Code P0328 is entered if the following conditions exist:

engine crankshaft speed is more than 1300 rpm; coolant temperature above 60°C; the amplitude of the knock sensor signal is above the threshold. If a permanent malfunction occurs, the “CHECK ENGINE” lamp lights up after 2 drive cycles.

1. The existence of conditions for the occurrence of code P0328 is checked.

2. The serviceability of the screen of wires 2 B and 88 G is checked.

1. Connect the adapter cable to the diagnostic connector. Start the engine and warm up to a coolant temperature of 60°C. Set the engine crankshaft speed to more than 1300 rpm.

How does a mechanic diagnose a P0328 code?

When diagnosing this error code, a mechanic will do the following:

- Connects the OBD-II scanner to the vehicle's diagnostic connector and reads all stored data and error codes

- Clear error codes from the ECM and test drive the vehicle to see if P0328 appears again

- Find out if the engine makes a lot of noise during operation

- Inspect the knock sensor for damage

- Check the cooling system as well as the engine for damage

- Checks the octane number of the fuel, as well as the fuel system

- Check the knock sensor voltage

- Checks engine coolant temperature and fuel pressure

- Will check the ECM according to the manufacturer's procedure

When is it diagnosed?

The conditions for the error to occur may vary for different car models, but general symptoms can be outlined:

- crankshaft speed level over 1300 RPM;

- warm car engine (coolant temperature exceeds +60 °C);

- The knock sensor signal level is below the limit values.

The sensor comes into operation only when fuel detonation occurs, so the absence of a signal from the meter is recorded at high speeds and a warm engine. As already mentioned, the error does not appear immediately - it is entered into the ECU memory only after the second trip in a row with the specified values.

Priora knock sensor

A knock sensor is a device that detects the knock levels of internal combustion engine processes. The installation location of such a device is the cylinder block. Maintaining it makes it possible to obtain high power, as well as achieve good fuel economy without causing damage to the engine.

The detonation process is the main defect of an internal combustion engine, since the force is considerable and it is impossible to ignore it. Among several different devices that are used as performance optimizations, the knock sensor is used to prevent knocking fuel combustions. Fuel detonation can be controlled thanks to the main indicator - the manifestation of high-pitched and ringing metallic sounds, which, according to indicators, are sometimes mistaken for the clicking sounds of the cylinder-piston group. If the process is strong enough, with faulty knock prevention systems the engine begins to fail.

What you need to know about the phase sensor

So, what is a VAZ 2114 phase sensor, how to find it and what are its signs of malfunction?

Device and purpose

DF installation location

DF is a regulator necessary to obtain data on the functioning of the vehicle engine and transmit this information to the ECU. As for the design, the DF consists of a sensitive component as well as a pulse converter. The design of the latter, in turn, includes an operational amplifier, an output stage, and a bridge circuit.

The sensing component located inside the structure operates on the principle of a Hall regulator. Its purpose is to transmit an impulse at the moment when a magnetically conductive component is located next to the microcircuit. As for the location of the VAZ phase sensor, it is located on the side of the cylinder block, next to the air filter element.

Malfunctions

A device failure can be identified by certain signs:

- increased gasoline consumption;

- malfunctions in the machine’s self-diagnosis;

- decreased dynamics when accelerating a car;

- Errors 0343, 0340 or a Check lamp may appear on the control panel.

The light bulb Check usually appears if the DF is inoperative.

How to connect DF correctly

Check and replacement

To check on an eight-valve engine, you must perform the following steps:

- At the multimeter terminal V1, you need to set the voltage to 13.5 volts; this probe is connected to pin E. At the second pin, which is connected to pin B, you need to set the voltage to 0.9 volts.

- After closing the contacts, a screwdriver or plastic steel should be brought to the end of the regulator. And if the DF is functioning properly, the voltage at output B should drop to 0.4 volts. If the readings differ, then the DF should be replaced (the author of the video is In Sandro’s garage).

As for the sixteen-valve engine, the principle is slightly different:

- The multimeter is set to operating mode V2, the voltage at output E should be set to 13.5 volts, and at output B to 0.4 volts.

