Causes of wheel imbalance

The appearance of imbalance is possible during normal operation of the vehicle, but it is usually preceded by the following events:

- getting the wheel into a significant hole, or driving along a road with a lot of potholes;

- hitting the curb with wheels, for example, when parking poorly;

- changing tires due to seasonality or wear of old tires;

- a large amount of dirt on the wheels, for example, after leaving the city;

- tuning a car with low-quality plastic caps with disturbed weight distribution;

- shrinkage processes that occur after running in a new tire;

- restoration operations were performed on the disc;

- There was a tire puncture.

Balancing Features

First of all, before performing this work, it is necessary to clean the wheel from any dirt adhering to it and remove dust from it. If there are pieces of ice or stones in the tire tread, they must also be removed. Old weights are also removed, and if a “forgetful” or unqualified tire fitter did not do this, then you should remind him of this need.

After the wheel is mounted on the stand, it is necessary to carry out preliminary measurements of the tire runout in the lateral and radial directions. This is done for comparison with the results obtained at the end of the procedure.

To ensure a good fit of the tire on the wheel rim, a special lubricant is used. If for some reason this is not done, then there is a high probability of mounting the tire on the wheel with a slight misalignment, after which it becomes impossible to completely balance the wheel. An incorrect fit cannot be determined visually from the outside. If the wheel does not balance, increase the pressure in the tire and tap it around the perimeter of the rim.

Some service stations have new balancing machines in their arsenal of modern equipment, which motorists call “3D tire fitting”. Using a laser, the geometry of both the tire itself and the disk is accurately measured. The magnitude of the beats is measured in three coordinates.

This equipment almost ideally carries out the installation of the tire on the disk, because it takes into account the individual defects of each of these two components and compensates for them mutually. A 3D stand is very expensive, and it requires special qualifications to operate it. You will not find such equipment at a small service station; it is only available at large stations in big cities - a large flow of customers allows you to quickly overcome its high cost.

What is wheel balancing?

Wheel balancing is the procedure for preventing imbalance between wheels, rims, hubs, suspension parts and fasteners. The need for periodic operation is due to centrifugal force.

During the balancing process, the mass of the wheel is located evenly relative to its center. When the procedure is performed correctly, vibration during vehicle operation is reduced and the service life of bearings and car tires is increased.

Benefits of wheel balancing:

- Comfortable ride on roads of any type and quality.

- No unnecessary noise from car wheels.

- Increased wheel usage.

- Ease of driving at various speeds.

- Car tires wear out equally and evenly on all sides.

Wheel balancing is required for any car, regardless of the condition of the wheels, tires or the newness of the model.

Consequences of not balancing wheels:

- Frequent bearing failures.

- Steering wheel vibration during vehicle operation.

- Early and uneven wear of car tires.

- Noise in the cabin.

- Immediate shock absorber failure.

- Unsafe movement due to each wheel acquiring its own centrifugal force.

- In advanced cases, the vibration of the wheels causes the bolts to become unscrewed and the ball joint to fly out or fall off.

How often should balancing be done?

According to the rules, balancing is carried out every 5000 km. In addition, balancing is carried out after a number of events:

After every tire change: it doesn’t matter whether it’s seasonal or not. When the steering wheel vibrates. When colliding with a curb. When falling into a ditch or hole.

Timely balancing provides a guarantee for the long life of the suspension and tires, so take the procedure responsibly.

Wheel balancing - causes of imbalance

Wheel balancing is the procedure of adding weights to the inner and outer parts of the rim or introducing special granules inside the tire, which, being attracted to the surface of the tire, balance the imbalance.

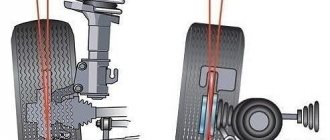

Unbalanced rotating masses on the wheel lead to imbalance. There is a strong deviation of the geometric center from the center of mass of the wheel. Important suspension elements gradually fail:

- Racks.

