Gazelle until 2009. Engine cooling system UMZ-4216

Engine cooling system (for a car with two heaters): 1 - radiator; 2 — drive belt for the generator and coolant pump; 3 — fan casing; 4 — hose for draining fluid from the heater radiators; 5 — hose for supplying liquid to the electric pump of the heating system; 6 — electric pump of the heating system; 7 — hose for draining fluid from the throttle assembly heating unit; 8 — hose for supplying fluid to the throttle assembly heating unit; 9 — thermostat housing cover; 10 — coolant pump; 11 — hose for supplying fluid to the radiator; 12 — steam removal hose; 13 — expansion tank; 14 — expansion tank cap; 15 — inlet hose; 16 - tee; 17 — hose for draining fluid from the radiator

The cooling system is liquid, closed type, with forced circulation of liquid. It consists of an expansion tank, a coolant pump, an engine cooling jacket, a thermostat, connecting hoses, a radiator and a fan impeller driven by a V-belt from the crankshaft pulley when the electromagnetic fan clutch is engaged.

The cab heater radiator and the auxiliary heater radiator (for vans with two rows of seats and minibuses) are connected to the cooling system. The system is filled with coolant through the neck of the expansion tank. The expansion tank is made of translucent plastic, which allows you to visually monitor the coolant level. The fluid level in a cold engine should be between the upper edge of the clamp securing the reservoir and the MIN mark. A steam removal hose is connected to the upper pipe of the tank, connecting the tank to the thermostat cover.

Elements of the engine cooling system and interior heating system (for a car with two heaters): 1 - radiator; 2 — fan casing; 3 — hose for draining fluid from the heater radiators; 4 — hose for supplying liquid to the electric pump of the heating system; 5 — electric pump of the heating system; 6 - electric valve for the heating system; 7 — hose for supplying fluid to the heater radiators; 8 — bypass hose; 9 — coolant temperature sensor; 10 — hose for draining fluid from the throttle assembly heating unit; 11 — hose for supplying fluid to the throttle assembly heating unit; 12 — steam removal hose; 13 — expansion tank; 14 — hose for supplying fluid to the radiator; 15 — hose for draining fluid from the radiator; 16 - inlet hose

The lower pipe of the tank is connected by an inlet hose to the radiator outlet hose. The tightness of the cooling system is ensured by the inlet and outlet valves in the expansion tank cap. The exhaust valve maintains increased pressure in the system when the engine is hot, compared to atmospheric pressure. Due to this, the boiling point of the liquid increases and steam losses are reduced. The intake valve opens when the pressure in the system decreases as the engine cools down. At the same time, the level of cooling

The remaining liquid in the expansion tank decreases.

If the cap is lost, you cannot replace it with a sealed cap without valves, even one of suitable size and thread - this will lead to an unacceptable increase in pressure in the cooling system (on a hot engine) and, as a result, leakage of coolant from under the hose clamps.

The circulation of liquid in the cooling system is ensured by

with coolant. The coolant pump is a centrifugal type, driven together with the generator by a V-belt from the crankshaft pulley. The fluid enters the pump through hoses from the expansion tank and radiator of the cooling system, from the heater radiator and the throttle assembly heating unit.

The pump forces coolant into the cooling jacket of the cylinder block, from where, through holes in the mating surfaces of the block and cylinder head, it enters the cooling jacket of the cylinder head and from there to the thermostat.

The thermostat helps accelerate engine warm-up, automatically maintains its thermal conditions within specified limits, and regulates the amount of fluid passing through the radiator. A metal cylinder with a heat-sensitive filler (wax) is installed inside the thermostat. The cylinder is hermetically sealed with a rubber insert. When heated, the filler melts and increases its volume, squeezing the insert. The rubber insert is deformed and pushes the rod, opening the thermostat valve.

The thermostat is installed in a housing, which is attached to the cylinder head with three bolts and a nut. The engine is equipped with a thermostat with solid filler TS-108-01 M.