- We again bring a screwdriver or plate to the DF body. If the DF is working normally, the voltage level will increase to 0.9 volts

To perform a replacement, you need to do the following:

- First you need to turn off the battery by removing the terminal from it.

- Using a 10mm ratchet wrench, unscrew the screw securing the device to the cylinder block. Disconnect the wires that are connected to the DF.

- Remove the DF and replace it with a new one. It is a good idea to clean the pad contacts from dirt or oxidation.

Additional comments for troubleshooting P0328

When diagnosing the P0328 code, it is very important to follow the diagnostic protocol to ensure all checks and repairs are performed correctly.

To make a proper diagnosis, a mechanic will need a professional scanner that can not only read stored error codes, but can also view data from various sensors, such as fuel pressure and engine coolant temperature, in real time.

Need help with error code P0328?

The company - CarChek, offers a service - on-site computer diagnostics; specialists from our company will come to your home or office to diagnose and identify problems with your car. Find out the cost and sign up for on-site computer diagnostics or contact a consultant by phone

What does it indicate?

The appearance of error P0325 indicates incorrect operation of the knock sensor, or more precisely, the presence of faults in its circuit. The device is installed on the cylinder block or intake manifold. It is designed to detect engine detonation using a piezoelectric element located in it.

The sensor perceives vibration of the cylinder blocks as an oscillatory movement. The pressure is then converted into a voltage signal and transmitted to the engine control module. Error code P0325 occurs when the sensor voltage level is too low or, conversely, too high. This does not have a critical impact on the operation of the engine as a whole, and the driver has time to safely get to the service station.

Often, along with the P0325 error, related errors appear, which also indicate problems with detonation. All of them occur due to damage to the sensor or the use of low quality fuel.

- P0326 – the sensor signal is outside the permissible limits.

- P0327 - decrease in the signal level of the knock sensor.

- P0328 - signal level exceeded.

What does P0327 mean?

Error P0327 on a VAZ 2114 means that the sensor transmits a signal at a low level. The minimum low threshold value for signal transmission is 0.5 Volts. For voltage to occur below the threshold level, malfunctions must occur in the sensor itself, as well as in the electrical circuit, which, on the one hand, powers the sensor, and on the other, information is transmitted. If there is a problem with the sensor or electrical circuit, the CHECK ENGINE indicator light on the instrument panel lights up and an error message appears on the display.

Important! A malfunction of the knock sensor is not critical for the operation of the internal combustion engine, but it worsens the dynamics of operation

Signs of a malfunctioning knock sensor

Resistance that should be in the sensor in good condition

Before considering the causes, it is necessary to look at the symptoms of the malfunction. So, let's look at what could be a warning sign that the knock sensor has failed:

- The engine is losing power.

- Overclocking potential drops.

- Fuel consumption has increased.

- The CHECK light came on on the instrument panel.

- Smoky exhaust.

- Presence of detonation.

- The engine started to stall.

Of course, an important reason for the failure of the knock sensor is the fuel mixture, namely the quality of gasoline itself. The lower the octane number, the lower the resistance to detonation. If the fuel detonates, it will not completely burn through the engine and you will hear the muffler firing.

Knock sensor diagnostics

The sensor is checked with a multimeter. In this case, the sensor is “knocked” with a screwdriver

To diagnose the knock sensor, it is removed from the engine and a voltmeter with a measurement limit of up to 200 mV is connected to it.

Next, they “knock” the sensor on a hard surface and look at the voltmeter readings. When tapping, the readings should change. If they do not change, this means that the sensor is not working. If they change, then the sensor readings change, but whether they are correct is in question!

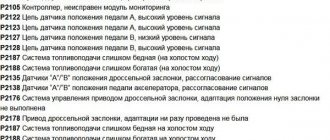

ECU signal about malfunction

Failure of the sensor will be immediately obvious by a characteristic knocking sound. Many motorists simply reset the “minus terminal” to reset the readings of the electronic control unit, but it is worth understanding the very reasons for the effect and eliminating them. Let's look at the ECU error codes that signal a failure of the knock sensor:

Errors Lada Kalina 1st generation - decoding

Important! The list can also be used for the VAZ Priora model - the digital codes are similar for both cars.

