engine

The procedure given in the article and recommendations for measuring compression in cylinders are applicable for gasoline carburetor engines of VAZ passenger cars - 2108, 21081, 21083, 2109, 21091, 21099, 2101, 2106, 2105, 2107, 21021, 210213, 1111 and a number of others similar (Moskvich, Izh, Volga...).

Measuring compression on injection engines has a number of features and will be discussed in a separate article. Tools and devices for measuring compression

2. Spark plug key.

3. Assistant.

1. Warm up the engine to operating temperature (80-90º).

2. Remove the fuel supply hose from the fuel pump.

3. We unscrew all the spark plugs, having first cleared their wells of dirt and debris.

What Compression Should Be on a VAZ 2107 ~ SIS26.RU

Compression in the engine of a VAZ 2106 car

Considering the fact that the VAZ 2106 produced more than 4 million units, there are still many of them on our roads. Accordingly, the issues of restoring the legendary “classics” are still relevant. For example, the question of what compression should be supported by a working Six engine.

The concept of compression, its measurement

This characteristic is not included in the technical data prescribed in the car manual. There is a slightly different concept. compression ratio. There is no direct relationship between these two parameters; they have only one thing in common. In both cases we are talking about pressure.

- The compression ratio is a calculated constant and has no units. For the VAZ 2106 engine and its modifications this is 8.5. This indicator is the result of dividing the total working volume of the cylinder by the volume of the combustion chamber. In simple terms, the fuel-air mixture entering the cylinder space is compressed by the ascending piston by 8.5 times.

- Compression is a variable value, its value depends on the technical condition in which the engine is located. This parameter shows what pressure occurs in each individual cylinder when the crankshaft rotates using the starter. Measure it with a pressure gauge that screws in instead of a spark plug, the unit is 1 kgf/cm2 or 1 bar, which is almost the same (1 kgf/cm2 is 0.98 bar).

Compression is measured to determine the degree of wear of the cylinder-piston group. Its values were empirically derived from practice. Measurements are carried out as follows: all 4 spark plugs are unscrewed, and in their place a pressure gauge with a check valve is screwed into each cylinder, and by rotating the starter determines the maximum pressure that each piston can pump. In the VAZ 2106 engine, the ideal figure is 13 kgf/cm2, but this is a rare case; this pressure occurs on new, just running engines.

Checking compression on an injection VAZ 2105,

2107 and 2104

How to measure compression

in the

VAZ

classic engine:

2104-2107

.

COMPRESSION MEASUREMENT VAZ 2106

How to correctly measure compression in cylinders. How to use a compression gauge. Compressometer. VAZ

Classy.

How to use measurement results?

If the measured value ranges from 11 to 12.5 kgf/cm2, then this is a normal working VAZ 2106 engine. It is important that the compression in all 4 cylinders is the same, a difference of more than 0.5 kgf/cm2 indicates a malfunction in one of them . As a rule, this is a burnt valve; this problem occurs when driving on low-quality fuel and high loads.

The measurement results, which showed a pressure of 10 to 11 kgf / cm2, indicate rapid engine repair. These results may not be completely accurate when the engine is running. This is the name for the phenomenon when engine oil begins to fall through the crankcase bleeder hose from the breather into the carburetor along with crankcase gases. The reason is simple: due to wear on the piston rings, excess pressure arises in the crankcase space, which pushes oil droplets through the breathing space into the carburetor.

The fat, along with the fuel, enters the combustion chamber and, after combustion, forms a deposit on its walls and a spark plug. When the oil hits very hard, it starts to fill the gap between the worn rings and the cylinder surface, then the compression readings will be higher and they cannot be maintained on them. That is, if the engine is blowing, then it’s time to replace the piston rings.

A compression ratio of 9-10 kgf/cm2 indicates wear of the cylinder-piston group or valves. In both cases, engine disassembly is required. Such an engine usually consumes oil and fuel, it is unstable, and part of the power is lost. However, it can continue to be used for some time, the main condition. compression in all cylinders

should be the same. If in some of them the valve burns completely, the pressure in it drops sharply and the cylinder will fail altogether.

