UAZ Patriot - replacing viscous coupling with electric fans

The cooling system of the UAZ Patriot engine contains an element called a “viscous coupling” or, as it is sometimes called, a “fluid coupling” - on which the fan is located.

It is necessary to protect against overheating and is activated only when the engine temperature begins to exceed operating limits. The viscous coupling on the UAZ Patriot is designed in such a way that it is connected to the engine crankshaft not directly, but through special disks, between which there is a working fluid. When starting a cold engine, the viscous coupling spins at a very low speed, much less than the number of engine revolutions.

Then, as the engine warms up, the metal plate in front of the viscous coupling heats up from the radiator and bends outward, which releases a special ball that closes the hole in the inner disk. It turns out that the working fluid has nowhere else to go and remains between the disks.

The working fluid used is a special one, so-called “dilatant”, based on silicone. When heated and stirred, it expands and becomes more like thick glue. Next, the fan speed increases to eventually equal the crankshaft speed. A serviceable clutch turns with little effort when the engine is turned off.

removing the viscous coupling — UAZ Patriot, 2.7 l., 2009 on DRIVE2

Operation scheme: When the engine is cold, cold air comes from the radiator, the bimetallic spring located in the center of the disk is straightened and presses on the pin. The pin pushes the internal spring support and the ball opens the side hole in the disk, so the working fluid from the interdisk space is freely ejected and does not block these two disks. The viscous coupling rotates with very strong slipping (you can easily brake the impeller with your finger), the air pressure is weak, and the motor cools poorly. As soon as the thermostat on the engine opens, hot coolant enters the radiator, then the air from the radiator begins to heat the viscous coupling itself and the bimetallic plate. This plate begins to bend OUTWARD, gradually releasing the pin. The pressure transmitted through it to the spring bracket of the ball weakens and at some point the ball tightly closes the hole in the inner disk. The working fluid of the viscous coupling has nowhere else to go and remains BETWEEN the discs. Consequently, slippage decreases SHARPLY and we hear the howl of air under the hood, we will assume that the impeller is blocked on the shaft. God forbid you stick your finger in - it will tear it off! The motor begins to cool, and at some point the bimetallic plate, cooling down, straightens, presses on the pin, which presses on the spring bracket, which releases the ball, the hole in the disk opens and the working fluid is ejected from the interdisk space, which means the impeller again begins to slip strongly. A serviceable clutch turns with little effort when the engine is turned off. Checking without the risk of tearing off unnecessary parts of the organization: - start a cold engine, cover the front of the radiator with cardboard (otherwise you will warm it up until the morning), notice at what speed the clutch rotates approximately when it is cold. We warm up the engine, set it to idle, and again look at the rotation of the clutch. Compare with the initial observation. It spins much faster, which means the clutch is theoretically in good working order. Also, when accelerating on a cold engine, a working clutch spins much slower than the engine speed. When the engine is hot, the clutch spins much faster at speeds above idle. The operation of the thermal plate can be checked with a hairdryer; when heated, you can see how it bends outward. When removing the viscous coupling, pay attention that there is a left-hand thread. (see www.strim-avto.ru/Article183.phtml)

With the onset of cold weather I decided to remove the viscous coupling. In winter I’ll drive like this, but in summer I need to think about an electric fan that can be switched off from the passenger compartment. My temple is not working, or rather, it somehow doesn’t work correctly, it doesn’t rotate correctly with the same force, and after stopping the engine, it turns with force, into the place of free movement. And even when passing through fords of 40-50 cm (I don’t go deeper), the entire engine compartment is splashed with mud. After watching videos on YouTube, and armed with a key for 32, I went to the car. I expected about fifteen minutes, but it was delayed for 3 hours! The key for 32 fit without problems, the problems started later. I did everything according to the instructions, remembering that the left thread was pressed on the belt and sharply hit the key. But it didn’t work out that way, the nut turned along with the pulley, after several unsuccessful attempts, I took an impact screwdriver and started hitting the edges of the nut, it didn’t help. I began to think about how to fix the pulley, I tried with a screwdriver, and a pry bar, and putting a socket in the spacer, but it didn’t work. I was ready to give up, but the fasteners from the hanging bookshelves caught my eye. The curved appearance of the fastener gave me the idea to make a puller out of it. The work began to boil, I cut off the unnecessary edge with a grinder. Using a 10mm drill, I drilled holes for the pulley bolts (having measured the distance between the bolt heads in advance), tried it - it slipped, measured, drilled, tried, sharpened, sawed. And finally,

All you need is a 32mm wrench and a homemade puller!

everything worked out, the nut moved, and then easily twisted by hand.

puller - something like that

how much space is created

At the same time, I disconnected the corrugation from the air filter and switched to the winter version

Pros and cons of viscous coupling

Let's start with the disadvantages, because it is because of them that owners prefer to install electric fans on the UAZ Patriot instead of a viscous coupling. And the most significant disadvantage, perhaps, is poor engine airflow at low speeds - for example, in traffic jams or when driving over rough terrain at low speed. After all, the efficiency of a viscous coupling directly depends on these very revolutions.

