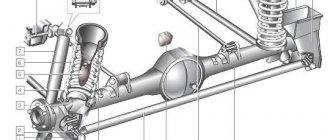

Front suspension

The weakest point of the front suspension is the shock absorber struts. The main task falls on them, and therefore the load is corresponding.

Disassembly and replacement

Many VAZ 2114 owners dream of installing air suspension. These are completely feasible fantasies, which, however, will require serious financial investments from you.

Therefore, if you have not yet saved up enough money for pneumatics, and the knocking in the front suspension of the VAZ 2114 haunts you, you will have to disassemble it, determine the causes of the malfunctions and put the entire structure back together. How to do it? Now we'll tell you.

- The car can be lifted using a lift, or simply placed on a viewing hole. It all depends on what resources you have. Be sure to apply the handbrake, remove the wheel caps, loosen the bolts and remove the hub nuts. The front must be effectively locked in order to remove the wheels.

- Now remove the ball joint pin. It is located in the swing arm on the A-pillar. After this, the front stabilizer strut is removed. It will have to be disconnected from the front suspension arm. Only now can you remove the stretch marks from the body. The next step will be to remove the ball joint. In case you forgot, it is located and attached to the steering knuckle.

- Now we proceed to remove the front suspension arm. To do the job as competently as possible, unscrew the bracket attached to the body. Now remove the lever along with the extension and bracket. Don't forget to remove the bolts securing the pads to the steering knuckle.

- Well, now in front of you is a fully assembled caliper. It is not recommended to completely remove it, since reassembling it can lead to unpleasant consequences and unnecessary financial costs. It is better to take a hook and hang it so that there is no load on the main hose. Next, you can press the splined shank out of the hub.

- Go to the engine compartment and from there remove the protective cam. For such an operation, you will need to unscrew the nuts on the telescopic strut, and then remove the strut from the suspension of the front of the car. It comes immediately with the hub and steering knuckles. The second strut of the front suspension is dismantled in the same way, and then the struts are removed from the bar.

- When removing the ball joint and steering knuckle bolts, be sure to use only socket wrenches. If you neglect this rule, you risk severely damaging the protective cover of the hinge. By doing this, you will incur unnecessary financial expenses on yourself.

- As you dismantle, inspect the condition of certain suspension elements and replace them if necessary.

- The assembly process is carried out almost entirely by analogy with disassembly. But there are a couple of nuances. The first is when installing the fastening bracket to the body, try not to damage the threads, so work carefully. Second, when installing the anti-roll bar, try not to cause longitudinal displacement of the cushion on the bar.

If your own experience is not enough, it is not worth adding to it, starting with similar work. It is better to immediately contact the specialists of a trusted service station. It will cost extra money, but the result of the repair will be completely worth it. Driving a faulty car is definitely not the solution to the problem.

How does the ball joint change?

To do this, you need to remove the front wheel mounting bolts and hang part of the car on a jack. Next, the nut securing the ball element is unscrewed. The support pin is pressed out of the lever. Similar to the previous case, this is done using a puller. If there is none, do not unscrew the nut completely. We press the lever with a pry bar and apply light blows with a hammer along the axis of the lever. Use a wooden block as a buffer. The next step is to unscrew the two bolts that secure the ball joint to the steering knuckle.

After this, the lever is moved to the side (with a pry bar), and the support is successfully pulled out. A working finger should not move with more than 0.8 millimeters of play in the support. Otherwise, it needs to be replaced, since there is a large output here. Before installing the dirt boot, it is recommended to coat the surface of the support with sealant. This way we will eliminate its premature delamination and deformation. It would also be a good idea to check the presence of lubricant in the ball. Some manufacturers save money and use very little lubricant. In this case, we purchase a specialized product and coat the entire perimeter of the element with it.

Replacing the front struts of a VAZ 2114

Chassis design

And now more about how to replace the front strut supports of a VAZ 2114 with your own hands. First, you should prepare the car for work - disconnect the battery, install stops under the rear wheels so that the car cannot be moved. And we begin:

- Raise the side to be repaired using a jack.