The same fate awaits a unit whose compression is less than 9 kgf/cm2. This pressure indicates the need for its overhaul. In such cases, if possible, all accessories are removed from the engine, unscrewed from the gearbox and completely removed from the supports to allow disassembly and repair to be carried out more conveniently.

At the same time, check the condition of the rubber parts of these supports; you may have to replace the cushions. Many motorists disassemble the engine directly on the car; this option also has a right to life, especially if it is necessary to replace only the piston rings.

sis26.ru

About compression of the VAZ 2107 - measurement and causes of reduced pressure

Compression is one of the most important data characterizing the condition of a car engine. Indicates the pressure in the cylinder at the moment of compression. If the compression of the VAZ 2107 engine is below normal or its value varies in each cylinder, then it is necessary to immediately begin repairing the engine. For a VAZ 2107 car, the optimal pressure value is 12 atmospheres, and if the value is below 10 Bar, then the internal combustion engine needs repair.

What compression should the engine have?

What are the standards for compression ratios and compression ratios for internal combustion engines? They are different. The compression ratio of a gasoline engine can vary from 10:1 to 13:1, 14:1, or even higher. The compression of a diesel engine is never lower than 20:1. Textbooks on automobile theory and all kinds of manuals define the compression ratio as: “... the ratio of the total volume of the cylinder to the volume of the combustion chamber. The compression ratio is determined using the following formula (VC)/C = CR, where V is the working volume of the cylinder, and C is the volume of the combustion chamber."

There are no formulas for calculating compression, since this value is no longer a calculated geometric value, but an absolute one. This, as mentioned above, is pressure. Compression depends on many factors, the main one of which is the quality of the tightness of the mating pairs - cylinder-piston, cylinder-valves, cylinder-throttle valve, etc.

VAZ 2107 internal combustion engine compression standards

If there is a possibility of a motor malfunction, then the first thing you need to do is measure the compression ratio. To assess the condition of the CPG of a VAZ 2107 engine, you should first find out what values are considered normalized. What compression should be on a VAZ 2107 is a question that all owners of classics ask when they need to check the condition of the internal combustion engine.

The higher the pressure during compression of the fuel-air mixture in the combustion chamber, the better. The standard pressure value when compressing fuel assemblies in cylinders on a VAZ 2107 is 10-12 atmospheres. But this indicator is not appropriate for all engines. As you know, sevens were produced not only with carburetor, but also with injection types of engines. For carburetor and injection internal combustion engines, the lower threshold is 10 atmospheres or 1 MPa. The engine is considered to be in excellent condition if the pressure gauge shows a value of 13 Bar (this happens with new engines). A run-in working motor has a pressure value of approximately 12 bar.

Knowing how many atmospheres is the optimal pressure in the cylinders at the moment of compression, you can resort to the procedure for measuring this value. To do this, you will need a special device, which we will learn about in the next section.

How to determine compression on a VAZ 2107

Before the compression on the VAZ 2107 is measured, you will need to initially prepare the appropriate tools. To carry out the work the following are used:

- Spark plug wrench for removing spark plugs.

- A compression meter is a special device for measuring pressure in internal combustion engine cylinders during fuel assembly compression.

A compression gauge is needed directly to find out the pressure in the cylinders. Moreover, this applies not only to gasoline engines, but also to diesel engines. It is recommended to use devices with a threaded type of mounting fitting, as the readings with their help are more accurate. If the instruments are ready to measure compression, then work can begin.

- First you need to warm up the internal combustion engine to a temperature of 70-80 degrees, otherwise the data will not be accurate.

- After this, the fuel line is shut off, which prevents fuel from entering the combustion chamber. To do this, you can simply pinch the hose with a special tool or turn off the power to the fuel pump on injection cars.

- Start the engine and wait until it stalls on its own.

- All spark plugs from 4 cylinders are unscrewed.

- We prepare the device for measurement. A compression gauge is screwed into the thread of the first cylinder. Now you can begin to carry out measuring manipulations.

- To check the pressure, you need to have an assistant behind the wheel. He must turn the starter while pressing the gas pedal all the way.

- Turn the starter until the readings on the device stop increasing.

- When the maximum value is reached, it is necessary to take readings and record them. A similar procedure is carried out for all remaining cylinders.

