The Chevrolet Niva suspension has an independent device. It is based on two wishbones located on both sides. To smooth out vertical vibrations, coil springs and shock absorbers are used. To eliminate strong rolls when cornering, anti-roll bars are used.

Suspension diagnostics.

From time to time, a knocking sound may appear in the front suspension of the Niva Chevrolet. If this problem occurs, it is necessary to immediately diagnose it. It starts with a visual inspection. It is best to do it on a lift or inspection ditch. The wheels must be hung to be able to check the play of the parts. First of all, rubber parts are checked - anthers and oil seals. They should not have visible mechanical damage, cracks or other signs of aging. It is also necessary to check that rubber-metal products do not have one-sided bulging of the mass or its separation from the reinforcement. In this case, it is necessary to immediately replace the parts.

After this, the protective covers on the balls are checked. They are non-separable, so if there is damage, it is necessary to replace the complete structure.

Particular attention should be paid to the cushions that are located between the hinges and the rubber bushings of the shock absorbers.

After this, the front levers of the Niva Chevrolet are inspected. They are held in place by bushings, which wear out over time.

Checking the clearance in wheel bearings.

If there is wear in this unit, then when driving or picking up a certain speed, strong vibration may be observed on the steering wheel. Over time, this can lead to more serious problems, such as uneven tire wear. This is due to the fact that there may be no clearance necessary for the hub to rotate. In normal condition it should be at least 0.15 mm. To adjust, you will need a wheel wrench, a 27 wrench and a hammer.

To check, you need to remove the wheel, then rock it in a vertical plane. For a more accurate check, you need to ask an assistant to press the brake pedal and rock the wheel again. If the knocking noise disappears, this confirms that there is a problem with the wheel bearing.

To eliminate the play, it is necessary to remove the cap and loosen the hub nut. To do this, it is better to use a suitable wrench. In this case, it is better to immediately replace the nuts with new ones, because the old one may return to its position and it will not be possible to properly lock it, since its sides may be damaged.

For tightening, it is better to use a torque wrench so that the force does not exceed 19.6 N*m or 2 kgcm.

Also, the appearance of a knock in the front suspension may be due to incorrect adjustment of the wheel alignment angles. To do this, you need to contact a specialized service to check these parameters on a stand. An incorrect angle leads to increased tire wear and fuel consumption. Over time, this causes suspension elements and wheel bearings to fail. The car loses control.

If knocking occurs in the front suspension, you need to pay attention to the exhaust system. A common noise at the front of the vehicle can occur when the muffler or resonator mount is misaligned. This manifests itself in a knocking sound when changing the throttle. It is better to check on a cold engine. To do this, you can grab the end of the exhaust pipe and swing it in different directions. In normal condition, the exhaust system should not produce any knocking noises. The appearance of noise will indicate damage to the fasteners. In this case, it is necessary to install the car on an inspection hole and more carefully check the exhaust system components.

Replacing wheel bearings

Among the main external signs that allow us to judge the need to dismantle the bearings for troubleshooting, it is worth highlighting the presence of increased noise during movement, as well as the lack of a positive effect from adjusting the nominal value of the gap between the bearings. To dismantle and then reinstall the wheel bearings, you will need a wheel mount wrench, several more wrenches, sizes 17 and 13, a flathead screwdriver, a small hammer, a special torque wrench, and a mandrel for pressing the oil seal. The required liquids for operation are a lubricant called Litol-24 and a little kerosene. In addition, you need to find a suitable container in which the removed parts will be washed.

The work process itself begins with removing the steering knuckle, removing the hub, spacer ring, oil seal, and internal bearing rings from its structure. Do not forget to rinse each part using kerosene prepared in advance. We carry out a visual inspection of the raceways of both bearing rings, as well as the working roller surface. Both the rollers and the rings must not have visible wear or chips. The defective part must be replaced together with the rings located on the outside. In this case, both parts of the car must be replaced at the same time.

Using a small hammer blow on the bit placed on the outside of the ring, you should try to press it out of your fist. Next, using the same simple taps with a hammer, you need to press the new outer bearing, until it stops, into the collar of the socket located on the rotary cam. Using Litol, we fill the empty cavities inside the rotary cam. Lubricant is applied to the outer sides of the bearing ring.

All that remains is to put back the parts previously removed from the steering knuckle and carry out the process of adjusting the clearance parameter between the wheel bearings.

Knock in the front axle.

As with a cardan drive, the resulting noise can be caused by a malfunction of the front axle. But this check can only be carried out with special equipment, so it is necessary to first exclude possible damage to rubber bushings, seals and silent blocks, since they are the most vulnerable components of the system, subject to frequent loads.

The Chevrolet Niva suspension ensures a smooth ride and controllability of the car, regardless of the quality of the road surface.

The safety and comfort of the driver and passengers depends on its condition.

Wear of suspension elements leads to an increase in braking distance. They can cause loss of control.

Therefore, owners need to monitor the condition of the elements and replace or repair them at the first sign of malfunction.

