External signs of error P1514

There are several simple external signs by which one can indirectly judge that there are problems with the idle regulator or its control circuit. Among them:

- after starting the engine, the car immediately stalls; the speed can only be maintained by additionally pressing the accelerator pedal;

- when stopping the car, if you do not maintain additional speed, the engine stalls (for example, when stopping at a traffic light);

- while driving, if you reduce the speed to idle, the engine begins to “cough” and the car starts to twitch; in some cases, it is noted that the engine stalls when moving to neutral speed or when the speed is reduced to the minimum value (idle) while the car is moving ;

- The Check Engine light on the dashboard comes on.

However, the signs listed above may actually indicate other malfunctions in the car, so it is necessary to carry out an accurate diagnosis by reading data from the electronic engine control unit (ECU) using special hardware and software.

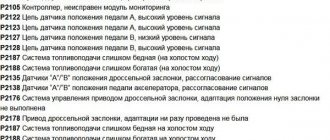

Diagnostics and fault codes of the Chevrolet Niva Niva ECM with controller ME17.9.71

The on-board diagnostic system signals the presence of a malfunction by turning on the indicator.

Then, the on-board diagnostic system must, using special equipment, obtain diagnostic information stored in the controller’s memory.

For this purpose, a serial information transmission channel is organized in the engine control system, which includes an ECM controller, a standardized block for connecting a diagnostic device (Fig. 1) and a wire connecting them (K-line). In addition to the block, the information transfer protocol and the format of transmitted messages are also standardized. In addition to obtaining information about detected malfunctions and the state of the engine control system, the on-board diagnostic system allows you to perform a number of verification tests by controlling the actuators.

The main component of the on-board diagnostic system is the ECM. In addition to its main task (controlling the combustion processes of the fuel mixture), it performs self-diagnosis.

When performing this function, the controller monitors signals from various sensors and actuators of the ECM. These signals are compared with reference values stored in the controller's memory. If any signal goes outside the control values, the controller evaluates this condition as a malfunction (for example, the voltage at the sensor output has become zero - short circuit to ground), generates and writes the corresponding diagnostic information to the error memory, and turns on the warning lamp (alarm) indicates malfunctions, and also switches to emergency operating modes of the ECM.

The on-board diagnostic system begins to function from the moment the ignition is turned on and stops after the controller enters the “standby” mode (occurs after the main relay is turned off). The moment of activation of one or another diagnostic algorithm and its operation are determined by the corresponding engine operating modes. Diagnostic algorithms can be divided into three groups:

1) Diagnostics of sensors. The controller, by monitoring the value of the sensor output signal, determines the presence or absence of a malfunction.

2) Diagnostics of ECM actuators (driver diagnostics). The controller checks the control circuits for opens, shorts to ground, or shorts to the power supply.

3) Diagnostics of ECM subsystems (functional diagnostics).

In the engine control system, several subsystems can be distinguished - ignition, fuel supply, idle speed maintenance, exhaust gas neutralization, gasoline vapor recovery, etc.

Functional diagnostics gives an opinion about the quality of their work. In this case, the system no longer monitors individual sensors or actuators, but the parameters that characterize the operation of the entire subsystem as a whole.

For example, the quality of operation of the ignition subsystem can be judged by the presence of misfires in the combustion chambers of the engine. Fuel adaptation parameters provide information about the state of the fuel supply subsystem. Each subsystem has its own requirements regarding the maximum permissible deviations of its parameters from the average values.

Fault indicator

The fault indicator on Chevrolet Niva cars is located in the instrument cluster.

When the warning light comes on, it means that the on-board diagnostic system has detected a malfunction of the ECM and the vehicle continues to move in emergency mode.

A flashing warning light indicates a malfunction that can lead to serious damage to the ECM (for example, misfires can damage the catalytic converter).

When the ignition is turned on, the indicator should light up - this way the ECM checks the serviceability of the indicator and its control circuit. After starting the engine, the indicator should go out if the controller memory does not contain the conditions for turning it on.

To protect against random, short-term errors that may be caused by loss of contact in electrical connectors or unstable engine operation, the warning light turns on after a certain period of time after detecting a malfunction in the ECM. During this period, the on-board diagnostic system checks for a malfunction.

