The cabin is equipped with supply and exhaust ventilation systems.

With natural ventilation, air enters the vehicle interior through lowered door windows and exits through the cracks in the interior panels of the front doors, the sunroof, as well as ventilation windows on the rear side pillars and rear windows of buses.

With forced ventilation, the windows and sunroof are closed, the outside air, without heating, is forced into the cabin by the heater fan.

Passing through the heater body and bypassing its radiator, the air enters the cabin.

To do this, move the lower handle on the control panel to the extreme left position and turn on the electric fan.

The direction of air flow through the cabin is controlled by rotating nozzles.

Forced ventilation should be used in hot weather at low speeds and in parking lots.

At speeds above 50 km/h, the interior is ventilated with the electric fan turned off, only due to the high-speed air pressure.

The cabin (salon) is heated with hot air.

Passing through a heated heater radiator (included in the engine cooling system parallel to the main radiator), the air is heated and supplied to the passenger compartment.

When outside air is taken in, it passes through a grille located between the windshield and the hood, abruptly changes direction and is separated from rainwater, which is drained onto the road through a plastic groove located in the engine compartment.

Next, the air passes through the air intake duct, the heater itself and (depending on the location of the dampers) is supplied to the windshield, door windows, and also to the driver’s and passengers’ foot area.

The heater consists of a plastic casing in which a radiator, two fans mounted on the electric motor shaft, upper, central and lower dampers and a control panel with three levers and switches are installed.

An additional resistor is installed on the left side of the heater, providing reduced rotation speeds of the electric fan.

The inlet and outlet rubber hoses are suitable for the heater radiator.

When the heater tap is open, fluid is drawn into the radiator from the cylinder head, and discharged into the engine cooling system pump.

To heat the cabin, by moving the right upper and lower levers of the control panel, open the heater tap, and by moving the dampers we direct the incoming air through the heater radiator.

When the car is moving, air will flow into the cabin even when the fan is turned off.

If there is a lack of warm air, as well as in parking lots, we turn on the electric fan.

By turning the switch clockwise, we select one of three operating modes of the electric fan.

To increase heating efficiency and, especially, speed up the warm-up of the cabin in the cold season, cabin air is recirculated through the heater radiator.

When the upper left lever of the heater control panel is moved to the extreme right position, the upper flap blocks the flow of outside air into the heater and opens the air intake window from the passenger compartment.

The constant circulation of “cabin” air through the heater radiator contributes to its intensive heating.

The redistribution of air flows in the cabin is carried out by the lower lever of the heater control panel.

When the handle is in the extreme left position, the air supply to the heater radiator is blocked and only the interior is ventilated.

In the middle position, air is supplied to heat the windshield and door windows.

When on the far right, the air is distributed in the same way as the middle position of the handle, plus it additionally flows to the foot area of the driver and passengers.

The upper right lever of the heater control panel is connected to the heater valve and controls the amount of fluid entering the heater core. When the lever is in the extreme right position, the valve is fully open.

Characteristics of the cooling system

The Gazelle was equipped with engines from the Zavolzhsky Motor Plant marked ZMZ 402, ZMZ 405 and ZMZ 406. The design, circuit and operating principle of all three cooling systems are similar. Of course, there are some differences, but they are not that big.

Like any other cooling system, the ZMZ 405 engine has both positive and negative sides. So, if the thermostat breaks down, the power unit begins to overheat very much, especially in the summer season, when the temperature outside is 30 degrees Celsius or higher.

The most dangerous thing in this case is the failure of the cooling fan.

Composition of the Gazelle cooling system

Any engine cooling system consists of certain components, each of which performs its own function. So, to understand what the entire structure of the system consists of and the purpose of the nodes, it is not enough to look at the diagram. Let's look at all the details, as well as their characteristics.

Radiator

The radiator is one of the indispensable parts of the cooling system. It is in this element that the coolant is cooled and circulates through the system. The Gazelle is often equipped with an aluminum radiator, in which tubes run in three rows.

It has an inlet and an outlet, where the hot “coolant” enters the first, and the cooled liquid comes out of the second. Cooling occurs due to the oncoming wind flow that passes through the part.

Electric fan

If the radiator cannot cope, a cooling fan comes to the aid of the radiator, which operates automatically when the temperature of the liquid in the system reaches 105 degrees. At the same time, the fan quickly and efficiently cools the radiator cells, and when the temperature drops, it turns off.

