Clear signs that the engine is sucking air, how to detect and fix it yourself

Hello, dear readers!

I think you know how an injector works in brief. It automatically makes the air-fuel mixture. Thanks to the sensors, the system works perfectly. If the sensor fails, the system malfunctions and the engine begins to “trouble.”

And if all the sensors are working properly, but the engine is still not working correctly, what could it be?

The most popular reason is air leaking into the system.

Air that does not pass through the mass air flow sensor is called unaccounted for. Accordingly, the engine will no longer work properly.

Signs that the engine is sucking air are:

1. Unstable operation at idle.

2. Dips when starting to move.

3. Cravings have gotten worse.

4. Fuel consumption has increased.

5. The Check light may be on.

As a rule, the main symptom is unstable engine operation at idle.

How can I find out on my own where the air is leaking?

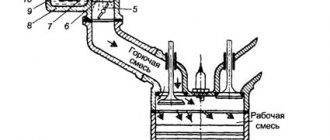

There is special equipment called a smoke generator device. Its principle is that smoke under pressure is released into the system and it begins to escape from the place where the system is not sealed.

Most often, this happens at the installation sites of injectors or sensors. As a rule, the problem is solved by replacing the O-rings. Over time, they become stiff and air begins to leak.

You don’t have to buy a smoke generator; it’s quite easy to make it yourself. Look what we need for this:

Plastic container, cigarette, two tubeless nipples, compressor for inflating wheels, hose.

We cut tubeless nipples into the container on both sides. We leave the spool on one side.

We connect the second hose to the intake manifold:

The mass air flow sensor should be removed and the air supply closed. You can use anything for this, say a package. In this case, a balloon was used.

Now we light a cigarette and insert it into the hose, close the lid and turn on the compressor:

It remains to be seen where the smoke will come from:

This way, you will know exactly where the air leak occurs and where the depressurization occurred.

We fix the problem, check it again with a smoke generator and are glad that we repaired the car ourselves.

Source

Air leaks in the diesel fuel system

In the fuel system of a diesel engine, airing occurs, as a rule, due to a leaky joint of the low-pressure fuel system pipes (from the tank to the filter and from the filter to the injection pump).

Cause of suction on a diesel car

Air leaks in a leaking fuel system occur because the atmospheric pressure is higher than that created when the pump sucks diesel fuel from the tank. It is almost impossible to detect such depressurization by leakage.

On modern diesel engines, the problem of air leaking into the fuel system is much more common than on older diesel engines. All through changes in the design of the fuel hoses, since previously they were made of brass, but now they make plastic quick releases , which have their own service life.

Plastic, as a result of vibrations, tends to wear out, and rubber sealing rings tend to wear out. This problem is especially pronounced in winter on cars with a mileage of more than 150 thousand km.

The main reasons for suction are often as follows::

- old hoses and loose clamps;

- damaged fuel pipes;

- loss of seal at the fuel filter connection;

- the tightness in the return line is broken;

- The seal of the drive shaft, the axis of the fuel control lever or in the fuel injection pump cover is broken.

In most cases, there is a banal aging of rubber seals , and the fuel system can become airborne if any of the branches, both forward and reverse, are damaged.

Signs of air leaks

The most common and common problem is that in the morning or after a long period of inactivity, the car stops starting quickly and you have to crank the starter for a long time (at the same time there is a little smoke coming from the exhaust - this will indicate that fuel is entering the cylinders). A sign of a large suction is not only a difficult start, but also when driving it begins to stall and stall.

This behavior of the car is due to the fact that the fuel injection pump does not have time to pass foam through itself only at high speeds, and at idle it cannot cope with the large amount of air in the fuel chamber. To determine that the problem in the operation of a diesel engine is related precisely to air leaks, replacing the standard tubes with transparent ones will help .

How to find a leak in a diesel fuel system

Air may be leaking in a connection, in a damaged tube, or even in the tank. And you can find it by elimination, or by applying pressure to the system to release it.

The best and most reliable way is to find leaks by elimination: to each section of the fuel system, connect the diesel supply not from the tank, but from the canister. And check one by one - immediately connect to the injection pump, then connect before the sump, etc.

A faster and easier option to determine the location of the leak would be to apply pressure to the tank. Then, in the place where the air is sucked in, either hissing will appear, or the connection will begin to get wet.

How does air leakage affect the operation of the VAZ 2114 engine?

