Hydraulic compensators are knocking: establishing the reasons

So. Car enthusiasts with extensive experience claim that there will be no knocking on a fully operational car. And if extraneous noise appears, it means something is wrong. Why can these nodes knock?

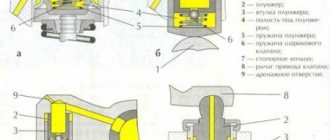

Among the main reasons are mechanical wear or wear that forms on the surface of the plunger pair. Also, extraneous sounds may occur due to unstable operation of the valve responsible for the oil supply.

The compensators do not knock all at once. Sounds can appear due to wear or failure of even just one part.

Checking the cylinder head check valve

When disassembling the pusher, you will come across a cylinder head check valve, which contains a ball with a spring. Inspect the cylinder head check valve; if these elements are damaged, then only replacing the pusher will help. The cylinder head check valve along with its components can be replaced entirely, but these parts cannot be found in every car store. They are not in demand, as it rarely fails.

Inspect the check valve ball and its spring

When you inspect the check valve, check whether it is dry or not. If the hydraulic compensator is working properly, then the check valve should be in oil. You can pour lubricant into it and see why the oil leaves.

Compensator valve

It happens that this very valve does not hold oil. Then, when the engine is cold, it may leak due to loose connections. This is how air enters the system. When warmed up, it disappears ten minutes after starting.

To diagnose this, you need to start the engine. Let the engine run for at least three minutes. You need to keep the speed at 2500. Then reduce it to idle speed, and then add speed again. This is enough for the air to completely escape and the compensator to stop knocking. But every time you start, the hydraulic compensators knock again and again when cold.

Inlet

It happens that this hole can become clogged, but it is intended for lubricant. How does the compensator continue to work as the engine warms up? The lubricant heats up, then the gap expands. The debris that covered the holes disappears, and oil begins to flow in quantities close to normal. However, when cooling, various viscous particles will clog the hole again, which will lead to poor lubricant access. This is why hydraulic compensators knock when cold.

To fix the problem, you can try changing the oil.

Oil filter

If it is clogged, then this is one of the reasons why the hydraulic compensators knock when cold. Extraneous sounds stop as the engine warms up. Then some of the lubricating fluid passes through the filter. However, in most cases, a miracle does not happen. The driver will hear a knock even when the engine is hot.

To get rid of this problem, you just need to replace the filter.

More experienced car enthusiasts constantly keep a “logbook”, where they write down the mileage when changing the oil, as well as the operation time. This helps a lot to complete it on time.

Why do hydraulic compensators knock when cold: Priora

This is a common problem on these models, as well as on many others from AvtoVAZ. Let's try to figure out where the knocking comes from and how to deal with the problem.

Here are some typical causes of knocking noises. So, if there is a knocking sound during a snack, and then the noise disappears, then this cannot be considered a problem. If extraneous sounds appear both on a cold and sufficiently warm unit when the speed increases, then most likely the unit will have to be replaced. Possible contamination - here you can get by with simple cleaning.

First aid for hydraulic compensators

Knocking hydraulic compensators on Priora. Before you climb into them, it is advisable to let the engine sit for at least a day without running.

- The engine oil turned out to be too soft , which is why the hydraulic valves literally break out of their places, creating a knocking noise. In this case, the springs may be damaged . It should be noted that excessively thick oil is also not good, because hydraulic compensators will have difficulty pushing the valve. In both cases, an oil change is required.

- The fuel and lubricants resource is coming to an end . If the oil is clogged with engine operating products, a knocking noise may occur. Accordingly, it should be changed. (see material oil change).

- The oil system is clogged . After cleaning everything should return to normal.

- The main valve plunger is worn out or jammed . In the case of a leak arising from a check valve, there is no need to talk about high pressure. Due to carbon deposits accumulated inside, the plunger could jam, which is why a characteristic knock appears. It's better to replace it.

- Due to the overheated motor, the expansion of the hydraulic compensator wells occurred . Accordingly, small parts move freely back and forth. To stop the knocking, you need to cool the engine.

- The oil level is too high or, conversely, too low . With a small amount of fuel and lubricants, too little pressure will be created to push the valve . If there is more oil than needed, then the space for their work is reduced.

If there is a knock, what should I do?

When you hear a knock, you need to check the elements for serviceability. To do this, perform the following steps:

- Checking the ball valve . If there is significant wear, the hydraulic valve will have to be replaced.

- If the plungers are worn out, the part is also beyond repair. In this case, the hydraulic compensators will have to be replaced.

- If the internal cavity of the pusher , then the part must be washed and then lubricated with a good oil composition.

If the hydraulic compensators are worn out or clogged, knocking noises begin when the engine is cold. At high speeds they usually quiet down.

