Self-replacement of VAZ 2106 front suspension springs

The reason for the need to replace the front suspension springs may be a violation of the integrity of the springs. This may be the result of mechanical damage or the occurrence of cracks, as well as in case of serious subsidence.

Worth reading:

- Self-replacement of the VAZ 2110 CV joint

- How to replace the steering rack of a VAZ 2115 yourself

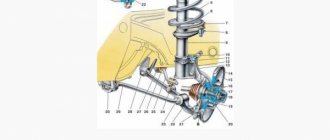

- Using a rope or wire, pull the upper arm higher, thereby providing access to the front suspension spring.

Self-replacement of VAZ 2106 front suspension springs

- Use a pry bar to pry the lower end of the spring and remove it from the lower arm support cup.

Self-replacement of VAZ 2106 front suspension springs

"Seven" and "Ten"

For appropriate repairs on the “classic” we will take the following tools:

- set of wrenches;

- wheel chocks.

Find out how much it costs to change brake pads and about replacing the rear strut on a Honda Stepwagon.

So, let's figure out how to replace the rear springs of a VAZ 2107. This is what needs to be done, and from the inspection hole.

- Unscrew and then remove the pressure regulator rod of the brake circuit system from the mount. It is also necessary to remove the brake hose tee.

- We unscrew the bolt of the lower shock absorber mounting, take it out, and remove the strut from the mounting.

- Next, having installed anti-roll pads under the front wheels, we lift the rear of the car with a jack so that the axle lowers.

- We take out the released defective part, as well as the lower and upper linings. We directly replace the spring from the rear suspension of the VAZ 2107, attaching pads to the new spare part.

- We do the assembly in reverse order.

From the instructions given it is easy to understand that the procedure is quite simple. At the same time, replacing the rear springs of a VAZ 2106 car is done in exactly the same way. If we talk about a VAZ equipped with front-wheel drive, then the technological process of such repairs is just as simple. To make sure of this, below are instructions for replacing parts on a VAZ 2110.

For work, we will take the same tools as in the previous case.

- Having dismantled the back of the rear seat and also removed the upholstery, unscrew the top nut of the pillar.

- We jack up the required part of the car (using anti-rollback stops and the gear is engaged), unscrew the lower mount of the rack, and then remove the bolt.

- We release the lower end of the strut from the suspension bracket, and finally, we remove the strut along with our defective part.

- We take out the spring gasket in the wheel arch, as well as the washer and cushion inside the passenger compartment.

- We remove our broken part from the shock absorber.

- We attach the upper insulating gasket to the new spare part with a rope.

- We install the spare part on the rack, attaching the lower gasket.

- We mount the strut with the spring in the reverse order, compressing the coils with a jack, which we install between the lower coil and the beam.

Changing the springs of the Priora is carried out according to an identical scenario. As you can see, the process does not cause any particular difficulties, but the labor intensity is slightly higher than that of the “classics”.

Popular budget foreign cars

Additionally, we will try to figure out how much more complicated this process can be in relation to other running cars of a non-Russian brand. To have something to compare with.

First, let's describe how replacement is carried out for a car such as a Chevrolet Lanos. To carry out the work, we will need the following attributes:

- set of wrenches;

- wheel chocks.

In this case, the rack does not work inside the coils of the unit being replaced. Considering this fact, we begin manipulations.

- We unscrew, then remove the bolt of the lower strut mounting, and after releasing the lower part of the shock absorber, remove it.

- Next, we lift the rear of the car so that the broken part is unloaded and comes out of the sockets. We take it out, as well as the top gasket. Then we remove the lower gasket from the socket on the suspension beam.

- We install a new spare part along with the lower and upper gaskets.

- We carry out further assembly from the reverse.

Here, in fact, everything. It’s somewhat reminiscent of the Zhiguli “classics”, isn’t it? One thing is clear: the process is quite simple.

Let's see if there are any differences when performing this procedure in an equally popular budget car. Moving on to specifics, let's determine how the springs of the Daewoo Nexia are changed.

To carry out the process we will need:

- set of wrenches;

- wheel chocks.

That is, everything is the same. Begin.

- We unscrew the nut of the lower shock absorber mounting and remove the lower part of the strut from the bracket.

- To release the broken part, we lift the rear of the car, like on a VAZ “classic”. However, there is another method: we jack up the desired side until the tire is sufficiently lifted off the ground, then with another jack we press down from the body onto the wheel, the turns are released.