Purpose and design of the front and rear

Chevrolet Niva is designed for driving on asphalt and off-road. Therefore, the car, in addition to all-wheel drive, has increased ground clearance. The latter performs three functions:

- Reduced shock loads on the body, wheels, bearings.

- Providing traction.

- Reduced body vibrations when driving over uneven surfaces.

The pendant is divided into two parts:

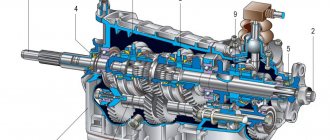

- The front one is shown in the diagram below. Includes four control arms (two on each side), ball joints, telescopic shock absorbers, coil springs and anti-roll bar. The front suspension is independent - vibrations of one of the levers do not affect the position of the other.

- The rear is shown in the diagram below. Includes rear axle beam, torque rods, telescopic shock absorbers and coil springs. The beam rigidly connects the wheels. They cannot oscillate independently. Accordingly, the rear suspension is dependent. This slightly reduces comfort and maneuverability. But the beam increases the rigidity and reliability of the structure.

In addition to the listed parts, the suspension also includes other elements: rubber bumpers, silent blocks, bolts, nuts, fasteners, gaskets, brackets. All of them are subjected to large dynamic and static loads. In addition, the rubber parts of the silent blocks and the boots of the ball joints dry out over time and need to be replaced even after the car has been stored in a garage for a long time.

Bottom line

Today, the Chevrolet Niva is a truly reliable and high-quality car. It is able to overcome all kinds of potholes, potholes, swamps, clay and stone terrain without much harm to the entire structure. At the same time, for some reason the manufacturer forgot to equip the Shniva with a more powerful power unit, at least 105-125 hp. The presence of a more powerful engine would make this car even more attractive in the eyes of potential buyers.

The chassis of the Niva Chevrolet includes front and rear suspensions. Since most of the troubles await the owners of this model in the front independent suspension, consisting of several transversely located arms, cylindrical coil springs, as well as shock absorbers and a stabilizer for greater lateral stability, it is its design and repair features that are worth considering in more detail.

Advantages and disadvantages

The car demonstrates good off-road qualities. They clearly appear after lifting to install rubber with an increased outer diameter.

Comfort in the cabin is preserved not only on asphalt. This is facilitated by the independent front suspension along with fairly soft springs.

However, many owners of the Chevrolet Niva note the insufficient strength of the reaction rods holding the rear axle.

Those who plan active off-road trips should take care of reinforcing the parts. Kits of reinforced reaction rods are sold for this purpose.

Also in need of attention are ball joints with silent blocks, which are not durable. To extend the service life of the hinges, it is necessary to monitor the condition of the anthers in order to change them on time.

Signs of trouble

Some problems can be identified by hearing while driving. Worn ball joints or silent blocks, faulty shock absorbers or broken rods knock, squeak or ring when driving on uneven roads.

In addition to extraneous sounds, suspension malfunctions manifest themselves as follows:

- Rocking or jumping of the body when driving over uneven surfaces.

- Pulling the car to the side.

- Increased braking distance.

- Deterioration in controllability.

- Accelerated or uneven tire wear.

Important: damage to the anthers can only be noticed upon inspection. If you do not replace them in time, dirt will get into the hinges and cause them to break.

Basic faults

Chevrolet Niva suspension parts are designed for different service life.

The levers, beam and anti-roll bar do not need to be changed even after 100-200 thousand kilometers.

But rubber-metal hinges, boots and bushings gradually lose their properties even while parked.

VAZ-2123 owners have to deal with the following malfunctions:

- Wear of silent blocks, ball joints.

- Damage or cracking of anthers.

- Reduced performance of shock absorbers.

- Breakage of jet rods.

In addition to replacing faulty parts, it is necessary to regularly check and adjust the angles of the front wheels.

Otherwise, the car's handling deteriorates, and the tires begin to wear out rapidly. Wheel alignment is checked every 10-15 thousand kilometers and after very strong impacts when falling into road potholes.

Is it worth doing the repairs yourself?

Any repair requires not only experience, plumbing skills and a standard set of tools. Most operations are performed on an inspection pit or overpass.

To replace ball joints and silent blocks, pullers are required, and checking and adjusting the alignment angles of the front wheels is carried out only on special stands.

Repairing a car yourself is worth it only if you have the necessary equipment and tools. It is often cheaper to go to a service station than to buy pullers or keys for a one-time job.

Suspension repair is a serious process on which your safety on the road depends. If you are not confident in your abilities or do not have the necessary tools, it is better to turn to professionals.

Tuning

There are ready-made suspension modification kits available in stores. Three types of tuning are popular:

- Lifting - increasing ground clearance by installing spacers under the springs and installing shock absorbers with increased travel.

- Reinforcement - replacement of reaction rods and other parts with more durable ones.

- Installation of air suspension, which allows you to adjust the ground clearance and stiffness in accordance with the road condition

The last option is the most complex and expensive. But it allows you to quickly adjust the behavior in accordance with operating conditions.

