How to understand that the hydraulic compensators of the VAZ 2112 are knocking?

It is very easy to check the hydraulic compensators: you need to remove the valve cover, bring the crankshaft to a position where the cams will not act on the compensators, and then press on the piston. If the hydraulics are working properly, the piston will move down, if not, it will stop!

This often happens due to insufficient oil. You can understand what exactly is knocking in the engine by the following characteristic signs:

- If the knocking noise disappears only at high speeds, it means that there is a faulty ball piston hidden somewhere, it must be detected and the failed compensator replaced

- When it starts knocking on a warm engine, this is a sure sign that the hydraulic valve has worn out and has completely exhausted its service life.

- If knocking occurs at high speeds, there is most likely excess oil in the system. The lubricant gets onto the cylinder head and disrupts the functioning of the compensators

Instructions for restoring the performance of hydraulic pushers

To access the hydraulic compensators, you will need to partially disassemble the gas distribution mechanism. The simplest test is to press the device with your finger - it should remain as rigid as possible. If the pressure causes the pusher to “fall through”, then the assembly is removed and washed. To do this, we suggest using the recommendations.

This is interesting: Adjusting doors on a Lada Granta - what to do if the front door does not open from the outside: do-it-yourself repairs

Required spare parts

Article numbers 2112-1007300-01 and 2112-1007300 indicate hydraulic pushers manufactured by AvtoVAZ - this is the catalog number. They need to be purchased for repairs. The price of the set is about 3,300 rubles (per piece – 220 rubles). You can also buy spare parts with article number 420007310 INA. They are suitable for replacing VAZ 2112 hydraulic compensators (16 valves), but the price of the set is higher - up to 2,700 rubles (per piece - 280 rubles). Another analogue is Herzog HL0 7300. Price 2700 rubles. The compensator Master-sport 2112-1007300-SET/16/-MS is also recommended for installation on VAZ 2110, 2111, 2112.

Tools required for repairs

To work you need to prepare the following tool:

- magnetic screwdriver;

- jack;

- a set of keys;

- rags;

- sealant or degreaser.

Independent replacement of VAZ 2110 hydraulic compensators 16 valves is completely justified economically. In car services, as of July 21, 2019, the price of repairs averages 3 thousand rubles. In addition to money, you will save personal time.

Sequence of operations

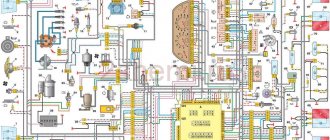

To replace the hydraulic compensators of the VAZ 2112 and other models, you need to drive the car into an inspection hole, drive onto an overpass, or lift it with a jack. It is important to ensure reliable fixation of the vehicle and sufficient illumination of the work area. Now you can start working:

- For safe work, you need to turn off the on-board power supply; to do this, disconnect the negative terminal from the battery.

- Removing the plastic engine shield - unscrew the four bolts.

- Now you need to loosen the mount of the generator on the mounting plate; to do this, loosen the nut.

- You need to remove the generator drive tension belt. To do this, loosen its tension by rotating the nut counterclockwise.

- Removing the engine intake manifold and receiver. The hole must be closed to prevent dirt and foreign objects from getting into them.

- Then you need to dismantle the right wheel and the plastic shield covering the engine compartment. Now use the pulley bolt to turn the crankshaft clockwise.

- The lower pulley rotates to the camshaft timing pulley mark to the antennae on the rear timing cover.

- The camshaft pulley fastenings are loosened and the timing belt is removed.

- To completely dismantle the camshaft pulleys, you need to check the marks on the timing belt housing. They must line up exactly with the marks on the pulleys.

- Using the heads, 15 fasteners of the cylinder head cover are unscrewed.

- Now twenty fasteners of the camshaft bearing housing are unscrewed.

- The camshaft bearing housing is removed.

- The camshaft is completely removed, along with the seals.

- A magnetic screwdriver is applied to the end of the hydraulic pusher, so it is removed from the head socket.

- New spare parts are installed in place of the old compensators in the cylinder head sockets.

- The cams and bearing journals are lubricated with oil, the shafts are installed in the head supports. Note! To easily distinguish the intake camshaft from the exhaust device, there is a belt on its first journal.

- Now you need to tighten the nuts until they touch the cylinder head of the bearings. The operation is performed in a certain sequence, it is shown in the figure.

- The valve cover, timing belt and pulleys are returned to their original locations. Further operations are performed in reverse order.