On a cold engine, the thermostat valve is closed and closes the outlet pipe of the thermostat housing cover leading to the radiator of the cooling system. In this case, the liquid circulates through the engine cooling jacket - in a small circle. Part of the liquid from the cooling jacket flows through a hose connected to the thermostat housing pipe into the heater radiator and then returns to the pump. Fluid enters the throttle body heating unit through a hose connected to the thermostat cover fitting and then returns to the pump.

Heater Gazelle business principle of operation.

The Gazelle Business heater is not a bad parody of foreign car heaters, but only at first glance. The heater is controlled by buttons and knobs on the electronic unit located on the control panel. The air in the heater, as on all Gazelles, is sucked in by an electric fan through the grilles under the windshield and, passing through air ducts and deflectors, enters the cabin.

Coolant is supplied to the heater radiator through a tap, the opening and closing of which is carried out by an electric drive. It is distinguished from the same taps of previous models by the presence of an additional fitting. When the valve is closed, the liquid is redirected back to the cooling system.

Characteristics and Application

The Gazelle radiator has the following technical characteristics:

- Material and type of execution - soldered model made of an alloy of brass and copper.

- The number of rows is three.

- Thermal efficiency indicator is 83 kW.

- The weight of the standard modification is seven kilograms.

- .

The variation in question is used in Gazelle-business class cars (power unit - UMZ-4216). In addition, there are analog models made of copper: GB-330242, 33027Ш, 330242-1301. Aluminum options: 33027 - 1301010/1301010-33.

Heater Gazelle business device.

The tap is controlled automatically by the heater control unit depending on the selected temperature. In addition, the temperature of the air supplied to the cabin is regulated by a central damper, which, by turning, directs the air flow, or part of it, through or bypassing the radiator.

In addition to the central damper, there are a number of dampers that redistribute the air flow. The dampers of the Gazelle Business heater, unlike previous models, are controlled by gear motors, not cables. The control is carried out by the heater control unit. The electric heater fan is located inside the housing and to access it it is necessary to remove and disassemble the entire heater. Despite the fact that the fan electric motor is imported, this arrangement completely negates all the advantages of the heater.

The speed of the electric motor is regulated smoothly by turning the handle on the control unit, due to the electronic regulator located on the heater body. To access it, as well as access to almost all elements of the heater, you need to remove the front panel completely. The only thing that can be changed without removing the panel is the heater core. To change it, just remove the glove compartment.

Quick replacement of the engine speed controller for the gazelle business stove

Problem and arrangement for a gazelle business stove

.

The stove does not work on a gazelle business

I found the reason for the failure of the interior heating motor.

Completion

It is not at all difficult to replace the Gazelle radiator yourself. You should not ignore the timely maintenance of this unit, since it is responsible for the heat in the cabin. At the first signs of a leak or in case of obvious signs of structural wear, it is recommended to replace the part. By following all the indicated steps, even a novice motorist can handle this work.

How to remove the radiator of a gazelle stove?

In winter, the car's heater plays a major role; it supplies the interior of the car with heat, thereby providing a comfortable air temperature for the driver and passengers. The stove in our country plays an integral role in the car. In winter, not only a pleasant temperature in the cabin, but also safety depends on it, since without it our windows fog up or become covered with frost. A stove breakdown in winter is certainly a nasty problem that needs to be solved recently. So, let’s look at the design of the main heater of a gazelle car.

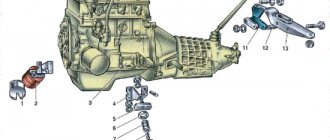

Main heater: 1 — bracket; 2, 4 — damper axis levers; 3 — bracket for fastening the drive rod shells; 5 — clamp; 6, 7, 17 — sheaths of cable rods; 8, 9 — damper drive racks; 10 — protective casing; 11 — OVU building; 12 — fan cover; 13 - seal; 14 — electric drive connector; 15 - screw; 16 — electric fan; 17 — two brackets for fastening the electric fan flange; 18 — thrust; 19 — heating radiator; 20 - gasket; 21 - cover; 22 - tap; 23 - hose

In most cases, in the summer, we close the tap (pos. 22) so that warm air does not flow into the cabin by gravity. With the onset of cold weather, we forget to turn it on and our stove does not allow heat into the interior. In this case, just open it and enjoy the warmth.

