Changing the oil in the GAZelle gearbox and checking its level

Let's start with monitoring the oil level in the gearbox.

Even if there are no visible leaks or oiling, this procedure is recommended every 20 thousand km. To check the oil level in the transmission, you need to clean the surface near the inspection plug. Then the control plug is unscrewed. Normally, the level should reach the bottom edge of the filler hole. In this case, you should check only on a warm gearbox. To warm up the box and the oil in it, you need to drive the car about 15 km. The machine itself must be placed on a level surface, since tilting will not allow you to assess the real level. After the engine is turned off, you need to wait about 10 minutes for the oil to drain from the walls and parts into the crankcase.

If topping up is necessary, use only the oil that has already been poured into the box. Using different types of lubricants and mixing them with transmission oils can lead to the lubricant losing its properties, chemical reactions to begin, sediment may form, etc.

- Now about changing the oil in the GAZelle gearbox. First of all, the box has a drain and fill plug. The filler plug is also a control plug (to determine the level).

- To begin with, as in the case of checking the level, the gearbox needs to be warmed up and the car placed on a flat area with an inspection hole, lifted on a lift or driven onto an overpass.

- Next, you will need to prepare a container for draining the waste, tools for unscrewing the plugs (hex wrench 12), as well as a special syringe for filling in fresh oil.

- Next, the drain plug is unscrewed and the oil is drained into the prepared container. By the way, if chips are visible on the drain plug magnet and/or in the oil, then it is very advisable to remove the pan and wash the gearbox housing. If there are no chips, but the oil is very dirty, then you can get by with flushing oil.

- After draining, the drain plug is cleaned of dirt and chips, then tightened in accordance with the tightening torque. Then unscrew the filler plug. Taking into account the different configurations of the GAZelle, it can be located on the left or right side of the gearbox.

- Now oil is poured into the box with a syringe until it begins to flow out through the edge of the filler hole. As soon as the oil flows, the plug is tightened.

- By the way, you can also fill the oil without a syringe through the hole for the gear shift lever. In this case, the lever is removed (the rubber casing is moved aside, the lever can be unscrewed by hand), then oil is poured into the crankcase hole until it begins to flow from the gearbox filler hole.

How to check the level?

Checking the oil level is carried out using standard technology to which every person is accustomed. To do this, the walk-behind tractor has a special probe that goes deep into the unit. Having taken it out of the hole, at the tip of the dipstick you can see a limiting strip, the level of which is equal to the oil level. If there is not enough liquid, it must be added. On the other hand, this nuance forces you to check the entire system, since a low level of lubricant indicates that it is leaking somewhere.

In addition to the standard dipstick, some models of walk-behind tractors contain special sensors that automatically show the amount of lubricant present. Even during the process of replacing the oil fluid, it can be used to determine how much the size of the lubricant composition has increased or its deficiency.

Sources:

https://abacarov.ru/obsluzhivanie/kak-zalit-maslo-v-reduktor.html https://serenity-service.ru/diagnostika-i-obsluzhivanie/kak-zalit-maslo-v-reduktor.html https: //stroy-podskazka.ru/motobloki/maslo/

Features of oil selection

How to change the oil in a Lada Priora engine yourself?

According to the manufacturer's recommendations.

The main criterion that you need to rely on when choosing gear oil is the list of technical characteristics of the gearbox and the manufacturer’s recommendations. Each vehicle has its own section in the operating instructions, which indicates which lubricant designation the car manufacturer recommends choosing. If you use a fluid lower in the category according to the API table, the unit will wear out and break faster. On the other hand, if you choose a gear oil located in a gradation higher than the recommended one, this will not lead to any practical advantages. First of all, the owner will have to significantly overpay, since the cost of such goods is much higher.

In the absence of recommendations.

If there are no special instructions, select gear oil according to technical characteristics as follows.

- For freight transport.