Besides this, there are other disadvantages:

- Additional load on the engine. The viscous coupling takes away part of the engine power, this is especially noticeable when overtaking on the highway, when the operating speed is almost in the red zone of the tachometer. Acoustic comfort also suffers - a characteristic noise and howl appears.

- There is no way to force the fan to turn on at full power, for example, in the same traffic jams.

- The clutch makes it difficult to access the idler rollers and drive belts, which significantly complicates and increases the time spent on repairs.

- There is a danger of fan blades coming off at high speeds, as well as the risk of damage to the main radiator from flying fan fragments, which may require expensive repairs with a complete replacement of antifreeze/antifreeze. Now imagine that this could happen on the highway, somewhere far from home.

- Cannot be repaired. The faulty clutch is replaced with a new one, although you can try drilling a few holes and fixing it with bolts so that it always rotates. But this repair method is only suitable for summer; in winter, the engine will take a very long time to warm up.

- A simple and fairly reliable design that can work for years without any maintenance.

- It is installed on the UAZ Patriot from the factory, so you will not have to modify anything if it is replaced.

- Does not create a load on the electrical part of the car.

As you can see, the viscous coupling has more disadvantages, so many Patriot owners eventually come to the idea of replacing it with electric fans.

Features of the gas distribution mechanism of the UAZ Patriot

UAZ Patriot engines usually have a timing chain drive. The ZMZ-40906 engine is equipped from the factory with 2 single-row plate-link chains. This type of timing chain is compared to the double-row or single-row rollers previously used on UAZ engines. link chains are considered not the most reliable and usually require replacement after about 100 thousand kilometers. When operating a vehicle, especially under conditions of increased loads, the timing chains wear out and stretch. The main sign that it’s time to replace the chains with new ones is extraneous iron sounds from under the hood (the chains “clank”), which are accompanied by a loss of engine power at low speeds. This means that the chain tensioners no longer allow maintaining the tension required for normal engine operation. Loose timing chain tension leads to chain slippage on the gear or to chain breakage.

How to remove viscous coupling

Usually, the viscous coupling from a UAZ Patriot car is not difficult to remove, although if the device has not been removed for a long time and the bolts have become sour, a hammer may be needed. So, the sequence of actions is as follows:

- First, remove the fan casing (diffuser). Using a small flat head screwdriver, remove the spacer clip pins located on the top of the diffuser and remove the clips. After this, the casing is removed from the engine compartment through the top.

- The nut securing the fan to the pump hub is unscrewed. Here you can’t do without a 32 open-end wrench. Attention, the nut has a left-hand thread, that is, you need to unscrew it to the right (if you look at the front of the car).

- Be sure to secure the drive belt by pressing it with your hand in the gap between the temple pulley and the power steering pulley. Otherwise, you will not be able to unscrew the nut. If even after this the nut does not unscrew, try to break it off with sharp blows on the wrench with a hammer.

- Unscrew the nut a little and, holding it with a wrench, rotate the fan impeller to dismantle it. Keep in mind that the fan weighs a lot, so do everything carefully.

- Remove the fan and remove the viscous coupling by unscrewing the four mounting bolts around the perimeter.

Removal and installation of the viscous coupling of the ZMZ-409 fan

A viscous fan drive clutch is installed on the vehicle.

The clutch allows you to reduce fuel consumption, reduce fan noise, and promotes better warm-up of a cold engine.

The viscous clutch is removed if it malfunctions, if the clutch does not turn on or does not turn on completely.

You will need a 32 key.

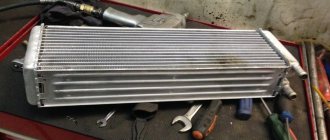

View of the viscous coupling assembled with the fan

To make it easier to unscrew the coupling, unscrew one pin

Unscrew the coupling shaft from the fan drive hub

Please note that the connection between the coupling and the hub has a left-hand thread

Remove the viscous coupling assembly with the fan

Unscrew the four nuts securing the fan to the coupling

Remove the fan from the coupling

Install the fan and clutch in reverse order

Source

About the electric fan

The electric fan covers all the disadvantages that the viscous coupling had. After installing it, it will be difficult not to notice the following improvements:

- The engine will stop overheating in traffic jams.

- You can force the electric fans to turn on at full power at any time, even while standing still, or program them to turn on based on temperature.

- The electric fan will not take power away from the motor.

- You can install two electric fans at once for reliability; if one of them breaks or is not enough for normal cooling, the other will take over its role.

- Access to rollers and belts is provided.