One of the most common problems when the stove

it works, but stops supplying warm air, this is a problem with the cable, the traction is weakened or completely lost. It is necessary to tighten the cable (pos. 19) so that when fully opened, the cable opens the damper one hundred percent and when fully closed, closes it. If such an operation did not help, then we check the inlet and outlet pipes; if the inlet pipe is warmer than the outlet pipe, then we can conclude that your stove radiator is clogged, you need it

take off

and clean

GAZELLE Replacing the heater radiator (stove)

Replacing the stove

on an old one

gazelles

.

Heater Gazelle business troubleshooting.

What to do if something in the heater does not work? Due to the design of the heater, diagnostics in case of failure of its parts is difficult. Initially, as always, you need to check the fuse.

Checking gearmotors.

Checking the gear motors of the windshield blower dampers and deflectors can be checked without completely removing the panels. It is enough to remove its lower part. The main damper motor is accessible from the driver's side. To check gearmotors, you need to disconnect the connector of its electric motor, the connector with a lock, and connect a tester to it in voltmeter mode or a test lamp. With the ignition and heater on, you must press the button that controls this damper. The control lamp should light up. If the lamp is on and the gearmotor does not work, it must be replaced.

If you are on the road and do not have the opportunity to replace the damper drive with window defroster, you can remove the rod from the damper lever on the driver’s side and turn it manually, locking it in the open position. To open the damper on the passenger side, you will need to unscrew the screws securing the gearmotor and, by turning its housing, secure it in the same way.

Checking the electric motor and speed controller.

To check the heater fan motor and the cause of its failure if the fan does not work, you will need to remove the air intake in the engine compartment. Inside the window that opens, two wires with a connector will be visible. To check the power supply, connect a test lamp to the connector terminals and, with the ignition on, turn the heater speed control toward maximum speed. The control lamp should light brightly. When turning the handle towards the minimum speed, the brightness of the lamp should decrease. This indicates that the speed controller is working properly.

If the control lamp is on and the fan does not rotate, then its electric motor is faulty. To check, measure the resistance between the motor terminals in the connector. Motor malfunction may be caused by stuck brushes. In this case, you can try knocking on the heater body. In this case, the operation of the fan can be restored before the next time it is turned off, possibly longer, but you can still get to the service center in a warm place.

If the control lamp does not light up when checking the power supply, the speed controller is faulty. If the speed controller malfunctions, you can temporarily connect the positive wire on the connector to the fuse near the battery with a wire. This will allow you to get to the garage or service station in winter.

Ways to solve the problem

Once it has been determined that the system may be air-filled, air must be removed from it. First, you need to check it for leaks so that there are no leaks at the joints. Also check all rubber hoses for cracks, and if any, the hoses need to be replaced. If at the junction of the rubber hose and the fitting it is not possible to eliminate leakage by pulling the clamp, then this connection must be disassembled and the fitting itself checked, perhaps a crack has appeared on it. This connection cannot be considered reliable, and in this case the fitting must be replaced. Also, the reason why it is not possible to correct leaks at the connection points of the pipe may be a malfunction of the clamp itself, or the rubber has become very “stiff” due to constant contact with the coolant. In this case, replacing the clamp and rubber hose will help.

Design of the cooling system for UMZ-4213 and UMZ-4216 engines on UAZ and GAZelle vehicles.

To increase energy performance, improve fuel efficiency, reduce toxicity and noise, models with an integrated microprocessor fuel injection and ignition control system were developed on the basis of the UMZ-421 carburetor engine: the UMZ-4213 engine for UAZ cars and the UMZ-4216 engine for GAZelle cars. The design of the cooling system on the UMZ-4213 and UMZ-4216 is somewhat different, since it has differences in the connection diagram of the expansion tanks and heating radiators.

General design of the cooling system of UMZ-4213 and UMZ-4216 engines on UAZ and GAZelle vehicles.