The operation of units found in trucks without hypoid gears will be effective if the oil is used at a level of at least GL-3. On the other hand, there are a number of exceptions. For example, a light gazelle needs exclusively GL-5 oil, which is poured not only into the rear axle, but also into the gearbox. When selecting the characteristics of gear oil for models with hypoid gears for gears, regardless of the technical complexity of the design, the choice comes down to products marked GL-5. The use of a lower-ranking lubricant results in insufficient protection of the hypoid pair from scratches and chips. - For passenger vehicles.

In passenger transport the situation is slightly different. Synthetic gear oil of class GL-5 is poured into the drive axles; for manual transmissions, class four is required. Before making a purchase, the owner must remember that GL-4 oils are not produced in the Russian Federation. Imported products of this level are an order of magnitude more expensive than Russian lubricants that have the GL-5 standard.

When selecting semi-synthetic gear oil, you should check its viscosity in advance. You should be guided by such reasoning. Lubricant with a viscosity of 24 sq. mm/s at a temperature of one hundred degrees Celsius, it is preferable for replacement if the vehicle is operated in a hot southern climate. If the machine is operated at moderate atmospheric temperatures, it is better to use products with an index of 90

When choosing gear oil for automatic transmissions, you should pay attention to products with indexes 75/80/85W-90. The last category may not be suitable for use in severe winter conditions

Gear oil with an index of 75 will allow you to forget about the troubles associated with the problematic operation of the gearbox, even at -40 degrees.

Which oil should you choose?

Let's consider the question, which oil is better for the Gazelle gearbox to make the car last longer? The automaker itself does not give specific recommendations for changing gearbox oil and regarding which oil is best for the Gazelle gearbox? The instructions only indicate the recommended viscosity of the lubricant - SAE 75W. This is the viscosity of the fluid that you will pour into the car transmission. We do not recommend filling the gearbox with oils with a lower or higher viscosity, as this will cause disruption to the operation of the gearbox and the entire vehicle as a whole.

When choosing a TM brand, you need to take into account the manufacturer’s recommendations, but it is also better to study forums and other information materials. Even when the oil specified by the car manufacturer turns out to be too expensive, it is better to choose it, since cheaper analogues can cost more due to the subsequent costs of repairing a breakdown of an expensive transmission. It is important to take into account the natural and climatic conditions in which the vehicle is planned to be operated.

The Gazelle is used year-round in different conditions, but if the transmission oil freezes, it will stop performing its main functions. Thus, you should try to select exactly the oil that will remain operational even at low ambient temperatures. If you live in northern regions with harsh winters, consult with car owners what kind of oil to pour into the Gazelle box. This will allow you to avoid mistakes that beginners usually make.

What kind of oil to pour into a worm gearbox

Rear axle gearbox

When choosing the oils that best suit your gearbox, at least 2 factors are taken into account:

Ambient temperature where the drive is operated;

Operating mode of the unit.

Considering the temperature regime, in the coldest climates, preference should be given to synthetic materials. Among these, the website “site” sells products of the following type: CA 2-100 and CA 2-100 Spray, which are resistant to sudden drops in temperature and aging; having universal application in gearboxes CA 2 series and others, manufactured by Kluberbio. At higher temperatures, oils based on mineral bases, such as the GEM line with modifications 1-46...680 N, which are resistant to any load, including wear and exposure to a humid environment, are better suited. All lubricants we offer have passed the necessary tests and meet special requirements for a number of properties and safety levels.

Also, the choice according to operating conditions is important, where you should pay attention to the load criterion before scuffing appears (at least 10-12, etc.)

This is interesting: Oil for pouring into hydraulic jacks - how and what to use

General instructions for replacing TM

Repair of the rear axle gearbox on a VAZ 2107

If you know which TM is right for you, then we suggest you familiarize yourself with the step-by-step instructions for changing the TM.

What will you need?

Before you begin the work process, you should prepare everything you might need, namely:

- hex wrench 12;

- syringe for collecting HM;

- rags;

- acetone;

- a container or tray for collecting used heavy metals;

- new TM (2 liters);

- one liter of engine or transmission fluid (for flushing the gearbox);

- 300 grams of kerosene or diesel.