For the sequence of replacing hydraulic compensators on the VAZ 2110 and other models, watch this video:

How to eliminate knocking on a VAZ 2112?

The reasons for the appearance of knocking noise from hydraulic compensators are quite clear: natural wear, low-quality engine oil, lack or excess of lubricant in the system. Monitor the engine oil level; if necessary, top up, don’t skimp. Also, you don’t need to save on oil changes - it’s more expensive for yourself.

As practice shows, repairing expansion joints is a waste of nerves and time. It is also impractical and, in the end, unprofitable. Check all the elements again, most likely one of the hydraulic valves is knocking. Replacing hydraulic lifters is a simple job.

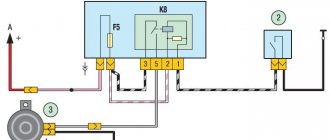

For normal operation, hydraulic compensators require an uninterrupted supply of oil, which is supplied under pressure. The supply occurs through a special channel with a check ball valve, which prevents oil from draining from the channel after the engine is stopped. In addition, there are channels located on the lower plane of the bearing housing, which supply oil to the camshaft journals.

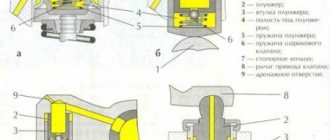

Hydraulic compensator design:

To enlarge the image click on the image!

The disadvantage of hydraulic compensators is their excessive sensitivity to the quality and purity of the oil. The presence of mechanical inclusions and other foreign elements in the oil leads to rapid failure of the hydraulic compensator plunger pair. This malfunction is most often accompanied by increased noise emission and intense wear of the camshaft cams.

Device

What to do if valves or hydraulic compensators on a VAZ 2112 16 valves are knocking? Before answering this question, it is necessary to understand the structure of the hydraulic compensator, which mechanics often abbreviate to “hydric”. It is from the peculiarities of its structure that the reason for some knocks follows.

The hydraulic compensator itself consists of a cylindrical piston, whose bottom receives the force from the camshaft pusher. There is a plunger located inside it. With its help, force is transmitted from the camshaft to the valve stem. The plunger moves quite freely in its seat. This is necessary to ensure a thermal gap. When the engine is running, the camshaft cam pushes the piston, which opens the valve through a plunger. The thermal gap is adjusted using oil supplied to the head under pressure. Accordingly, adjustment occurs by changing the pressure. To avoid oil leakage from the hydraulic valves during parking, a ball valve is used.

Let's summarize. Hydraulic lifters are knocking - reasons

- Hydraulic lifters can knock due to problems with oil, including the fault of a faulty oil system, as well as as a result of a mechanical malfunction of the hydraulic compensator itself.

- If hydraulic compensators knock when cold , but the knock disappears when hot, then, according to experienced mechanics, there is nothing wrong with this; this phenomenon occurs in most car owners.

- If the hydraulic compensators knock when hot , that is, after the engine has warmed up to operating temperature, this is a clear sign of a malfunction that must be eliminated immediately.

Approximate price of hydraulic compensators

Unlike foreign-made cars, parts for the VAZ-2112 are affordable. In most auto parts stores for domestic cars you can find a set of hydraulic compensators for a sixteen-valve engine at a low price - about two thousand rubles. Before purchasing, carefully examine each pusher to avoid purchasing a defective part.

Among manufacturers of spare parts for VAZ-2112 engines, the INA brand occupies a leading position, but it is very often counterfeited. In order to make the right choice, watch a video in advance about the features of branded hydraulic pushers. Pay close attention to how much a set of pushers costs, since a high-quality spare part cannot be cheap.

Source

Problems in the oil system that can cause knocking in hydraulic compensators:

- Clogged oil channels (dirt in the channels, plaque);

- Airy oil system (air present in the system increases the compression ratio of the oil). Air in the oil can occur as a result of high or low oil levels;

- Clogged oil filter;

- The wrong oil has been filled in (does not match: viscosity, fluidity, quality, temperature characteristics);

- There may be interruptions in the operation of the oil pump;

- Overheating of the engine, as a result of which the oil burned, losing its viscous and lubricating properties.