The cooling system is liquid, closed, with forced circulation of liquid and an expansion tank, with liquid supply to the cylinder block. Includes a water pump, thermostat, water jackets in the cylinder block and cylinder head, radiator, expansion tank, fan, connecting pipes, as well as body heating radiators.

For normal operation of the UMZ-4213 and UMZ-4216 engines, the coolant temperature must be maintained within plus 80-90 degrees. It is permissible to operate the engine for a short time at a coolant temperature of 105 degrees. This mode can occur in the hot season when driving a car with a full load on long climbs or in urban driving conditions with frequent accelerations and stops.

Design of the UMZ-4213 engine cooling system on a UAZ vehicle.

Design of the UMZ-4216 engine cooling system on a GAZelle car.

Operation of the cooling system of UMZ-4213 and UMZ-4216 engines on UAZ and GAZelle vehicles.

Maintaining normal coolant temperature is carried out using a two-valve thermostat TS-107-01 with a solid filler. When the engine warms up, when the coolant temperature is below 80 degrees, a small circle of coolant circulation operates. The upper thermostat valve is closed, the lower valve is open.

The coolant is pumped into the cooling jacket of the cylinder block by a water pump, from where, through holes in the upper plate of the block and the lower plane of the cylinder head, the liquid enters the head cooling jacket, then into the thermostat housing and through the lower thermostat valve and connecting pipe to the inlet of the water pump. The radiator is disconnected from the main coolant flow.

For more efficient operation of the interior heating system when circulating liquid in a small circle, and this situation can be maintained for quite a long time at low negative ambient temperatures, there is a throttle hole with a diameter of 9 mm in the liquid outlet channel through the lower valve of the thermostat. Such throttling leads to an increase in the pressure drop at the inlet and outlet of the heating radiator and more intense circulation of liquid through this radiator.

In addition, throttling the valve at the liquid outlet through the bottom valve of the thermostat reduces the likelihood of emergency overheating of the engine in the absence of a thermostat, since the shunting effect of the small circle of liquid circulation is significantly weakened, so a significant part of the liquid will go through the cooling radiator.

Additionally, to maintain the normal operating temperature of the coolant during the cold season, UAZ vehicles can have shutters installed in front of the radiator, with which you can regulate the amount of air passing through the radiator.

When the liquid temperature rises to 80 degrees or more, the upper thermostat valve opens and the lower valve closes. The coolant circulates in a large circle through the radiator.

For normal operation, the cooling system must be completely filled with liquid. When the engine warms up, the volume of liquid increases, its excess is pushed out due to increased pressure from the closed circulation volume into the expansion tank. When the temperature of the liquid decreases, for example after stopping the engine, the liquid from the expansion tank, under the influence of the resulting vacuum, returns to a closed volume.

On UAZ vehicles with a UMZ-4213 engine, the expansion tank is directly connected to the atmosphere. The regulation of fluid exchange between the tank and the closed volume of the cooling system is regulated by two valves, inlet and outlet, located in the radiator plug.

Important nuances of replacement

When replacing the device, some shortcomings are possible, which during daily use of the car can result in an unpleasant surprise, including a coolant leak. To prevent this from happening, the following nuances should be taken into account:

- adjacent surfaces must be cleaned of dirt;

- when replacing the device, the O-ring must be replaced;

- The thermostat must be oriented correctly;

- the fastening bolts must be tightened tightly;

- it is necessary to check the strength of the hose connections;

- After installation, you need to let the engine idle to make sure the connections are secure.

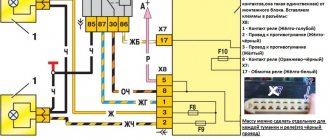

Gazelle stove diagram

Engine tuning options

Since the UMZ 421 family engine is designed for heavy trucks, minivans, off-road and all-terrain vehicles, utility vehicles, atmospheric tuning by mechanical means does not even make sense to consider. But it is quite possible to install an urban quiet type turbine. To do this you need to follow these steps:

- replacement of standard injectors with 440CC modifications from the manufacturer Subaru;

- modification of the intake manifold to integrate an intercooler;

- grinding of combustion chambers and channels inside the cylinder head;

- ShPG and shafts remain standard;

- Instead of a combined exhaust tract, a direct-flow spider 63 mm in diameter is mounted.