After eliminating the causes of the malfunction, the alarm will turn off after a certain delay time, during which the malfunction does not appear, and provided that there are no other fault codes in the controller’s memory that require turning on the alarm.

Conditions for generating error code P1514

For different brands and even car models, the conditions for generating the P1514 code may differ, albeit slightly. Let's look at this using the example of domestic injection VAZs. So, for an IAC closure error to form, the following conditions must be met:

- the car engine is started;

- the DC voltage value in the vehicle’s on-board electrical circuit is in the range from 7 to 16 V;

- The electronic engine control unit, while checking the idle speed regulator, detected a lack of load at the output (no electrical signal).

When the above conditions are met, the Check Engine warning light comes on immediately.

What does the error mean?

Trouble P0135 is a generic OBD-II code indicating that the oxygen sensor (Bank 1, Sensor 1) voltage does not meet the minimum and maximum voltage values calibrated for the ECM.

When the oxygen sensor heater reaches operating temperature, the oxygen sensor begins to respond to the oxygen content in the exhaust. The control unit monitors how long it takes for the sensor to start working. If the control module determines (based on coolant temperature) that too much time has passed before the oxygen sensor begins to operate, it will set the P0135 fault code.

Reasons for the error

There are several reasons that could be the source of error P1514. Among them:

Idle speed control

- Complete or partial failure of the idle air regulator. This is usually expressed in a violation of the insulation of its windings (a change in the value of electrical resistance). It is also possible that it may be physically contaminated, or its seat or electrical contacts may be contaminated. If the regulator is old, then physical wear of its individual elements or an increase in play is possible.

- Damage to the IAC control circuit. This could be a break in the individual wire(s) or damage to the insulation.

- Poor electrical contact in the IAC control circuit. There may be oxidation on the contacts, damage to the so-called “chip”, dirt on the contacts, and so on.

- Throttle valve not fully closed or throttle pipe clogged.

- Clogged upper tube of the crankcase ventilation system.

- The so-called “glitch” of some ECU firmware. This is especially true for domestic Lada cars with firmware “January-7.2”.

Each individual reason for the formation of code P1514 is eliminated in its own way. Usually the work is not difficult, but quite labor-intensive.

Common diagnostic errors

A few simple recommendations that will help you avoid mistakes when diagnosing DTC error P0135.

- Correct any exhaust system problems upstream of the oxygen sensor to prevent excess oxygen from entering the exhaust stream.

- Check the oxygen sensor for engine oil or coolant contamination. They can damage the oxygen sensor.

- Repair any damage (wiring, connectors, etc.) associated with the oxygen sensor to prevent erroneous sensor readings.

- Check the removed oxygen sensor for damage from a broken catalytic converter. Replace the catalyst if it is damaged.

What and how to check

When diagnosing error P1514, be sure to check the following data:

- The insulation resistance value of the electrical windings of the idle speed control. To do this, use a multimeter with the ability to measure electrical resistance. If such a device is not available, you can use an ohmmeter (this option is less convenient). If the resistance value is low, the windings are damaged.

- Check the mechanical condition of the regulator, its cleanliness and the fit of some other elements, which will be discussed below.

- Integrity of the regulator control circuit. This can also be done using a multimeter, but in the “dialing” mode. The purpose of the test is to find the location of the wire break.

- Insulation resistance value of the regulator control circuit. If the circuit is not broken and the resistance value is low, it means that the insulation somewhere in the circuit (on the wires) is most likely damaged.

- Check that the throttle valve opens completely.

The algorithm for specific actions will depend on the make and model of the car, since everyone’s electrical circuits are different. However, the general algorithm will be the same for everyone. Let's look at it using the example of a common domestic car - the VAZ-2107 with an injection engine. So, the verification algorithm will be as follows:

- If the engine is running, turn it off. Disconnect the terminal block from the idle speed control. Turn on the ignition (without starting the engine). Using a multimeter, measure the insulation resistance value of the IAC windings. You need to measure in pairs between contacts “A” and “B”, and then between “C” and “D”. The corresponding value should be in the range of 40...80 Ohms or close to it (for VAZ cars, but for foreign cars it will be similar). Otherwise, damage to the winding and/or its insulation occurs. Repair in this case is impractical, and in fact, impossible, so the IAC needs to be changed completely.