- We remove the wheel. Need I say that you need to loosen the bolts in advance?

- Place the brake pipe to the side so as not to damage it.

- Using keys “17” and “19”, unscrew the bolts securing the strut to the hub. These bolts and nuts can be thrown away immediately - reuse is unacceptable. Firstly, there is a plastic lock on the thread, and it is designed for a small number of tightenings. Secondly, metal fatigue affects and the bolt can become deformed when tightened.

- On a VAZ 2114, the front strut can be replaced without removing the spring. But you still have to unscrew the nut and remove the tie rod end.

- Using a key set to “13” you need to unscrew all three nuts that secure the support bearing housing to the car body.

After this, the entire rack assembly can be removed and a new one installed in its place. As you can see, replacing the front struts of a VAZ 2114 is not that difficult. But if you install an old spring, you will have to tinker with disassembling the old unit - this can be problematic, since long-term use takes its toll on it. Rust appears, the metal “sticks”, sometimes even penetrating lubricant cannot help.

The repair procedure is the same on both sides. Installation of a new rack is carried out in the reverse order

It is important to observe the tightening torque of threaded connections, since your safety depends on it. Use a torque wrench for convenience.

At this point, the replacement of the front struts of the VAZ 2114 is completed, you can continue to use the car.

How to replace the lever?

To do this, raise the front part of the car (alternately on each side with a jack). Next, unscrew the nut securing the ball joint and, using a puller, remove the ball joint pin from the lever. Next, unscrew the nut securing the extension.

The stabilizer link is disconnected from the lever. Next, unscrew the nut that secures the suspension arm to the body. If it is sour, use a “liquid key”.

At the next stage, you can safely remove the lever from the stretch outward. The new part is installed in the reverse order.

Selecting products by labeling

Design features and possible malfunctions of VAZ-2107 suspensions

So, the driver came to the store to buy new springs. How to make the right choice?

The decoding of the markings shown below can help with this:

2101 - perfectly fits standard sedans equipped with rear-wheel drive; 21012 - rigid springs, which are mainly used on special vehicles; 2102 - originally created for Russian station wagons

When installing this product, the vehicle's ground clearance increases, which is quite important if the vehicle is operated off-road; 2018 - usually installed on any vehicle with front-wheel drive, except for Oka and those cars that have a 16-valve power unit under the hood; 2110 - these products were created for expert Russian models from VAZ; 2111 - work on models such as VAZ 2111 and 2113. Only on rear-type suspensions; 2112 - analogue of 2111, only for front-type suspension; 2121 - most often installed only on all-wheel drive vehicles

First of all, this is a simple Niva.

The markings are easy to understand. But it is still necessary to understand how the manufacturer influences the choice of springs.

Symptoms of ball failure

First of all, the problem begins with a torn boot. Because of this, dirt, water and sand get inside. Thus, they wash out the lubricant from the ball mechanism.

As a result, the element begins to work “dry”, and corrosion processes begin. In practice, this results in loud knocks and squeaks from the suspension. Next, the wheels will begin to spontaneously change their trajectory.

There will also be uneven wear on the tire tread. As you turn the steering wheel, the knocking noise intensifies. If you notice the problem in time, you can eliminate emergency consequences.

Front suspension

Do-it-yourself spray booth, design features and stages of work

In fact, the front suspension design of the VAZ 2114 is much more complex than the rear one. Judge for yourself, because its design includes a total of 41 elements. The main one is the shock absorber strut. It is mounted on the steering knuckle using two bolts. The bolt passing through the holes of the rack bracket is equipped with an eccentric washer and a similar belt. When the steering gear is turned, the top bolt also turns. This causes the entire car to turn.

Front design

The weakest point of the front suspension is the shock absorber struts. The main task falls on them, and therefore the load is corresponding.

Disassembly and replacement

Many VAZ 2114 owners dream of installing air suspension. These are completely feasible fantasies, which, however, will require serious financial investments from you.

Clamp

Therefore, if you have not yet saved up enough money for pneumatics, and the knocking in the front suspension of the VAZ 2114 haunts you, you will have to disassemble it, determine the causes of the malfunctions and put the entire structure back together. How to do it? Now we'll tell you.