- We install the new spare part in the reverse order, not forgetting the lower and upper linings.

Well, apparently, the process of replacing the rear spring on the Nexia is reminiscent of the previous procedure.

In all cases of this repair, we must not forget about important details. First, stubborn threaded connections are pre-treated with a penetrating lubricant. Secondly, for your own safety, it is better to compress the coils with universal ties before removing the part. However, they will require additional costs; you can do without them only with extreme caution!

The price of torment

By the way, about costs. Not everyone will decide to even undertake such a seemingly minor repair. For those who find it easier to turn to qualified craftsmen, we will provide a table of the average cost of work in relation to large Russian cities. Here she is.

| City | Cost for 1 piece. |

| Moscow | from 500 rub. |

| St. Petersburg | from 500 rub. |

| Ekaterinburg | from 400 rub. |

In the second column, the price starts from the figure for VAZ cars; this type of repair on good foreign cars will cost twice as much.

So, the main difficulties associated with repairing rear springs were indicated. The information provided is intended to greatly help motorists who have problems of this nature.

You can change the rear springs yourself even in the absence of an inspection hole (only a jack is sufficient). You can find out the dimensions of the socket heads and spanners required to unscrew the upper or lower shock absorber mountings in the repair and operating manual for your car model. In some cases, having two jacks will make the process much easier.

Replacing rear suspension springs will be much easier if you use special ties. For example, on a VAZ 2101, 2102, 2106, 2107, you can remove the old spring and install a new one using conventional installation, but the design of the rear suspension of many other cars will not allow such a trick. We will show you how to change rear springs without zip ties, but we recommend using this method only if absolutely necessary. The price of screeds is not so high as to sacrifice your own safety.

DIY Replacement Guide

We will demonstrate the replacement procedure using the example of a VAZ 2101-2107. After reading the instructions, you can easily carry out this procedure on another car, since the basic provisions apply to all types of rear suspension.

- Loosen the wheel bolts.

- Raise and secure the rear part of the car on the supports. Be sure to install the wheel chocks diagonally (if the rear right side is raised, the chocks are installed under the front left wheel).

- Unscrew the lower shock absorber mounting. If for any reason problems arise with the bottom bracket, you can unscrew the top mount. The shock absorber will limit the travel of the beam (on cars with rear-wheel drive and all-wheel drive - the rear axle), so we need to disconnect one of its fasteners from the car body.

- Using a pry bar, pry the lower end of the spring by the coil to release it from the mounting groove. There is no need for such manipulations if the spring is slightly tightened with ties.

When tightening, be sure to ensure that the coils are tightly secured by the claws of the ties. If the spring jumps out, it can cause serious injury!

How to properly install new springs

On many cars, there are special grooves in the upper and lower cups for fixing the outer turns. During installation, it is important not only to clean the seats from dirt, but also to ensure that the outer turns are positioned correctly.

Just on the VAZ 2101-2107, the upper rubber spacer, like the metal ring, have a special groove. In order not to guess the location of the spacer, before installation, secure it with adhesive tape to the upper turn, and then install it in its assembled place. During the operation of the car, the rubber damper often sticks to the body, so to remove it you will need a large impact screwdriver or a crowbar. We recommend watching the video, which clearly shows the process of self-replacement.

Springs must be changed in pairs - on both sides of the axle at once.

Beam with silent blocks

This type of beam is installed on Daewoo Lanos, Opel Astra F, Vectra A and many other foreign cars. In order not to tear the silent blocks, it is advisable to unscrew their fastenings. If defects in rubber products are detected, we recommend replacing the silent blocks of the rear beam at the same time. Please note that replacement must be done one at a time, since the beam is attached to the body only with silent block fastenings and shock absorbers.

As practice shows, the rear springs can be changed without unscrewing the silent blocks. To increase the beam travel, it is enough to jack up the lower part of the beam on the opposite side. To do this, lift the body with a jack and secure it on the supports. Remove the wheels, then place the jack as close to the end of the beam as possible. Raising in this place will provoke lowering of the beam on the replacement side.