- Similarly, with the ignition on, you need to check the voltage at the contacts of the block relative to ground. This is also done using a multimeter set to constant voltage measurement mode. If on all contacts relative to ground the voltage value is in the range from 4 to 6 Volts, then there is a weak connection in the idle speed control harness block.

- Turn off the ignition. Disconnect the wiring harness connector from the controller. You need to use a multimeter to measure the resistance value of the wires between the contacts of the harness block, at which the voltage is 4...6 V, as well as the corresponding contact of the controller block. If, as a result of the measurement, it turns out that this value is less than 1 ohm, then this indicates a malfunction of the controller. If the resistance is more than 1 ohm, then you need to look for an open circuit.

- Check the resistance value between all idle air control contacts and ground. The corresponding value should be in the range of 19...21 kOhm or close to it. If this is not the case, it means there is a weak connection in the IAC harness block.

We are looking for the cause of misfire in the cylinder

Car owners whose cars are equipped with “electronic brains” are a little more fortunate in this matter, since it is possible to use an auto tester. Thanks to the “brains” and testers, you can see, for example, where exactly misfires occur in cylinder 1 or 3.

In addition, using the scanner you can also determine the direction of the search itself. If the scanner showed you code P0204, and you know that this is an injector malfunction. Code P0300 indicates random misfire in all cylinders. Therefore, we can conclude that the air-fuel mixture is deteriorating, which means that the reason may lie in high air suction at the recirculation valve or in low pressure due to a faulty pump.

If a misfire occurs in a car that does not have an electronic assistant, then you will have to look for the cause using “old-fashioned methods.” They begin with checking the electrical equipment located under the hood: spark plugs, explosive wires, after which the compression in the cylinders and the condition of the fuel pump are measured.

If none of the versions are confirmed, there are two options: either continue the search on your own, or go to a service station for help, where they will help you fix the problem for money.

How to resolve error P1514

The method for eliminating error P1514 depends on the reason that led to its appearance. In general, the following options are possible:

- Replacing the idle air control. This is the most expensive case in terms of money, but the easiest to work with. As practice shows, failure of the IAC is very typical for domestic VAZs . A good option would be to check the regulator before replacing it by replacing it with a similar one that is known to work. This will save you from unnecessary financial costs. And periodically (every few months) check the condition of the sensor.

- Repair or replacement of the IAC control circuit. If the insulation is worn out (shorts to ground, causing the car to stall), then you need to find the location of the damage. This is quite a labor-intensive matter. First of all, you need to inspect the places where the wires are bent, the places where they come into contact with the metal body of the machine, and the places where they are connected with ties. In the simplest case, use electrical tape or heat shrink to restore the insulation of the wires (having previously cleaned their surface). The worst case scenario is to completely replace the wires (ready-made harnesses can be found on sale).

- Inspect contact connections. This especially applies to so-called chips. If the car is old, then there is a high probability that the plastic holders have become unusable due to age and temperature changes, which is why the contact becomes loose. You need to try to repair the chip, or simply replace it with a new one. You should always check the contact connections at the input directly to the computer, especially if the wiring is old.

- Perform mechanical cleaning of the IAC and its seat. In some cases, it is noted that error code P1514 occurs when the IAC itself or the machine’s ventilation system becomes significantly clogged with dust or debris. In this case, it is recommended to dismantle the idle speed control and wash it thoroughly with a cleaning agent. After cleaning, it is advisable to lubricate the moving elements of the regulator, but not thickly (you can use the common WD-40 or its analogues) so that dust or dirt does not settle on the lubricant. Also, if necessary, flush the throttle pipe. Check the condition of the upper crankcase ventilation tube.

- If the throttle valve does not close completely, it is necessary to loosen the drive cable slightly so that it closes completely.

- Check the total engine mass. This is especially true if, in addition to the error code P1514, there are some others.

An interesting fact is noted for modern VAZs with firmware “January-7.2” (this could be “Kalina”, “Granta” or another Lada). On numerous forums, their owners note that error P1514 “falls out” for them just like that, due to a “glitch” of the control unit, and in fact, the IAC and its wiring have nothing to do with it. This problem can be resolved by flashing the ECU. Car owners recommend HL52, FL52 or DZ36. However, remember that, firstly, you need to reflash the control unit in a good, trusted car service center, and secondly, even if such firmware is available, it still makes sense to check the regulator and its wiring. However, in this case, you need to start repairs not by flashing the firmware, but simply by resetting the error. This can be done programmatically or simply by disconnecting the negative terminal on the battery for a few seconds.