- Steering gear.

- Wheel bearings.

With a seemingly small unbalanced mass of 20 g, colossal loads are placed on a 14-inch wheel: at a speed of 100 km/h they are comparable to the blows of a 3-kilogram sledgehammer operating at a frequency of 800 blows per minute.

The suspension, shock absorber, and unbalanced wheel come into resonance. Vibrations spread throughout the body. This causes the steering wheel to wobble, making the ride uncomfortable, tiring and even dangerous. Therefore, wheel balancing is a mandatory procedure that must be included in routine maintenance.

Read more about the design of a modern suspension in the article: “MacPherson Suspension”.

Correct wheel balancing

The highest quality balancing is guaranteed by following a number of rules:

- The disc must be cleaned of any dirt. Quite often there is a lot of it, not only on the inside, but also on the outside. Automation calculates how much cargo needs to be hung in one or another part of the wheel. If you balance a dirty wheel, then you risk losing all balance on the first bump, after lumps of dirt fall off your disk;

- It is recommended to remove all old balancing weights;

- Quite often there are situations when the tire does not completely fall into place. It is not always possible to notice this from the outside, but this can have a rather strong effect on the balancing;

- Plastic caps, which are often put on immediately after the balancing procedure, can also significantly increase the imbalance in newly balanced wheels.

Approximate cost of wheel balancing

The cost depends on the prices of the selected car service or a specific tire shop. Usually balancing is done for relatively little money. The cost is primarily affected by the diameter of the wheel - the larger it is, the more expensive the procedure will be.

In addition, the type of wheel used matters. Balancing a steel disc is usually less expensive than correcting an imbalance in an aluminum disc. Finally, the final cost of the procedure takes into account the type of weights used.

In most tire shops, balancing is done as part of the seasonal tire replacement work.

Currently, the average cost of balancing one wheel with a diameter of 15 inches with a steel disk in Russia is 170 rubles. Accordingly, the total cost for all four discs will be 680 rubles.

These are average prices. There are both small garage-type workshops that offer this service cheaper, and premium services, where the cost of such an operation can be even higher than that of official dealers.

It is worth considering that the indicated prices do not include the wheel replacement service. Therefore, to get the full picture, you need to make an adjustment, adding about 50-100 rubles to the cost for each 15-inch wheel.

This is why you need to balance your wheels more often.

Even minimal changes to a tire can cause imbalance when driving. 1gai.ru tells how to recognize broken wheel balancing, and how much it costs to do it.

Wheel balancing is important for proper wheel rotation and vehicle movement. First of all, wheel balancing is about the safety of car operation and your comfort behind the wheel. Balancing the wheels allows their weight to be properly distributed for optimal rotation. Usually, when you bought new tires at a tire shop, during tire fitting work, specialists select certain weights for each wheel for optimal wheel alignment.

Unfortunately, over time, the balance in any car gets lost. For example, if your car hits a curb even slightly, the wheel may become unbalanced. Wheel balancing also changes when tires wear unevenly. As a result, the wheel that has worn out the most is out of balance in relation to the other wheels. As a result, an imbalance occurs when the wheels rotate while the car is moving.

The worst thing is that in this case, rubber wear begins even faster. And that is not all. If measures are not taken at this moment (re-balancing the wheels, replacing a heavily worn tire with a new one), then after a longer period of time, out-of-balance and unevenly worn wheels can lead to damage to the steering and even premature wear of the car’s suspension.

This is why it is so important to have your wheels balanced immediately at the first sign of imbalance.

Myth: Vulcanizations ruin tires so they can be returned to them

Not a single normal tire shop, and especially during the re-shoe season, wants the client to return with a flat tire. This is extra work for which you don't get paid. And the schedule during this period is tight - there are queues. Why else would they need all this trouble? But there are situations when, when beading a wheel, the sealing compound is applied unsuccessfully (the very moment when the tire is lubricated with a special paste or, in extreme cases, with oil or soap). In this case, the tire may go flat overnight, especially if the driver immediately after changing shoes put on a load, deciding to drift in the fresh snow.