From the factory, on a UAZ Patriot with air conditioning, a so-called “sparka” is installed in front of the air conditioner radiator (on the street side) - two electric fans in a plastic case. But they have little effect on the main radiator, and besides, they make a lot of noise. Therefore, if you have already decided to install electric fans instead of a viscous coupling, you can safely remove them.

Installation process

To install an electric fan, it is not at all necessary to visit a service center; everything can be done independently at home. First of all, it is necessary to select or manufacture a base for electric fans (frame or “screen”) that matches the size of the engine cooling radiator.

Dimensions of a homemade screen so that nothing touches the body anywhere

Secure the fans to the frame using studs, close all gaps between the electric fan and the frame using door seals - this is necessary to create a directed flow of cold air for effective cooling of the radiator. A standard plastic (or iron) viscous coupling fan casing is needed for exactly the same thing.

Electric fans can be selected from another car, various options are possible, choose the one that is most affordable for you. Alternatively, you can take electric fans from a Toyota Celica as a basis, ordering their delivery from Vladivostok, as the person in the video did.

The following electric fans are also suitable: “Termal 404615S” - analogues: “Nissens 85616”, “Sat ST-DTW1-201-0”. Electric fan from Volga or VAZ 2110. In some cases, there is no need to make a homemade screen; everything fits on the “original” mounts. In the case of “Termal 404615S” you don’t have to redo anything.

The best way to install electric fans is one in which everything is connected to the connectors of standard electric fans, then there is no need to purchase additional equipment, such as:

- thermal relay;

- several meters of thick cable;

- iron insert in the thermostat pipe for the thermostat;

- temperature sensor.

You will just need to adjust the activation temperature of the electric fans in the engine control unit (make it lower), because from the factory these values are too high. It is recommended to replace the thermostat with a new one with a lower opening temperature. At this point, the procedure for replacing the viscous coupling with electric fans can be considered complete.

How to Remove the Fan Pulley on ZMZ 409

Auto Private

Replacing cuff crankshaft UAZ Patriot

Page 1 of 2.7

A sign that the front crankshaft oil seal needs to be replaced is oil leaking through its lip. Oil is sprayed onto the rotating crankshaft pulley, which is why the entire front of the engine and engine bay are lubricated.

A sign that the rear crankshaft oil seal needs to be replaced is oil leaking through its lip. The oil is sprayed by the rotating flywheel inside the clutch housing and then flows through the gaps between the crankcase and its booster. In case of severe leakage, the clutch plate lubricates the clutch plate and of course the clutch slide. Causes of clutch disc lubrication and clutch housing oil leakage, you will like input shaft leakage.

Engine oils and transmission oils have different smells, so with some skill it is possible to determine which seal is the problem. There is another method for determining the type of oil. Dip the oil into water, which is poured into a vessel with a narrow layer (you can use a puddle). Transmission oil will spill over the entire surface of the water in the form of an iris film, and motor oil will remain in the form of a drop, similar to a grain of lentil. When replacing the front seal, the crankshaft

If a leak occurs, check the cleanliness of the crankcase ventilation system, as it will become clogged by leakage even when the filler box is clogged. You will need: a "36" wrench, a 17-head wrench (otherwise a special wrench for attaching the crankshaft nut), a screwdriver, a utility knife (two), a hammer and teeth.

To replace the front crankshaft oil seal, follow these steps:

1. Install and secure the chain cover. Before installing in a narrow layer, apply sealant to the edges of the chain cover, cylinder block cover and cylinder head. Reinstall the chain cover, being careful not to damage the crankshaft seal. Replace both hydraulic tensioners.

Recommendations

Comments 52

Thanks, I'll get to it soon.

I also threw out the temple, installed a vent from the hover, the next step is to install the cover without a pulley, question about the belt, did it fit correctly? A car with air conditioning?

Fits just right, with air conditioning

Or maybe take a 2000 belt and throw out the deflection pulley.

This twin is not suitable; the blades are sharpened to work in front of the radiator; you need a twin from a Chevy Niva or Nissan.

This twin is useless, you should install a Nissan one

“WHISKY” still has a plus. When the engine is warm in the summer, it smoothly picks up speed and stays at approximately the optimal speed (doesn’t suck too much). The same cannot be said about the electric Carlson. I went hunting last summer, drove through flowering fields, in short, a lot of fluff... and pollen. The result, for example, Niva 214, there is a fur coat on the front... I have an adequately clean radiator... Even the front Carlson did not turn on, i.e. whiskey was enough to keep the engine temperature normal - t

In the heat of summer, yes, there is a plus. In my area, 8 months a year the temperature rarely rises above 10 degrees, even one fan copes with more than enough. And with whiskey in winter, there is underheating and excessive consumption of gasoline.