You also need to find a place where you will change the TM. An overpass or a garage with a pit will do.

Step-by-step instructions for flushing the unit and replacing the substance

Before directly changing the TM, it is necessary to warm up the car so that the fluid in the unit is more fluid. After this, you can drive onto a pit or overpass.

Unscrewing the transmission filler plug using a hexagon

- First, you need to clean the gearbox breather from dirt and dust - for this we use rags and acetone.

- Then we climb under the bottom of the car, find your gearbox and, using a 12-mm hex wrench, unscrew the transmission fluid drain plug.

- Place a previously prepared container for draining the TM under the drain hole and wait 20-30 minutes until the liquid is completely drained.

- If the used consumables are dark in color or contain metal shavings, the unit must be washed.

- We screw the drain plug into place, having previously cleared it of dirt.

- Here on the side of the unit we find the filler plug and unscrew it using a hexagon.

- We take an oil syringe and use it to fill the unit with about one liter of oil (both transmission and engine oil will do) and about 300 grams of diesel fuel or kerosene.

- Then tighten the filler plug.

- Now you need to place stops under the front wheels.

- Next, turn on the first speed and turn on the engine for a few minutes, accelerating.

- Then we install the car on the wheels, climb under the bottom and unscrew the drain plug again, placing a container under it in advance.

Filling transmission oil into the gearbox using an oil syringe - We wait 10-15 minutes until the flushing liquid is completely drained.

- Once again you need to clean the hole plug and screw it into place with a hexagon.

- Now unscrew the filler plug and use the same oil syringe to fill it with new TM.

- TM must be poured until it flows out of the hole - at least 1.2 liters must enter.

- Screw the filler plug into place.

- We make a test trip, after which we need to check the unit for leaks.

Now you should know how much consumable material is needed for the box of your Gazelle, how to change it correctly and which TM is suitable for this. If you are not sure that you can carry out this process correctly, then it is better to seek help from professionals.

When to change

The replacement frequency is on average 50 thousand kilometers for cars with a manual transmission, and 30 thousand for an automatic one.

It is more often necessary to change the oil on cars that are used in difficult conditions, which include:

In a new car, it is recommended to replace it after the first 2-3 thousand mileage. The fact is that at the initial stage of work, new components undergo the so-called “grinding in”, which is characterized by increased formation of wear products.

Many car owners change the oil in the gearbox at the same time as the manual transmission, since both units use transmission fluid.

Be sure to check the level and condition of the oil in the gearboxes after purchasing a car on the secondary market. Usually, before selling, owners change lubricants only in places where they can be easily checked. Gearboxes are not one of these.

Front gearbox

Changing the oil in the front gearbox occurs according to the following steps:

- Place the car on the inspection hole.

- Unscrew the special plug using a hex screwdriver.

- Drain the necessary remaining transmission fluid into a special container.

- Unscrew the system plug using a special key.

- Using a syringe, draw a portion of new lubricant and carefully pour it into the system.

- Clean the breather on the crankcase housing.

- Tighten the drain plug with a hex screwdriver.

On average, 1.5 liters of oil is poured into the front gearbox system.

Oil level in rear gearbox

Before you start draining the waste fluid, you need to check its level. This can be done by installing the machine on an overpass or on a viewing hole

It is important to ensure that the surface is absolutely flat. Next, you need to unscrew the filler plug (it must first be cleaned with a wire brush)

When the oil spills out a little during this action, it means that there is enough working fluid and the plug has been closed absolutely hermetically. If the contents of the gearbox will not spill out, then you need to place your finger in the hole and run along the bottom edge. In the case when the liquid reaches this level, we can talk about the permissible norm. If the level drops below the edge, you should immediately find out the cause of the leak and eliminate it before changing the oil. First of all, it is worth determining whether the seals are leaking - this is the most common cause of leakage. You can detect a leak by simply inspecting the seals. They may have oily stains.