And yet we should not forget about the crookedness of some hard workers. These can inadvertently cut the rubber, and often damage the rims, especially when working with low-profile tires. Unfortunately, the market for these services does not imply professional education; there are many amateurs here, and even a schoolboy can become a tire fitter.

Balancing your wheels yourself

Now let's look at the question of how to balance wheels on your own.

The most important thing is not to rush! Rushing may have a negative impact on the final result, and then you will still have to go to a technical service point.

First stage: preparatory. When preparing for the balancing procedure, you need to buy special self-adhesive weights. These weights will serve as balancers located on the disk itself. Their main task is to maintain balance.

The wheels themselves must be clean and cannot contain any small objects, such as stones. The dirt must be completely removed from the tires. Be sure to remove the cap, if present. Then take a jack and use it to lift one side of the car, freeing 2 wheels. Check the free rotation of the wheels.

Second stage: we determine the heaviest point of the wheel. To this end, we do the following:

- Turn the wheel clockwise until it stops. When you reach the stop, mark the lowest point. To do this, we put a mark with a special bright marker.

- Turn the wheel counterclockwise. In the case when, upon reaching the stop, the mark is again at the very bottom, we have found the heaviest point.

- After this, we proceed to balance the opposite wheel. Place weights on both sides of the disc rim.

- Spin the wheel and add weights until the wheel marked with a dot stops in different positions.

These four stages must be carried out on each wheel. And to be sure that you did everything correctly, you need to drive a vehicle for two or three km. If you did something wrong, you will feel vibration in the steering wheel.

What consequences can occur if balancing is performed incorrectly?

Incorrect or untimely balancing can lead to many adverse consequences. And it’s good if you just feel vibration in the steering wheel, or discomfort while driving. In the most advanced cases, this can lead to very unpleasant and even dangerous consequences.

- This is not safe as the braking distance increases. The car becomes more difficult to control. As a result, this can lead to emergency situations.

- It becomes more difficult to control the vehicle. There is a beating of the steering wheel, which not only distracts the driver, but also makes it difficult to control. The load on the suspension increases.

- The service life is reduced, and individual parts may even collapse.

- The rubber wears out. Rubber deteriorates unevenly, which leads to imbalance. Most often, wear occurs on the outside and inside of the wheel.

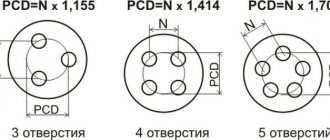

What wheel imbalances can there be?

There are two types of wheel imbalance on your vehicle. The first one is dynamic. It occurs when the weight of the wheels begins to fluctuate while driving. The wheel begins to move from side to side. The dynamic type of imbalance develops when the weight is shifted to one side of the wheel centerline.

Second type: statistical. This type develops when the wheel has an excessively heavy or light section. The wheels begin to oscillate up and down.

I would like to say that balancing wheels on your own is not particularly difficult; if you do it several times, you will acquire the necessary skills and will do it perfectly.

However, for the very first time, it is better to watch thematic videos that can be found in large quantities on the Internet.

Another tip: after the first time, check the correctness of the procedure at service stations.

If you want to be one hundred percent confident in the safety of the procedure performed with your own hands, the final balancing can be performed at the same service station, but using specialized equipment.

And one more recommendation: to achieve the best result, before starting the procedure, check the relative position of the disk and tires. Very often, the tires are misaligned relative to the rim of the disc, which causes an imbalance. This often happens after repairing and dismantling a tire or tube.

And in conclusion, we consider it necessary to repeat once again that the safety on the road, your own life and the health of your family members depend on how well you carry out self-balancing of the wheels of your vehicle. Balancing should be carried out regularly, or even better, create your own car maintenance schedule, which includes this procedure.