Turbocharger for UMZ 421

After flashing and tuning, tuning can add 30 - 50 hp. sec., the engine becomes “tractor-like” and has powerful torque in the lower speed range.

Thus, the 4218.10 motor with a very average resource due to defects in the casting of the cylinder block is considered to be the base motor in the series of the manufacturer UMP. But in all subsequent versions, not only this defect was corrected, but also other design solutions were used to improve performance and service life.

How the stove works in Gazelle Business

For correct diagnostics and repairs, it is necessary to know the structure and operating principle of the heater in order to diagnose a breakdown or carry out repairs at the first sign of a malfunction, preventing failure of the entire unit as a whole. Most faults can be predicted by indirect signs and their progression can be prevented. To do this, you need to know and understand what each element is responsible for and what the principle of its operation is.

Car cooling system

In Gazelle Business the stove is an integral part of the engine cooling system. When the engine operates, a large amount of heat is generated that must be removed. Heat is released due to fuel combustion and from rubbing surfaces. If the heat is not removed, the engine will heat up very quickly and fail. The cooling system has two circuits (small and large circle), they are separated by a thermostat. When the liquid is cold, it circulates in a small circle, and when it warms up, it circulates in a large circle. This allows you to quickly reach operating temperature and not overheat. During the warm season, heat is released into the atmosphere, and when cold weather sets in, part of the heat is spent on heating the cabin.

Heating

After we have figured out how the cooling system works, we can move on to heating the interior. The heater circuit on a Gazelle car is identical to the heaters of other cars that have a liquid-cooled engine. Fluid can circulate through the heater core whether the thermostat is open or not. For better heating, the heater fluid comes from the hottest part of the engine (the cylinder head). Therefore, on an engine that has not yet reached operating temperature, warm air still comes out of the deflectors. The heater has a valve in its design that either allows liquid to flow into the radiator or dumps it back. And the temperature of the air leaving the deflectors depends on how much it is open. The valve position is adjusted from the heater control panel. The faucet is equipped with an electric drive that changes the position of the valve. It is also possible to change the blowing intensity and direction from the control panel. The intensity is controlled by a motor with an impeller, the rotation speed of which changes the intensity of the airflow.

Repair of main components

Repair of parts and the entire engine cooling system can be found in the ZMZ 405 repair manuals. The most common system breakdowns are the water pump and thermostat. Replacing the pump is quite simple:

- Drain the coolant.

- The drive belt is dismantled.

- The water pump mounting bolts are unscrewed.

- The old pump is removed and a new pump is installed. It is important not to forget to install the gasket.

- Install the belt into place.

- Fill the system with coolant.

Replacing the thermostat is carried out in the same way as a pump, only the element itself is located in a housing that consists of two elements. To change it, you just need to drain the liquid and disconnect the pipe. Then remove the cover and change the thermostat directly.

Recently, radiators have become a common malfunction; they become punctured by pebbles on the highways when the speed is high enough. Typically, motorists try to solder this element, but it does not always work.

Design of the cooling system for UMZ-4213 and UMZ-4216 engines on UAZ and GAZelle vehicles.

To increase energy performance, improve fuel economy, reduce toxicity and noise, models with an integrated microprocessor fuel injection and ignition control system were developed on the basis of the UMZ-421 carburetor engine: UMZ-4213 engine for UAZ cars and UMZ-4216 for GAZelle cars. The design of the cooling system on the UMZ-4213 and UMZ-4216 is somewhat different, since it has differences in the connection diagram of the expansion tanks and heating radiators.

General design of the cooling system of UMZ-4213 and UMZ-4216 engines on UAZ and GAZelle vehicles.

The cooling system is liquid, closed, with forced-type liquid circulation and an expansion tank, with liquid supply to the cylinder block. It includes a water pump, a thermostat, water jackets in the cylinder block and cylinder head, a heater, an expansion tank, a fan, connecting pipe sections, and also body heating batteries.