Sometimes, as a preventive measure, it is recommended to check the MAF ADC. It also makes sense to clean the internal contacts of the main and fuel relays. As a last resort, replace them (if they are significantly worn and/or burnt). For VAZ cars, it is preferable to use a throttle position sensor (TPS), manufactured in Kaluga. If possible, replace with one.

Some car owners experience error P1514 because they fill the gas tank with fuel with a lower octane number than prescribed by the car manufacturer. This is explained by the fact that either in the regulator itself or in its wiring there is some kind of minor damage, which under normal conditions does not show itself. However, when pouring low-octane gasoline, the engine begins to vibrate more, which is why hidden “diseases” may appear. This usually results in broken insulation or electrical contacts somewhere in the circuit.

Please note that when P1514 occurs, the engine control module no longer controls the idle speed control. However, after it is eliminated, IAC control resumes immediately after turning off/on the ignition system.

How serious is P0135?

- An oxygen sensor voltage that is outside the acceptable parameters may indicate problems with the exhaust system or engine.

- If the catalyst is damaged in front of the oxygen sensor, it cannot read the correct values.

- If any oxygen sensor malfunctions, the engine control module (ECM) may not be able to properly adjust the air-fuel ratio. This may result in increased fuel consumption and possible premature failure of some other engine components.

About notOshibka.Ru

Consent to the processing of personal data

I hereby confirm and give my voluntary consent to the website neoshibka.ru (Internet address https://neoshibka.ru/) in accordance with Article 9 of the Federal Law of July 27, 2006 N 152-FZ “On Personal Data” for processing and the use of my personal data specified during the registration process, commenting, or when filling out any other contact form on this site, with or without the use of automation tools, including collection, recording, systematization, accumulation, storage, clarification (updating, changing ), extraction, use, transfer (distribution, provision, access), depersonalization, blocking, deletion, destruction of personal data in order to collect statistics and improve the services provided by the site. The processing of personal data is also carried out for the purposes of my information notification (distribution of information, if desired, there is an unsubscribe function) and for conducting analytics and statistics.

I am aware that:

- This consent to the processing of my personal data specified during registration on the Site, sent (filled out) using the Site, is valid for 20 (twenty) years from the date of registration on the Site;

- Consent can be withdrawn by me based on a written statement in any form;

- Providing personal data of third parties without their consent entails liability in accordance with the current legislation of the Russian Federation.

How to troubleshoot P0172

Fuel trim monitoring uses the oxygen sensor to operate, meaning fuel trim codes are not oxygen sensor codes.

Code P0172 together with error P0175 or errors in the mass air flow sensor. If you see a P0172 with a P0175 code or MAF-related errors at the same time, you can likely rule out individual cylinder, ignition, and fuel injector problems. Instead, focus on the fuel injection system and air flow sensor.

Contamination of the air flow sensor can distort air measurements, so the fuel injection calculations are changed. Cleaning may solve the problem. Replacing the sensor, along with a new air filter and properly sealing the air ducts, would be a more reliable solution.

Check fuel pressure. Make sure it is in the proper range. Excess pressure, for example caused by a faulty pressure regulator or a pinched return line, will cause more fuel to be injected than the ECU expects.

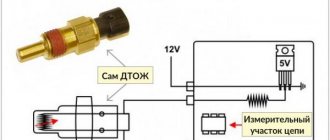

Check that the DTOZH (coolant temperature sensor) and IAT (intake air temperature) sensor readings are correct. The control unit may not detect faulty sensors, so it is useful to check that the temperature sensors are within normal ranges. For example, if the engine was running for half an hour on a hot day, the DVT value should be at least 80 °C. If the ECU still reads 0°C, it will enrich the FA ratio to compensate, resulting in an over-rich condition.

P0172 with other Bank 1 DTCs. If you only have a P0172 with simultaneous Bank 1 DTCs, such as cylinder misfire, then focus on Bank 1.

Fuel pressure drop. With the engine running, record the fuel pressure, then stop the engine. Fuel pressure may drop slightly but should remain stable for at least 10 to 15 minutes. If fuel pressure continues to drop, you may have a leaking fuel injector, resulting in a rich condition and possible misfire.