“WHISKY” still has a plus. When the engine is warm in the summer, it smoothly picks up speed and stays at approximately the optimal speed (doesn’t suck too much). The same cannot be said about the electric Carlson. I went hunting last summer, drove through flowering fields, in short, a lot of fluff... and pollen. The result, for example, Niva 214, there is a fur coat on the front... I have an adequately clean radiator... Even the front Carlson did not turn on, i.e. whiskey was enough to keep the engine temperature normal - t

And the fan fuse will never blow)

I put the key in and with a sharp blow of a rubber hammer it came out immediately. It also twists. For those who doubt electro. A question to answer the question: the Japs and GAZelles have electric and normal ones, but they are warm in winter.

I tried this method, the pulley slipped. then I tried using a screwdriver to fix the slightly unscrewed pulley bolts - I bent them for nothing (

Well, the idea of removing the viscous coupling passed when I saw melted hot-melt adhesive that was used to seal the end of the steering shaft. Kind of hints about the temperature under the hood, right? And this is with forced cooling. But the question is different: will the standard fans blow in the right direction? They are designed for installation in front of the radiator.

change the polarity and it should be fine

But personally, I do not support the idea of replacing the viscous coupling with an electric fan

A viscous coupling is needed in a UAZ. It always spins and provides some kind of cooling. Would you say that it consumes too much horsepower for its low efficiency? Well, okay, but it is absolutely energy independent. The fuse will not blow in it, the wiring will not fray. It just exists and is always spinning.

My thesis is simple, there should be a viscous coupling, and an additional electric fan should help it

I didn’t think much about a technical solution. On the first Patriot, an additional electric fan was installed from the factory. Its radiator is the same, it matches the Bukhanochka absolutely. You just need to take the Patriot Carlson, buy it and install it.

Is it efficient enough?

Enough. Repeatedly tested in Altai, the Urals and Mongolia. There were times when I wanted to have not one, but two such fans, but that was a couple of times, when in July, when at exactly noon, when in the heat of the day, when on a steep mountain pass.

We begin to look for something similar to the Patriot Carlson. Here it is, my dear one, being sold on Bazashop for a little over three thousand. But without wires for switching. Some wires are sold nearby, but do they fit here? This is a UAZ, there are a thousand modifications of them!

You need to take the kit. So that the fan itself, the wires, and all sorts of tubes are there right away.

Found. Here he is, dear. A little different from purely patriotic, but the meaning is the same. I ordered it as a gift for the New Year, bought it and threw it in the garage to age. I didn't even open the box. Why put it in winter? Summer...maybe it won't come at all.

Summer came suddenly. Yesterday and the day before yesterday, weather forecasters hinted at snow, and today - hellish plus 25. The heat is unbearable, it’s scorching, it’s a thrill! We need to quickly install an additional fan.

The box, as expected, contained the propeller itself, wires for connection, a coolant temperature sensor and a tee to fit into the pipe.

Installation is simple. In my case, even very simple; The oil cooler has been plugged for a long time, hanging purely for show.

You need to unscrew the oil cooler and screw in the fan. If for some strange reason you don’t want to part with the oil cooler, you’ll have to add another stage and screw it back on.

I really didn't want to remove the radiator for this. But this was not necessary.

Let's end the idle chatter and begin the installation.

Unscrew the oil cooler. It is convenient to turn the upper bolts from above, and the lower ones (forever your KO) from below.

To rotate from below, the loaves have a tricky door. The car was designed very conveniently.

We unscrewed the oil cooler and threw it into the pile, which is waiting for a trip to the purchase of ferrous and non-ferrous metals.

Good good! You love useless oil coolers, I get it. You don’t have to throw it away, but carefully put it aside for later reinstallation on top of the electric fan, all the fasteners are provided there for this purpose.

Unscrew the corners. We throw it in the same pile as the oil cooler.

What remains is a bare radiator, on the ears of which we will mount an additional electric fan.

We run to the store and buy a handful of M8 bolts and the same nuts. The original bolts that we unscrewed are a bit short, and the manufacturer did not include normal ones in the kit. Let's write a minus into his karma for this.

Adding four bolts and four nuts to the kit is a trifle, but how nice it would be. You wouldn’t have to crawl out of the hole, look for nuts that aren’t very useful in storage, wash your hands, run to the store...

Using a hammer and an anvil, the nuts take their place in special grooves. Now they are not simple nuts, but mortgages.

In order not to break out the lower mountings of the radiator, slightly loosen the bolts. The radiator becomes a little more movable, which is required to fit the fan.

Then everything is even simpler. We screw the fan to the ears. The manufacturer says in the instructions that the fan should be installed with the wire facing down. But for the life of me, it’s impossible to stage it like that! I installed it with the wire facing up. I hope there is nothing criminal in this.

We cut the upper pipe and insert a tee for the temperature sensor.

Our motto is cut seven times and try on once. I didn’t have time to think, maybe it would be better to put the sensor in the lower pipe, since everything was already installed. I hope this will be okay too.