When pouring later, it is advisable not to pour too much. Since the pressure in the gearbox increases when driving, fluid pours out through the breather. In addition, the efficiency of the gearbox parts will be negatively affected, and a sufficient amount of oil mist will not form in the sealed cavity.

How to change the oil in a VAZ gearbox

There is a periodic replacement of fluid for the VAZ 2107 gearbox twice a year, which is indicated in the vehicle maintenance card. For this purpose, transmission oil is used. It is necessary to replace it before operating the car in summer or winter. It is advisable that the replacement be made after the trip, since the fluid will be hot, which will ensure its better drainage from the crankcase. The temperature of the oil drained after driving the car can be 90 °C.

A special container is prepared to drain the waste liquid. Unscrew the drain plug on the bottom of the crankcase and screw it back when the liquid has already been drained. The gearbox first washed to begin filling it with new lubricant. If the color of the drained liquid is black, it means it contains metal filings, which indicates a faulty condition of the gearbox.

To troubleshoot the gearbox, it is removed and repaired. Flushing is carried out using oil that has a high viscosity, for example, spindle oil. About a liter of working fluid needs to be poured into the gearbox. Then one rear wheel should be aligned and the engine should be started, engaging first gear. A minute after turning off the engine, flushing is carried out. Next, the hole plug is unscrewed, and new lubricant is pumped into the gearbox with a special syringe.

It is necessary to ensure that the normal level of lubricating fluid at the lower edge of the filler neck is correct. When the gear oil is filled, tighten the plug to check the breather. It must be in good condition, since its function is to relieve excess pressure in the gearbox, which is formed when the liquid is heated.

How much oil is in a Gazelle Bridge ~ SIS26.RU

How much oil is in a Gazelle box?

how much oil

Indeed, there are technical parameters, it would seem, how much oil is not only in the box, but also in other units with which the gazelle is equipped is quite understandable, but in fact, this is a little wrong.

From the manufacturer’s point of view, all the necessary volumes are well documented, for example, the Gazelle 406 cooling system will hold exactly 11 liters (if it has not been modified), and

How much oil a gazelle will use in the gearbox can only be found out at the service center when replacing it.

Let's try to figure out how much oil is in a gazelle box, and at the same time let's try to figure out which oil is better.

Why does the oil volume in a gazelle gearbox depend, and why are the numbers different?

In fact, according to technical data, the oil volume in a gazelle gearbox ranges from 1.2 to 1.6 liters, depending on the modification. But not everyone is aware that the gearboxes themselves differ even within the same version of the gazelle, and that is why the oil volume can vary within certain limits. In fact, no matter how much a new gazelle costs, the box on it will be one of three. And regardless of the other data, 2 liters for changing gearbox oil is enough for all options.

Fluctuations in volume depend on the number of gears, the size of the drive gears and some other factors; ideally, the volume approximately corresponds to what the manufacturer claims. But don’t be surprised if the service asks you to pay not 1.6 but 2 liters. You won't get rich with 400 grams of oil, even if it is very high quality oil. Speaking of oil, what is the best oil for gazelles?

Changing the oil in the GAZelle rear axle gearbox

Changed the oil

in the rear

axle

after 20 thousand km in Grand Starex

https://youtube.com/watch?v=2BB7tLEhXx0

Changing the oil in the rear axle gearbox on a gazelle (part 1)

Subscribe TO - Follow Instagram.

A few notes on choosing oil for gazelles.

When servicing a gazelle yourself, there are several operations, for example, replacing the rear spring with a gazelle, during which, among other things, you can also service the rear axle (which will never be superfluous), and some particularly advanced “specialists”, realizing how much oil is in the gazelle axle, purchase one 4-liter canister directly to the checkpoint and bridge. This, of course, allows you to save money, but it is the wrong decision.