Misfire in the cylinder. A cylinder misfire will result in the release of unburned fuel into the exhaust stream. Diagnose and correct misfires before attempting to diagnose a rich mixture

Pay attention to associated error codes such as VVT (variable valve timing) or ignition system.

Exhaust. Check exhaust for leaks between cylinder head and oxygen sensor

Although the exhaust system appears to be a positive pressure system, air can enter the partial vacuum created by the exhaust gas pressure pulses. Atmospheric oxygen arriving before the DC distorts oxygen measurements.

Posts 1 page 12 of 12

Share104-10-2013 01:53:19

- Author: Rashid

- Newbie

- Registered: 03-10-2013

- Invitations: 0

- Posts: 3

- Respect: [+0/-0]

- Positive: [+0/-0]

- Car make: Subaru TRAVIQ

- Time spent on the forum: 56 minutes

- Last visit: 29-10-2013 22:27:48

Hello, please tell me what error 1514 is, if anyone knows and how to fix it

Share204-10-2013 10:01:29

- Author: Lekc

- Elder

- From: Omsk

- Registered: 24-12-2008

- Invitations: 0

- Posts: 1321

- Respect: [+21/-0]

- Positive: [+4/-2]

- Gender: Male

- Age: 40 [1979-10-10]

- ICQ: 321826222

- Car make: SUBARU TRAVIQ

- Spent on the forum: 2 months 12 days

- Last seen: Yesterday 09:10:45

P1514 Throttle valve control system malfunction. I had one of these come out when the chain broke. Valve train chain. I got it.

First, try resetting, if it happens again, dig.

Share304-10-2013 13:40:16

- Author: Rashid

- Newbie

- Registered: 03-10-2013

- Invitations: 0

- Posts: 3

- Respect: [+0/-0]

- Positive: [+0/-0]

- Car make: Subaru TRAVIQ

- Time spent on the forum: 56 minutes

- Last visit: 29-10-2013 22:27:48

I reset the engine, it runs fine for a while, then it starts to sputter again and gives the same error, they checked the cylinders, the pressure in the cylinders is excellent.

Share404-10-2013 18:19:56

- Author: udgin

- Elder

- From: Perm

- Registered: 09-12-2010

- Invitations: 0

- Posts: 806

- Respect: [+3/-0]

- Positive: [+9/-1]

- Gender: Male

- Age: 39 [1981-02-04]

- Car make: Subaru Traviq, 2002, Z22SE, automatic transmission

- Time spent on the forum: 13 days 3 hours

- Last seen: Yesterday 18:00:52

It will be useful: Volkswagen transporter t5 and t4 fuse diagram: location and replacement methods

Share504-10-2013 18:35:36

- Author: Rashid

- Newbie

- Registered: 03-10-2013

- Invitations: 0

- Posts: 3

- Respect: [+0/-0]

- Positive: [+0/-0]

- Car make: Subaru TRAVIQ

- Time spent on the forum: 56 minutes

- Last visit: 29-10-2013 22:27:48

You understand, the car is in a car service center, so to call it, if it were a normal service in the vicinity, then no questions would arise, but I am conveying the words that the mechanic told me

Share604-10-2013 22:23:59

- Author: Volodia24

- Elder

- From: Krasnoyarsk

- Registered: 05/31/2009

- Invitations: 0

- Posts: 1695

- Respect: [+34/-0]

- Positive: [+6/-0]

- Gender: Male

- Age: 56 [1963-06-01]

- Car make: Subaru Travig S-PG 2001, Z22SE automatic transmission FA

- Spent on the forum: 21 days 0 hours

- Last seen: Yesterday 23:20:55

Mechanic or electrician? Isn't the throttle valve itself stuck?

Share715-10-2013 15:32:19

- Author: Traviq

- Newbie

- From: Krasnoyarsk

- Registered: 05-04-2013

- Invitations: 0

- Posts: 14

- Respect: [+2/-0]

- Positive: [+0/-0]

- Car make: Subaru TRAVIQ

- Time spent on the forum: 9 hours 59 minutes

- Last visit: 01/30/2020 12:33:43

Similar situation. Error 1514 pops up from time to time (z22se engine) more details about the problem: 1. The dynamics are gone, it feels like someone is holding it by the ass. 2. The hum in the exhaust system has increased. 3. When you press the gas pedal to the floor in neutral, the needle rises to 6000. Then there is something similar to a cutoff sound and the check light comes on (error 1514). The error resets, but the next time you hit the floor in place or press the gas slowly while moving, 1514 pops up again.