When to do wheel balancing and wheel alignment

In general cases, wheel alignment and wheel balancing is necessary every 7000-8000 km. This is justified by the usual concern for the car and travel safety. Also, reasons for traveling to a service station may be work related issues.

For balancing:

- changing car tires;

- aggressive driving with slipping;

- falling into a deep hole at high speed;

- installation of new disks.

For wheel alignment:

- routine diagnostics;

- serious impacts to the suspension;

- chassis repair;

- visual damage to tires (wear on one side).

All of these points make it clear that it’s time to go to the experts for service. Also, the car itself will help you determine whether it’s worth going for a wheel alignment or balancing. If vibration of the steering wheel, uneven or monotonous noise from the chassis is detected, you should immediately show the wheels to a mechanic.

Additionally, a broken camber can disrupt tire calibrations. If the wheels are at an angle, one part of the rubber wears out more, which invariably leads to a violation of weight distribution.

Is it necessary to do balancing when changing wheels on rims?

When replacing tires on cast or stamped wheels, balancing is required. This is justified by the disturbed weight distribution of the tire and disk itself. When leaving the assembly line, products have errors that can disrupt the ideal symmetry of the axis of rotation. The consequence of the effect is rapid wear of the chassis and vibration on the body or steering wheel. If the tire is not beaded, the procedure is not necessary, but recommended. During operation, the weights may become dislodged, and the possibility of the tire itself rotating is also not ignored. Thus, tires must be serviced every time the wheels are handled.

Is it necessary to have wheels balanced every season?

When installing a replacement set of tires or wheel assemblies after storage, rebalancing is critical. This requirement is especially relevant when changing tires on one set of wheels. Each slope has its own weight distribution. For example, a winter studded model will differ significantly from the summer version. If it is installed in place of an old tire, the weights will be placed in the wrong places, causing severe shaking or vibration.

Thus, the annual transfer from winter to summer and vice versa is accompanied by the mandatory delivery of wheels to a special machine.

Do new tires need balancing?

Each tire leaves the factory with balance flaws. At the same time, models from trusted brands may have a greater error than budget-type options. When such a tire is placed on a wheel rim, the disproportionality is transferred to the product assembly, which guarantees runout in the suspension or vibration of the steering mechanism. Experienced motorists, when purchasing a new set of tires, are required to balance all wheels. In this case, old weights or marks are completely removed from the rims.

Does it make sense to balance the rear wheels?

Correct weight distribution of the ramps or discs is a prerequisite for adequate suspension performance. Improperly balanced wheels greatly damage the car, regardless of the axis of location.

Thus, the procedure must be performed for all four tires installed on the car.

Is rear wheel balancing necessary?

You will probably ask, is it necessary to balance the rear wheels, since they are involved in driving the car? Of course, it is necessary, because the rear wheels are no less susceptible to mechanical stress than the front ones. And an imbalance will cause the same consequences.

Think about how the front wheels will behave during a trip if the rear wheels are hit by an impact opposite to the direction in which the car is moving? That's right, the front wheel will “slip” and the front suspension will suffer from such an impact. Now imagine that such impacts occur at least eight hundred times per minute? I suppose there is no point in explaining anything further.

We recommend: How to replace brake discs on a VAZ-2114 yourself

Some tips for improving wheel balancing

To check the accuracy of the tire mounting procedure, after it has been carried out, you can remove the wheel from the balancing stand and then put it back on. Repeated diagnostics will certainly show the presence of an imbalance. For wheels made using light alloy casting technology, a discrepancy of 3 grams per side is acceptable. In the case of steel stamping, the plus or minus can reach five grams.

Some tire centers have special installations that help with “finishing” balancing. It is in no way an alternative to the procedure carried out on classic stands, but serves as an important addition with which you can determine the static imbalance of not only the wheel, but also the entire assembly consisting of wheels, hub and brake disc. The maximum weight of weights used during “finishing” balancing should not exceed 15 grams.

