However, in reality this is far from being the case: non-compliance with the manufacturer’s requirements regarding bolt pattern is fraught with a destroyed steering mechanism and a broken suspension, and this is only in the best case, much worse - that poor-quality broaching can lead to the wheel simply unscrewing while driving, endangering the lives of passengers and a driver of great danger. Therefore, you should consider not only the designation of the bolt pattern, but also its place in the disk markings, the symbols used for this and their meaning, as well as other information that is no less important and may be useful.

Size indicators

When purchasing a car, especially the first one, the owner rarely thinks about the fact that he should choose wheels carefully. Kits on the market often differ because they are designed for different cars, although there may not be any visible differences.

In order for the selection to be accurate and the wheels to fit the car, a number of sizes are taken into account. If there is an error in determining one of them, the disks will not be installed, but even if successful, operation of the machine will become unsafe. Before measuring the bolt pattern, you should understand what is included in it. Among the main sizes:

- number of holes for mounting the wheel (in the marking it is designated as LZ);

- distance between screw holes;

- the diameter of the circle along the edges of which holes for the bolts are made (in the disk marking it is designated as PCD);

- hub window indicator (you can find it out by the DIA number);

- degree of disc overhang (the ET marking is responsible for it).

Each of the characteristics is important when choosing a disk set. Their accounting becomes mandatory if wheels are purchased remotely - if they are incompatible, you will need to spend time communicating with the seller, returning the goods, or searching for a new set.

Passenger cars typically use 3-6 bolts per disc, which is much less than trucks. Given the diameter and weight of their wheels, each requires 12-15 bolts to secure.

Important! Domestic cars, especially Soviet-made ones, mostly have 4 bolts for installing disks. The Niva is an exception; its wheels use 5 bolts.

You can determine the exact number of fasteners needed to mount the wheels by looking at the stock wheels. By simple inspection it will become clear how many sockets are in the wheel and how many bolts are needed for them.

Main settings

There are several main sizes that play a key role in choosing the right and suitable wheels for each specific car. If you make a mistake on even one of them, the kit simply will not fall into place. The machine cannot be operated on wheels whose parameters do not meet the stated requirements and design features. Before trying on a bolt pattern, every motorist should know what exactly he has to measure, and what dimensions play the main role. We are talking about the following main sizes:

- the number of bolt holes on which the wheel is installed (indicated by the letters LZ in the marking);

- the distance provided between bolt holes;

- the diameter of the circle where the holes for the mounting wheel bolts are located, PCD marking is used;

- indicator of the diameter of the hub or central window: both concepts are found, but they are essentially synonymous, this parameter is marked with the letters DIA;

- overhang size, this value can be easily recognized by the ET marking.

It should be understood that each of these parameters, the presence of which is provided by the bolt pattern, is extremely important in the matter of choosing suitable wheels. Therefore, you need to carefully approach the purchase so that you don’t have to change the kit, overpay for delivery and simply waste time searching. If we talk about passenger vehicles, then the number of windows for mounting bolts can range from 3 to 6 units. Trucks have many more of them. Basically there are from 12 to 15 windows. The domestic auto industry, which is based on AvtoVAZ, uses 4 inlet holes for mounting bolts. The only exception was the legendary Niva, on which 5 mounts were installed. Only the holes can be counted the easiest. To do this, just take a visual look at the car. You can easily see exactly how many bolts are used to secure the wheel.

How to measure yourself

It’s possible to find out the bolt pattern yourself; this is possible with a ruler (preferably a caliper). They measure the distance between the windows, and the ruler has an error because it does not take into account the bend. You can take measurements in several ways, which are combined for greater accuracy.

Adjacent holes

This parameter is determined taking into account the indicator of the circle where the central part of the slot made for the mounting bolts is located. The diameter can be easily calculated using a ruler, although a compatibility table has been developed for popular cars. If a ruler is used, then the distance between adjacent bolts is measured in a straight line.