My personal conclusion is that the problem in the exhaust system and the damper itself has nothing to do with it. I could be wrong , an autopsy will show. I will knock out the afterburner, then the catalyst one by one.

PS The filters have been changed, the pressure in the rail is normal, the spark plugs are new, the EGR is plugged, the soldered EGR blende works perfectly.

Share815-10-2013 17:45:58

- Author: Evgeniy-ensk

- Elder

- From: Novosibirsk

- Registered: 22-12-2008

- Invitations: 0

- Posts: 523

- Respect: [+3/-0]

- Positive: [+0/-0]

- Time spent on the forum: 9 days 4 hours

- Last visit: 02/14/2018 19:25:39

What kind of EGR trick is this?

Share916-10-2013 00:39:40

- Author: Volodia24

- Elder

- From: Krasnoyarsk

- Registered: 05/31/2009

- Invitations: 0

- Posts: 1695

- Respect: [+34/-0]

- Positive: [+6/-0]

- Gender: Male

- Age: 56 [1963-06-01]

- Car make: Subaru Travig S-PG 2001, Z22SE automatic transmission FA

- Spent on the forum: 21 days 0 hours

- Last seen: Yesterday 23:20:55

Share1024-10-2013 13:49:47

- Author: Traviq

- Newbie

- From: Krasnoyarsk

- Registered: 05-04-2013

- Invitations: 0

- Posts: 14

- Respect: [+2/-0]

- Positive: [+0/-0]

- Car make: Subaru TRAVIQ

- Time spent on the forum: 9 hours 59 minutes

- Last visit: 01/30/2020 12:33:43

I got to the garage. The autopsy showed that I was wrong.

I unscrewed the first lambda, started the car, no changes. I measured the pressure in the cylinders, everything is normal. I removed the valve covers and the cause was found. The top bolt of the damper (the longest one) broke off. I turn the crankshaft until the marks match, the marks on the camshafts match, and on the crankshaft the mark has moved two teeth forward. The only interesting thing is that the chain did not rattle, apparently one bolt on the damper is enough to prevent the chain from beating and being tensioned, but apparently it jumped at the moment of start. The only good thing is that the valve was not bent. I would like to note that after diagnostics they sent Atlantic Motors without a second thought to get a new damper (the guys don’t want to work at all).

Now on topic: Maybe just clean the damper? cases for half an hour along with removal (definitely won’t be superfluous);

cylinder pressure is excellent

If it's not a secret, what is it? I have 13 points in the first three, and 12.5 in the fourth.

Share1124-10-2013 14:14:53

- Author: rom

- Local

- From: Krasnoyarsk

- Registered: 15-12-2010

- Invitations: 0

- Posts: 447

- Respect: [+2/-0]

- Positive: [+9/-1]

- Gender: Male

- Age: 48 [1971-07-27]

- Car make: Subaru Travig 2002 white

- Time spent on the forum: 7 days 3 hours

- Last visit: 01/21/2015 08:58:20

I would like to note that after diagnostics they sent Atlantic Motors without a second thought to get a new damper (the guys don’t want to work at all).

I have long said that Atlantic is no longer the right service to turn to.

Share1204-11-2013 00:27:26

- Author: Traviq

- Newbie

- From: Krasnoyarsk

- Registered: 05-04-2013

- Invitations: 0

- Posts: 14

- Respect: [+2/-0]

- Positive: [+0/-0]

- Car make: Subaru TRAVIQ

- Time spent on the forum: 9 hours 59 minutes

- Last visit: 01/30/2020 12:33:43

The broken bolt is defeated, the chain is set to the marks. The car became playful again, error 1514 does not light up.

Hello, please tell me what error 1514 is, if anyone knows and how to fix it

Has the problem been resolved? If so, why did you issue 1514 and how was it treated?

What triggers P0118

Reasons for the code “high signal” of the coolant sensor:

- in general, this is any breakdown of the sensor;

- The device becomes clogged and issues incorrect notifications. Therefore, it is advisable to dismantle the assembly and inspect it thoroughly, clean it, check it;

- The detector connector is damaged. Old plastic may crack, the tight fit of the “chip” is broken, and fasteners break off;

- break of two or any of the wires on the device circuit to the ECU;

- Short-circuit of wiring to each other or to ground when they are chafed;

- incorrect functioning of the ECU, its failures.