Reasons why there is no compression in the cylinder

Poor (small) compression in one or all cylinders indicates engine wear. There is an old and simple way to determine why compression has disappeared. You need to pour a tablespoon of engine oil into the spark plug hole and repeat the measurements:

- if the pressure has increased noticeably, it means the piston rings have poor sealing;

- if the pressure has not changed, then there may be several reasons (for example, leaking valves, broken gaskets under the cylinder head, there is a crack or burnout in the walls of the combustion chamber, in the piston bottom).

There is another, more accurate way to find out why compression has disappeared. To do this, you will need to modify the spark plug. We remove the insulator from it, and weld the valve of the car camera to the metal body. Next, set the cylinder piston to the ignition timing position, remove the radiator caps and oil filler neck, screw in the manufactured adapter and pump air into the cylinder using a pump (create pressure in it):

- if air enters the exhaust pipe, it means the exhaust valve is poorly sealed;

- If air goes into the intake manifold, there is a problem with the intake valve.

- if bubbles appear in the expansion tank, then check the cylinder head gasket;

- If there is a hissing sound in the oil filler neck, it means that the piston rings are not properly sealed.

Engine diagnostics using compression measurements in the cylinders allows you to quickly and accurately determine its condition without disassembling, and in some cases will help avoid major repairs of the power unit. Have you ever experienced a lack of pressure in the cylinders? What was the cause of the malfunction? If engine problems persist, check the fuel rail pressure.

Keywords: Lada Granta engine | Lada Kalina engine | Lada Priora engine | Lada Largus engine | 4x4 engine | Lada Vesta engine | lada xray engine | Niva engine | universal article

6

0

The administration of Togliatti filed a lawsuit against AvtoVAZ, new details

Basic equipment Lada Kalina 2 standard (photos, features and options)

- How to open the secret menu of the Lada XRAY radio

How to remove the steering wheel on a Lada Largus with your own hands

Compression and compression, what's the difference?

In everyday life, when we talk and say compression, we mean compression; in reality, they are not the same thing. So what is the difference between compression ratio and compression?

The most obvious way to prove this is a mathematical calculation. Look at the figure below as you can see from here that the compression ratio in the simplest interpretation of the formula is the ratio of the working volume to the volume of the combustion chamber.

In reality, for a more accurate measurement, the formula looks like this:

where v3 is the volume of the compression meter. For the calculation, the coefficient 1.2 ‒ 1.3 is used (determined by the Poisson equation) and the formula has the form P=ε*1.2. From here we have that with a compression ratio of 10 kg/cm 2, the compression should be in the range of 12-13 kg/cm 2. Ideally, the values obtained by the compression meter should coincide with the calculated ones.

What Compression Should Be on a VAZ 2107 ~ AVTO-MELVIN.RU

What compression should be on a VAZ-2109 car

The first symptoms of problems in the operation of the VAZ-2109 engine are known to all owners of Russian cars: leaving one wanting the best dynamics, increased gasoline consumption, partial or almost complete lack of response to the accelerator pedal, lack of traction, the car moves with great effort, emanates from the exhaust pipe dark smoke.

At first, the most experienced driver blames the spark plugs, and later the piston system comes into question. To check the condition of the piston rings, we carry out independent diagnostics of the operation of machine parts.

To do this, you need to find the engine compression.

Even if the carburetor is acting up, you need to check the compression first - this approach will allow you to accurately detect faults in the VAZ-2109, remove them and move on to regulating the carburetor.

Instructions for checking compression of VAZ-2109

To measure compression, you need to prepare special tools:

- a compression gauge consisting of a soft flexible hose, a pressure release button and a tip with a measurement panel;

- spark plug key.

When diagnosing yourself, you cannot do without an assistant. Annotation on measuring compression of a VAZ-2109 injector and carburetor looks like this:

- Turn on the car engine and heat it to a temperature of 80 to 90 degrees.

- Remove the hose from the fuel pump that drains gasoline.

- Carefully unscrew the spark plugs, first cleaning the wells from adhering dirt and debris.

- Remove the armor wire located in the center from the toggle switch cover, fix the spark plug in it and place it on top of the engine.

- Place the compressor tip in the recess of the first cylinder; the device does not necessarily need to be screwed in; it can be pressed against the hole with your hands.