How to change springs without ties

If on a VAZ classic you can do without tightening, then on many other cars, removing old springs and installing new springs without tightening is simply impossible. In the absence of a puller, you can get out of the situation as follows:

- jack up the beam on the replacement side;

- Twist the spring with thick wire from two opposite sides. Remember that the effort is serious and you need to approach the matter responsibly;

- lower the beam and pull out the spring;

- compress the new spring using a stop and a lever in the form of a beam of sufficient length or a metal channel. Secure it in a compressed state with strong wire;

- install a new spring element;

- lift the beam until the spring contacts the pads;

- loosen the wire.

You should resort to this replacement method only if it is impossible to use safe repair methods!

Do I need to change springs when replacing struts and shock absorbers?

If they have not sagged and all the coils are in place, then it is not necessary to change the springs when replacing shock absorber struts.

So, we continue to rebuild the suspension. Today we’ll look at how to change the front springs, since the factory ones have already reached 220 thousand and are pretty tired, although the ground clearance is normal. To do this, I purchased similar springs from VAZ JSC with new spacers and a front spring remover.

Before replacing, to compare the effect, we will measure the distance from the floor to the wheel arch of the front wings before and after replacement with new springs, silent blocks and shock absorbers.

As we can see, the car has a skew of 1 cm on the right side, which is not critical. Out of curiosity, let's measure the thickness of the new spring rod - if you subtract the painting, it is approximately 13 mm.

And the free length is 37.2 cm.

For work we will need: - Keys and sockets for 13, 22 - Central spring puller (brace) and ball joint remover (preferably) - Pry bar or large screwdriver, hammer, metal brush - WD-shaker or other “liquid wrench”

We hang the car, remove the wheel, remove the shock absorber, loosen the nuts of the silent blocks of the levers, remove the stabilizer bracket and cushion - we will also replace it with a new one.

Now loosen the nut securing the lower ball joint pin to the steering knuckle and tear off the pin. We have already discussed how to do this earlier. We place the puller plates under the maximum lower and upper coil of the spring and tighten until the lower end moves away from the cup and the tension between the levers is relieved.

It is worth keeping in mind that the puller is weak, the bearing under the lower plate fell apart when replacing the second spring, although it works well without it if you lubricate the washers. Production, it seems, is Kostroma. Now we fix the upper lever with the hub assembly, remove the ball joint pin from the steering knuckle and lower the lever down, carefully remove the spring with the spacer.

Inspect the spring for damage. As we can see, there are traces of corrosion and interturn wear.

Let's measure the remaining length in the free state - compared to the new spring, there has been a shrinkage of about 1 cm.

Now, using a puller, we tighten the new spring, placing the cups approximately under the second turn from above and below.

We put a new rubber spacer on the spring and fix it with tape or tape so that the end of the rod rests against the recess on the spacer. We carefully place the spring between the levers, orient the lower end of the rod so that it rests against the recess on the metal cup of the lever.

Using a jack, insert the ball joint pin into the steering knuckle and tighten it. Now we remove the puller and install the new shock absorber back. Also, we put on a new stabilizer pad and fix it.

We tighten the silent blocks of the levers under load and put on the wheel. Now let's re-measure the distance from the floor to the wing.

As we can see, the front suspension has risen by 3.5 cm, which shows us how much the old springs were already weakened - taking into account the length in the unloaded state, they lost about 2.5 cm in elasticity. Yes, and visually the lower arm has slightly changed its angle.

It remains to check the wheel alignment, since the angles of the levers have changed.

Hello, in this article you will learn how to replace the front springs on a VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107. Front springs are usually replaced when they sag significantly. Front springs usually sag for a long time, but if you often drive a loaded car, this will happen much sooner. As the springs sag on bumps, the suspension begins to “break through” more often, which makes the ride not entirely comfortable, and in some places not safe. The cost of new springs on the automotive market ranges around 800 rubles. To replace the front springs you will need: spring ties, heads or wrenches for 13, 22 and two jacks (one of them is better hydraulic). First of all, jack up the car, remove the wheel and shock absorber. Next, use a 22mm wrench to loosen the fastenings of the front suspension arm.

Now we slightly raise the lever with a jack and unscrew the two nuts securing the stabilizer bar bracket with a 13mm wrench

Then unscrew the nut on the ball joint pin

After this, you need to carefully lower the lever with a jack (be careful, the spring will force the lever down). Also, most likely, the anti-roll bar will catch on the studs, disengage it with a pry bar

Lower the lever all the way and remove the spring

Before installing the front spring in place, you need to tape a spacer to it with electrical tape and tighten the spring with zip ties

After this, carefully lift the lever with a jack, the main thing is that the lower coil of the spring fits into the groove on the lever

Now we tighten the nut on the ball joint pin, loosen and remove the ties through the lower technological hole in the lever and assemble everything in the reverse order.