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Good afternoon! I want to look for air leaks in the engine this evening. According to all the symptoms, he is there somewhere. The question is by what means to look for it and in what places? Maybe later this information will be useful to someone, but first of all to me. This leaves three questions: 1. Where are the most likely places for air leaks? 2. How to determine (diagnose)? 3. How to treat?

One of the ways you buy carb cleaning fluid. and carefully water all the joints, if the speed starts to float somewhere, then there is a hole there

Just don’t pour on the release or you’ll burst into flames.

You can water it with something flammable - revs up means suction here, enrichment is not provided.

A different approach to determining air leaks

An effective way to determine air leaks is to measure the level of vacuum in the intake system, i.e. in the behind-the-scenes space. Ideally, these indicators should be below 300 mmHg.

Measurements can be taken by removing the hose that connects to the valve that controls the damper

air circulation inside the car. The question immediately arises: what instrument to take measurements with?

To do this, it is recommended to visit an auto parts store, where you will be offered a large selection of such devices. In principle, this can be done using any suitable device, but you need to take into account its operating range.

Consequences of air leaks

An air leak will cause unwanted air to enter the engine where it is not intended. This reduces engine performance and causes some systems that rely on vacuum to malfunction.

Because air leaks cause engine inefficiency, you will notice the "Check Engine" light on your dashboard. You will also experience acceleration problems - this is because fuel is not delivered efficiently to the combustion chambers. Vacuum is used to operate actuators, sensors or brakes.

If there is a vacuum leak, some of the sensors may begin to malfunction, forcing you to make unnecessary repairs.

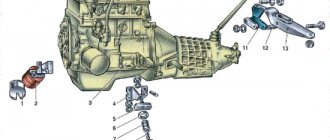

Places where there may be suction

Air leakage can be anywhere where it passes to the combustion chamber, be it the intake corrugation or the receiver. There are several places where system depressurization occurs quite often.

Places of possible suction:

- Joints of the corrugation with the sensor and throttle assembly;

- Idle air control;

- Small breather;

- Vacuum brake booster;

- Absorber tubes;

- Injector rings;

- Intake receiver gaskets;

All of the above places are prone to air leaks in the VAZ 2114 system and if leaks are suspected, it is necessary to inspect these particular suspicious places.

Briefly about each place

Corrugated joints

The corrugation is connected to the throttle assembly and the mass air flow sensor through a clamp; sometimes this clamp may not provide reliable tightening, which leads to suction.

RXX

The idle air control is installed in the remote control through an o-ring, which ensures the tightness of the system. Often this ring loses its properties and begins to let air through.

It should be noted that the IAC is installed only on cars with a mechanical throttle.

Breather

The small breather communicates with the intake corrugation through a clamp; relaxation of this clamp leads to possible air leakage in front of the throttle assembly.

VUT

The vacuum brake booster is connected to the intake receiver through a special hose, which can become damaged and begin to let in unwanted air; also in the VUT, the membrane and intake fitting are often damaged, which leads to air leaks through the brake booster.

Injector rings

To seal the junction of the injectors with the cylinder head, special rubber rings are used, which ensure reliable tightness of the system and prevent its depressurization. Due to high temperatures, rubber rings tend to lose their elasticity and become rigid, which leads to air leakage through them.

Receiver seals

The plastic receiver is connected to the cylinder head through rubber sealing rings that adhere to the surface of the head. Due to high temperatures, they lose their properties and begin to let in excess air.

Engine Inspection

To identify air leaks, you must first understand how the engine intake system works.

Air enters through the air filter. The throttle valve controls it by creating a vacuum. Know that a car is leaking air when it makes a hissing sound after starting.

Vacuum hoses wear out during operation and become brittle. This leads to their damage. Carefully inspect the hoses on the engine and replace them if necessary. The engines are different from each other. Refer to the repair manual for hose identification.

Causes of air leaks, how to determine

Unaccounted air can be called that which enters the system past the throttle valve, or past the air meter on injection machines. This air leak can be caused by various reasons and damage.

Any engine - gasoline and diesel, carburetor and electronic injection - needs air to function properly. This is the most important component of the fuel mixture. Depending on the type of fuel, air has its own very precise proportion in it. This is important, because if more air enters the intake manifold, and then into the combustion chambers, than was calculated at the factory, the engine will begin to operate unstably and lose power.