- Proceed to measure pressure. The assistant must take the driver's seat and press the gas pedal all the way, then turn the key in the ignition and start the starter for more than 3-5 seconds.

- Watch how the compression meter values change at this time, the dynamics of increasing readings should be recorded, and also write down the highest position of the arrow. After fixing is completed, release the pressure by pressing the release button.

- These steps must be performed for each engine cylinder separately, so as not to forget the characteristics, record them on a piece of paper.

How to analyze the obtained compression meter readings

The analysis of acquired data is carried out based on 3 characteristics:

- Highest pressure value. A good pressure, which should be in the standard in the VAZ-2109, is from 12 to 13 kg/cm2, which is approximately from 1.2 to 1.3 MPa.

- The usual pressure is considered to be from 10 to 11 kg/cm2. (1-1.1 MPa).

- You cannot do without repairs if the compression gauge indicates values from 8 to 9 kg/cm2, which is from 0.8 to 0.9 MPa.

Checking compression on injection VAZ 2105, 2107 and 2104

How to do a compression

in the

VAZ

classic engine:

2104-2107

.

Standard for different engines

The pressure in the engine cylinders depends on its type. The compression in a diesel engine should be no lower than 28 kg/cm2, although in earlier domestic models a pressure of 20 kg/cm2 was considered normal, while the spread of values between the cylinders should be no more than 2-3 kg/cm2.

On most gasoline imported and domestic cars, normal engine compression should be within 10 - 13 atmospheres, including on the VAZ 2107, and on VAZ models of the “tenth” family it is slightly higher, from 11 atmospheres. The compression difference in the cylinders should be no more than 0.5-1 kg/cm2.

What are the cylinder compression standards for VAZ engines?

Engine specifications must indicate “minimum cylinder compression values.” If you cannot find such data, determine the compression standards yourself using the formula:

Compression (kgf/cm2) = compression ratio (see technical specifications of internal combustion engine) * coefficient (for VAZ min 1.2, max 1.3)

A few examples:

- The compression ratio of modern VAZ 21126 and VAZ 21127 engines installed on Granta, Kalina and Priora is 11. We multiply the values using the formula and get the compression standards: 13,2..14,3.

- For the Vesta engine (VAZ-21129) the compression ratio is 10.45, the compression standards will be: 12,5..13,6.

- For Niva (VAZ 21213, 21314) - 11,3..12,2.

If the compression gauge values in all cylinders are within the normal range, this does not mean that everything is fine. Different compression in the cylinders is also bad. It is important that the difference between all readings is minimal. Compare the minimum and maximum compression values in the cylinders. According to technical standards, the difference should be no more than 1 kgf/cm2 or 10% .

Signs of poor compression

Friction between the piston with rings and the cylinder leads to an increase in the gap, and as a result there will be:

- increased oil consumption, as it will be poorly collected by oil scraper rings and burn in the combustion chamber;

- increased amount of smoke due to burning oil, which follows from point 1 (in some cases this may be due to faulty valve stem seals);

- As a result, power decreases. This drop will be especially noticeable on small displacement engines;

- increased amount of smoke from the breather. The breather is available on both carburetor and injection models.

The higher the compression, the better: the fourth tale

Often, from apologists for various additives, you hear how the compression jumped after the next treatment of the engine. Growth up to 15 bar, up to 17 bar! But we must keep in mind that in normal condition, even after restoring the gaps to the state of a new engine, you will not get compression higher than standard.

Where do the numbers come from? Usually, on a disassembled engine, it is clear that after processing the combustion chamber is overgrown with something unknown and, as a result, the volume of the compression chamber has decreased. But these deposits interfere with heat removal from the combustion chamber. Hence detonation, glow ignition, etc. So we shouldn’t rejoice at the unprecedented increase in compression, but vice versa.

Change in specific fuel consumption at fixed speeds (2500 rpm) in two engine variants - basic and with rings in which the gaps are increased. Compression has dropped, but in terms of consumption this is noticeable only at low loads.

Source

Reasons for low compression

As mentioned above, a decrease in compression occurs for several reasons, these are:

- engine service life;

- violation of maintenance (delayed oil change);

- use of low-quality oil;

- engine overheating;

- Driving with a cold engine (thermostat malfunction).