How to check hydraulic compensators - video

Types of knocks

We've sorted out the structure, now let's look at the causes of knocking and their varieties. After all, knocking can happen in different ways and some of the sounds are quite harmless:

- The knocking noise appears upon startup, but disappears almost immediately. This is a common phenomenon characteristic of “hydrics”. It occurs due to ball valves remaining open, oil gradually leaking out of them. During engine operation, the amount of oil is restored. Actually, you don’t need to do anything here. This is a normal technical process;

- The knocking is heard constantly, but disappears when the speed increases. This problem can occur if the ball valve is faulty, or if the part is contaminated with low-quality oil;

- Knocking occurs only on a hot engine, in case of increased wear of the hydraulic valve. When cold there may be no knocking;

- If knocking is heard only at high speeds, but not at low speeds, then the reason is in the oil. Check the oil level and condition. If the level is higher than usual, the crankshaft whips up the oil during operation, and a kind of foam forms in it. It gets through the oil intake into the cylinder head and, accordingly, into the hydraulic compensator, the operation of which is disrupted. If the level of lubricant is too low, it simply does not reach the hydraulics. In both cases a knock will be heard.

How to solve the problem of knocking hydraulic compensators?

- You can try changing the oil if it has been changed for a long time or looks bad (dark brown color, bad smell, etc.). As a rule, after replacement, the knocking of hydraulic compensators disappears. If the knocking does not disappear, you will have to take out the main battery and see what’s wrong.

- If adding oil did not lead to anything, and washing the engine did not give any result, you can try another way to solve the problem of knocking hydraulic valves. The principle is to remove the main hydraulic valves, perform a visual inspection of them, in case of insignificant wear and normal condition, you can disassemble and wash the hydraulic compensators. When removing, I recommend remembering or writing down where which hydraulic compensator was installed. After washing, everything is assembled and the operation of the engine is checked; if washing the hydraulic compensators does not lead to anything, the only way out is to replace the hydraulic compensators .

Replacing hydraulic compensators on a Priora 16 valves

If, when starting the 16-valve Priora engine, you hear knocking noises in the engine compartment, which will disappear as the power plant warms up, then you should check the hydraulic compensators (HC). When every start of a cold engine is accompanied by a knocking sound, this is a clear sign of a worn hydraulic compensator.

Hydraulic compensators are sensitive to the quality of lubricant. If mechanical impurities are present in the oil, the part may fail ahead of schedule. Faulty hydraulic compensators cannot be repaired. After installing new compensators, you may be upset by the knocking of the remaining main valves - this is normal, but not for a long time.

Determining the faulty hydraulic compensator

Hydraulic compensators, which are also called hydraulic pushers, adjust the engine valve clearances on the Priora 16 valve. Below is a diagram of how the main body is dismantled and replaced, but first you should find out how to identify a defective part among the rest.

Checking compensators is carried out as follows:

- In turn, press on each main body with a screwdriver. Check that the camshaft cam is facing the pusher with its back;

- If the compensator is working properly, you will need to apply considerable force to press it;

We click on each compensator and check whether it is working or not - Did the pusher go down easily? It is faulty and needs to be replaced.

There is another method - place the cams with the protrusions facing up. Now you need to check if there are gaps between the cams and the main body. When recessing the tested part of the Priora 16, it is necessary to compare the speed of its movement with the rest of the pushers. If you find a gap or the main body drops too quickly, then you should remove the pusher and inspect it for contamination.

Checking the cylinder head check valve

When disassembling the pusher, you will come across a cylinder head check valve, which contains a ball with a spring. Inspect the cylinder head check valve; if these elements are damaged, then only replacing the pusher will help. The cylinder head check valve along with its components can be replaced entirely, but these parts cannot be found in every car store. They are not in demand, as it rarely fails.

Inspect the check valve ball and its spring

When you inspect the check valve, check whether it is dry or not. If the hydraulic compensator is working properly, then the check valve should be in oil. You can pour lubricant into it and see why the oil leaves.

Replacing expansion joints

Experts recommend letting the Priora with 16 valves sit for two days and not start it. This is done to ensure that all the HA lubricant flows into the crankcase.

After checking how many pushers in the system are malfunctioning, you can go to a car store and purchase new parts for the Priora 16 and some consumables: oil seals, camshaft plugs, anaerobic sealant.