What codes (the first letter of all is “P”) accompany them, they can also indicate a more specific reason:

- 0115 – faulty electrical circuit;

- 0116 – signal out of acceptable range/performance;

- 0117 – low signal;

- 0119 – unreliable contact.

Common cause of code P0118

The most common cause of P0118 is an open or shorted wire. That is why inspection, checking contacts and circuits is extremely desirable.

Severity level of error and threat to vehicle

With P0118, the ECU switches the engine into emergency operation. The problem is relatively minor and does not lead to serious consequences. The machine can be used fully with the exception of the inconveniences described below, and the load on the system increases and its wear becomes more intense.

The consequences are not critical, but still have a certain negative impact:

- unstable operation of the engine when warming up, and it lasts until the engine reaches the required operating temperature, which can cause some harm to the system and accelerate its wear;

- fuel consumption increases;

- the level of carbon on engine components increases, corrosion becomes more intense;

- emergency mode often leads to problems in the ignition system;

- Exhaust toxicity increases, and accordingly, the catalyst and EGR system are more loaded;

- the impellers of the cooling system may not work correctly, intermittently, unstably, or turn on/off spontaneously;

- the valves of the adsorber, the idle speed control unit, the ignition system, and the fuel supply are overloaded.

In an emergency state of the internal combustion engine, the t° of the cooling mixture is forced to be +80° (+176° F) or is slightly different for different brands (+92° C). The value is set after 60 seconds, during which t° is assumed to be +20. The vehicle can be used, but there is a risk that if the actual temperature of the liquid for cooling exceeds the threshold value, problems will arise with the motor.

Description and meaning of error P0598

This is a generic powertrain diagnostic trouble code (DTC), which means it covers all makes/models 1996-newer. However, specific diagnostic steps will vary depending on the vehicle. Codes P0597, P0598 and P0599 all refer to the engine's electronically controlled thermostat. They are general codes, meaning they apply to all vehicles using this type of thermostatic control, however only a small number of manufacturers use this type of system. So this trouble code article is basically identical for all three codes. Diagnostic trouble code P0598 indicates that a fault has occurred with this system where the control voltage is low. For the most part, German manufactured vehicles like BMW, Mercedes, Audi, Mini, Volkswagen, Opel and Jaguar use this system. An electronically controlled thermostat consists of various temperature and load sensors, a computer program and a control housing with a built-in thermostat. ConceptBy monitoring coolant flow or engine temperature electronically, the throttle part increases fuel economy and reduces emissions, while reducing temperature under load increases power.

see also

Error p0351 p0352 p0353 p0354 - what does it mean

P0336 - Crankshaft sensor error

P0340 – camshaft sensor error

Error P0108

PCS system error

Error P1514 stands for “open idle air control control circuit.”

However, on some machines it may be called differently. External signs of an error are the car’s lack of idle speed, especially in the cold season and immediately after a cold start. Often the cause of the error is problems directly with the idle air regulator (its complete or partial failure) or with its electrical circuit (the insulation on the wires is frayed, contacts are lost), as well as other adjacent components that affect the operation of the IAC. Eliminating the error consists of either replacing the IAC or repairing the electrical circuit (renewing contact in the connector, replacing insulation or entire control wires). In fact, error P1514 is not critical, and it is quite possible to drive while maintaining engine speed using the accelerator pedal, but this causes certain inconvenience to the driver (for example, forgetting about it, you can stall at an intersection), so it is advisable to correct the error as quickly as possible after it appears .

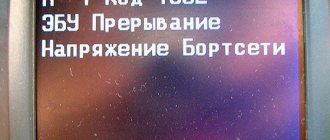

ECU error 1602 on VAZ 2110

I advise you to double-check the generator, perhaps the diodes are faulty, check the voltage at the terminals again, it should be 13.7-14.0 V. In general, error 1602 often pops up when the battery is disconnected from the power supply, there is nothing wrong with this error, it will disappear on its own after a while, they fall into the category of “good mistakes”. Perhaps the error occurred due to a large voltage drop during startup (bad battery, cold, thick oil, etc.), due to the voltage drop, the unit automatically increases the opening time of the injectors to compensate for the fuel supply. Check the ground on the ECU, either because of it or because of the TPS.