There are also reasons when additives will not help and repairs are needed, these are:

- piston burnout;

- valve burnout;

- burnout of the gasket between the cylinders;

- rings are stuck (sometimes “cured”).

Faults such as burnout are almost immediately noticeable, but some can only be determined after diagnosis.

What to do if the compression in the engine is too low?

The main reason for loss of compression is, of course, loss of tightness. But where exactly did the depressurization occur? You can check this as follows.

50 ml of engine oil is poured into the “suspicious” cylinder and the compression is measured again. There are two options. If compression

remains the same low, then the air is coming out somewhere above, in the combustion chamber, and this could be either a leaky throttle valve, a burnt valve, or a breakdown of the cylinder head gasket.

Or even all together. If the compression

has increased significantly, then the cause is “stuck” piston rings. And if the difference between the factory compression and the existing one exceeds at least 20-25%, then a bulkhead is inevitable. That is, a major engine overhaul.

How to increase compression in an engine? Do engine additives help improve compression? Not always, but they help. And before you start capital expenditure on expensive repairs, this opportunity is worth taking advantage of. But if the result turns out to be zero, then your car is on its way to the service station.

Correct, and most importantly preventive diagnostics of engine systems and components is the key to its trouble-free operation. Compression in the engine cylinders must be monitored periodically. In the same way - as with all other systems, assemblies and components of the engine and the entire vehicle.

Only professionals can carry out competent professional diagnostics and identify the reasons for the drop in compression in the engine, especially if you have not an ancient carburetor car, but a modern foreign car.

Use the form below to find specialized service stations nearby and sign up for service at any time convenient for you.

Recovery methods

To increase the compression in the engine, if you are sure or suspect that the rings are stuck, you can pour 100 grams of clean oil into each and give them time to “throw away”. Sometimes turning the crankshaft in both directions a few degrees. The procedure can be repeated.

The second, more effective method, you need to take: 1 part clean motor oil, 1 part acetone and 1 part kerosene. Stir and pour 50 ml into each cylinder, tighten the spark plugs and leave for 10 hours. Unscrew the spark plugs and crank the engine with the starter for a few seconds. We install the spark plugs, start it and heat it up to 40 degrees no more. Drain the oil, flush the system, change the filter and fill in new oil.

There are also special means that are also used to combat increased compression, which occurs when there is more carbon deposits on the piston and in the combustion chamber.

The second method is to restore pressure by adding additives to the oil. There are quite a lot of them on the market with varying effectiveness. I wrote about the use of the Suprotek additive, the effect of its use is positive.

Engine diagnostics

If the piston burns out, the tightness in the cylinder is broken, the engine starts poorly and runs unevenly, just like with a burnt out valve. The engine does not start well (or even does not start) when the rings are stuck.

The rings lay down

You can check compression without a compression gauge. If you need to identify which cylinder is faulty, then just unscrew the spark plugs and crank the engine with the starter, and by closing the holes with your finger, control the process of air intake and release. If there is a major malfunction (a burnt-out piston or valve), you will identify this cylinder immediately, since it will be less able to suck in and push out air.

In other cases, it is better to use a compression meter to accurately diagnose compression.

To check the compression in the cylinders with your own hands, you need to have a compression gauge. This is a device that measures pressure (from the Greek manós, loose), and can be supplied with different attachments for different holes.

Checking the compression in the engine cylinders is carried out by two people. To ensure that the readings are correct, warm up the engine before starting the test; when cold, the values will be lower. Further:

- Unscrew the spark plugs and insert a compression gauge into the holes one by one;

- the air damper must be open (the gas pedal is depressed);

- hold the device in the hole until the reading stops.

Do not “drive” the starter for a long time, otherwise it may burn out. For most cars, the compression ratio in the cylinders is considered normal from 10 to 12 kg/cm2.

Oil check

If the test shows low values, then you can determine what exactly is to blame in the following way. Pour 25-35 ml of clean oil into each cylinder and check again. Moreover, if:

- the values have increased almost to normal, then the cylinder-piston group is worn out or the rings have become stuck after overheating;

- there is no compression in 1 cylinder or two, this may indicate burnout of the piston, valve, or destruction of the rings.