By the way, the knocking may not go away even after installing new hydraulic compensators. This is a temporary phenomenon, and when the parts rub in, the sounds will disappear . If the knocking starts after an oil change, the reason may be poor-quality fuel or a worn-out filter.

Hydraulic compensators and “Accent”

The reasons for the knocking are standard here. The owners write that the problem can be solved by changing the oil. More experienced owners believe that if hydraulic compensators knock when cold (Accent is no exception), this is nothing more than a feature of the engines.

But in general, most drivers change oil with a viscosity of up to 5W30, and this allows you to completely get rid of the knocking of these mechanisms in the engine.

The oil pump should be checked. It may not be producing the required pressure. Many also recommend lubricant products from.

How to eliminate the knocking of hydraulic pushers on Lada Priora

Timely and high-quality maintenance of the engine oil system is the key to flawless operation of the hydraulic compensator mechanism. After all, the unit is designed for use throughout the entire resource of the power plant.

Use of recommended lubricant

When the hydraulic pushers just start knocking, the manufacturer recommends changing the lubricant to a proven option. Therefore, when the question arises of what kind of oil to pour in principle, it is worth analyzing reviews to determine the acceptability of a certain model of oil product for hydraulic compensators.

Of course, the best choice for Lada Priora will be the composition recommended by the manufacturer, specified in the instruction manual. However, not all current popular products are included in the list.

An analysis of opinions shows that, indeed, with the universal viscosity of 10W-40 or 5W-40 specified by the factory, not every oil is suitable. For example, Shell Helix Ultra 5W-40 causes knocking already at 15,000 km, while on Liqui Moly Optimal Synth 5W-40 the hydraulics are silent even at 80,000 km.

Reviews show that it is optimal to choose the following lubricants:

- Total Quartz 9000 Energy 5W-40.

- Mobil Ultra 10W-40.

- Wagner Windigo 10W-40.

Flushing

Many owners, in advanced cases, resort to general engine flushing. However, the effectiveness of such an event in the fight against knocking GCs is low. This is explained by poor oil pumpability in the area of the hydraulic pusher chambers.

If changing the lubricant does not help, the best solution is to remove the cylinder head cover and find which hydraulic compensators on the Lada Priora 16-valve engine are knocking and determine the reason for this. Defective parts are identified by diagnosing running resistance with a wooden wedge. A fast movement speed in comparison with other hydraulic supports indicates wear of the hydraulic module, the presence of a constant gap indicates its coking.

Attention! The wooden wedge must be pressed against the non-working surface of the cams.

Effective removal of carbon deposits inside the cylinders is their local washing. Worn assembly modules cannot be repaired.

Additives

Additive compounds help delay identifying the causes and cleaning the timing belt. There are several products available in the market. The most popular products are from Liqui Moly and XADO. The effectiveness of substances depends on the specific case. Fans of motor additives often equate this class of chemistry with a waste of money.

How to check hydraulic compensators yourself

You can check the condition of the spring.

You can also measure the size of the gaps between the guide bushing and the valve stem. If the gap is large, it must be eliminated.

Then you should turn the crankshaft so that the knocking valve begins to open. After this, you can turn the spring. The valve will turn with it. After starting the engine, the knocking noise should disappear completely. If the hydraulic compensators are still knocking when cold, the Priora needs to repeat the above operations. It is best to replace the damaged unit with a new one.

Sequence of actions on Lada Priora

- Both terminals are removed from the battery.

- The wires on the injectors and on the ignition coil are disconnected, the cable is removed from the throttle, the air filter and all other wires that prevent access to the engine intake manifold are removed.

- Before removing the manifold, you will have to remove the belt from the generator, then unscrew its mounting bolt. After this, the generator can be moved to the side and you can get to one of the intake manifold mounting bolts (there is no other way to get to this bolt).

- The next step is to remove the ramp and fuel injectors (if the car has air conditioning, you will also have to remove its hoses so that they do not interfere).

- All other manifold mounting bolts are unscrewed, after which it is removed.

The valve cover is unscrewed with a 12 mm socket wrench.

- Now you can remove the valve cover, timing pulleys and camshafts.

Removing a previously unscrewed valve cover

- Since we now have access to the hydraulic compensators, all that remains is to replace them with new ones (we should also change the seals on the camshafts and the sealant on the valve cover).

After removing the cover, the camshafts are removed

Worn hydraulic compensators are removed from their sockets

- After this, the above components are reassembled. The instructions below are suitable for cars with 16 valves.

We recommend: How to replace windshield washer nozzles

Replacing hydraulic compensators on a VAZ-2112 is not so easy, but you can do it yourself. Of course, this will require time and effort. The choice of product should also be taken quite seriously, because the resource of use depends on the quality.