Firstly, there are manufacturer recommendations, and you should not neglect them. If GAZ recommended gearbox oil with certain characteristics, you can purchase a more expensive and high-quality oil, but not a cheaper one.

Secondly, the gearbox and the bridge operate under completely different conditions, both in terms of load and thermal conditions.

Thirdly, if the crankshaft can turn the gearbox shaft in cold weather, even if the oil has “frozen,” then the gearbox will definitely not be able to “turn” the axle.

What does it mean? This means that gearbox oil must be more durable, less viscous and resistant to sub-zero temperatures. Seems obvious. But axle oil should be even more frost-resistant and at the same time more viscous. There is no paradox here - these are units that work in the “counter direction” and we must keep in mind that the start of the checkpoint is not the start of the “bridge”, and a beautiful canister is not always a good thing.

This is why gearbox oils must be chosen not from brands (it doesn’t work for a gazelle - we don’t have the same clearances yet), but from experience. Search forums on the Internet, chat, many will not refuse advice for a specific gearbox and mileage figures, and at the same time they will tell you which oil to choose for the axle. Well, if you find a colleague with exactly the same car, he will tell you exactly how much oil you need to pour into the gearbox.

Oh yes. When changing the gearbox oil, do not forget to leave exactly what you filled in for topping up - half a liter (or better yet, a liter, so that it will last for a long time). After 3-5 thousand kilometers you will have to top up, and it’s better to top up exactly what you filled in.

Which oil is better to choose?

In the gearbox of the above car, the transmission fluid does not change as often as in the engine. The manufacturer recommends that consumers change the fluid less frequently than once every 4-5 years or every 75 thousand km, whichever comes first. According to Gazelle car owners, it is better to replace the fluid every four years or more often, or once every 60 thousand kilometers. In practice, the fluid in the gearbox deteriorates and loses its properties more often, so experts recommend replacing the fluid more often than recommended during operation and undergoing many tests. And the gearbox itself very often suffers from this. This unit has a particularly difficult time when the car owner fills in a product that is of poor quality or does not meet the technical parameters.

So which oil is best to choose for your Gazelle? This question was probably asked by every happy owner of a Gazelle car. And not in vain, because the optimal operation of the unit depends on the properties and characteristics of the TM in the gearbox. Unfortunately, the car manufacturer does not give clear recommendations on which brand of TM should be filled. However, the instruction manual states that the fluid viscosity marking should be “SAE 75W”.

Gazelle car gearbox removed

When choosing a TM, several factors should be taken into account:

- First of all, these are recommendations from the specialists of the automobile concern. You should not ignore the recommendations. If experts advise pouring a TM with certain properties, then it is better to buy a more expensive TM.

- Even with a frozen TM, the car’s crankshaft will be able to turn the gearbox shaft, but the gearbox itself will definitely not be able to turn the axle, so the fluid must be resistant to negative temperatures.

In practice, most car enthusiasts fill their cars with “Total 75W-80” . The latter brand of fluid is the most common when purchasing for replacement. This TM is mineral and has the following technical characteristics:

- the viscosity indicator at an engine operating temperature of 100 degrees is 8 mm2/s;

- the viscosity indicator at an engine operating temperature of 40 degrees is 49 mm2/s;

- the density of the consumable material is 877 kg/m3 at a temperature of 15 degrees;

- the pour point of the liquid is -45 degrees Celsius ambient temperature;

- the ignition temperature of TM is 208 degrees.

One and a half ton truck GAZ-3302

There were practically no small commercial vehicles in the USSR, and of the relatively small trucks in the Soviet Union, only the GAZ-AA “lorry” was produced. But by 1950, production of the legendary truck was discontinued; subsequently, cargo was transported only by vehicles with a carrying capacity of at least two tons, and the dimensions of such vehicles were impressive. The need for transportation of small consignments of goods and cargo arose with the development of the market in Russia; the first in the class of light commercial vehicles (LCV) was the Gazelle.