We connect the wiring according to the male-to-female type, so you don’t get confused. We place the relay on a conveniently protruding bolt, and throw two ground contacts there.

Actually, everything is ready. You can test the device and check its functionality. First - in a kettle with boiling water. Then - to the mountains. I hope I can get away somewhere this summer.

Congratulations to everyone on May Day! As they say, we will fan the world fire on the mountain for all the bourgeoisie!

Congratulations to everyone on the upcoming Victory Day! Clear skies above everyone! So that we don’t need to travel to Europe in tanks, but only in motorhomes built on the basis of the UAZ Bukhanka.

UAZ Patriot: replacing the viscous coupling with an electric fan

Owners of the UAZ Patriot SUV are aware of this vehicle problem, when in hot weather the engine heats up and reaches 100 degrees Celsius. This, of course, is an unpleasant sight, which is observed mainly on hot summer days, when the temperature outside is +30 degrees and above. The reasons for the heating of the engine of the UAZ Patriot SUV are known - the fan cannot cope with its properties. In this article we will look at why the fan, which is designed to cool the engine radiator of the UAZ Patriot SUV, does not cope with its functions, and we will carry out minor repairs to eliminate this problem.

The essence of the problem

Let's start with the fact that the engineer of the Ulyanovsk Automobile Plant equips UAZ Patriot SUVs with radiator cooling fans, which are driven by a viscous coupling.

A viscous coupling is a mechanism presented in the form of two flat disks. Viscous coupling allows you to transmit torque using a special silicone-based fluid.

The operating principle consists of several plates mounted on the driven and drive shafts. They rotate in a container with liquid, which changes its properties when heated. When the liquid is mixed while the drive shaft rotates, it changes its properties (expands) and thereby creates pressure in the chamber. As a result, the disks of the driven shaft engage, causing it to move.

This viscous coupling drives the fan on the UAZ Patriot SUV. Everything would be fine if it were not for such a minus, which gives impetus to the search for its elimination. This disadvantage is that the viscosity of the liquid depends on the mixing speed. When the UAZ Patriot vehicle is braking and the engine is idling, the fluid loses its properties as a result of the rotation of the drive shaft slowing down. This causes the cooling fan to slow down and the temperature in the engine gradually rises. This phenomenon occurs when you have to stand in a traffic jam in the summer heat or move over rough terrain at low speed. Although the viscous coupling is an innovation, its use on the UAZ Patriot SUV is unsuccessful. We will look at how to eliminate the problem of engine overheating below, but for now we will list the disadvantages of using a viscous coupling.

Flying impeller blades

Disadvantages of viscous coupling

The disadvantages of using a viscous coupling on a UAZ Patriot SUV include the following factors:

- Engine temperature instability, which varies depending on crankshaft speed.

- Engine load.

- Difficult access to rollers and belts.

- There is no way to force the engine cooling fan to turn on.

- Inconsistent fan speed. It is possible that the fan blades may come off, which could result in a hole in the radiator. As a result, it becomes necessary to replace the radiator and install a new fan.

There is no way to repair it. If the product does not function, then repair is no longer appropriate and it must be replaced with a new one.

Theoretically, it is impossible to repair the product, but in practice it is possible. To do this, two holes are drilled in the viscous coupling hole, through which bolts are threaded and fixed to the drive disk. This repair allows the fan to rotate regardless of changes in fluid viscosity.

To get rid of this problem, it is necessary to install an electric fan instead of a viscous coupling. Such a system is much more reliable, efficient, and, most importantly, rational. We will consider the advantages of such a system further.

Electric fan instead of viscous coupling: advantages

The advantages of installing an electric fan instead of a viscous coupling are:

- Maintaining a constant engine temperature.

- When the car is stopped and idling, the engine does not heat up.

- This frees up access to the belt and rollers, making them easier to replace.

- Possibility of manually turning on the electric engine cooling fan.

- In addition, if one fan fails to cope or it breaks down, then in this case two units are installed, which compensate for each other’s work if necessary.

So, we found out that instead of a viscous coupling for cooling an SUV engine, it is rational to install an electric fan. To do this, you need to remove the viscous coupling from the UAZ Patriot SUV.

Removing the viscous coupling

Removing the viscous coupling is not particularly difficult and can be done with your own hands if you have the necessary tools. But you still need to know the process of removing the product and some important points. So, removal of the product is carried out in the following order:

- First you need to remove the fan shroud. Let's take a closer look at how to do this: Using a small screwdriver, you need to remove the spacer clamp pins. They are located on the top of the casing.

- The clamps are then removed.

- The casing is removed by lifting it up.

Removing the viscous coupling is much easier, since to do this you need to unscrew the four mounting bolts around the perimeter of the product and remove them. After this, you can remove the viscous coupling and proceed to the next stage of work.