This unit is turned on and off using a coolant temperature sensor and an electronic engine control unit, which regulates all engine operation processes.

Thermostat

The thermostat is one of the elements that is familiar to almost all motorists. The element helps warm up the engine and also cool it. As you know, car engines have two cooling circles, each of which performs its own function. So, if the thermostat is closed, then the liquid circulates in a small circle without the participation of the radiator.

Typically, this system is necessary for quick and efficient warming up of the power unit. When the thermostat opens (at 65-70 degrees), the coolant begins to circulate through the radiator, which allows it not to overheat.

temperature sensor

The temperature sensor is the only electrical part of the engine cooling system that reads system temperature data and sends it to the electronic engine control unit. Subsequently, the “brains”, based on the data received, make a decision whether to turn on the cooling fan or not.

It is worth noting that the malfunction of this sensor usually brings many problems to the owners of the power unit, since based on temperature data, not only the activation of the electric fan is regulated, but also fuel consumption, as well as the operation of auxiliary systems.

Expansion tank

The expansion tank is a plastic container that is located above the other elements of the cooling system and shows the level of “cooling” in the engine. In addition, excess fluid from the system is squeezed into it.

Expansion tank plug

A very important cooling element is the expansion tank plug, since it is through it that hot or boiling coolant will be squeezed out if the power unit overheats. It also serves as a valve that indicates problems in the cooling system.

Water pump

One of the most important elements of the engine is the water pump or simply pump. This unit ensures coolant circulation throughout the entire system. The faster the pump runs, the faster the engine cools.

The pump is driven by a generator belt, which is driven by the crankshaft pulley. Gazelle 405 engines have a modern water pump installed, which is not dismountable, therefore, if it fails, the element is replaced as an assembly.

Heater and other components of the stove

The radiator is equipped with a tap that can adjust the direction of movement of antifreeze. Either more of it enters the radiator, or a reverse discharge occurs. If you need to increase the flow of hot air, you just need to open the tap larger. This is roughly how the heater on a Gazelle functions - and it’s convenient to make adjustments even from the passenger compartment, using the control panel. The faster the impeller rotates, the more the intensity of the motor increases, increasing the warm airflow.

This diagram would be incomplete if it did not reflect the electric damper drive. With its help, you can change the direction of hot air supply - you can direct it to the upper body, arms or legs, or warm a frozen windshield. Having passed through the main pipes, the heated antifreeze enters the radiator and at the same time heats it up. After this, the finally heated air enters the air ducts and then into the cabin for heating.

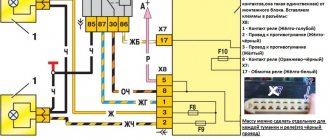

In order to correctly diagnose the operation of the stove on a Gazelle, you will have to acquire such an assistant as an electrical connection diagram, on which all devices in the circuit are plotted. If something is not working correctly, it will tell you where to look for the problem and in what area. This will allow you to first carry out the correct diagnosis, and subsequently repair work. This is especially true in cases where a fault occurs on the road, and there is no way to take the car to a service station for repairs. A minimum amount of knowledge and operating principle plus a diagram is all that is needed to troubleshoot the problem.

Repair of main components

Repair of parts and the entire engine cooling system can be found in the ZMZ 405 repair manuals. The most common system breakdowns are the water pump and thermostat. Replacing the pump is quite simple:

- Drain the coolant.

- The drive belt is dismantled.

- The water pump mounting bolts are unscrewed.

- The old pump is removed and a new pump is installed. It is important not to forget to install the gasket.

- Install the belt into place.

- Fill the system with coolant.

Replacing the thermostat is carried out in the same way as a pump, only the element itself is located in a housing that consists of two elements. To change it, you just need to drain the liquid and disconnect the pipe. Then remove the cover and change the thermostat directly.

Recently, radiators have become a common malfunction; they become punctured by pebbles on the highways when the speed is high enough. Typically, motorists try to solder this element, but it does not always work.

Conclusion

The cooling system of the 405 Gazelle engine is quite characteristic and typical for power units. It includes a radiator, electric fan, water pump, thermostat, temperature sensor and other elements. The cooling system is easy to repair because it has a simple design. Restoring the functionality of the nodes can be done at home.