Also check out

- How to replace the support bearing of a VAZ 2110 without wheel alignment

- Installation of new front struts on Lada Priora cars

- How to replace a VAZ 2110 timing belt and tension roller at home

- Remove the suspension spring, remove the spring gasket from the upper support cup. After this, you can replace the front suspension spring.

Self-replacement of VAZ 2106 front suspension springs

To do this, do the following:

- Use electrical tape to secure the gasket to the spring and install the part in place.

Self-replacement of VAZ 2106 front suspension springs

- Place the blade in the hole for the shock absorber, supporting the spring with it, and fix the lower coil. There is a screw surface on the lower arm that indicates the correct position of the spring. Installation should achieve this position

Self-replacement of VAZ 2106 front suspension springs

Self-replacement of VAZ 2106 front suspension springs

- Having installed the lower coil in the correct position, jack up the lever and load the spring. Using a mounting spudger, seat the spring onto the screw surface.

Self-replacement of VAZ 2106 front suspension springs

- Increase the load on the spring, install the stabilizer bar between the two studs that secure the bracket.

Self-replacement of VAZ 2106 front suspension springs

Self-replacement of VAZ 2106 front suspension springs

20

- Reassemble everything in reverse order.

After this, the replacement of the VAZ 2106 suspension springs can be considered complete.

You can check it out:

- Installation of new front struts on Lada Priora cars

Shock absorbers for VAZ 2101-2107

Shock absorbers for the VAZ 2101-2107 family (classic VAZ models), like all shock absorbers produced by the SS20 company for other cars, have several versions: “Standard”, “Comfort-Optima”, “Highway” and “Sport”. The presence of different settings options allows you to choose shock absorbers that suit your driving style.

Share with your friends

Applicability

- VAZ 2101

- VAZ 2102

- VAZ 2103

- VAZ 2104

- VAZ 2105

- VAZ 2106

- VAZ 2107

Advantages of SS20 shock absorbers for VAZ 2101-2107 (“classic”)

- the ability to select the characteristics “Standard”, “Comfort”, “Highway” or “Sport”;

- Stable performance under harsh operating conditions (due to larger fluid volumes and improved cooling) without compromising damping characteristics;

- increased resource;

- extended operating temperature range from -50˚С to +100˚С;

- 1 year unlimited mileage warranty;

- stability of characteristics and quiet operation of shock absorbers throughout their entire service life.

Guarantee

- Description

- Buy

Shock absorbers VAZ 2101-2107 (these VAZ models have a more common name - “ classic ”), like all shock absorbers produced by the SS20 company for other cars, have several versions: “Comfort”, “Highway” and “Sport”. The presence of different settings options allows you to choose shock absorbers that suit your driving style.

Front shock absorbers SS20 for VAZ 2101-2107

Rear shock absorbers SS20 for VAZ 2101-2107

The family of VAZ cars with a classic layout has earned a popular reputation as simple and fairly reliable inexpensive cars to operate. At the same time, the level of driving comfort and smooth ride also contributed to the love of our compatriots for the VAZ classics. But over the years that the family remained on the assembly line, both the speed of movement and the requirements for car handling increased. At the moment, we can say with confidence that in modern conditions, when driving both in the city and on the highways, cars of the VAZ 2101-2107 family are forced to reduce speed and do not provide an acceptable level of controllability and stability at speeds of even 90 km/h. Therefore, when developing and testing shock absorbers 2101-2107, the main attention was paid to improving the car’s handling while maintaining maximum comfort, and improving the car’s behavior on country roads.

The shock absorber housing for the “classic” SS20 production was enlarged compared to standard shock absorbers, which made it possible not only to increase the oil volume, but also to use larger diameter pistons, which significantly reduced the specific loads on the elements of the valve system and increased their service life. Pistons with a “skirt” are used, providing excellent sealing and stability of shock absorber characteristics with an extended service life. The lower and upper silent blocks of the front shock absorber have an original design that is superior to the factory shock absorber for the VAZ 2101-2107 family in terms of reliability and damping capacity.

