A creaking sound in the front suspension when turning the steering wheel can cause a lot of concern about the condition of the car. Owners associate extraneous noise in vehicle components and assemblies with the approach of imminent repairs associated with significant material costs. It doesn’t matter whether it’s a squeak when driving, knocking in the engine compartment, in the transmission area, or any other part of the car. Do not panic about this and immediately go to a car service center. First, you need to perform a visual diagnosis of the node that is suspicious; it is quite possible that there is no cause for concern as such.

In this publication, we will consider the causes of knocking noises from the front suspension, since most motorists consider their occurrence to be a dangerous phenomenon (this should not be ruled out). Let's start analyzing everything in detail.

Is the squeak really that bad?

Drivers who consider the occurrence of extraneous noise in the suspension area to be a harbinger of a serious malfunction, in most cases, turn out to be right. In reality, provided that the unit is adjusted correctly, extraneous sounds should not appear at all. Note that the source of the squeak can be any element of the chassis, especially this phenomenon occurs due to the friction of parts at the points of their contact. Often, such problems occur on cars with high mileage. However, various types of noise can also occur in the components and assemblies of a new vehicle, which are the result of either improper operation or adjustment, or serious breakdown.

For example, when driving on a highway at a speed not exceeding 100 km/h, a creaking noise may occur in the front suspension when turning the steering wheel, and its character is different each time. Note that in this case, its appearance is not always characterized by the presence of damage, since in most cases the occurrence of extraneous noise from the front suspension is associated with the poor condition of the road surface, which causes an imbalance of its elements and they begin to “hum.” Most car owners mistakenly consider these sounds to be the source of serious problems.

Results

Let's summarize our work: the spring package is tightened evenly with clamps with the necessary clearance, the sheets are coated with grease among themselves, new anti-squeak washers and silent blocks with bushings are installed. The result is the absence of squeaks and rattles, as well as almost professional knowledge of spring suspension problems.

Thus, from a fairly large list of reasons for the appearance of extraneous sounds in springs, the problem in each case is determined individually after inspection and diagnosis.

We hope your springs are not the source of your headaches, but if you need help, our company can fix your spring problems in no time. We always offer several solution options, from the most budgetary to complete overhaul of the spring suspension.

Reading time: 8 minutes

Many car enthusiasts who have been driving for several years often encounter the problem of extraneous noise produced by their wheels. The most common complaint to mechanics at service stations is the situation when a wheel squeaks when driving at low speeds, and there is always a logical explanation for this problem, as well as methods for eliminating the shortcomings.

What can squeak in the rear and front suspension?

There is no definite answer to this question, since any part, regardless of its condition, can produce various noises. The interaction of suspension elements with the vehicle body causes extraneous sounds that change depending on the trajectory of movement. Often, various noises are produced by CV joints, bearings, shock absorbers, springs and parts of the brake system.

Let's move on to analyzing the occurrence of noise in the suspension. First, you should pay attention to its levers. Due to the presence of any defects or damage to these parts, a sound of a different nature occurs. Very often silent blocks fail. This breakdown is also accompanied by the occurrence of oscillatory movements of the steering wheel. It would seem like an insignificant breakdown, but it can lead to tragic consequences, since it causes loss of vehicle controllability.

When carrying out visual diagnostics of suspension elements, it is necessary to pay attention to the tie rod ends, since they cause serious play in the steering wheel. Very often, a squeak in the front suspension is evidence of wear on the ball joints; in this case, their replacement is recommended. These elements regulate the rotation of the front wheelset and are subject to constant high loads, so they must always be in good condition. If they are not replaced in time, the car may become uncontrollable while driving.

If the outer CV joint is damaged on bumps and when entering a turn at medium speed, you can hear a distinct grinding noise, which may additionally be accompanied by a cracking sound. When inspecting it, it is worth paying attention to the condition of the rubber boots, which prevent dirt from penetrating into the mechanism, which significantly accelerates the wear of the hinge.

Despite the presence of many different elements in the suspension design, most often the source of external sounds is the shock absorber. The part loses its performance characteristics and begins to make noise for the following reasons:

- insufficient level of working fluid or gas;

- development of valves;

- piston wear;

- damage to seals, springs and rods.