For correct diagnostics and repairs, it is necessary to know the structure and operating principle of the heater in order to diagnose a breakdown or carry out repairs at the first sign of a malfunction, preventing failure of the entire unit as a whole. Most faults can be predicted by indirect signs and their progression can be prevented. To do this, you need to know and understand what each element is responsible for and what the principle of its operation is.

Car cooling system

In Gazelle Business the stove is an integral part of the engine cooling system. When the engine operates, a large amount of heat is generated that must be removed. Heat is released due to fuel combustion and from rubbing surfaces. If the heat is not removed, the engine will heat up very quickly and fail. The cooling system has two circuits (small and large circle), they are separated by a thermostat. When the liquid is cold, it circulates in a small circle, and when it warms up, it circulates in a large circle. This allows you to quickly reach operating temperature and not overheat. During the warm season, heat is released into the atmosphere, and when cold weather sets in, part of the heat is spent on heating the cabin.

Features of the functioning of the Gazelle cooling system

It is the stove that is one of the key parts of the cooling system not only of a gazelle, but also of any other vehicle. When any engine is running, it is accompanied by the release of a large amount of heat. Fuel burns and metal surfaces rub against each other. If heat is not removed, overheating and very rapid failure of entire motor components will occur.

For this reason, the cooling system has 2 circuits at once, which are called the large and small circle. Until the cooling working fluid has heated up, it passes through a small circle, and when heated, it passes through a large circle. In this case, the thermostat turns on, which distributes the flows. This is how a car engine does not overheat, but also quickly reaches operating temperature. The resulting heat is used to heat the interior in winter, and in summer it is simply released outside into the atmosphere.

Heating

After we have figured out how the cooling system works, we can move on to heating the interior. The heater circuit on a Gazelle car is identical to the heaters of other cars that have a liquid-cooled engine. Fluid can circulate through the heater core whether the thermostat is open or not. For better heating, the heater fluid comes from the hottest part of the engine (the cylinder head). Therefore, on an engine that has not yet reached operating temperature, warm air still comes out of the deflectors. The heater has a valve in its design that either allows liquid to flow into the radiator or dumps it back. And the temperature of the air leaving the deflectors depends on how much it is open. The valve position is adjusted from the heater control panel. The faucet is equipped with an electric drive that changes the position of the valve. It is also possible to change the blowing intensity and direction from the control panel. The intensity is controlled by a motor with an impeller, the rotation speed of which changes the intensity of the airflow.

Changing the position of the dampers changes the direction of the airflow (to the face, to the legs, to the chest, to the glass). The heated coolant from the engine enters the heater radiator through the highways, causing it to heat up. At this time, air blown by a fan passes through it. Then it passes through air ducts, the dampers of which are open. The hot air then enters the car interior and heats it. To repair or diagnose a malfunction of this equipment, there is an electrical diagram that shows all the components of the electrical devices. And in case of breakdowns or incorrect operation of devices, it is necessary to read it in detail in order to understand where it is powered from and how the failed device is regulated.

When you know the principle of operation and the device, it is much easier to navigate in case of breakdowns. After all, to successfully carry out repairs, it is important to understand the cause of the malfunction, otherwise the repair will not be completed successfully. For correct diagnosis, it is also important to understand the algorithm of operation of the entire mechanism as a whole. Currently, a driver does not have to know how to repair a car; there are service stations that can handle repairs of any complexity. But it happens that a breakdown catches you on the road, and there is no opportunity to use the services of specialists. This is when knowledge of the structure of a car and its mechanisms comes in handy. When you know how the Gazelle stove works, then if a malfunction occurs on another car, it will be easier to navigate when repairing or diagnosing, since in all cars they are almost the same, with the exception of small nuances. And you can easily diagnose the problem.

How it works

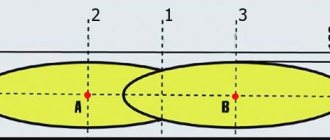

On the side of the electric fan unit there are 2 dampers on GAZelle cars. Between these dampers there is a special jumper, which changes its position depending on the operation of a special regulator located on the front panel. As you know, the furnace equipment control unit is located on the center console.

Both dampers close and open synchronously. They are driven by a special drive connected to an external regulator on the control unit. When air is taken in through the engine compartment, depending on the position of the dampers, it can pass through the heater radiator or bypass it. This directly affects whether cold or hot air will enter the cabin.

But if the dampers do not move synchronously, the stove will not work normally. In this situation, mandatory repairs are required.