Thus, the shock absorber for the “classics” (VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107) of the SS20 brand is a reliable design that will allow you to forget about a number of problems that arise when operating a car with standard shock absorbers. In addition, with SS20 products you will protect yourself from counterfeits: all SS20 products have branded packaging, stickers, and dot markings.

Instructions for working with rear springs

Before you begin the replacement, you should slip 2 boots under the wheel located at an angle from the one being removed. Replacing the rear springs begins with unscrewing and removing the wheel, after which you need to place a block at the end of the rear axle beam and lower the jack. How to tighten the steering rack on a VAZ 2110, 2112. The entire mass of the car will fall on the block and compress the spring. The block should be positioned in such a way that it does not interfere with unscrewing the lower shock absorber mount. Stands for viburnum: characteristics. Features of rack repair. A detailed description of how to change the front struts, supports, springs and bearings on a viburnum. Further on the annotation.

- Loosen the shock absorber mounting nut, unscrew it and remove the long bolt. The shock absorber must be unscrewed so that the spring can be removed later.

- Place 2 ties on the reverse sides of the coils of the spring and secure firmly by pressing the studs with a wrench.

- Raise the car body with a jack until you can remove the spring together with the ties.

- Usually, the rubber spacer sticks to the metal of the body and remains in the glass, only the steel ring falls out. Therefore, it is necessary to pry up the rubber using a long flat screwdriver and remove it from the socket.

- Loosen the grips of the ties, alternately unscrewing the studs with a wrench. Rearrange the ties on the new spring and tighten it to the approximate size of the old one.

- Place a new rubber spacer with a steel washer on the upper coil of the spring. How to replace the rear springs of a VAZ-2101-07, tips in. Its configuration is such that it should coincide with the shape of the upper turn.

About suspension springs for VAZ cars

Further production of the spring is divided into the following stages:

1. Heating the rod and winding the spring in a hot state; 2. Hardening in oil and low tempering; 3. Shot blasting, used to remove oxidation products and harden the surface layer; 4. Cold draft of the springs (the springs are pressed three times until the coils touch, their length decreases by approximately 18 mm, and at the same time the springs become “unwilling”); 5. Protective Coating - A protective epoxy coating is applied to rear suspension springs operating in more severe conditions. The front springs can be coated with a special black enamel based on chlorinated rubber. It is worth noting that the technology for applying epoxy coating is quite complex and was mastered only at the Volzhsky Automobile Plant. Other manufacturers, as a rule, use enamel coating of springs; 6. Static load control is the last operation in the manufacture of springs. At this stage, which absolutely all products go through, springs that do not fall within the tolerance are rejected, and the rest, depending on the obtained control load value, are divided into two classes. Springs with a positive load tolerance range belong to class A, and those with a minus tolerance – to class B. In this case, the springs are marked with paint (a stripe is applied with a spray on the outside of the coils) corresponding to the class.

READ Installing rear seat belts on a VAZ 2107

Table 1 shows the markings of produced springs

How to replace the rear springs of a VAZ-2101-07, tips in the process.

Spring marking colors for VAZ, GAZ, IZH, ZAZ, AZLK

If you carefully study the table, you will see that there are markings in other colors. Let's take a closer look at it. These are springs designed primarily for installation on the rear suspension of station wagons. Previously - VAZ-2102, now - VAZ-2104 and VAZ-2111. They differ in slightly longer length due to the specifics of these cars. Can these springs be installed on sedans or hatchbacks? To answer this question, you need to know the purpose of installing these springs. If this is due to the desire to increase ground clearance due to body sagging associated with aging, then this installation makes sense. This will in no way affect the driving performance of the car. However, if such a rearrangement serves the purpose of increasing the vehicle load beyond the permissible norm, then this operation will entail premature wear and destruction of the body. And here the car enthusiast must decide for himself what is more important for him: keeping the car in technically sound condition for many years or getting the most out of it in a short time, and then scrapping it with a light heart.

The color of the spring is not a constant value. Different manufacturers may change this color. The thickness of the rod is also a question; for example, Phobos makes springs even with variable rod thickness. He (Phobos) makes springs with variable pitch, therefore, cannot withstand the specified number of turns. The height can also vary, because Some manufacturers, to simplify the technology, make the rear springs 2101 and 2102/04 the same height, but of different stiffness. Other manufacturers reduce the height to increase the car's stability in corners. Therefore, to identify springs, it is most acceptable to use the outer diameter of the spring, because This size is attached to the car, and spring manufacturers cannot change it arbitrarily. Springs of the same diameter can be distinguished by the color of the marking, because This is also an established standard with some tolerance for color perception (for example, red = brown).