- The car can be lifted using a lift, or simply placed on a viewing hole. It all depends on what resources you have. Be sure to apply the handbrake, remove the wheel caps, loosen the bolts and remove the hub nuts. The front must be effectively locked in order to remove the wheels.

- Now remove the ball joint pin. It is located in the swing arm on the A-pillar. After this, the front stabilizer strut is removed. It will have to be disconnected from the front suspension arm. Only now can you remove the stretch marks from the body. The next step will be to remove the ball joint. In case you forgot, it is located and attached to the steering knuckle.

- Now we proceed to remove the front suspension arm. To do the job as competently as possible, unscrew the bracket attached to the body. Now remove the lever along with the extension and bracket. Don't forget to remove the bolts securing the pads to the steering knuckle.

- Well, now in front of you is a fully assembled caliper. It is not recommended to completely remove it, since reassembling it can lead to unpleasant consequences and unnecessary financial costs. It is better to take a hook and hang it so that there is no load on the main hose. Next, you can press the splined shank out of the hub.

- Go to the engine compartment and from there remove the protective cam. For such an operation, you will need to unscrew the nuts on the telescopic strut, and then remove the strut from the suspension of the front of the car. It comes immediately with the hub and steering knuckles. The second strut of the front suspension is dismantled in the same way, and then the struts are removed from the bar.

- When removing the ball joint and steering knuckle bolts, be sure to use only socket wrenches. If you neglect this rule, you risk severely damaging the protective cover of the hinge. By doing this, you will incur unnecessary financial expenses on yourself.

- As you dismantle, inspect the condition of certain suspension elements and replace them if necessary.

- The assembly process is carried out almost entirely by analogy with disassembly. But there are a couple of nuances. The first is when installing the fastening bracket to the body, try not to damage the threads, so work carefully. Second, when installing the anti-roll bar, try not to cause longitudinal displacement of the cushion on the bar.

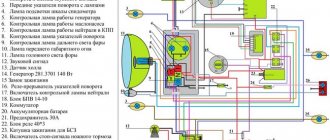

Working with the front and rear suspension of a VAZ 2114 requires increased concentration and knowledge of the structure of this unit. Therefore, before starting repairs, be sure to familiarize yourself with the suspension diagram and study the recommendations from the operation and repair manual. You can even watch several video tutorials that clearly explain the replacement and repair of front and rear suspension elements.

If your own experience is not enough, it is not worth adding to it, starting with similar work. It is better to immediately contact the specialists of a trusted service station. It will cost extra money, but the result of the repair will be completely worth it. Driving a faulty car is definitely not the solution to the problem.

The front suspension of the VAZ-2114 receives the full load of the body, as well as not only the weight of the engine itself, but also the load force of the transported cargo. Therefore, this element must be very durable. Not many motorists know how the front suspension works, its elements, as well as the nuances of its operation.

Chassis of VAZ 2114: description, repair

Fundamentally, the chassis designs of front-wheel drive VAZ cars of various models are similar to each other, however, there are differences. It will be useful for car enthusiasts to understand the question of what the VAZ 2114 suspension consists of, to know the causes and types of malfunctions, and to be able to eliminate them.

Front suspension device

Suspension type: independent, telescopic. Let's take a closer look at the main components and elements that make up the front suspension of the VAZ 2114.

- The basis is the main rotating support element - the front pillar. Assembled into a single unit with a cylindrical spring, a swivel bearing, and upper and lower support cups. The strut is attached to the steering knuckle of the hub with the lower bracket, secured to the body with three bolts at the top and rests against the glass with the upper cup. Has a steering knuckle for attaching a tie rod pin.

- Front hub assembly with ball joint, double row bearing, brake disc and caliper. The ball joint is fixedly screwed to the lower suspension arm, the support pin is inserted into the seat at the bottom of the hub and screwed with a nut.

- The lower suspension arm is attached to a brace, which is attached at both ends to the body side member using two brackets. On one side of the brace there is an attachment point for the anti-roll bar, in which one end is fixed. The second end of the stabilizer is fixed to the suspension extension of the second front wheel, thus connecting them together.