How to do wheel balancing

Wheel balancing machine

Before submitting the wheel to a computer stand for balancing, it is advisable to thoroughly wash and clean the tread and disc from dirt, small stones and sand. Their presence will not allow you to carry out the procedure correctly, and you will not get the expected result. Also, before starting balancing, the master must remove all previously installed balancing weights, regardless of their location.

Both front and rear wheels need to be regularly balanced. You should not single out only the leading pair, hoping that the mechanical impact on the other two wheels is less. Uneven wear can appear on any of the four treads, which will entail the consequences already described above.

The wheel balancing procedure itself is carried out on a special balancing machine or stand. The principle of its operation is to install a wheel on a rotating cone, which is automatically controlled by a computer program. The latter determines the exact type of imbalance and indicates where it is necessary to install a special weight to level the center of gravity.

The average weight of a zinc or lead load ranges from five to sixty grams, and is set manually by the master. The specialist also selects a balancing weight option (adhesive or padded), which is used in accordance with the type of wheel rim.

A modern method of computer diagnostics and balancing allows us to identify the slightest aspects of axial displacement that are invisible to the human eye. And it makes it possible to optimally correct the existing situation, which negatively affects the overall technical condition of the car.

Basic rules for good wheel balancing

Why the steering wheel pulls to the left or right - main reasons

As with any technology or procedure, there is a certain list of rules or advice, following which you can achieve a better result. Balancing car wheels is no exception, since this process uses the laws of physics, which means it is better to adhere to the rules.

- Before you start balancing your car wheels, make sure that the wheel geometry is correct, otherwise the whole process will be pointless;

- The weight of the weight for balancing a wheel with normal geometry should not exceed 60 grams. If a weight of greater mass is required, then it is worth checking the geometry of the disk, the correct assembly of the disk and tire, and the wear of the tire;

- The permissible deviation when re-balancing a car wheel should be no more than 5 grams. If the tire was removed from the balancing machine and then returned to it again, then this should be the maximum difference, no more;

- The larger the wheel, the stronger and more reliable it must be installed on the axis of the balancing machine, otherwise it will affect the quality of balancing;

- The assembly of the disk and tire is individual for each wheel, so a slight deviation is allowed on each side of the wheel, weighing 10 grams;

- Before balancing, the car wheels, disk and tire must be cleaned of dust, dirt and other parts in the tread. Such factors greatly influence the correct balancing of wheels;

- The tire must be put on correctly and on the side of the rim (most often this concerns the procedure for changing a car’s shoes from summer to winter tires). Once installed on the car, the tire will fall into place almost immediately, but the balancing will be disrupted;

- Plastic wheel caps can play a significant role in tire imbalance; most often, problems arise with low-quality hubcaps. If an imbalance appears, first double-check that the hubcaps are installed correctly and only then proceed with balancing the car’s wheels.

As you can see, the procedure for balancing car wheels is not that complicated, but at home, without special equipment, it is almost impossible to do balancing. It is best to have your wheels balanced at trusted service stations, or ask your friends where they had this procedure done. An inexperienced specialist will only worsen the imbalance rather than eliminate it.

If the steering wheel wobbles or the car body vibrates, do not delay or delay wheel balancing, otherwise you will have to pay ten times more on damaged suspension or car body parts.

Video review of proper wheel balancing:

How is wheel balancing done?

Before you begin balancing, the wheel should be prepared. First, it is thoroughly cleaned, all old weights are removed, washed, and dried. Check that the tire is installed correctly. The wheel should be slightly lowered, the air pressure in it should not exceed 0.2–0.3 kgf/cm2.

At tire shops, balancing is carried out using special balancing stands or machines. But you can try to eliminate the imbalance at home without a stand, however, the accuracy of such a procedure will be much lower.