Why do you need to check?

It is recommended to measure compression at least once every 15-20 thousand kilometers . Its deviation to a lesser extent leads to the fact that the fuel mixture is not compressed to the required level and ignites at a slower rate, as a result of which the engine overheats and its power is significantly reduced.

Increased compression, on the contrary, causes early ignition of the mixture, as a result of which it detonates, creating additional loads on the piston elements.

If there is a difference in compression in the cylinders of one engine, the mixture will ignite at different rates, creating an imbalance in the coordinated operation of the pistons and camshaft(s).

What does low compression lead to?

Most often, compression in the cylinders does not increase, but decreases. This may be a consequence:

- wear or damage to compression rings;

- wear or burnout of valves;

- damage to the cylinder head gasket;

- cracks in the cylinder head.

These problems can cause:

- reducing engine power;

- deterioration of dynamic performance;

- increased fuel consumption;

- “forcing” oil into the air filter housing (in carburetor engines);

- oil getting inside the combustion chambers (the engine “eats” oil, which is characterized by bluish exhaust smoke).

If you find the listed signs in your car, be prepared to at least replace the piston and, at maximum, overhaul the engine. But before you start repairing it, you should make sure that the compression is really low.

The procedure for taking measurements

Before checking engine compression, it is necessary to ensure that the battery is fully charged and the starter is working properly. Otherwise, you will get underestimated indicators and start repairing the power unit instead of continuing diagnostics and looking for other reasons.

There are several ways to measure pressure - “cold”, “hot”, with the throttle closed and fully open. Practice shows that the most accurate results are obtained by checking on a warm engine, performed according to the instructions:

- Start the engine and bring the coolant temperature to 70 °C.

- Remove the high-voltage wires and turn out all the spark plugs and, on a diesel engine, the injectors.

- Disconnect the injectors from the controller by disconnecting the corresponding connector. Another option is to turn off the power to the fuel pump by removing the required fuse.

- Screw the compression gauge nozzle into the hole of the 1st cylinder, open the throttle valve by pressing the gas pedal, and turn the crankshaft with the starter 5–10 times.

- Take readings and repeat the operation on the remaining cylinders.

If you do not want to touch the electronics, then you don’t have to turn off the injectors of the gasoline engine; this will not affect the accuracy of the readings, but during diagnostics a small amount of fuel will enter the oil sump.

The fuel supply on a diesel engine with a mechanical injection pump is turned off using the cut-off lever. Based on the measurement results, the following conclusions are drawn:

- If the measurement values differ by no more than 1 bar and are close to optimal, the piston group and valves are in good condition.

- The same situation, but the indicators are close to the minimum threshold. The resource of the power unit is almost exhausted, you can drive further and add oil, but prepare for repairs.

- When the pressure in one of the cylinders is 2-3 bar lower than the others, check again by pouring 5 ml of engine lubricant into the spark plug hole. If the compression has increased, this means that the piston group is faulty, since the oil has sealed the fit of the rings. The readings remained the same - a burnt valve was to blame.

If the pressure in all cylinders is below normal, a major overhaul will have to be done. It is useless to carry out a test with adding oil - the engine still needs to be disassembled.

How and what to measure

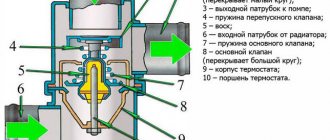

Compression is measured with a special device - a compression meter. It is a pressure gauge with a hose, at the end of which there is a fitting, either metal with a thread for a spark plug hole, or rubber in the form of a cone.

The process of measuring compression using a compression gauge involves placing a fitting in the spark plug hole and cranking the crankshaft with the starter until maximum pressure is reached.

Compression in a cylinder can also not be measured, but checked and compared with other cylinders.

To do this, unscrew all the spark plugs except one, and manually (using a wrench on the generator pulley nut) turn the crankshaft until the piston reaches top dead center.

Then they check the second cylinder, the third and the fourth in the same way, and compare the applied forces. Of course, this method is not comparable to measuring with a compression gauge, but it can help to understand which cylinder has a problem.

What should the compression be in VAZ cars?

The average compression rate for unboosted VAZ engines is 8-9 atmospheres, for forced ones with a reduced combustion chamber - 11-13 atmospheres.