For proper operation of the UMZ-4213 and UMZ-4216 engines, the coolant temperature must be maintained within the range of plus 80-90 degrees. Short-term operation of the engine is allowed at a coolant temperature of 105 degrees. This mode may appear during the heat of the year when the car is driving with a full load on long climbs or in city driving conditions with frequent accelerations and stops.

Design of the UMZ-4213 engine cooling system on a UAZ vehicle.

Design of the UMZ-4216 engine cooling system on a GAZelle car.

Operation of the cooling system of UMZ-4213 and UMZ-4216 engines on UAZ and GAZelle vehicles.

Maintaining normal coolant temperature is done using a two-valve thermostat TS-107-01 with solid filling. When the engine warms up, when the coolant temperature is below 80 degrees, a small circle of coolant circulation operates. The upper valve of the thermostat is closed, the lower valve is open.

The coolant is pumped into the cooling jacket of the cylinder block by a water pump, from where, through holes in the upper plate of the block and the lower plane of the cylinder head, the liquid penetrates into the cooling jacket of the head, further into the thermostat housing and through the lower valve of the thermostat and the connecting pipe section - to the pump inlet for water. The heating device is disconnected from the main coolant flow.

System modernization

The main problem that causes electronics to fail is moisture. And in the tap the liquid circulates constantly, even when the shutter is closed. And when the oil seal leaks, liquid floods the entire electrical part, and it fails.

Installation of shut-off valves

To avoid this, you can install conventional shut-off valves, fitting them to the outlets of the cooling system. But in order to open or close the supply of hot liquid, you need to move the tap to the desired position manually. And since it is installed under the hood (in a regular place), it is not possible to do this while driving. But this mechanism has a much greater resource.

Pre-sealing

Before installing a new electric faucet, you need to disassemble it and fill the electronic board with hot glue to avoid moisture getting on it, coat all joints with sealant. This method can only prolong performance, because if liquid gets into the electronic part, the electric motor will be damaged, without which the mechanism will not be able to function correctly.

Gazelle stove diagram

Reviews from car owners

There are the most controversial reviews about the UMZ 4216 engine - some Gazelle owners praise UAZ engines and believe that they:

- have good traction;

- consume fuel moderately;

- inexpensive, and easy to repair.

Indeed, the UMZ 4216 engine is very simple, especially since it has significant similarities with the ZMZ-402 internal combustion engine. The design of the power unit is familiar to many drivers, and such an engine can be repaired almost in the field. Some difficulty for car owners is the electronic equipment of the engine - after all, the injector is somewhat more complex than a carburetor device.

You can also hear extremely negative responses from owners of Gazelles with UAZ engines:

- the engine is prone to overheating;

- Sensors often fail, so the engine starts to stall and not move;

- The engine consumes oil, it leaks from wherever possible.

Unfortunately, a lot of defective products come from the Ulyanovsk plant, and mostly those drivers who have received a defective internal combustion engine complain about the Ulyanovsk engine. There are several characteristic ones that are quite common on UMP 4216:

- the intake manifold cracks and begins to suck in air;

- the pump does not provide the required oil pressure;

- the electromagnetic cooling clutch refuses to work, and the motor begins to overheat.

Drivers of such unsuccessful Gazelles note that the engine often has to be “modified with a file.” It has also been noticed that if the engine is completely rebuilt with your own hands, breakdowns occur much less frequently, the main thing is to assemble the engine using original good quality parts.

Sources

- https://RoomAvto.ru/drugoe/shema-ohlazhdeniya-gazel-biznes-2.html

- https://personarossii.ru/remont/shema-cirkulyacii-ohlazhdayushchei-zhidkosti-gazel-biznes-4216-sistema/

- https://motorchina-online.ru/marki/gazel-dvigatel-421-sistema-ohlazhdeniya.html

- https://mr-build.ru/newteplo/sistema-ohlazdenia-umz-4216.html

- https://avtika.ru/termostat-na-gazel-405-dvigatel-kakoy-stavit/

How the stove works in Gazelle Business

For correct diagnosis and repair, it is important to know the structure and operating principle of the heater, so that at the first sign of a breakdown, you can identify the problem or make repairs, preventing failure of the entire unit as a whole. Most breakdowns can be predicted by subtle signs and their progression can be prevented. To do this, you need to know and understand what any of the components is responsible for and what the meaning of its work is.