VAZ brand expert

Error p0404

With us from 07/31/09

I advise you to contact an authorized dealer who has the necessary diagnostic equipment and qualifications. As a rule, this is cheaper than long agony.

With us from 06.09.10

I also have the same problem because of code 1602. I remove the terminal from the battery and put it back after 15 minutes (I give it a wait), and still, immediately when I turn on the battery, it shows code 1602. I looked at the masses, it seems that they are pressurized everywhere and are not oxidized. I don’t even know what to do. And diagnostics are very far from home. Yes, by the way, what voltage input should be at the input to the controller at terminal 18? And what output from the generator should be no less and no more?? Please help me.

With us since 09.26.07

to fatim-sergey: Has the car’s behavior changed? Regarding the indicators, I think it’s better to look in a book. But don’t worry, there is nothing fatal about this error.

With us from 09.25.10

For no apparent reason, the car stopped showing signs of life at the moment of ignition. The battery works - all the lights are clearly lit. The BC showed 1602, after disconnecting the battery it malfunctioned and froze. Help!

With us since 09.26.07

Chevrolet Niva error codes: decoding and description of meanings

to drCE: error 1602 - loss of mains voltage in the controller. Accordingly, the issue is most likely in the wiring.

With us from 03.23.11

I arrived normally in the morning and started starting it and nothing says 1602, what should I do? I planted the battery, I think it might just work to charge it, but I’m already afraid of this; I’ve never had this happen before; what can I see for myself? Can you tell me what to check?

With us from 05.12.10

to fantic: You need to start by checking the fuses.

With us from 03.23.11

And where do the fuses come into play? I have exactly the same problem, I put it on at night and fuck it, we die in the morning BC flash writes right away 1602 and here we are, and in the end we start like this since 15, what should we do, what’s the reason. S P A S A Y T E

With us from 03.23.11

predyhi are normal

With us since 02/05/11

to fantic: Look at the ground on the ECU (on the motor side) - several wires on the screw to the head on the thermostat side. Basically, this is an error due to penetration of the mass or due to the TPS. So look and check.

With us from 05.12.10

fantic: what do fuses have to do with it? I have exactly the same problem, I put it on at night and fuck it, we die in the morning BC flash writes right away 1602 and here we are, and in the end we start like this since 15, what should we do, what’s the reason. S A S A Y T E #

Decipher this for me:

I put it on for the night and fuck it, we die in the morning

what do you put and where and who dies?

With us from 04/13/11

Yes, I got the same error after WASHING the internal combustion engine. I just looked around everything. I tried to change the brains, there were fewer errors, but still 1602 remained, maybe the fuse block itself (oxidized or not) WHAT TO DO HELP

With us from 05.12.10

to artem-2115: Of course, oxidation can affect the voltage drop. But you wrote that you climbed everything. Or not all?

Check the controller and fuse box connectors especially carefully.

With us from 03/06/12

Guys, I have this problem! When I start the engine, everything works fine, but only when the car starts to heat up and the engine temperature rises, the engine starts to work worse and jerks (what could be causing this?)

besides, when you remove the clamp, the error disappears, but when you move again, it appears again, and the consequences are repeated!

please tell me why this could be?!

Diagnostics produces errors such as:

1602 - feeding by. 30, reset

P0131 Oxygen sensor circuit low voltage (bank 1, sensor 1)

P0134 The oxygen sensor (bank 1, sensor 1) does not work - but it was replaced

With us from 05.12.10

to pavel_007:

You probably have 2 problems.

1. This is a voltage leak and, as a result, a drop in circuit voltage. Check the battery and generator operation.

2. Oxygen sensor malfunction. That's why it pulls.

With us from 03/14/12

What to do? I leave the car overnight and in the morning the battery is zero. After charging, the on-board computer shows error 1602

With us from 03/19/12

Good day, today my check light came on. It shows error 0628 RB circuit, short circuit to ground. What does this mean?

With us from 05.12.10

drozdenko1976:

What to do? I leave the car overnight and in the morning the battery is zero. After charging, the on-board computer shows error 1602 #

Look for a leak. Possible alarm. Check the leakage current directly at the battery.