Installing springs that are not provided for by the design and loading the car beyond measure will not prolong its life. The same can be said about spacers, which are often installed between the spring and the body. If the spring sag, then no spacer will save it, since in such a spring the interturn distance is reduced, and this is dangerous because the spring stroke before the turns close is reduced. If such a spacer is used together with a normal spring, then this will increase the ground clearance, but at the same time the rebound stroke will decrease and the compression stroke of the shock absorber will increase, which in general is also not very pleasant. Finally, it is completely stupid to stick rubber inserts between the coils of a sagging spring. The spring simply ceases to perform its functions and at one point may simply burst, if before that you have not yet managed to fly into a ditch due to the disgusting handling of the car.

Now let’s look in more detail at the non-standard springs that AvtoVAZ used on its cars over the years. Springs - 21012.

They are made from a rod of a larger diameter than conventional springs, and are installed only on the right side of the front suspension of cars with a classic layout with right-hand drive to level the car due to significant redistribution of weight.

In addition, the same springs are installed on individual vehicles with left-hand drive (on both sides). Springs - 2108

in export version. They are marked with white and blue colors for the front ones and brown and blue for the rear ones. Our advice: stay away from these springs. After all, their only difference is that a car with these springs has a reduced ground clearance and they are intended for driving on European autobahns, and not on native potholes.

If they offer you springs - 21099

(and they have been showing up in advertising lately), then know that they just want to “heat you up.”

There are no “99” springs in nature. Springs - 2110. Springs

- 2108 are installed on the front suspension of the VAZ-2110 car as standard. “Tens: with a 16-valve engine are equipped with reinforced springs - 2112. And at the rear of this family springs are most often installed - 2110 euros (except VAZ-2111 ).

Next, let's talk about the rules for installing springs that exist at the Volzhsky Automobile Plant. Firstly, it is allowed to install only one class of springs on the suspension of one car. In exceptional cases, if class A springs are installed on the front suspension and there are no corresponding springs for the rear suspension, it is allowed to install springs belonging to class B on the rear suspension. For a car equipped with class B springs at the front, installing class A springs on rear suspension is unacceptable. It should be noted that in any case, springs of the same class must be installed on the right and left sides of the same vehicle axle.

In general, despite the apparent simplicity of the part we are describing, it is absolutely impossible to determine its suitability in garage conditions (and even in service station conditions). To do this, you need rather bulky special equipment that allows you to load the spring and determine the degree of compression depending on the applied load. Attempts by anyone to restore old springs also seem like a thankless task. Relevant studies were carried out at AvtoVAZ, and based on the results obtained, it was concluded that the game is not worth the candle, since the service life of the restored spring is very small.

Sources:

https://sgp55.Ru/vaz/kak-pomenyat-pruzhiny-na-vaz-2106.Html https://motoshkolads.Ru/remont/kak-pomenyat-pruzhiny-na-vaz-2106.Html https:// detali-avto.Com.Ua/info/pro-pruzhiny-podveski-avtomobilej-vaz/

Removing and installing the rear spring. Rear shock absorbers for VAZ 2106 - what you need to know. VAZ Classic.

Removing and installing the rear

double spring. A detailed article on how to change the timing belt on an 8-valve Lada Kalina engine, advice from grant providers, exact algorithm and recommendations. How to install electric window lifts on a VAZ 2108 - VAZ21099 with your own hands. Conventional mechanical windows are a rarity on modern cars, but there are plenty left on the streets. Subscribe to my video channel: .

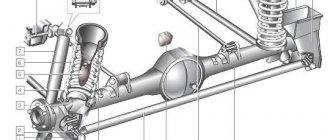

1 — lower longitudinal rod; 2 — rubber bushing; 3 — bracket for fastening the lower longitudinal rod to the body; 4 — spacer sleeve; 5 — upper longitudinal rod; 6 - additional travel buffer

compression;

7 - spring

;

8 — upper spring cup; 9 — progress buffer

; 10 — upper insulating gasket of the spring; 11 — shock absorber; 12 — lower insulating gasket of the spring; 13 - transverse rod.