Installation

Installation or replacement of viscous couplings with electric fans is carried out at home. First, you will need to find a frame with electric fans that are suitable for installation under the cooling radiator of a UAZ Patriot SUV. There are several options, and each driver chooses the one he likes best, or the one he can get.

Therefore, you can take the electric fan of a Toyota car as a basis. The video below provides complete information about the installation of the structure.

So, to do this you need to do the following:

- Remove the negative terminal from the battery.

- The radiator shroud must be removed.

- Place the electric fan in front of the cooling radiator.

- The structure is secured into standard holes.

- The supply wires of the products are being laid. The video shows their placement.

- The cable is connected to the vehicle control system via a thermal relay.

- You will need to replace the thermostat with a new one and do not forget about the new seal.

- Finally, the casing is put on the radiator, and we begin to check the system.

We start the engine and check how the system heats up. When the sensor reaches the 90 degree mark, the first electric fan should work. You must first set the response temperature of the first and second products. The second should operate at a temperature of 93-95 degrees.

How to Remove Transmission Oil from a Driveway

Automatic transmission oil is an oil-based lubricant. As with any oil-based stain, it takes more than just water to clean this mixture of oil and other chemical compounds from concrete or asphalt.

While sealing transmission fluid-filled cat litter or other absorbent substances in an airtight container and placing it in an outside trash container is often a safe bet, waste collection policies vary greatly by state, county, or city. Contact your local public works department or check their website before disposing of transmission fluid—depending on your location, there may be special rules or measures for collection.

Once you've drank as much transmission fluid as possible, oven cleaner—a common household solvent and degreaser—will be your secret weapon for treating the remaining stain. Cover the entire stain with a generous coat of cleaner and let sit for 10 minutes. Scrub the stain with a stiff brush, then rinse thoroughly with a hose set to high pressure—be sure to use plenty of water to safely dilute the oven cleaner. Repeat as needed until the stain is completely gone.

In addition to home remedies, online and auto parts stores offer specially formulated oil-based concrete stain removers designed for fluids such as motor oil, brake fluid, antifreeze and transmission fluid. While some commercial options work just like the vacuum cleaner trick, requiring application and rinsing, others liquefy and turn to powder, absorbing the stain. Once they turn to powder, simply shake off the powder and discard it. While they may be more powerful than oven cleaner and more effective on long-lasting stains, absorbent oil stain removers can last for hours rather than minutes. Brands vary greatly between manufacturers, so always read and follow instructions and warnings carefully before use.

Warning

Commercial oil stain removers are typically designed for concrete surfaces and can damage aggregate-based asphalt roads. Please read the manufacturer's label before purchasing.

Replacing a viscous coupling with an electric fan

To cool the radiator, a fan is used, driven from the engine crankshaft through a special clutch. Under prolonged loads and elevated air temperatures, the performance of the impeller is not enough to remove heat.

Installing an electric fan on the UAZ Patriot instead of a viscous coupling allows you to increase the air flow drawn through the radiator honeycombs and improve the temperature parameters of the power unit under conditions of increased load.

Key for removing viscous coupling on UAZ Patriot ZMZ 409

Key for removing viscous coupling on UAZ Patriot ZMZ 409

Post by lexmak » May 28, 2021, 02:51 pm

Any factory key for 32 with a thickness of no more than 9 mm. Found in nature.

Well, that's all.

Key for removing viscous coupling on UAZ Patriot ZMZ 409

Post by igorstrong » 06 Jun 2021, 07:30

Key for removing viscous coupling on UAZ Patriot ZMZ 409

Post by lexmak » 06 Jun 2021, 17:49

Key for removing viscous coupling on UAZ Patriot ZMZ 409

Post by Petrivq » 16 Jun 2021, 08:24

The essence of the problem

The viscous coupling is a sealed housing filled with a viscous silicone-based working fluid. Inside the casing there are 2 disks with guide vanes; torque is transmitted by oil flows.

The characteristics of the liquid allow you to smoothly regulate the rotation speed of the output shaft and the fan impeller installed on it. The design ensures that the thermal regime of the motor is maintained at medium and high speeds.

When the engine speed drops to idle mode, the intensity of mixing of the working fluid in the clutch body decreases, which causes a decrease in the fan speed. A drop in air flow speed causes the radiator and engine jacket to overheat. The problem occurs when driving in long traffic jams or when driving on rough or swampy terrain at low speed.

An additional concern is the safety of the structure. In the center of the coupling there is a bimetallic plate that controls the bypass valve.

When the element is cooled (by the air flow from the radiator), the impeller rotates at low speed.

As the element warms up, the valve closes, and then the impeller accelerates sharply. At this point, there is a risk of injury to the driver servicing the engine. There have been cases of plastic impeller rupture (due to previous damage).