In order to eliminate the imbalance at home, you need to lift the car using a jack so that the wheel rotates freely. First it spins to the right. After stopping, a chalk mark is placed at the highest point. Then it spins to the left, the procedure is repeated. The distance between the marks must be divided in half and a new mark must be placed. After this, special weights with spring clamps are installed on both sides of the mark on the tires for balancing, which are mounted under the tire, while the weights are held on the wheel rim. Then the wheel is spun again by hand. If after stopping the weight occupies the lower position, then everything is fine, its weight is sufficient. If it ends up at the top, then you should replace it with a heavier one. By moving the weights to the same distance from the mark, it is necessary to ensure that after unwinding, each time the tire stops in a new position, chaotically. If this can be done, then the wheel is pumped up and you can start balancing the other one. The imbalance on the front wheels is corrected at their hubs. But the rear ones should be unscrewed and moved to one of the front hubs for balancing.

At service stations and tire shops, this procedure is carried out using special equipment. After all the preparatory procedures, the wheel is installed on a balancing machine with a fastening cone.

Correct wheel balancing, the most accurate, is done on a special computer stand. A wheel is installed on it and its parameters are set. After that, spinning it in different directions, using a computer, the lightest place and the missing weight are revealed. The car service specialist simply adds weights to the disc in the required places to eliminate the imbalance.

It is worth considering that the total weight of the installed weights should not exceed 60 grams. If their total weight is higher, it is worth thinking about whether the wheel is assembled correctly, whether the disk is deformed, or whether the tire is stale. If the tire is just from the store, and is installed correctly, there is no damage to the disk, then the need to attach weights with a total weight of more than 60 grams. indicates her marriage and may serve as a reason to return to the store.

After the usual, some tire centers perform final wheel balancing. It is carried out after installing the tire on the car, since here the imbalance of the wheel is checked and eliminated simultaneously with the hub and brake disc. To do this, the wheel is spun and by using a final balancing device, the imbalance of the entire assembly is revealed. It is leveled using the same weights. Moreover, their weight should not be more than 15 grams

It is important to understand that this is not an alternative to computer stands or machines, it is simply a way to improve the quality of balancing

How to do wheel balancing yourself

Some users do not know that you can balance your wheels yourself at home. The procedure can be applied to conventional stampings and castings without modification.

Motorists use two methods.

Without removing the wheel.

The essence of the process is to mount the weights in the right places. The sequence is done like this.

- Raise the desired wheel using a jack.

- Completely clean it of foreign stones and dirt.

- Prepare weights weighing from 10 to 50 grams.

- Turn the disk against the machine's direction and, after it stops, mark the highest point.

- Repeat the procedure again and apply a second mark. The middle of the gap between the risks will be the easiest part.

- Next, you need to install weights on the disk. The goal is to have the lightest side on the bottom.

- After this, a static balance is selected. The installed weights are moved 2-3 cm from the center and the wheel is rotated in the direction of travel.

- After stopping, you need to spin the tire again. If necessary, the loads are moved further apart. The goal is to ensure that the disc stops in a different position each time.

With the wheel removed from the car.

The essence of the procedure is to correctly hang the tire on the rim using a special cone. The rotating device was popular during the USSR, when there was no abundance of service stations.

Here's how to properly balance your wheels.

- Secure the cone strictly in the center of the hub.

- With the reverse side of the tool, place it on a stump or brick in a vertical position (the wheel will be horizontal).

- Place a weight on the part of the rim that is higher than the rest.

- Pump the tire slightly with your hand and wait until it stops.

- If necessary, add more weights.

The driver is required to ensure that the wheel is positioned strictly horizontally.

You can watch the video on how to do balancing at home.

You can also use special granules to balance wheels. The products are poured into the tire and independently distributed throughout the cavity. The service life of the product is equal to the operating time of the tire itself. However, the method did not take root in the Russian Federation and CIS countries. The high price has its effect.