Exhaust gas outlet (0000)

- 30 – open circuit or failure of the air sensor to the catalyst;

- 31 – break in the wiring from the short circuit to the vehicle;

- 32 – a similar incident involving contact with other wires;

- 36 – open circuit of the line after the catalytic converter;

- 37 – damage to the cable winding with a short circuit to the machine body;

- 38 – wiring break with short circuit at BS.

Interruptions in the air supply to the internal combustion engine (0101)

- 102 – damage or malfunction of the mass air flow sensor;

- 103 – short circuit in the MAF wiring;

- 112/13 – failure or incorrect operation of the fuel mixture temperature sensors in the intake manifold;

- 115-116 – violation of antifreeze t° sensors – there is no cooling of the system or the main airflow is not working properly;

- 117-118 – open circuit of the coolant temperature sensor power supply/short circuit;

- 122/123 – defect in cable insulation at the TPS;

- 130/131 – error/break in DC circuit No. 1;

- 132 – short circuit of sensor No. 1 PCV;

- 133/134 – the air sensor connection is broken (sometimes it’s enough to clean the terminals and connector) or the wiring is damaged;

- 135 – malfunction of heater DK2;

- 136 – contact with the body of the DK2 highway;

- 137/138/140 – uncontrolled signal DK2 or break of the corresponding line;

- 141 – failure or interruption of heating of DC2;

- 171/172 - violation of mixture formation in the first case - depletion, for the second - excessive enrichment.

Error codes Lada Kalina 1.6 liters, indicating an uncontrolled violation in the fuel line (0200)

- 201-204 - a rupture in the control line for injectors 1-4, usually manifested by tripling or even doubling of the internal combustion engine, and the power plant may not start;

- 217 – critical temperature rise of the engine block;

- 230 - Lada Kalina error, accompanied by a drop in power or problems starting the power plant, is caused by a violation of the fuel filter relay circuit;

- 263/266/269/272 – the injector control driver has failed in sequence from No. 1 to No. 4;

- 261/267/270/264 – insulation violation of the injector control wire with a short circuit to vehicle ground for elements 1-4;

- 262/265/268/271 – similar to the previous point, only with a 12 volt touch.

Error codes Kalina 8 valves caused by incorrect ignition activation (0300)

- 300 – misfire or no spark for all pistons;

- 301/302/303/304 – similar to the previous number with clarification for each boiler sequentially;

- 325 – problems with the functioning of the DD;

- 327/328 – the mixture detonation sensor does not work correctly;

- 335/336 – failure or incorrect information is received from the DPKV unit;

- 337/338 – similarly with touching ground or other wires;

- 340 – wire break or DRF has failed;

- 342/343/346 – incorrect operation of the phase distribution indicator, possible short circuit;

- 351-354 – poor contact to the ignition coils, or damage to the wiring, for all boilers in series;

- 363 - dry pistons, no gasoline or oxygen, possible blockage or air bubble in the line.

Secondary equipment not related to the ECM (0400)

- 422 - the catalyst is clogged, excess pressure forms in the pipe, usually a complete replacement of the unit is required;

- 441 – the adsorber purge valve is faulty; cleaning or repair may be required;

- 443-445 – rupture of the purge line with the formation of a short circuit (possibly to the body);

- 480/481 – the insulation of the power cables to the main radiator fan is damaged.

Lada Kalina engine error - incorrect crankshaft speed (0500)

- 501/502 – electronic speed sensor readings are too low or high;

- 503 – contacts on the DC have oxidized, the block may be damaged;

- 505 – XO floats, you need to check the regulator;

- 506 – the engine does not hold idle speed, throttle adjustment is required;

- 507 – similar to the previous paragraph, speed float is added, TPS repair may be necessary;

- 511 – the XX regulator is faulty, perhaps it should be replaced with a new one;

- 560/562/563 – voltage surges in the vehicle network – we are looking for where the short circuit is.