At first, the one and a half ton GAZ-3302 vehicles were equipped with ZMZ-402 (Ai-92) and ZMZ-4021 (A-76) engines, mechanical 4- and 5-speed gearboxes, and a “Tchaikovsky” rear axle. The cabin was designed for three people, including the driver; the lorry could be equipped with an awning, which all on-board vehicles were equipped with from the factory.

The four-speed gearbox was frankly weak for a light-duty truck, and by 1996 the plant stopped installing them; cars were now equipped with only a 5-speed gearbox. Manual transmission. Also around this time, a bridge of its own design was developed for Gazel, and the Tchaikovsky (type GAZ-3102) was removed from the production line. In 1997, the car went into production with a carburetor 110-horsepower internal combustion engine ZMZ-4063.10.

In the entire history of its existence, the GAZ-3302 was restyled only twice - in 2003 and 2010, and since 1995, the all-wheel drive truck 33027 has been produced. In the last year of the pre-restyling version (2002), the production of vehicles with an extended frame began, the chassis received the index 330202. Although the vehicle's carrying capacity remained almost the same, it was already possible to transport long loads on a vehicle with an extended body. The technical characteristics of the GAZ-3302 (model 1994-2003) are as follows:

- number of doors – two;

- number of passenger seats (including passenger seat) – 6;

- body type – pickup;

- load capacity – 1500 kg;

- wheelbase – 290 cm;

- curb weight – 1600 kg;

- rear/front wheel track – 156/170 cm;

- maximum weight of a loaded vehicle (total weight) – 3.5 tons;

- dimensions (length/width/height) – 5,120/1,970/2,120 m (height is taken from the cabin, excluding the awning);

- ground clearance (clearance) – 17 cm;

- wheel rim radius – R16;

- tire size – 175/80;

- gas tank volume – 60/70 liters, depending on the vehicle modification;

- front/rear suspension - dependent, on leaf springs.

It should be noted that the first Gazelles were equipped with 60-liter plastic fuel tanks, and only later they decided to install 70-liter metal gas tanks. On the rear axle of the onboard GAZ-3302 there are two ramps on each side, the rear axle is mounted on springs.

Modifications of the UMZ engine ;”!:

Unit “421600” is the basic power unit of the series. There are negative aspects, but the engine is popular and in demand among owners of Gazelle cars. The base itself has a number of distinctive features that affect the set of auxiliary equipment. Thus, engines “4216.100402” and “42161.1000” are supplied with the old mount, the second motor is used on Economy class cars. For engines with brackets for a hydraulic-based power steering wheel, the marking looks like “...1000402.10”. The modification with new fasteners is marked “...1000402.20”.

Recommendations

Better then ENEOS GEAR 75W-90 GL-5, the oil has been tested - the flight is excellent!

Lukoil 75w90 normal flight

And if it’s also in a company store, then in any case it’s better than any castrol and zekov. I use Lukoil myself

Well, yes, cheap oils are less likely to be counterfeited. I have semi-synthetic in the Lukoil engine and in the gearbox too. At -40 it starts, the engine is clean, what else is needed))) The only thing I do in severe frosts is press the clutch, well, it doesn’t bother me)

Yes, yes, but I wouldn’t say that Lukoil is cheap?!

Well, there are cheaper ones, but I chose this oil as optimal for myself, specifically I pour Lukoil Lux into the engine, 5w40 in winter, 10w40 in summer

I would stay on Castrol. If you want cheaper, then TNK. I don’t recommend Lukoil to the bridge, for some reason it makes noise.

Why is the bridge with Lukoil noisy? I'm fine.

I don’t know. After TNK I added onions because... there was no money and the bridge began to rustle immediately

Strange? Everything is fine with me, but where did you get the oil?

Not at a gas station. Maybe that's the problem.

We also took it at a gas station and everything was fine, but then we took it in the store for comparison and it froze at -30

Stay on camtrol or mobile. As a result, it will cost less if they are replaced

The main thing is that it is GL-5 and not lower.

