How the system works

There is nothing supernatural in the very principle of operation of such a system. It is most often used to heat the rear window, but some car models implement heating of the front window, side glass and wiper locations when turned off.

The task of such a system is to create conditions on the surface of the glass that prevent frostbite or fogging. As you know, at temperatures below zero degrees Celsius, moisture freezes and ice forms. Therefore, to eliminate this phenomenon, it is enough to ensure the surface temperature is above zero degrees, and icing will not occur.

This is done quite simply - conductive strips are created on the glass, one end of which is connected to the vehicle’s on-board network, and the other through an appropriate control circuit to ground. When the heating is turned on, current begins to flow through such conductors; thanks to the generated heat, the glass is heated, which causes it to be freed from the formed ice.

A similar scheme is used not only for the rear window, but also for the windshield. The thickness of the filaments used for heating in this case is less than when implementing rear window heating.

Possible device malfunctions

If the rear window heating does not work, it means that one of the components listed above has failed or its electrical circuit has broken. You can check all the components of the heating device yourself if you have at least the slightest idea about machine repair. Below we will consider in detail the reasons for the malfunction of each node.

System fuse

Initially, if problems arise with heating, you should ensure the integrity of the safety element. Its burnout will affect the performance of the device. Each car manufacturer places this fuse in different places in its models. To quickly find its location, it is recommended to use the vehicle’s operating instructions or service book.

You need to remove the found element and check for suitability. The blown fuse should be replaced with a new one, otherwise further attempts to troubleshoot the heated glass will be pointless.

Relay

One of the reasons for the failure of the glass heating may be a malfunction of the relay; this element is located in the mounting block. The relay turns off the heating when the motor stops running. This device cannot be restored, so it is replaced with a new one.

Electrical wiring faults

If the fuse and relay are in good condition, it is necessary to diagnose the electrical wires. They probably broke, burned out or broke off at the attachment point. In this case, the heating strips will not receive voltage.

Test the condition of the power supply wires as follows:

- You need to turn on the heating button.

- Using a multimeter, check the voltage at the first and second terminals connecting the wires to the heating “buses”. They are located at the bottom or on both sides of the glass. Lack of voltage causes the heater to not work.

The first thing you need to do in this case is to clean the terminal contacts and all areas of the connection; they may oxidize and not allow current to pass through. If the tester still outputs "0", then there is a break somewhere in the wiring. A visual inspection of the entire electrical circuit path is performed. Having discovered suspicious or damaged areas, you need to connect them, since a break may have occurred in these places.

Threads

Heating strips are also susceptible to damage. Before looking for a problem area, you should become familiar with the working process in threads.

Voltage is supplied to the entire heating unit and is evenly distributed over each parallel-connected strip. As a result, these tapes act as conductors of electric current. Due to resistance, they heat up to a low temperature, which is quite enough to remove ice and snow from the surface of the glass. If the integrity of one of the threads is broken, the electric current will stop circulating through it, and heating of this area of \u200b\u200bthe glass will not occur.

Violation of thread integrity

Controls

When you press the button, the indicator should light up, notifying you that work has begun. If the switch is activated, the indicator lights up, but heating still does not occur, it means that the button contacts have become unusable. As a result, electricity is not supplied to the heater. A worn power switch cannot be repaired - a new one must be installed.

Is the rear window heating working and how to check?

An initial conclusion about how well the rear window heating works or does not work can be made based on observing whether the glass is cleared of ice, and how evenly over the entire surface. If some of the heating filaments do not work, the result will be isolated areas covered with ice. In this case, you can think about restoring the heated rear window.

Often, the cause of heating failure can be not only the burnout of the heating element filaments. Among the possible reasons it is enough to mention:

- failure of contact in the terminals supplying voltage to the heater;

- failure of the switch or relay for turning on the heating system;

- The fuse in the heating circuit has blown.

As a rule, the most common defect will be broken heater filaments ; in all other cases, to restore heating, a simple external inspection is sufficient to identify a blown fuse or broken contact. In those cases when the rear window heating does not work due to breaks or microcracks in the heating filaments, it is quite problematic to detect the specific place where the circuit failure occurred.

The fact is that heating filaments are typically connected in parallel, so using a tester to find the location of the damage is useless; the connections will “ring” through parallel circuits. You need to look for damage visually using a magnifying glass, having previously determined which of the tracks is not working.

Signs of breakdown

The main manifestations of why the rear window heating does not work include:

- complete shutdown of heating;

- Not all strips work;

- periodic performance of elements.

Experienced drivers will immediately notice when the heating is not performing its function sufficiently. In winter, the first sign of incorrect operation is fogged up windows when the heater is running for a long period of time. If the rear window heating refuses to turn on or functions intermittently, it means there is a break in the electrical circuit. All components of the heating device should be checked.

How to restore heated rear window

When a damaged area of the heater filaments is found, it is worth thinking about how to restore the heating in full. Of course, you can restore it simply by replacing the glass, but this is a rather expensive operation, while there are several ways that allow you to eliminate the defect on your own, without too much effort. Before work, it is necessary to prepare the place where a break is detected and the heating filaments will be restored. To do this, the conductive path in the right place must be carefully cleaned of varnish and degreased with alcohol. A characteristic metallic sheen should be visible on the prepared area.