The resulting figure is multiplied by a coefficient determined by the number of holes in the disk. It should be said right away that the transverse circumference of VAZ cars is standardized at 98 mm, and in Niva it is 139.7 mm. The coefficients are as follows:

- 3 bolts - 1.155;

- 4 fasteners - the value for multiplication is 1.414;

- 5 — 1,701;

- 6 bolts - 2;

- 10 pins - 3.326.

Far windows

Instead of nearby holes, you can determine the bolt pattern even with a ruler with minimal error, using distant windows. The easiest way to measure wheels is if there is an even number of bolts - 4,6,8. The length of a straight line drawn between opposite holes will indicate the required value.

If there are 5 bolts on the disk, the distance between holes that are not adjacent is measured. The resulting figure is multiplied by a coefficient of 1.051, which gives the most accurate PCD result.

Hub window diameter

The hub center window size is specified in the bolt pattern charts and the complete bolt pattern formula mentioned below. Even if there is no ready-made information at hand, the results can be easily obtained with a ruler or a more accurate caliper. For example, the window diameter in the VAZ model 2110 is made at 58.6 mm.

Interesting!

It is not always possible to measure this indicator due to the irregular shape; Daewoo Nexia has such in its pre-restyling body.

In addition to the listed characteristics, disc offset is also important. It refers to the location of the vertical axes of symmetry of the wheel in relation to the point of alignment with the hub. The offset can be negative, as well as zero or positive, but even if the selection for it was unsuccessful, the disk can be installed. This is undesirable, because the car’s suspension will begin to function incorrectly and will greatly impair driving safety.

Is it possible to install a product with inappropriate parameters?

It is possible to install the product on a car with unsuitable bolt pattern parameters. For this purpose, special rings called centering rings are often used. With their help, you can set a parameter specifically for installing selected disks. This may result in errors in balancing and violation of suspension geometry. Therefore, it is strictly not recommended to carry out such operations, since they can disrupt the performance of the machine in motion.

The bolt pattern is an important parameter that can be used to determine how the disc is attached to the chassis structure. You can measure it yourself or find out from official sources, which is preferable.

One of the wheel rim parameters is the bolt pattern. Each manufacturer of foreign cars determines the value of the bolt pattern of wheel rims only for their own or standard rims, while for non-original vehicles this parameter differs by a fraction of a millimeter.

Is it important? What are fractions of millimeters? However, when installing “non-standard” rims, fractions of millimeters play an important role while driving. Remember, it is necessary that the wheel bolt pattern readings exactly match the factory dimensions of your wheels.

Bolt pattern formulas

To accurately determine whether the kit and car make are compatible, bolt pattern formulas are used that indicate the parameters of the disks. There are abbreviated and full values, but absolutely all parameters are indicated only in the latter.

Full

This formula is used by disc manufacturers who apply the appropriate markings to their products. It looks like: 8Jx15 H2 4x100 ET0 D54.1 and for an inexperienced car owner it is a random set of numbers and letters. In fact, each parameter can be deciphered:

- 8 Jx15 - the first number indicates the width of the rim, the diameter being 15 inches. The X here represents the type of wheel, in this case they are cast or forged. The letter J indicates the possibility of using the wheel only on cars with single-wheel drive - rear or front, because all-wheel drive is designated as JJ.

- H2 - Displays the number of haps, which are otherwise called horse lugs. They hold tubeless tires on the rim and there are products with one hub or without it at all. These elements secure the tire, preventing it from depressurizing, and also help to corner more efficiently.

- 4x100 is a PCD indicator, the first digit in which reflects the number of bolt sockets, the second - the transverse diameter of the circle.

- ET0 - gives an understanding of the disc offset, in this case it is zero. If the number is 40, this is a positive offset, and the designation ET-40 shows a negative offset.

- D54.1 - this designation indicates the diameter of the hub window, the figure is given in millimeters.

The diameter and width of the wheel rim are indicated in inches, while other characteristics are reflected in millimeters.