Front suspension diagram for VAZ 2114

The wheel is turned by a steering rod, which pulls the eye on the stand and turns the entire assembly, while at the top it turns on a support bearing, and at the bottom on a ball joint. The anti-roll bar ties the suspension on both sides together and makes it work in sync.

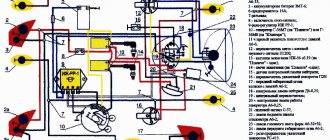

Rear element design

Suspension type: dependent, on a rigid transverse continuous beam. The structural elements of the rear suspension and the methods of their connection in the VAZ 2114 are as follows.

- The base is a cross beam. The structure is welded, in the shape of the letter “H”, only with a long cross member. The two front ends of the beam are secured to brackets bolted to the rear side members of the vehicle. The method of connection to the brackets is hinged, on rubber-metal bushings. The rear ends of the beam have mounting flanges for wheel hubs. The hubs are bolted to the flange; a protective casing, brake cylinder and pads are mounted on them. Inside the hub there is a double row radial bearing. The brake drum is mounted on top of the pads and secured to the hub with guide pins.

- The lower end of the strut with a cylindrical spring is attached to the rear ends of the beam on the other side of the hubs. The upper end of the shock absorber rests against a glass welded to the body through a rubber spacer.

Rear suspension diagram for VAZ 2114

The rear suspension diagram is shown in Fig. 2. The rear chassis of the VAZ 2114 car operates as follows: the transverse beam works like a swinging pendulum, the attachments to the side members do not allow it to move along the axis of the car. Racks with springs attached to the opposite end of the pendulum limit its up-and-down movement and serve as a shock-absorbing and partially supporting element for the wheels.

Brief description of faults

In most cases, chassis repairs can be done yourself. The main malfunctions, as a rule, are associated with the failure of the shock-absorbing front and rear struts, since they are the most loaded structural element. The racks absorb dynamic loads from the car body, from the wheels when overcoming uneven road surfaces and lateral loads from the influence of steering rods, which increases at low speeds.

Two tools are required to remove and install the stands. The remaining tools are in every car enthusiast's garage:

- spring ties;

- a puller for pushing the steering rod pin out of the lever; it can also be used to press out the ball joint if necessary.

Smaller suspension malfunctions occur due to wear of the rubber seals and rubber-metal bushings (silent blocks). They are much easier to replace than a stand, although sometimes a device is also needed to press out silent blocks.

Stabilizer

This element of the front suspension of the VAZ-2114 is designed to reduce the roll of the car when cornering. The part does not have a complex structure and consists of a flexible beam, as well as a pair of silicone silent blocks. The element has a small stroke, which ensures vehicle stability on the road.

Attached to the front side members with the central part. The side parts are connected to the suspension arm on the “knuckles”. The stabilizer has a long service life - more than 100 thousand kilometers.

Usually it is the silent blocks that fail. But to replace them you need to remove the stabilizer completely. Below we will tell you how to do this.

Do-it-yourself rear suspension disassembly

Knowing the structure of the VAZ-2114 suspension, you can disassemble it competently and quickly, and with your own hands. The first step is to find an inspection hole or lift. In the trunk, the lining is disconnected, and the nuts holding the struts are loosened. Then unscrew the wheel bolts. Next, dismantle the brake system cables. It's best to do this as a group.

After this, remove the drum, pipes and hoses of the brake system. Now you can move on to the racks. In order to disconnect them, remove the rubber cushions, nuts and washers on the body. Then additional stops are installed for the front wheels. The back should be raised. After this, you can remove the springs and struts. When the brackets securing the beam to the body are removed, then the entire beam can be removed. On the VAZ-2114 car, the suspension is quite simple. You can easily replace worn parts and reassemble in reverse order.

Rack

This is one of the main elements of the front suspension of the VAZ-2114. The strut combines a spring and a hydraulic shock absorber. Thanks to this part, the suspension absorbs and absorbs bumps in the road. To allow the element to rotate (at the same angle as the front wheels), a support bearing is provided at the top. The stand itself is mounted on the body cups in the engine compartment. Unlike the rear, 80 percent of all loads are placed on it. After all, all the important components and assemblies are concentrated in front - the engine, gearbox and attachments.