Viscous cooling fan coupling: where it is located and how it works

The fan rotation speed changes smoothly, steplessly; a fan with a viscous coupling never turns on and off instantly

In all-wheel drive transmissions of passenger vehicles with a longitudinal engine position, a standard viscous coupling performs the functions of an ersatz differential or a special locking element that complements a conventional differential. However, from a design point of view, the device is represented by a plurality of round driving and driven plate elements with projections and holes, which are located inside a completely waterproof housing filled with dilatant liquid.

The fan rotation speed depends on the heating of the engine: the more the viscous coupling is heated, the more the inlet channel opens, and the more liquid enters the working chamber.

In the absence or insignificant volume of automobile oil inside the working chamber, free rotation of the drive disk is observed. Only in the process of gradual warming up of the engine and increasing the temperature of the antifreeze does the bimetallic plate heat up and expand, which causes the opening of the intake valve system, penetration of the working fluid into the chamber and an increase in the speed of rotational movements of the ventilating impeller. As the adhesion coefficient decreases, the difference in the rotational speed of the housing and the viscous coupling drive shaft increases noticeably, which slows down the operation of the fan impeller.

Disadvantages of viscous coupling

The viscous coupling installed in the fan drive has a number of disadvantages, including the following:

- dependence of the intensity of radiator blowing on the speed of the power unit;

- the clutch housing and air diffuser prevent access to drive belts and tension rollers;

- there is no possibility of forcing the fan to turn on during prolonged increased load on the power unit;

- due to constant power take-off, fuel consumption increases slightly;

- increased load on the drive belt and tension rollers, which leads to premature wear of parts;

- slow heating of the cooling system due to constant fan operation;

- noise when spinning the impeller (after the bimetallic switch is triggered);

- increased load on the front cover of the power unit, which causes loosening of the fastening and oil leakage;

- The coupling design does not provide for repairs and replacement of structural components.

Selection and replacement of couplings

As for replacement, you need to remove the old device and put a new one in its place, and then check its functionality. In practice, more difficulties arise not with the replacement itself, but with the selection of spare parts.

Having figured out which part is needed, you should also pay attention to the manufacturer. Taking into account the fact that viscous couplings are produced by only a few companies, it is optimal to choose from the leading manufacturers: Hella, Mobis, Beru, Meyle, Febi. As a rule, the same manufacturers also produce other parts (cooling radiators, thermostats, suspension units, etc.).

Advantages of an electric fan instead of a viscous coupling

Advantages of using an electric drive for the radiator cooling impeller instead of a viscous coupling:

- ensuring the specified engine temperature regardless of the crankshaft speed;

- stable cooling of the power unit when idling (without moving or when moving at low speed);

- it is possible to force the electric motor to turn on using a toggle switch located in the car interior;

- It is allowed to install 2 fans (to increase the reliability of the design and improve airflow to the radiator).

Role in the internal combustion engine cooling system

A viscous coupling fan is installed on vehicles with a longitudinal engine (usually all-wheel drive and rear-wheel drive models). With this arrangement, it is most advisable to connect the radiator fan pulley to the water pump pulley. As you know, rotation of the water pump is transmitted by a service belt from the crankshaft pulley.

The disadvantage of this design is that the rotation speed of the fan impeller will always be proportional to the crankshaft speed. Such a device will result in the engine being excessively cooled at high speeds in cold air conditions, which will reduce its efficiency. In addition, the permanent connection of the impeller and the crankshaft pulley will increase mechanical friction losses, which will take away power and increase fuel consumption.

The viscous fan coupling allows you to adjust the rotation speed of the impeller depending on the engine temperature.

Device

The difference in the design of viscous fan couplings for Toyota, BMW, Mercedes, Audi. is minimal, since they are all designed and work according to the same principle.

A shaft with a connecting flange is attached to the cooling pump drive, so its rotation speed is always proportional to the crankshaft speed. A drive pulley, in turn, is attached to the shaft, which rotates in the working chamber. The working and backup chambers are separated by plates. The transition between chambers is only possible through inlet valves and return passages. Initially, the backup chamber is filled with special silicone oil. The drive pulley, or disk, as it is also called, has oblique teeth around its circumference, which, when rotated, allow the oil to be expelled back into the reserve chamber. The surface of the drive disks, like the dividing plates, has special ribs that turn the working chamber into a kind of network of labyrinths through which silicone oil circulates.

Removing the viscous coupling

The sequence of actions when removing the viscous coupling from the ZMZ-409 gasoline power unit installed on a UAZ Patriot:

- Remove the guide diffuser located around the impeller. To secure the assembly, spacer clips are used, which are removed with the tip of a flat-head screwdriver. The deflector housing is removed upwards from the gap between the engine and radiator.