Abbreviated

The abbreviated digital characteristic is simplified; it contains only two indicators. the 4x98 formula reflects that the wheel has 4 bolts located along a 100 mm circumference. This is the standard bolt pattern of the VAZ 2110; other cars also have circles from 100 to 139.7.

Before purchasing wheels, measure the hub. There may be no differences, for example, a disk with a 98-th circle will visually fit on a hub with a diameter of 100. In practice, such a disk will not fit tightly to the hub, the wheel will be skewed, and safety will be at risk.

Compatibility tables for different cars

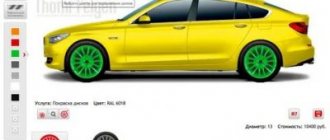

To make it easier to select wheels, below we will post compatibility tables for some car brands. These tables contain only general information, and before purchasing you should definitely pay attention to the labeling and other parameters.

Wheels should be selected based on compatibility rather than aesthetic characteristics. Make sure that absolutely all parameters correspond to the standard ones, so as not to endanger the lives of road users.

Bolt tables

Calculating the bolt pattern is rarely used, because there are compatibility tables. The driver needs to find a table for a specific model and look at the parameters for it. They include all popular cars used in Russia.

| Bolt pattern | Cars |

| 4*98 | VAZ; Fiat Panda, Lineo, Qubo; Ford Ka; Lancia Delta; Peugeot Bipper. |

| 4*100 | BMW Z1; Chery; Chevrolet Aveo; Daewoo Lanos; Dacia Logan; Fiat Punto; Hyundai Accent, Getz, Solaris; Honda Accord; VAZ Largus. |

| 4*108 | Audi 80; Citroen Berlingo; Ford Fiesta, Mondeo; Mazda 2. |

| 5*100 | Audi A1 (2.3), TT; Chrysler Neon, Sebring, PT Cruiser; Honda Civic; Nissan Sunny, Sunfire; Seat; Skoda Fabia Subaru Forester, Impreza, Legacy, Outback; Toyota Avensis and Camry; Volkswagen Golf, Bora, Beetle, Polo; GAS Siber. |

| 5*108 | Aston Martin Vanquish; Citroen C5, C6; Ford Focus, C-Max; Renault Clio, Kangoo; Land Rover. |

| 5*112 | Audi A3, A5, A6, RS4, RS5; Bentley; BMW; Mercedes-Benz; Ssang Yong Actyon, Chairman; Volkswagen Jetta, Transporter. |

This table does not contain all the bolt patterns, because there are many more cars. You need to look for the bolt pattern yourself for a specific car, this will help you accurately select the wheels.

Additionally! If the discs are still selected incorrectly, they can be processed by widening the hub window and changing the locations of the holes for the bolts. This is very difficult to do; in most cases, attempts end not only in disk damage, but also in accidents.

The disc bolt pattern is extremely important, because if it is selected incorrectly, the suspension will not work as it should and the car may get into an accident. To make an accurate choice, they focus on several indicators, including the diameter of the hub, the number of holes, and the size of the circle. There are also bolt patterns that will allow you to quickly select a set of wheels compatible with your car.

Features of bolt patterns of different types of disks

Today on the market you can find the following types of wheels for cars:

- stamped (steel);

- cast (light alloy);

- forged.

Steel models have gained popularity due to their modest cost, as well as the ability to straighten dents (they rarely crack and usually do not require expensive welding). Straightening is available for them due to their high strength - such a model will not burst even in a direct collision. The stamping bolt pattern must comply with standard standards.

Cast models are quite light, but not so durable during operation. The bolt pattern of wheel rims, the compatibility tables of which are presented by each manufacturer, must also fit into the standard standard.

Forged models are quite rigid and durable. During operation, they do not burst (it is extremely difficult to even make a dent on them), and are also not subject to the destructive effects of corrosion. In addition, if a forged wheel has a dent, it can be repaired by rolling it in a car service center.