A faulty shock absorber makes itself felt when driving on a poorly paved road, when the vehicle simply begins to roll from side to side. If such a problem is detected, it is necessary to immediately take measures to eliminate it, since further normal operation of a vehicle with damaged elements is out of the question.

An effective measure for detecting malfunctions of suspension components is periodic preventive inspections (at least 2 times a year).

Causes of characteristic knocking noise when turning the steering wheel and their elimination

The control mechanism of a car is damaged, as a rule, due to two things: frequent off-road driving and water getting inside the rack. However, other problematic factors are also known. Let's look at them in more detail below.

This is one of the most common causes of knocking. The wheel arch protective cover, made of plastic, becomes loose and begins to knock. Experienced drivers easily distinguish it from other sounds, as the plastic knocks characteristically. The solution to the problem is quite simple - you need to firmly fix the plastic element, which will take no more than a couple of minutes.

Steering faults

The steering system includes many different components, each of which can fail. Most often the following parts of the rack make themselves felt:

- plastic support sleeve - when worn, play appears on the steering wheel;

- shaft bearings, which also cause backlash if damaged;

- an increase in the gap between the teeth, which is accompanied, in addition to backlash, by dull knocks during rotation;

- steering cardan - tends to fail on SUVs due to an increase in the gap in the spline connection;

- anti-friction gasket - when it fails, the pressure pad begins to vibrate, making a knock directly on the rack body.

Power steering (power steering)

Steering systems with power steering often have problems associated with fluid leaks or pump damage. In the event of a breakdown, the driver will feel not only an increase in effort and a tight steering wheel, but also a regular decrease in the fluid level, knocking, and a strong hum when turning. When moving along a straight path, front-wheel drive cars will “fidget” on the road and wobble.

Usually the power steering system begins to knock in late autumn, when it gets colder. The reasons are different, perhaps the belt is simply not tensioned sufficiently. But more often silent blocks and bearings are damaged.

Power steering problems, when clicks are heard when turning the steering wheel:

- the pump is damaged;

- decreased fluid level;

- air has entered the system;

- the belt is loose.

CV joint and wheel bearings

If the grenades are damaged, an unpleasant metallic grinding sound appears when the steering wheel is turned completely to one or both sides.

As a rule, the malfunction of the hinges is associated with a rupture of the boot, which protects the parts from dirt and moisture. Even a small crack is enough to require replacement of these elements of the car's chassis.

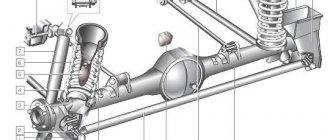

Suspension faults

This includes various defects. For example, this could be damage to the shock absorber strut or support bearings. In this case, the knocking intensifies when cornering, especially at high speeds, since additional load is placed on the parts. Excessive force initially causes the spring to break. As a rule, this happens at the top or bottom, at the extreme points of the damper.

The stabilizer bar may also be partially damaged and begin to make dull knocks when the wheels turn while driving. You can forget about a comfortable ride until the problem is solved, since the car will wobble along the road, requiring constant control by the steering wheel. The body will also begin to roll and shake heavily when braking or maneuvering.

Unusual causes of steering wheel knocking

Sounds in the steering wheel can also begin due to atypical cases. For example, as mentioned above, this could be a stone hitting the subframe. It gets stuck there, causing the steering components to naturally move as you turn one way or the other. The knocking occurs when the original position is restored, when the elements jump off the stone when the steering wheel rotates back.

Non-standard situations also include:

- deterioration of rubber silent blocks of the suspension and ball joints, which is why, due to the misalignment of the lever, a characteristic knocking sound may occur when turning the steering wheel;

- wear of steering tips and rods due to natural wear and tear, which creates play, creaks and knocking when turning - for diagnostics it will be enough to jack up the car on the side where the noise is coming from;

- the fastening nut between the steering wheel and the tip may be loosely tightened - as a rule, this happens after the wheel alignment procedure, when the master simply forgets to tighten it sufficiently;

- The front hub bearing, if it fails, can also cause knocking and poor control, so when replacing the bearing, you need to tighten the nut more tightly.