Detailed suspension repair diagram

So, let's look at a brief diagram of how to disassemble the suspension of a VAZ-2114 car:

- The car must be placed on a lift. Of course, you can use the inspection hole, but this is quite inconvenient and not entirely safe, since dismantling will be carried out on both sides at the same time.

- The first step is to dismantle the caps (if any), disks and loosen the wheel bearing fastenings.

- Next, disconnect the ball joint and also remove the steering rod.

- Unscrew the fastening and remove the stabilizer.

- The next step is to dismantle the lever.

- We remove the caliper.

- We remove the outer CV joint from the hub.

- Now you can remove the brake drum from the steering knuckle mountings.

- We dismantle the steering knuckle.

- Remove the shock absorber strut assembly.

- We disassemble the removed parts.

- Assembly is carried out in reverse order.

Thus, the entire suspension assembly can be replaced. If we take time, then complete disassembly of the VAZ-2114 suspension will take approximately 8-12 hours, if no difficulties arise. Some “kulibins” make it easier to speed up the process, and if the suspension to be removed will no longer be installed. It is worth noting that this method is dangerous and contrary to safety regulations, especially if the motorist has never performed this process. Let's briefly look at how the accelerated process occurs:

- Unscrew the stabilizer.

- We dismantle the upper mount of the shock absorber struts.

- Unscrew the steering rod and brake hoses.

- Carefully unscrew the lever mount.

- The suspension feeds downwards in the assembly.

Tuning

Tuning suspension for VAZ-2114

Many motorists, in order to improve the stability and maneuverability of the car, install a sports version of the suspension, both rear and front.

It fits perfectly into the seats and is attached to the body without requiring any modifications. The sports suspension has greater stability and maneuverability, and can also withstand a load on the suspension that is 2 times greater than the standard one. The cost of this option is about 30-40 thousand rubles.

Tuning suspension installed on a car

Levers

At the front, the VAZ-2114 uses independent wishbone suspension. These elements ensure the transmission and absorption of shocks that occur when the car hits an uneven surface. The front suspension arms of the VAZ-2114 are made of high-strength steel XK-60, so they can easily withstand high loads.

The element is attached with one part to the ball joint, and the other to the body on a bracket. Levers do not have a specific resource. Some don't change them for decades.

Therefore, you need to navigate based on the signs. The main symptom is delamination of rubber on a metal bushing.

Also, the lever must be replaced in case of a serious collision with a hole (in which the disk was bent) and after an accident. Otherwise, due to deformations, there will be problems with wheel alignment, as well as constant tire waste. How is the front suspension repaired on a VAZ-2114?

Usually the entire lever changes, as does the strut. The cost of a new element is from 700 to 1 thousand rubles. The lever is interchangeable with the first generation Lada (that is, the “nine”).

Lada 2115 *****KRASAVITSA***** › Logbook › Front suspension

Good day everyone! Now we got around to the front suspension, before that we bought all the spare parts for the front suspension

tuning of the front suspension of the VAZ 2115, modification of the chassis of the VAZ 2113-2115Replacement of shock absorbers and springs of the front suspension of the VAZ 2114, VAZ 2115, VAZ 2113, Lada Samara 2

Springs (and shock absorbers on Lada 2115) should only be replaced in pairs (on the front and/or rear axle).

We carry out the work on an inspection ditch or overpass, but it is also possible on a flat horizontal platform.

To replace the springs and shock absorbers of the front suspension, remove and disassemble the guide spring strut.

There are two options for removing the guide spring strut of the VAZ 2113. In the first option, it can be dismantled as an assembly with the steering knuckle and brake disc without loosening the nuts of the lower and upper (adjusting) bolts securing the strut to the steering knuckle. This option is convenient if, after completing the work, you do not plan to adjust the angles of the front wheels.

But since after replacing shock absorbers, steering tips and springs it is necessary to adjust the wheel alignment angles, we will consider the second option.