ZIC G-FF 75W85 - this ZIC is for the gearbox, it does not fit in the rear axle. For the rear axle you need this ZIC G-5 80W-90.

TNK semi-synthetic, hypoid GL-5 75W90

Well, TNK is not a bad oil either.

Zeke. We poured it personally into 4 or 5 bridges. After a maximum of 3000 km it turned brown (not whitish, without water). I filled some with TAD 17, and some with Lukoil p/s. The tank itself is flooded. Problems arose for the first time (on the street -35 and below). I didn’t bother with the expensive stuff; I had to cross the bridge anyway. I don’t skid right away when it’s cold, I don’t accelerate sharply and I drive slowly until the oil warms up everywhere. A friend drove a TAD for 100k km+ and had no problems at all. After the bridge is repaired, I’ll also flood the TAD - cheap and cheerful

Well, why are you perverted? The Volga Bridge was designed in the 60s. What kind of oil was there back then? That's right, nigrol! Pour TAD or TM and don't worry, it won't do anything for him. Well, it's OK to add. The Volga is good because it eats all sorts of things. I kept a Volga for five years, I was in the TM bridge and didn’t know what a bridge was.

then you need to pour Autol M-8 into the engine, it digests everything))) In the presence of modern normal oils, is it necessary to pour some kind of shit?

Again, no need to go crazy. What does the engine have to do with it? My friend has a 406. And the 406 is designed for other oils. I ran the 402 on mineral water. TNK I agree in the cold TM is not an option, but the questioner does not live in Khanty-Mansi Autonomous Okrug,

Gazpromneft 8590 price around 170 liter

All-metal van Gazelle Next

NEW IN GAZELLE NEXT VAN

- All-metal body with Next style design; the volume of the cargo compartment and the openings of the side and rear doors have been increased

- Completely renovated interior

- The frame with reinforced cross members and additional amplifiers is designed for a total vehicle weight of up to 4.6 tons - so the safety margin of the 3.5-ton GAZelle is large.

- Diesel engine Cummins 2.8L; torque increased from 270 to 330 Nm, power - from 120 to 149 hp.

- ZF Sachs driven disk with a diameter of 280 mm - for transmitting increased torque

- Gearbox with modified front and rear crankcases, additional shaft support, reinforced ring gears, bearings with higher load capacity, imported synchronizers in first and second gears; remote gear shift drive (joystick)

- Cardan shaft with flange mounting to the gearbox and splined longitudinal movement compensator

- Rear axle with reinforced axle shafts and drive gear bearing

- Independent double wishbone front suspension; elastic element - springs

- Rear suspension with new suspension and shock absorber mounting to the frame cross member

- Rack and pinion steering with hydraulic booster

- 80 liter plastic fuel tank

Checking and changing the oil in the gearbox and rear axle of GAZelle Next

The oil level in the gearbox and rear axle must be checked every 20 km of the vehicle.

It is recommended to change the oil after sixty kilometers of the vehicle.

Brands of oils poured into gearboxes and gearboxes

At temperatures from -25 to +40˚ C Lukoil TM-5 oil SAE 85W-90, API GL-5.

Duplicating oils: “Super T-3 (SAE 85W-90, API GL-5 or TM-3-18 SAE 90, API GL-3.

At temperatures from -40 to +25˚ C, Lukoil TM5 SAE 75W-90 oil.

The volume of oil poured into the rear axle gear housing is 1.65 liters.

The volume of oil poured into the gearbox is 1.2 liters.

Checking the oil level in the rear axle

We place the car on the inspection ditch.

Unscrew the filler plug. We check the oil level, which should be at the lower edge of the filler hole.

The requirement that the oil level be no lower than the edge of the filler hole is explained by the fact that the rear hub bearings are lubricated with transmission oil from the rear axle housing.

If the oil level in the crankcase is low, it will not flow through the crankcase stockings into the hubs and the bearings, working without lubrication, will fail.