Troubleshooting Techniques

The rubber creaking of the suspension while driving indicates damage to various oil seals, anthers and protective covers. These parts are not repairable, so only replacing them can save the situation. When inspecting the vehicle's chassis, it is necessary to pay attention to the presence of mechanical damage and the degree of natural wear of all rubber elements.

Diagnostics of shock absorbers

The problematic components of the suspension are shock absorbers, which quickly fail due to the unsatisfactory condition of the roads. A properly functioning part should not have any oil leaks, and when the vehicle rocks, the shock absorber should dampen vibrations. Note that these signs appear first, in contrast to third-party noises when the car rocks, and are direct evidence of the failure of the shock absorbers. In this condition, the mechanism can still work for some time, but it is better to replace it immediately.

You can check the shock absorber like this:

- Remove the part from the car and inspect the condition of its upper and lower fasteners.

- Place the shock absorber in a vertical position.

- The performance of a shock absorber can be assessed by acting on its rod. If the resistance when moving the rod down is significantly less than when it moves up, then the mechanism is working properly.

- Free movement of the rod can be caused either by the penetration of air into the part or by a loss of liquid or gas level. In this case, oil leaks are clearly visible on the shock absorber body.

You can slightly extend the life of the shock absorber by replenishing the level of working fluid in it. However, such a measure will only have an effect if its body is intact. In addition, you can replace worn out parts of the mechanism.

Checking the condition of the springs

Sagging springs also negatively affects the performance of the suspension. This is caused by their natural wear due to the aging of the metal. To verify this, you do not need to carry out complex diagnostics. You just need to walk around the car and pay attention to its position. If the springs do not perform their function, the vehicle's ground clearance will be significantly reduced. Please note that camber adjustment cannot be performed on a vehicle with sagging springs.

Diagnostics of ball joints

Checking the lower suspension arms will show the condition of the ball joints. It is most advisable to carry it out by lifting the car on a lift, or using a pit. Using a pry bar, you should carefully press the silent blocks located on the lower arms. If they are in good working order, there should not be even the slightest play. And their rubber parts do not have any damage (cracks, abrasions, dented places).

Ideally, check the silent blocks and ball joints on a lift, or by jacking up the front of the car. After this, you need to unscrew the support mount from the lower arm. Next, we rotate its body to assess the condition of the ball. Evidence of its serviceability is the complete absence of play and the free, effortless movement of the body. Due to the elasticity of the rubber parts of the silent blocks, the lower arm should always be in a horizontal position.

Inspection of silent blocks

Determining the presence of production of these elements is quite simple. To do this, you need to swing the opposite rods from side to side. The presence of play in them is a harbinger of component failure. In this case, it is better to replace them immediately, since further operation of the vehicle with damaged silent blocks has an extremely negative impact on the performance of the suspension.

Why do springs break, symptoms of failure?

The spring looked almost new

The working environment of the suspension spring can be called complex, so during operation it is easy to damage the protective coating of the coiled body of the element and expose the steel, which can very quickly begin to corrode under the influence of salts. But most of all, the spring element suffers in winter, when water, salt and sand get between the coils, which leads to its damage.

Typical symptoms of a broken suspension spring:

Irregular knocking and vibration on uneven surfaces; Characteristic dull impacts when turning the wheels hard or braking heavily; There is a difference in the height of the machine along the longitudinal axis (the left side is higher than the right, and vice versa) or between the front and rear parts; Strong rolls when driving and braking

Conclusions that suggest themselves

As you can see, there are plenty of reasons for the occurrence of third-party noise in the front suspension area. However, most of them do not pose any danger to the further operation of the vehicle. Despite this, experienced auto mechanics advise carrying out a full diagnosis of all elements of the chassis when noise occurs in the suspension area, because only during this process can the condition of all component components be fully assessed.

Restoring the front suspension is not difficult, so any car owner can independently carry out repair work, during which damaged parts will be replaced.