It is mandatory to take into account that for a passenger car the maximum weight of cargo on one wheel with a new tire should not exceed 60 grams. Otherwise, this is a serious reason to return the product to the store, since this violates GOST.

Do I need to wash wheels before balancing?

Before directly calibrating the wheels, it is imperative to wash them thoroughly. When the disc hits the machine, it must be perfectly clean. Small pebbles stuck in the tread and dirt affect the accuracy of the device readings. The rule is relevant for all sizes of wheels, regardless of whether it is a Gazelle or a Porsche - 100% must be washed.

All stages of the process

At service stations and tire fitting stations, technicians eliminate defects of unevenly divided mass using compensating weights in certain places. The process is performed on special equipment.

The equipment automatically determines the place where the weight needs to be installed. The wheel dimensions are entered into the computer. The equipment will then select the optimal point for additional cargo. This is static balancing.

What type of weight to use depends on the disk and its parameters. This can be zinc or lead weight. They differ in weight - usually the weight ranges from 5 to 100 grams.

There is also dynamic balancing, however, this service is not provided everywhere. The problem is the equipment - in most cases it is very old. The wider the wheel, the greater the chance that dynamic imbalance will appear.

Final balancing is performed after static and, if possible, after dynamic. When the car is suspended, special equipment is installed under the wheels, the wheels are spun to high speeds, the system takes measurements and marks the places where the load should be installed. The system also calculates the weight of the load itself.

This process requires serious equipment, available only in professional wheel centers.

There is also automatic balancing, but it is not for cars, but for trucks. The master pours a special granule, beads, and sand into the wheel. During movement, due to centrifugal force, the material is attracted to the tire inside. The result is self-balancing. It is a pity that the technology is not available for passenger cars.

Equipment

There are different types of equipment – stationary and mobile. Stationary machines can determine the amount of imbalance of only the dismantled wheel. These machines can be electrically or manually driven.

On the first models, the disk rotates due to an electric motor. In the second case, you need to turn it manually

It doesn't matter what makes the disk spin - it doesn't affect the accuracy one bit

Simple models of machines work with steel disks and several types of cast ones. More complex equipment can work with disks of any design without problems. The program itself is capable of placing a weight at any point.

The electronic part of serious stands is capable of performing a lot of useful functions. For example, it can divide large loads into many small ones and distribute them to different points. This mode is effective if the imbalance is huge.

In this case, the stand shows several points. Another useful feature is optimization. The electronics analyze the imbalance of the tire and wheel, then find the optimal position relative to each other, thereby ensuring maximum balance. Using this function, you can reduce the amount of weight on the disk.

Mobile equipment is rolling stands for cars. They can be used for balancing without removing the wheels. The advantages are that the stand also takes into account other rotating masses - these could be hubs, brake discs or drums. Most often, such stands are used for finishing work after a stationary stand.

How to do balancing correctly

The wheel is thoroughly cleaned and then installed on the machine. Next, the equipment calculates the weight of the weights and the mounting points.

The mechanic installs the weight and checks the balance. If all indicators are normal, then the wheel is installed on the car. If there is no balance, then the process continues further.

Errors

There are a number of rules that must be followed:

- The disk must be thoroughly cleaned. There is usually a lot of dirt on the outside and on the inside. Automation calculates the weight of the weights. If you work with a dirty disk, you can lose your balance already on the first bump, when large dirt falls off the disk;

- Be sure to remove all old weights;

- It often happens that the tire simply does not fit into place. This is not visible from the outside, but it affects the balancing process;

- Hubcaps and other accessories can add imbalance.

These mistakes are often made at tire shops, because they work not on quality, but on volume and speed.

Wheel balancing | Regional Tachography Center

» Articles » Wheel balancing

This simple procedure should be carried out regularly by every car owner if he wants the vehicle to work properly. The service life of the suspension, braking system, steering mechanism, and therefore the driver’s safety, depends on the position of the tires and wheels relative to each other. In our article we will tell you everything about balancing car wheels: you will find out what it is, why and how often it needs to be done.