If necessary, add oil with a syringe until it comes out of the hole.

We wrap the filler plug.

About level control

The lubrication level of the unit is checked after every 20 thousand km. This must be done even when no visible leaks are detected. If the lubricant level drops for some reason, transmission oil is added to the gearbox housing.

The operating instructions for GAZelle cars do not indicate a specific volume of lubricant to add to the gearbox, since depending on the modification of the car, the amount of oil can be in the range of 1.2-1.6 liters. Therefore, we recommend purchasing liquid in a 2-liter canister; any excess will be useful for refilling.

Before you start checking the fluid level, you need to thoroughly clean the breather, its cover and the nearby surface of the gearbox housing, after which you should turn the plug several times. The amount of lubricant is located at the lower edge of the filler hole, so cleaning it from dirt is extremely necessary.

Let's take a closer look at the process of monitoring the oil level in the gearbox of a GAZelle car:

- You only need to check the quantity when the gearbox is warm. To do this, it will be enough to drive 10–15 kilometers.

- The machine should be installed on an overpass or inspection hole; even a slight tilt in the horizontal plane is unacceptable.

- It is necessary to allow the lubricant to drain from the walls to the bottom of the crankcase. During this time, use a rag to thoroughly wipe the filler hole cover, which is also a control hole.

- You need to unscrew the plug and observe the hole. If a thin stream of lubricant flows through it, this is not evidence of a normal oil level. Next, you need to add fluid to the gearbox using a syringe and check again.

- Stopping the flow of lubricant after topping up will indicate a normal fluid level in the system.

- You can now tighten the plug and continue operating the vehicle.

Important! You only need to add lubricant to the car’s gearbox of the same type that was previously filled.

It is unacceptable to operate the car with a low oil level in the gearbox of the Gazelle Next and other models. Since insufficient volume can cause air pockets, which will affect the amount of lubricating fluid supplied to the gears and bearings of the gearbox.

Drain and filler plugs

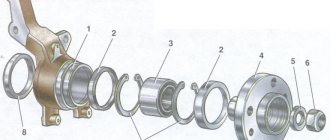

Rear axle differential Gazelle NEXT gear type. The differential box consists of two parts, left and right. They are bolted together. The driven gear is bolted to it. The differential box contains two semi-axial gears and four satellites that are in constant mesh.

Thrust washers are installed between the differential box and the ends of the semi-axial gears and satellites. The satellites rotate around axles, which fix each other in the differential box using recesses in the central part.

Rear axle Gazelle NEXT with Cummins ISF2.8 engine in section. Main components and parts.

Tapered roller bearings are pressed onto the axles of the differential box. The beam housing contains seats for the differential bearings and the adjusting nuts for the differential bearings.

The Gazelle NEXT rear axle differential, complete with driven gear and bearings, is attached to the gearbox housing with two bolted covers. At the factory, the crankcase housings and bearing caps are machined together, so the caps are not interchangeable.

Adjusting nuts provide the necessary lateral clearance between the main gear gears and preload of the differential box bearings. The adjusting nuts are secured against movement by locking plates, which are bolted to the bearing caps. The axle shaft with its splined part is installed in the axle gear.

Rear axle hub Gazelle NEXT with Cummins ISF2.8 engine.

The outer part of the axle shaft, made in the form of a flange, is attached to the rear wheel hub with nuts or bolts. Studs are pressed into the hub to secure the wheels and brake drums. The inner and outer bearings are adjusted and fixed in the axial direction using an adjusting nut with a locknut. Behind the inner bearing, a seal is pressed into the hub.

Transmission oil used in the Gazelle NEXT rear axle with a Cummins ISF2.8 engine.

The following gear oils are recommended for use in the Gazelle NEXT rear axle with a Cummins ISF2.8 engine:

At temperatures from minus 25 to plus 40 degrees, the following is poured into the Gazelle NEXT rear axle:

— Transmission oil Lukoil TM-5, SAE 85W-90, API GL-5.