Malfunction of on-board wiring lines (0600)

- 601 – failure or unstable operation of the ROM;

- 603-604 – incorrect data from internal or external RAM circuits;

- 607 – possible disruption of the detonation line;

- 615-617 – damage to the power supply wire of the auxiliary PC with a permissible short to 12 volts or ground;

- 627-629 – breakdown of the fuel pump power supply with the possibility of a short circuit;

- 645-647 – the clutch of the air conditioner pump unit is de-energized with or without a short circuit in the wiring;

- 650 is a typical Lada Kalina check error, indicating that the corresponding lamp on the dashboard has burned out:

- 654 – the electrical line of the engine speed meter is faulty;

- 685-687 – breakdown of the insulation of the main relay power cables with a possible short circuit;

- 691-692 – rupture of the wires supplying voltage to the main fan with the possibility of a short circuit to the remaining parts of the wiring.

Additional error codes on Lada Kalina (1000)

- 102/115 – disappearance of resistance or breakdown of the DC;

- 123-124 – incorrect formation of the XX mixture;

- 127-128 – similar to the previous paragraph, only at low load;

- 135 – damage to wiring DK1;

- 136-137 – incorrect mixing of air and gasoline components at low load on the internal combustion engine;

- 140 – the difference between the actual and calculated load is too large;

- 171 – potentiometer readings are underestimated;

- 172 – the opposite meaning of the above paragraph;

- 386 – incorrect data from the combustible mixture detonation channel sensor;

- 410 – break in the adsorber purge line;

- 425-426 – also with short circuit to ground or network;

- 500 – break in the fuel pump network;

- 501-502 – similar with a ground fault or 12 volts;

- 509 – critical overload of the idle speed controller;

- 513-514 – short circuit of the remote control sensor at idle speed of the internal combustion engine;

- 541 – the fuel pump has “died” or the voltage on the line has disappeared, it is also possible that a crack in the liner may form with fuel getting inside the structure;

- 570/600 – an erroneous impulse is received from the APS or there is none at all (sometimes cleaning the contact group helps);

- 602 – the ECU “shorts” at 12 volts;

- 603 – the firmware has crashed – a reboot is required;

- 606/616 – the rough road sensor indicates incorrect information (it begins to act up due to shaking on the “beautiful” asphalt);

- 612 – the ECU data was reset incorrectly, a forced reboot is required;

- 617 – the pothole indicator has died for a long time or the terminal has come loose;

- 620-622 – irreparable failure of the PROM, RAM or EEPROM blocks, respectively;

- 640 – software “glitch”;

- 689 – no problems were found during diagnostics – the encodings shown are false.

Common errors when diagnosing code P0332

The most common mistake made when diagnosing the P0332 code is not performing a thorough check to properly determine the cause of the problem. This often results in the mistaken replacement of the knock sensor when the problem is, for example, worn or damaged electrical wires or connectors or a fault in the engine cooling system or exhaust gas recirculation system. Before replacing the knock sensor, it is necessary to perform a thorough diagnosis and consider all possible causes of the error.

Determining and decoding errors on the VAZ 2114

Error p0171

Self-diagnosis of a car allows you to identify faults, but some of them are rarely identified. An odometer is used for diagnostics.

Self-diagnosis of VAZ 2114

The sequence of actions is as follows:

- Press and hold the odometer button and turn the ignition key to the first position.

- Release the odometer button and press briefly again. As a result, the firmware version will be displayed.

- Now, to see the error codes, you need to press and release the odometer button again.

Error codes are in the form of numbers from 1 to 9 and two-digit numbers, unlike those displayed by the on-board computer. Thus, you can use the odometer to identify some car faults. The most common errors are shown in the table below.

Diagnosis of faults using special equipment

To identify faults, service stations usually use the car’s on-board computer and a laptop with specialized applications. In this case, it is possible to obtain error codes that correspond to various problems. The most common of them are shown in the table.

If errors occur with other codes, you should read the information about them in the file that comes with the car diagnostic application, or search on the Internet.

The controller clears the memory after turning off the engine with the ignition and disconnecting power from the battery for 10-15 seconds. In this way, you can determine after repair whether the malfunction has been eliminated.

Errors in the VAZ 2114 occur quite often, so the ability to recognize them will not be superfluous to carry out proper car repairs. For correct diagnosis, you will need a computer with a special program and an understanding of the on-board computer readings.