In order to accurately determine the standard compression ratio, use the table that indicates the compression ratio in the cylinders of eight- and sixteen-valve VAZ engines.

| Number of valves | 16 | 16 | 8 | |

| Engine volume, l | 1,5 | 1,6 | 1,5 | 1,6 |

| Cylinder diameter/piston stroke, mm | 82/71 | 82/75,6 | 82/71 | 82/75,6 |

| Compression ratio | 10,5 | 10,3 | 9,9 | 9,6 |

What engines is the VAZ 2107 equipped with?

The VAZ 2107 model was produced from 1982 to 2012. Over the 30 years of its existence, the car has been repeatedly refined and changed to more accurately meet modern requirements. Initially, the “seven” was conceived as a small-class rear-wheel drive car in a sedan body. However, in some countries the VAZ 2107 was refined and modified, which is why it can be considered a universal car model.

Depending on the year of manufacture and the country of origin (at different times, the VAZ 2107 was produced not only by the Russian AvtoVAZ, but also by factories in European and Asian countries), the model was equipped with different types of propulsion systems:

- LADA-2107 (engine 2103, 1.5 l, 8 cells, carburetor);

- LADA-21072 (engine 2105, 1.3 l, 8 cl., carburetor, timing belt drive);

- LADA-21073 (engine 1.7 l, 8 cells, mono injection - export version for the European market);

- LADA-21074 (engine 2106, 1.6 l, 8 cl., carburetor);

- LADA-21070 (engine 2103, 1.5 l, 8 cl., carburetor);

- LADA-2107–20 (engine 2104, 1.5 l, 8 cells, distributed injection, Euro-2);

- LADA-2107–71 (engine 1.4 l, 66 hp, engine 21034 for A-76 gasoline, version for China);

- LADA-21074–20 (engine 21067–10, 1.6 l, 8 cl., distributed injection, Euro-2);

- LADA-21074–30 (engine 21067–20, 1.6 l, 8 cl., distributed injection, Euro-3);

- LADA-210740 (engine 21067, 1.6 l, 53 kW/72.7 hp 8 cells, injector, catalyst) (2007);

- LADA-21077 (engine 2105, 1.3 l, 8 cl., carburetor, timing belt drive - export version for the UK);

- LADA-21078 (engine 2106, 1.6 l, 8 cl., carburetor - export version for the UK);

- LADA-21079 (rotary piston engine 1.3 l, 140 hp, originally created for the needs of the Ministry of Internal Affairs and the KGB);

- LADA-2107 ZNG (engine 21213, 1.7 l, 8 cells, central injection).

That is, in total there were 14 versions in the VAZ 2107 line - either with carburetor engines or with injection ones.

Technical characteristics of VAZ 2107 (carburetor)

The VAZ 2107 was initially equipped with a 1.5 and 1.6 liter carburetor. In the USSR in the 1980–1990s, almost all produced models were equipped with engines of this size - this power was quite enough for trips around the city and country roads. The engine uses AI-92 gasoline to create the air-fuel mixture. There were also 1.3 and 1.2 liter carburetors, but they were not particularly popular.

How to check it yourself

Having a compression gauge and an assistant at hand, measuring compression will not be difficult.

- Warm up the engine to operating temperature.

- Shut off the fuel supply to the cylinders. For carburetor engines, disconnect the hose that goes from the carburetor to the fuel pump; for injection engines, remove the fuel pump fuse and let the engine run until the fuel is used up from the system.

- Disconnect all high voltage wires from the spark plugs.

- Unscrew the first spark plug and insert the compression gauge fitting in its place.

- Have a helper run the starter for a few seconds until the pressure gauge needle stops moving up.

- Take pressure gauge readings and compare them with standard values.

- Carry out the same procedure for all cylinders. Compare the compression ratios in the cylinders.

Measuring compression in your car’s engine: how to do it?

Measuring engine compression with a mechanical compression meter is carried out according to the following algorithm. You should remove all the spark plugs from the cylinders and crank the engine crankshaft idle, measuring the compression in each cylinder in turn:

— it is desirable that the engine is warm, although this is not critical;

— the fuel supply must be clearly turned off;

— if the engine is cranked by the starter, then the battery must be charged and the starter, accordingly, must be in working order;

— the engine can also be cranked manually using the crank (if there is one) or using the appropriate key on the ratchet; cranking the gears, belt or chain of the timing mechanism by hand will not give correct compression measurement results.