Leaks in the intake manifold

If your hoses are fine, the problem may be with the intake manifold. The intake manifold gasket leaks from time to time, causing air leaks. It is located between the cylinder head and the manifold.

To check the tightness of the intake manifold, place the car on the handbrake. Start the engine and let it idle for a few minutes.

Apply the soap solution to the area between the intake manifold and the cylinder head or at the base of the carburetor. Listen to the sound coming from the engine. If it is smoothed out, then air leaks occur at the intake manifold and require repair.

Symptoms of air leaks

The first sign of air leaks is the Check Engine light coming on. There are many reasons to turn on this light bulb. You'll need to rule out other problems before you decide it's a leak. But be sure that it is an air leak if it is accompanied by hissing from the engine and loss of power.

Is your car not developing full power? It could be an air leak.

Leaking can cause additional engine problems such as fuel inefficiency.

How to determine the location of air leaks

It is difficult to identify the location of air leaks if there are no special devices. Often, if there is a small crack in pipes or vacuum hoses, it is impossible to find it without special equipment. Although the presence of air leaks can be determined by ear - by a characteristic whistle or hiss.

Checking the tightness of the brake vacuum booster and its connections

It is quite easy to identify a faulty vacuum seal. As a rule, it is enough to press the brake pedal 3-4 times with the car turned off and hold it. After this, the power unit should be started. If the pedal sinks a little, it means there is no suction.

There is another method. If the engine responds to pressing the brake pedal, then you should plug the vacuum line to the booster, for example, with a bolt the size of the hose. After this, warm up the power unit and take a test drive. If the engine begins to work smoothly and without interruptions, then the vacuum booster is to blame.

Also on domestically produced cars, such as VAZ 2106-2115, suction occurs at the junction of the vacuum booster with its pipe. This can be easily checked with soapy water: use a spray bottle to spray the assembly generously, and if there are air bubbles, the faulty connecting element should be replaced.

Using a compressor

This method is not the most effective, but it can help identify air deaeration in the system. To do this, you need to disconnect the air filter and use an adapter to connect the compressor to the air supply system, while closing the system. As a rule, fuel filters from GAZ cars are excellent as an adapter, since they have a large body and a small inlet.

In order to eliminate leaks through the piston, it is recommended to remove the camshafts and ensure that the valves are completely closed. Then it will be possible to pump some pressure into the intake. After this, the leakage site will make itself known with a loud whistle or hiss.

Joint watering method

Air leakage will make itself felt if the area is generously watered with soapy water. Typically, a leaky node will begin to bubble. This procedure should be done with the engine running. Usually, after water gets on the problem unit, the power unit responds by decreasing speed.

You can also treat the connections with a flammable liquid, for example, aerosol carb cleaner. After reaching the leak point, the cleaner penetrates the intake, causing the engine speed to increase and then drop. This method is very effective if the problem is leaky gaskets, worn injector rubber bands, or loose connections.

Smoke generator

This is one of the most effective methods that is practiced at service stations. The smoke generator clearly indicates the location of the air leak. It is attached immediately after the mass air flow sensor to the intake manifold. After the smoke enters the inlet, it is immediately distributed throughout the entire space, after which a slight pressure is created, under the influence of which the smoke comes out of the air leaks. This method is very effective and allows you to easily identify the problematic part in the intake system. The cost of smoke testing is 600-900 rubles, depending on the region.

If desired, you can make a smoke generator yourself. To do this, you will need a glow plug from a diesel engine, an iron or glass jar, a hose and a nipple for tubeless tires. How to make a smoke generator from these items? Everything is extremely simple: you need to make three holes in the lid of the jar. One is for the nipple, the second is for the glow plug, and the third is for the outlet hose. Then pour glycerin or motor oil into the container so that the glow plug is slightly immersed in it, and put on the lid. We connect 12v power to our heater, after which smoke will begin to be emitted, then we connect the output pipe to the stopped engine and pump it with smoke by connecting a car compressor to the fitting from the tubeless camera.

Vacuum hose repair

If your vacuum hose is damaged, you don't have to buy a new one. The hose is long. You can cut off the damaged part and reattach it to the engine.

The most common damage is at the ends of the tubes. Always ensure that the clamps are tight to prevent further leaks.

After repairs, start the engine and leave it idling. Listen for any hissing sounds.

If you decide to replace the vacuum hose, use one that is similar in length and diameter. Vacuum tubes are designed for specific locations, such as the brake booster or PCV (Power Crankcase Ventilation) system.