Under what conditions is it diagnosed?

To diagnose error P0325 as accurately as possible, a number of conditions must be met.

- First of all, the possibility of false positives should be eliminated. Using a diagnostic scanner, reset the error and perform a test drive. If the P0325 error code appears again, go to the next step.

- Perform a performance check of the knock sensor (knock sensor). For these purposes, a multimeter is used, which determines the voltage level of the sensor under pressure. Then the circuit of the electronic control unit is checked for breaks.

- If you do not have a multimeter, the test can be performed mechanically. It's very simple. To do this, it is necessary to lightly hit the engine at idle speed as close as possible to the location of the knock sensor. If this device is working properly, the ignition angle will automatically change and the speed will decrease.

- Test the performance of the engine control module by contacting a dealer service center.

Purpose and location of the knock sensor

A knock sensor (DS) is a device that is installed on the outside of the cylinder block wall to monitor the appearance of abnormal vibrations caused by detonation in the engine, that is, explosive self-ignition in the combustion chamber of the working mixture. The DD produces an alternating current signal, the voltage amplitude and frequency of which depend on the vibration parameters of the cylinder block.

Photo of Priora knock sensor

Each level of intensity and frequency of oscillations of the engine walls corresponds to its own signal. The engine control controller constantly analyzes the data received from the engine. When detonation occurs in the cylinders, the amplitude of vibrations of the corresponding frequency increases, and the DD generates a signal, after processing which the controller adjusts the ignition timing, making it later, which leads to the suppression of detonation of the working mixture.

The Priora DD consists of a washer-shaped plastic body, which has a hole in the center for a bolt with a 13-head head, and on the side there is a two-pin connector for connecting wires from the controller. The main part of the DD is located inside the case - a sensitive piezoceramic disk element, which, in fact, generates voltage (signal) when exposed to vibration.

The DD Priora is installed on the cylinder block, namely: on its front wall under the intake module, next to and slightly above the dipstick socket for monitoring the oil level in the engine. It is not visible from the top of the hood. It can only be seen from below, for example, from a pit, when the lower engine protection is removed.

Main symptoms of code P0327

Error P0327 associated with the knock sensor has the same symptoms that are observed when other errors of this monitoring device appear:

- The dynamics of the internal combustion engine are disrupted;

- The ECU puts the car into emergency mode when the engine does not spin up more than 3-5 thousand revolutions per minute, and the speed barely exceeds 50 km per hour;

- Engine operation in idle mode is not stable. It may stall if not supported by the accelerator.

- Black smoke appears from the exhaust pipe due to an unoptimized fuel-air mixture.

How to fix

Fuel detonation, that is, its spontaneous combustion, can ultimately lead to engine destruction. Therefore, it is important that the sensor works correctly. To do this, it is highly recommended to resolve the P0325 error as soon as possible.

There are several effective solutions to this problem:

- Thoroughly clean the contacts or replace damaged wiring (depending on the actual cause of the error).

- Replace or repair the wiring in the area from the knock sensor to the engine control unit.

- Replace the damaged knock sensor, as this element is not repairable.

- Update the control unit software or replace this device.

Error P0325 is called Knock Sensor 1 Circuit Malfunction, that is, “a malfunction in the knock sensor circuit.” For its accurate diagnosis, a special device is used - a multimeter. There are several ways to solve this problem, depending on the specific cause. Typically, for these purposes, the contacts are cleaned, the wiring between the sensor and the control unit is changed, or the sensor or control unit is replaced, depending on which device is not operating correctly.

Causes of error P0327

To eliminate the errors themselves that appear on the display screen, it is important to eliminate the causes that generate error P0327 and possible other problems associated with the operation of this sensor:

- The device is installed and connected incorrectly;

- Has factory defects or defects acquired during operation that prevent the correct transfer of data to the ECU. Such defects include oxidation of contacts, their poor fastening, short circuit in the wiring harness;

- Broken wires in the circuit also prevent the transfer of information to the on-board computer;

- Short circuit in the DDD power circuit.

- Failures in the on-board computer.