At a professional car service center, compression is measured with the throttle valve open and closed, and the difference in readings may indirectly indicate some defects in engine operation. When the damper is closed, less air will flow into the cylinders, and the compression will be low - about 0.6-0.8 MPa. When the throttle is open, the picture will be different - the causes of engine defects can be determined from the attached table at the bottom of the article.

In any case, one should take into account not only the dynamics of pressure increase, but also the maximum compression values. And most importantly, in any case, the results of compression measurements in cylinders are calculated, relative values, and one should rely specifically on the difference in pressure in different cylinders. If in three cylinders the compression is, for example, 11-12 atm, and in the fourth cylinder it is 7-8 atm, then the problem is concentrated there. Here we should look for the reasons for the loss of tightness of the cylinder-piston group.

What do you mean by compression?

One of the main characteristics of the engine, given in the car’s operating instructions, is the compression ratio. This is a dimensionless coefficient showing how many times the air-fuel mixture is compressed before ignition. It is calculated as follows: the volume of one cylinder (including the combustion chamber) is divided by the piston stroke. This parameter is constant and changes only with deep tuning of the engine - boring the cylinders, installing a different crankshaft, and so on.

Uninformed car enthusiasts confuse the compression ratio with compression - the real pressure created by the pistons when the crankshaft is rotated by the starter (200-300 rpm). The characteristic changes as parts wear and is measured in the following units:

- Atm (atmosphere);

- kgf/cm 2 (kilogram-force per centimeter) = 0.97 Atm;

- MPa (megapascal) = 9.9 Atm;

- Bar = 0.99 Atm.

To identify a malfunction of the main engine elements, you need to measure the compression in all cylinders and compare the obtained values with the optimal value. Why does compression decrease during engine operation:

- The working surfaces of the rings, pistons and cylinders wear out, and the gap between them increases. When the crankshaft is turned by the starter, the piston does not have time to “pump up” the pressure in the combustion chamber - part of the air escapes through the cracks into the crankcase.

- The valve plates gradually burn out, do not fit tightly into the seat and allow gases to pass through.

- A “stuck” valve or a completely burnt-out piston does not allow pressure to be created in the cylinder.

- Scratches and scuffs on the cylinders also lead to gas leaks.

Optimal cylinder pressure

To determine the moment of critical wear of the cylinder-piston group, you need to know what compression rate is considered satisfactory. Here there is a relationship with the compression ratio - the higher it is, the greater the pressure that occurs in the combustion chambers when the crankshaft rotates.

At the moment there are 3 types of motors with different parameters:

- old power units with a low compression ratio (up to 8.5);

- modern gasoline engines, where the fuel mixture is compressed 9–11 times;

- diesels with a compression ratio of 16–24.

The combustion chamber of a diesel engine is small in size, so ignition of diesel fuel occurs due to strong compression.

The optimal pressure values in the cylinders of various power units were obtained based on repeated practical measurements. When the engine is warmed up to operating temperature, the battery is charged and there are no problems with the starter, the compression in the engine should be as follows:

- On diesel - from 2.4 to 3 MPa. The first indicator is the minimum acceptable level at which the car is able to start.

- The optimal pressure in the cylinders of an injection power unit is 1.4–1.5 MPa. Compression may be reduced to a level of 1.1 MPa.

- In old carburetor engines of VAZ and other brands, the minimum threshold is 1 MPa or 10 Bar. A unit in excellent condition should show a result of 13 bar.

Note. If we analyze the measurement data, we can identify the following pattern: the optimal pressure is equal to the compression ratio multiplied by a factor of 1.4–1.5.

When to replace

According to the manufacturer's instructions, replacement should be carried out after traveling 10 thousand km when driving long distances and every 6 thousand km if trips were carried out mainly over short distances.

Also, the moment of replacement can be determined by the oil pressure sensor. Long service life dilutes the oil, so a cold engine shows high pressure, but after warming up the indicator drops significantly. Such differences signal the need for maintenance.