How to find out which hydraulic compensator has failed

Acoustic diagnostics are usually sufficient. If this method does not help, then press the knot with a screwdriver. A normally functioning structure will compress if sufficient force is applied. If it is easily pressed through, then it is faulty and should be replaced as soon as possible.

In the second method, you should install the cams of the camshaft mechanism one by one with their protrusions facing upward. Here you need to make sure that there is a certain gap between the cam and the pusher. When pushing the compensator down, try to compare it with known-good parts. If there is a gap or the lowering speed is high, then you need to clean or replace the element.

Eventually…

From all this it is clear that knocking when cold can occur for a variety of reasons. If the expansion joints are noisy and it doesn’t stop, then you need a replacement. But you can use modern additives, which, according to manufacturers, reduce noise levels. You can also count on an oil change to help. Now you know why hydraulic compensators knock - you can easily find and eliminate the cause yourself.

The most common malfunction of modern engines is the knocking of hydraulic compensators. There are many reasons, most of them related to the quality of the oil. This material will tell you what to do in case of this malfunction and how to deal with it.

What is a hydraulic compensator and how does a hydraulic compensator work?

A hydraulic compensator is a simple device for automatically adjusting the clearance in the valve drive, eliminating the need to disassemble the engine during its maintenance. A hydraulic compensator, in common parlance “hydrik,” is a miniature hydraulic cylinder that changes its length when engine oil is pumped inside.

The volume of oil compensates for the gap between the valve stem and the camshaft cam. Oil enters the cavity of the hydraulic compensator through a valve with a very small hole, and comes out through the natural clearances of the valve pair. How well the “hydric” works depends on the supply of oil and on the condition of the plunger pair, the absence of wear or jamming.

Communities › Lada Priora Club › Blog › Selecting hydraulic compensators

Hello everyone! It is planned to replace all the hydraulic lifters (16 pieces), but after reading the forums I still couldn’t decide on the manufacturer (apparently motorists don’t sit on the forums). There is no information on ratings among manufacturers. For now I stopped at the Lada-Image (Perm) or Ina (100% original) plant. But which will be the highest quality and most durable? There are also many other manufacturers, such as: RUVILLE, Keno, Trial, Herzog, TSN, MANOVER, QML, BAUTLER, LGR, etc. Help me make a choice!

Tags: 21120-1007300-86

Comments 39

I always took INA, never had any questions

I took NPA through Autodok, the second year, everything is fine, the oil is Rosneft.

Why npa?

Based on the principle of value for money.

INA, but the original is unlikely to be found cheaper than 3500, and only if someone doesn’t want to make money. It’s funny to read that INA has a lot of defects... Of course, a lot, if you charge 1500-2500 per set.

if you have a varik, take the original one, take them, they go for 400 thousand

Is this from personal experience or did the mechanics share information?

was a prior. drove 500 thousand. Sold it, keeps driving. I made capital for 200 thousand. The valve burned out. (Inna installed hydraulic pushers, and STK forged pistons with grooves) the engine was sharpened for the first repair. my head went completely over. The only old ones left were the distributors and the elbow. By 500 thousand I didn’t burn oil, I never heard a clatter from the engine, regardless of the starting temperature from -30 to warm! Mobil oil 3000 5 w40 always gasoline exclusively 95 or 100. in the interval from 200 to 500 thousand I changed only the oil and the pump rollers belt twice. I didn't use any additives. but the master who made the motor is an arch-pedantic person!

Is this from personal experience or did the mechanics share information?

but the shitty iron is still from Priora

Let me ask cautiously, what caused the desire to change them? I changed the brand of oil and the problem went away. Mileage 163,000 km. Hydraulics from the factory

The desire is mechanical wear of several hydraulic compensators (perhaps they were already installed from the factory with a proper fit). In this case, the brand and viscosity of the oil is irrelevant.

When do you need to replace hydraulic compensators on a Priora?

How to determine that the hydraulic compensators on a Priora need to be replaced?

A clear sign that one of the 16 hydraulic compensators has failed is the presence of a knocking sound in the engine. This knocking noise may appear on a cold start and disappear when the unit is warm. If the engine is knocking, then it is certainly better to have it rebuilt and checked to understand why there is an alien sound coming from the engine. But the reason why hydraulic compensators knock on a cold engine may also be that they simply do not contain oil. After a couple of minutes, the knocking of the hydraulic compensators usually disappears and does not recur until the next cold start.

Knocking after replacement

Usually new parts don't knock.

If you still hear sounds, then this is a manufacturing defect or a problem with the valves. In order to perform an accurate diagnosis and make sure that there is nothing wrong with the valves, it is necessary to check their fastenings. There is a possibility that the parts did not shrink as required. We simply tighten them and thereby remove the knock of the hydraulic compensator.