Car cooling system

In Gazelle Business, the stove is considered an important part of the engine cooling system. During engine operation, a lot of heat is generated that needs to be removed. Heat is released due to fuel combustion and from rubbing surfaces. If the heat is not removed, the motor will quickly heat up and break down. The cooling system has 2 circuits (small and large circle), they are divided by a thermostat. When the liquid is cool, it moves in a small circle, and when it warms up, it moves in a large circle. This makes it possible to quickly reach operating temperature and not get too hot. In the warm season, heat is released into the atmosphere, and when cool weather sets in, part of the heat is spent on heating the cabin.

Once we understand how the cooling system does not stop working, we can move on to heating the cabin. The heater circuit on a Gazelle car is similar to the heaters of other cars that have a liquid-cooled engine. Liquid can circulate through the heat exchanger of the heater no matter whether the thermostat is open or not. For better heat supply, the fluid for the stove comes from the hottest part of the engine (from the cylinder head). Thanks to this, on an engine that has not yet reached operating temperature, pleasant air still comes out of the deflectors. The heater has a valve in its design that either allows liquid to flow into the heating device or discharges it back. And the temperature of the environment leaving the deflectors depends on how much it is open. The valve position is adjusted from the heater control panel. The faucet is equipped with an electric drive that changes the position of the valve. It is also possible to change the blowing intensity and direction from the control panel. The intensity is controlled by a motor with an impeller, the rotation speed of which changes the intensity of the airflow.

Changing the position of the dampers changes the direction of the airflow (to the face, to the legs, to the chest, to the glass). The heated coolant from the engine penetrates through the line into the heater of the stove, causing it to heat up. At this time, air blown by a fan passes through it. Then it passes through air channels, the dampers of which are open. Then the hot air enters the car interior and warms it up. For repair work or diagnostics of breakdowns of this equipment, there is an electrical diagram on which all components of electrical devices are indicated. And in case of breakdowns or incorrect operation of devices, you need to read it in detail in order to understand where it is powered from and how the failed device changes.

When you know the working principle and device, it is much easier to navigate in case of breakdowns. After all, to successfully carry out a repair, it is necessary to understand the cause of the breakdown, otherwise the repair will not be completed successfully. For correct diagnosis, it is also necessary to understand the method of action of the entire mechanism in general. Nowadays, a driver does not have to know how to repair a car; there are service stations that deal with repairs of varying complexity. But it happens that a problem catches you on the road, and there is no opportunity to use the services of professionals. This is when knowledge of the automotive device and its mechanisms comes in handy. When you know how the Gazelle stove works, then if a breakdown occurs on another car, it will be easier to navigate when carrying out repairs or diagnostics, since in all cars they are almost equal, except for small invisible moments. And you can easily determine the breakdown.

Diagnostics

There can be many reasons why the Gazelle Business stove does not work. And for a successful repair, you must first identify the cause of the malfunction, and only then begin to eliminate it:

- The first step is to check the coolant level in the expansion tank. A low coolant level leads to the formation of an air plug in the cooling system, and since the heater is the highest point, the “plug” will be there.

- Next, you need to check the coolant temperature. During the cold season, the engine cools down rapidly before it has time to reach temperature. The temperature sensor may be faulty and show an incorrect temperature value.

- Then you need to check the cabin radiator; it is clogged and may not allow a sufficient amount of coolant to pass through it. You can check this by testing the inlet and outlet pipes; they should be approximately the same temperature. If the inlet pipe is hot and the outlet is cold, then the reason is a clogged radiator.

- If the inlet pipe is also cold, then you need to try the pipe that goes to the radiator from the engine compartment to the tap. If it is hot, then the problem is that the faucet is not working.

- Well, if the pipe to the faucet is cold, then there are more options