We hang and remove the wheel from the side of the rack being removed. Turn the steering wheel in the opposite direction until it stops. Remove the cotter pin...

Use a puller to press the pin out of the lever. If there is no puller, unscrew the nut not completely, insert a mounting blade into the spacer between the steering rod and the strut lever, and hit the end of the strut lever with a hammer.

When subsequently installing the spring strut guide, aligning the marks does not guarantee accurate setting of the specified wheel camber angle, but allows for a slight deviation from the original value.

Using a 19mm socket, unscrew the nut of the upper bolt, holding the bolt from turning with a wrench of the same size.

We remove the rod with the working cylinder from the strut body and drain the shock absorber fluid into a container.

Install the spring with ties on the lower support cup of the strut.

We install the upper support cup of the spring, the upper support, attach and tighten the rod nut with a special wrench. Remove the spring clamps.

We recommend adjusting the angles of the steering wheels at a service station. THIS is the rubbish that I changed =)

ATTENTION ! A twin-pipe shock absorber that is not pumped before installation is a common cause of failure of the shock absorber piston system. This is a violation of the installation instructions and a possible reason for a non-warranty case! If air remains in the inner liner of the shock absorber, the shock absorber may not perform its function correctly.

Failure to operate leads to noise, knocking when the shock absorber operates and its possible failure.

Based on long-term work experience, engineers of the Samara-Lada OJSC company have prepared optimal recommendations for shock absorber pumping technology:

Before installing a twin-tube shock absorber on a car, it must be brought into working condition. During transportation and storage, in twin-pipe shock absorbers, the working fluid can flow from the inner to the outer cylinder, and boost gas enters the inner cylinder. In this case, the shock absorber will make knocking noises when operating in the car’s suspension, and its throttle valves will be destroyed. To avoid damage to the shock absorber, it MUST be brought into working condition (pumped) before installation. For this:

1) Turn the shock absorber over with the rod down and compress it smoothly, without jerking;

2). Fix the shock absorber rod in this position for 2-3 seconds;

3). While holding the rod, turn the shock absorber over with the rod up, fix the shock absorber in this position for 3-6 seconds;

4) Keep the shock absorber in a vertical position for the specified time and smoothly extend the rod to the end of the stroke;

5). Turn the shock absorber over with the rod down and pause for 2-3 seconds. and repeat operations 1, 2, 3, D 5-8 times;

6) Having finished pumping the shock absorber, following the sequence, stop at step 4;

7) Holding the shock absorber vertically, with the rod up, perform a control operation (with sharp but short movements of the rod, make sure that the piston moves smoothly, without failures). A well-pumped shock absorber means smooth piston movement without failure.

After pumping, the shock absorber should be in the working position, with the ROD VERTICALLY UP, until it is completely installed on the car. I am completely satisfied with the suspension! =) Thank you all for reading the entire post to the end! Thank you all for your attention! Good luck to everyone on the roads!

conclusions

Selecting and installing a spacer for VAZ-2114 shock absorbers to increase ground clearance is quite simple. Even a novice motorist can cope with this task.

It turns out that my husband installed spacers for me secretly :) I thought there were factory ones at the back. Now I'm convinced that this is a revision. It’s clear why my butt is raised so much...

This seems like a joke. If someone is serious about using the 2114 for cargo purposes, it would be better to sell it right away. In a year or two he will simply ruin the car.

VAZ 2114 is a popular car in our country that requires proper maintenance. Its frequency depends on driving style, year of manufacture of the car, road conditions and other factors. When the rear of the car begins to sag, you need to replace the VAZ suspension springs. A large selection of such parts is presented on this website. All products here are of high quality, they are sold at an affordable price.

Rear and its device

The rear system is much simpler than the front. A dependent suspension is installed here. This is a rigid continuous beam. A continuous beam is used as a base. This is a metal part made by welding. Its shape resembles the letter “H”, but here the transverse part is longer. The front ends of this metal beam are attached to two brackets, which are screwed to the side members at the rear of the car. The method of mounting the brackets holding the beam is hinged on silent blocks.