Important: the law regards some tuning options as re-equipping a car. In such cases, you need to go through the certification procedure and make changes to the technical passport.

Repairs or diagnostics can be carried out either at a specialized car dealership or independently. And in order to save money, many prefer the second option. And if you also prefer the second option, this article will help you with this.

An excellent domestic SUV is the Chevrolet Niva; the front suspension, just like on any other car, requires timely maintenance so that it lasts a long time.

Purpose and design of the front suspension

It serves as a connecting element on the Chevrolet Niva, providing elasticity between the wheel and the vehicle body, thanks to the perception and damping of vibrations of the acting forces, and this element is positioned as independent.

Also, the main advantage of this car, as mentioned above, is the presence of independent front suspensions. On both sides there are two wishbones, cylindrical coil springs, a telescopic shock absorber, and a transverse stabilizer.

Also in this design there are such elements as:

What devices, tools and consumables will be needed for repairs?

High-quality repairs to the front suspension of a car can only be carried out after the preparatory stage.

Tools for work:

- a set of keys (mostly 6,13, 27);

- screwdrivers;

- torque wrench;

- hammer;

- balloon type wrench;

- basin or bucket;

- lithium grease;

- metal brush;

- jack.

To quickly disassemble elements, pullers are used specifically for silent blocks . Kerosene will be required to flush the units. A beard is useful for a plumber's tool. It can be used to knock out bolts or knock off rust.

Suspension diagnostics

- Check that all rubber parts are free of signs of wear, aging and mechanical damage.

- Also check that there are no various cracks or signs of aging on the rubber-metal hinges, or that the rubber has not come off the reinforcement. If you find such elements, they should be urgently replaced with new ones.

- Check the condition of the protective covers of the ball joints and hinges. If they seem worn out, you will have to replace the entire hinge assembly.

- Pay attention to the condition of the bushings of the rubber lower and upper hinges.

- Check the condition of the rubber-metal bushings of the levers at the lower and upper hinges.

- Inspect the rubber bushings on the stabilizer bar, check the condition of the stabilizer brackets, which are attached to the arms and side members.

Diagnostics of the front suspension of Niva Chevrolet

In order to check the technical condition of the front suspension elements, you need to drive the car onto a lift or inspection ditch. In the latter case, the wheels are suspended using a jack or other lifting device. Diagnostics begins with a visual inspection of the structural elements of the suspension.

For example, rubber parts should not show signs of material wear and there should be no mechanical damage to such parts. Hinges made from a mixture of metal and rubber should not show cracking or signs of aging. If defects are found, the parts must be replaced.

Next, we check the condition of the protective covers of the hinges and the ball joint on each side. If damage is found on these elements, they will have to be replaced. We inspect the rubber cushions on the upper hinges, and the rubber bushings of the shock absorbers on the lower hinges. The algorithm for detecting defects is identical to the previous cases.

Inspect the bushings on both arms. It is also necessary to check the condition of the bushings located in the stabilizer for lateral stability. Don’t forget about the safe fastening of the stabilizer brackets and body side members on the lower arm.

Independent Wheel Bearing Clearance Repair

If you feel or feel vibration in the steering column while driving, then most likely the clearance on the front wheels in the bearings of the hub itself has increased, so their service life will be reduced, and the tires will begin to wear unevenly. And if there is no gap at all, then the hub will rotate tightly, which will also lead to a decrease in service life, so its gap should be greater than zero fifteen ml. Adjustment of the front bearings is carried out using a wheelbrace wrench, a twenty-seven wrench and a hammer.

- A wheel that is in a suspended state should be rocked; if there is play, the gap must be adjusted. After this, press the brake pedal and rock the wheel; if there is no play, then there is a gap in the bearings.

- It is necessary to dismantle the decorative cap and unscrew the lock nut from the hub, and hold it with a wrench to prevent it from turning. When repairing the chassis while adjusting the hub, it is advisable to install new hub nuts, since even after adjustment there is a high probability that the old ones will take their original place, which will not allow them to be properly locked. If this is not possible, then you can take the nut from Drugov’s car.

- Then you need to twist the hub nut so that the torque is 19.6 Nm. turning the hub several times, ninety degrees in two directions, will install the bearing itself. After this, loosen the adjusting nut and tighten it to 6.8 Nm. Having done all this, simply unscrew the nut twenty-five degrees.

- After everything is done, change the collar of the nut on the pin of the external drive joint.

- After the adjustment is made, check how the wheels rotate; if they rotate easily, then everything is fine. The final check can be made only after driving several kilometers without braking, assessing how the hub heats up.

Gap adjustment

The first step is to remove the decorative cap, then unscrew the hub nut and, at the same time holding the hub from turning with a wrench, unscrew the nut. When adjusting the hub, it is imperative to have a new hub nut on hand, because once the adjustment is completed, it is unlikely to be securely locked in its old place. Most likely, the bead will be damaged due to the previous locking. And if you don’t prepare in advance, the process may drag on.