Step-by-step instruction:

- Work begins with removing the air filter, wiring, which will prevent you from removing the coil and intake manifold. Also remove the throttle body. The most difficult thing will be to dismantle the collector - its mount is located under the generator. To get to it, you need to unscrew the generator fasteners and remove its belt. Using a suitable tool, move the Lada Priora generator to the side;

Unscrew the bolt and proceed to removing the return manifold - Now you have access to the bolt - it should be unscrewed using a wrench with a flexible nozzle;

We unscrew the fasteners and remove the manifold - now we have access to the cylinder head - Next, remove the ramp with the injectors. If you have a Priora with air conditioning, then in addition to the injectors you will also have to remove the air conditioning pipes. Take them aside;

We need to remove the air conditioner pipes, the arrows point to their fastenings - We lift the left edge of the manifold, move it to the side and remove the valve cover. There are special recesses on it - pry them out with a flat screwdriver;

Removing the cylinder head cover - Let's move on to the timing belt - remove it along with the pulleys. Now we can dismantle the camshafts along with the bed;

The cylinder head belt must be removed to get to the cover fasteners. - So we got to the compensators. Professionals recommend replacing all hydraulic compensators, even if only one pusher is pressed through. This is done to ensure even wear. If this is not possible, then we replace the faulty main body;

- It is convenient to remove the pushers from their installation places using a powerful magnet. Now you can check the cylinder head check valve and determine the cause of the malfunction;

- It is recommended to lubricate the surface of new hydraulic tappets with engine oil, and only then carry out installation. Reassembling the motor is performed in reverse order. Don't forget to change the camshaft seals. The head cover gasket also requires replacement; coat it with sealant before installation.

DETAILS: How to set contactless ignition on a VAZ 2101

After such repair of expansion joints, the knock may remain. If a lot of time has passed and the defect does not go away, then it is worth checking the cylinder head itself. Perhaps the hydraulic compensators are knocking due to the lack of the required amount of lubricant. Check the oil channels in the cylinder head. If they are clogged, you will have to clean them.

Which company should I purchase spare parts for replacement?

Owners of Priora 16, who have already encountered the replacement of these components, recommend installing INA hydraulic compensators. The pushers from the VAZ 2112 have also proven themselves; they are produced by. If these options are not available in the store, then take the standard set for Lada Priora.

vazremont.com

Conclusion

| Have you encountered knocking noise from hydraulic compensators? |

The knock of hydraulic compensators on the 16-valve VAZ 2112 engine is distinguished quite simply, and determining the cause is not difficult. So, you can eliminate the cause of the knocking in a fairly simple and proven way.

The video story will tell you how to replace hydraulic compensators, as well as diagnose them in case of extraneous knocks and sounds.

System structure

Hydraulic compensators produced by AvtoVAZ

The hydraulic compensator is a cylindrical piston that transmits the force of the camshaft pusher. The internal part has a plunger that transmits force to the valve. This is what provides the thermal gap. In order for the valve to open, the piston pushes the camshaft cam, which in turn pushes through the plunger, which acts on the valve. The thermal gap is adjusted by oil under pressure. The ball valve prevents oil from leaking.

Conclusion

If a characteristic sound is heard when starting the engine, this can most likely be considered a sign that the hydraulic compensators are knocking in the engine. They are designed to automatically adjust the gaps that appear at the valves when the engine heats up and cools down.

Hydraulic compensators and their operation

In order for hydraulic compensators to operate stably, they will require a constant supply of oil. To do this, there is a channel in the block head with a ball (valve), which prevents the oil from draining after the engine is stopped. There is a similar valve at the bottom of the bearing, through which oil is supplied to the valve neck for lubrication.

Recommended engine oil for VAZ 2112

It should be noted right away that these parts are sensitive to the quality of the oil. If there are any impurities in it, then the plunger pair of the hydraulic compensator will fail within a short time. This will affect the operation of the motor. Noise will appear and the camshaft cams will wear out intensively. If the hydraulic condenser is faulty, it cannot be repaired. It just changes to a new one.

Hydraulic compensators in the cylinder head

When a knocking sound in the engine is constantly heard, the cause of its occurrence should be identified. To do this, you must adhere to the rules given below.

Hydraulic compensators are always checked when replacing valves!

System structure

Hydraulic compressors, or hydraulic valve pushers as they are also called, are designed to automatically adjust their thermal clearances. Simply put, they are a kind of gaskets between the camshaft cams and valves, capable of changing their thickness.

The hydraulic compensator consists of a cylindrical body, as well as a special plunger consisting of a bushing, a spring and a ball valve. Their use on the VAZ-2112 engine makes it possible not to periodically check thermal clearances, as on the 2108 engine (valve adjustment).

- Replacing the door lock cylinder of a VAZ 2109: algorithm of actions

- Replacing the thermostat on a VAZ 2114 2115 with your own hands Photo instructions on how to change the thermostat

- Replacing the distributor on a VAZ 2107 with your own hands Photo instructions on how to change the distributor on a VAZ 2107

- Let's figure out how to remove the rear bumper on a VAZ 2114