Balancing car wheels: what is it, what is it for, what affects it and when to do it

The term refers to the process of uniformly distributing the mass of the tires relative to the supporting axle.

Many drivers do not understand the practical value of this procedure, so they do not carry it out, considering it a waste of time and effort. Several decades ago, when passenger vehicles could not reach the same speed as they do now, there was some truth in this statement. Now the speed characteristics of new models have increased significantly, and even Russian roads allow you to feel the “delights” of an unbalanced car. They are especially pronounced when the needle on the speedometer is above 70.

The car begins to vibrate and rattle, so much that the shocks are felt even in the cabin. This causes the tires and wheel bearing to wear out prematurely and the suspension to become loose. Road grip decreases, the equipment stops listening to you and begins to wobble. To prevent loss of control and an accident, correct the imbalance.

How often should wheels be balanced?

In order to determine the frequency of this technical procedure, consider two factors:

- Condition of the roads. If you find smooth asphalt in our country, you can check the distribution of wheel weight no more often than every 12 km. For cars that often travel over rough terrain, the axle becomes loose more often, and the condition of the discs will have to be checked after each quick trip. If you damage one of them by falling into a hole at speed, you will have to replace it.

- Your driving style. If you try not to brake sharply or start moving, don’t like to drive and carefully drive around bumps, the tire and tread will last you a long time. Otherwise, you will have to check their condition every 5–7 thousand kilometers.

Most car enthusiasts do not know whether they need to balance their wheels every season. Yes, this should be done even if you purchased separate wheels for “winter” and “summer” tires. We also recommend paying attention to other situations that require this procedure:

- Falling into a hole at speed. Disc deformation occurs due to a strong impact.

- Use of studded tires. Uneven road surfaces cause some of the studs to wear off. The weight shifts to one side and the balance is disrupted.

- Bulkheading. Even if you entrusted the car dealership with the job, you should check the quality of the work. Inexperienced and unscrupulous mechanics often do not think about the correct location of the axle.

- Rubber quickly deteriorates. Most often, the reason is a broken wheel alignment of the car.

- Long trips. After every long trip exceeding 2 thousand km, check the suspension.

- Washing. A strong jet of water can knock down or displace weights that contribute to the correct distribution of masses relative to the reference point.

How is wheel balancing done?

To carry it out, you need a computer and professional tools; you cannot do this at home. In a car service, the machine will automatically determine where the main weight should be. Ask the mechanic how long ago the meter was calibrated and ask to see the corresponding entry in the technical book. If you are refused or the date does not suit you, go to another salon. An untuned machine will produce incorrect data. You will just waste time and money, but will not solve the imbalance problem.

Before placing a wheel for inspection, auto mechanics wash it or clean it with a stiff-bristled brush and remove all old weights.

New ones are selected based on the disk type:

- stamped models - printed on edge;

- cast – adhesive on the inside.

Adhesive weights are a less practical option. They fall off due to temperature changes and high humidity. If you choose it, make sure that before gluing the technician degreases the area of rubber on which the additional weight will be placed. Please note that any attempts at decoration, including decoration with caps, will lead to an imbalance.

The weights are made of zinc or lead and can weigh from 5 to 60 grams. If more mass is required, the problem is the disc warp, not the tire position. Experts distinguish two types of imbalance:

- Static. Related to wheel alignment. The elements become parallel to each other. You can easily identify it yourself, without the help of an auto technician. Spin the tire. If the oscillations at the end of the rotation are pendulum-like in nature, you have correctly identified the problem.

- Dynamic. The axis of inertia and rotation do not converge with each other. The center of gravity is calculated correctly, but the angle is changed.

Now you know what wheel balancing affects, whether it needs to be done when changing tires to new ones, and what the rules are for replacing and carrying out this important procedure.

Source: https://rctahograf.ru/balansirovka-koles/