- To remove the impeller you will need a 32 mm wrench. It is possible to use a standard spanner or socket. Since the nut has a left-hand thread (to increase safety during operation), the tool rotates to the right (when viewed from the radiator of the car). To prevent the clutch from spinning, you need to press the poly V-belt by hand (into the gap between the clutch pulley and the drive wheel of the hydraulic power steering pump).

- Unscrew the impeller using a wrench or manually. Since the element is heavy, it is important not to drop the part into the gap between the engine and the radiator. If dropped, the radiator tubes may be damaged by the sharp blades of the impeller.

- It is possible to remove the coupling together with the front cover of the ZMZ-409 engine, which is attached to the front of the block and the head cover with 6 bolts. Instead of a standard part, an aluminum panel from the ZMZ-406 engine is installed, which is distinguished by the absence of fastening points for the viscous coupling. During installation, it is necessary to replace the gaskets and wipe the mating surfaces from any remaining engine oil. The bolts are tightened in the sequence specified in the power unit repair instructions.

Do-it-yourself pump replacement in the Patriot cooling system

You will need a complete replacement of the water pump on a UAZ Patriot of EURO-3 standard in 2 cases: when access to engine components is required or when for some reason it is necessary to repair/replace this device.

What tools will you need before starting the replacement:

- Regular mounting blade.

- Key 12'.

- Various screwdrivers.

- Hexagon 6'.

The replacement itself, if the car has a 409 engine, is carried out in the following sequence:

- The SUV must be set to the handbrake before starting work.

- The next step is to drain the coolant from the system.

- It is necessary to remove the power steering pump from the bracket.

- The viscous coupling located in the fan drive is also removed.

- The generator drive belt must be dismantled.

- You also need to remove the pulley with the reflector. For this purpose, the pulley should be fixed using a regular screwdriver, and then unscrew the 3 screws, after which both the reflector and the pulley itself can be easily removed.

- The power steering pump bracket is mounted on special bolted connections that need to be unscrewed.

- The bracket itself is removed directly.

- The pipes located near the pump are mounted on clamps, which should be loosened as much as possible.

- There are 2 bolted connections on the front of the HV that need to be unscrewed.

- There is 1 bolt on the back of the pump, which also needs to be unscrewed.

- The last step is to remove the pump without any effort.

After removing the pump, you can safely begin repair work. Basically, a complete replacement of the device is required, and before installing a new mechanism, do not forget to thoroughly clean all sealing areas, and be sure to install new gaskets.

To avoid coolant leaks in the future, always apply sealant to the gaskets. Installation of a new pump is carried out in the reverse order of removal.

Electric Fan Installation

Replacing viscous couplings with electric fans begins with purchasing or making your own metal support frame for electric motors, which is then placed on the inside of the radiator.

On some vehicles equipped with an air conditioning system, an additional air conditioning heat exchanger with electric fans (installed on the outside of the radiator) is used. It is not recommended to remove the elements as they are controlled by the air conditioning controller to keep the air inside the vehicle cool.

For cooling, 2 fans from the Gazelle or from the “classic” VAZ models are used. When purchasing an impeller, you should consider the direction of air flow created by the blades. Additionally, it is necessary to replace the sensor in the thermostat housing, which activates the operation of the electric motors.

There are several types of sensors that are triggered at a liquid temperature of +87...+97°C. An additional toggle switch for manually turning on the engines is located in the car interior (on the dashboard or center console between the seats).

It is allowed to use fan units from Nissan X-Trail SUVs, which are equipped with a 4-channel patch cable. The devices are connected to the power unit control controller and to a temperature sensor (with a response threshold increased to +95...+97°C).

The signal from the control unit turns on the impellers with an operating capacity of 40% of the maximum value. With a further increase in temperature, a sensor located in the thermostat housing is triggered, allowing the fans to be switched to maximum air supply.

There have been cases of using a fan from Hover (catalog number 1308100K00V1), which is equipped with additional resistance to obtain 2 speeds of rotation of the impeller. The product is supplied with a plastic frame, which is installed on the UAZ Patriot radiator with minor modifications.

Before installation, you will need to cut down 2 support brackets, which are placed on the lower edge of the plastic diffuser. For mounting, standard holes on the radiator are used, intended for installing the original guide casing.

For fixation, metal spring latches from the interior heating unit on “classic” VAZ models are used. Holes for bolts are drilled in the parts, with which the brackets are attracted to the radiator frame. The lower part of the fan frame is held by standard brackets attached to the radiator housing.

There are gaps on the sides that are closed with a sealing edging. To connect to the on-board network, use the power plug for the air conditioner fans; switching on occurs at a temperature of 97°C.

The switching circuit ensures that one impeller rotation speed is obtained. To obtain the second performance stage, an additional air conditioning fan must be connected to the power plug.

The advantage of using a Chinese product is a reduction in noise and vibration levels; there is no increase in the load on the on-board electrical network. It is possible to modify the product by installing a smooth fan acceleration controller.