Track restoration can be done in the following ways:

- Using special conductive paste. It is applied to cold glass. When performing work, do not turn on the heating. The path, prepared as described above, at the site of damage should be limited on both sides with adhesive tape. The paste is then applied to the area that is not working. It hardens, as a rule, within 24 hours; you can check and use the heating after this day has passed.

- Using metal filings. This method allows you to restore functionality when there is no paste. For this, pre-prepared small iron filings are used. During the work process you will need transparent glue and a magnet. It must be secured over the area where the damage is detected, and then iron filings must be applied to this place. The magnetic field will force them to line up along the section of the track that is not working. Having leveled the sawdust and ensured electrical contact with the damaged area, they are covered with a layer of glue. You can check whether the repairs have been successfully completed and whether the heating is working in one and a half to two hours.

- Using shavings and paint, in this case shavings of non-ferrous metals are used. It is mixed with paint in such a way that a mass similar to plasticine is obtained. Using tape, a kind of stencil is formed around the damaged area. The heating is turned on, and the prepared mixture is applied to the desired area, and a characteristic hissing may occur at the point of contact, but after a while it disappears. This mixture hardens in twenty to thirty minutes; you can check and use the restored system after an hour.

There are some other methods that allow you to restore a non-working heating system, but those described are the simplest and most accessible.

Unfortunately, such methods are unlikely to be applicable to windshield restoration. It uses thinner conductive tracks and the repair area will appear quite rough, impairing the driver's visibility. For a car, heated rear window is not a luxury, but can significantly improve driving safety. And if it does not work, then with the help of fairly simple techniques you can restore its functionality. ”alt=””>

Source: znanieavto.ru

Phased renovation

First, diagnostics are carried out to determine the reason why the glass heating does not function. If it is a relay or fuse, then further actions are already clear. A repair kit is purchased depending on the manufacturing technology of the device. It is important to determine the place where the current does not pass to the heating strips, and then consider repairs.

Finding a Cliff

Visual diagnostics help when the rear window is foggy. Once you turn on the heater, you will see exactly where the stripes have broken. Other techniques:

- The ignition and heating system must be turned on. One voltmeter probe is applied to the ground (any metal part of the body), and the second, pre-wrapped with foil, near the center of the heating strip. A break will be detected at the point where the voltage rises to 12 V or becomes close to zero. Ideally it should be 5 V.

- The probe of the device is applied to the positive contact of the heater, the other is moved along the strip of the negative terminal. When the voltage is zero, the location of the break has been found.

- The ohmmeter is switched to “kilo” mode. The probes are applied to the opposite terminals of the heater. A piece of cotton wool is soaked in distilled water and the strips are processed. When the instrument needle twitches, a defect has been detected.

You can restore the functionality of the threads using glue. There are repair kits on sale with instructions that include this composition. This type of glue can withstand a serious temperature range from – 60 °C to 100 °C. Sequencing:

- The problem area is being prepared. It is wiped with a rag soaked in alcohol.

- The edges of the strip are cleaned with zero grade sandpaper. Two careful movements are enough to remove plaque and carbon deposits.

- The area with the torn strip is covered with tape.

- Conductive glue is applied to the prepared area with a brush or syringe with a thickness of no more than 1 cm.

- The tape is removed after a day of waiting.

A special repair kit will help correct defects in large areas - from 10 cm or more. The kit consists of the heating tapes themselves, polymer resin (in a can) and stencils. Instructions:

- Find where the thread breaks.

- Prepare a strip of the required size.

- Remove the protective film.

- Fix the element in the problem area with resin.

- Give time to dry.

You can restore the heating function not only using traditional methods. For this, a combination of copper or brass filings and paint is possible. They can be obtained by filing the corresponding bars. The paint should be selected to match the shade of the threads or use BF-2 glue. Instructions:

- Mix the ingredients in equal proportions until the consistency of a soft dough is formed.

- Turn on the heating.

- Determine the contact by the hissing sound it makes.

It is practiced to solder the broken area using zinc chloride. Here you should choose solder that contains a minimum amount of tin (POSS-4-6, POS-18). A copper or silver wire can be used to repair a large damaged area.

Heated mirrors are an additional option that is not available on all cars. These systems consist of the same conductive strips that are applied to the substrate of the front glass sheet from the inside. Heated positions are switched on simultaneously. Finding and fixing the breakdown occurs in a similar way as described above. If only one of the heaters does not work, then the wiring or heating filaments are repaired.

Why doesn't the heated glass work?

- Safety and button. The simplest and most easily repaired breakdown is the fuse and the power button. It happens that the electric heating itself is absolutely fine, but the problem is a blown fuse or a non-working button. To check whether this is true or not, find in the fuse block the one that is responsible for the operation of this unit and check its serviceability. Pay attention to the power button, it is often illuminated; if the button does not light up, there may be a problem with it. Check the contacts and its serviceability.

- Wiring. Poor contact or poor wiring integrity is always the cause of device failure. Without power or in case of power failure, the electrical appliance will not work. Check the contacts and integrity of the wiring; a multimeter is suitable for this. We turn on the glass heating and measure the voltage at the wiring terminals. We connect one probe of the device to “+”, the second to ground, that is, “-“. If the device does not show voltage, the wiring is damaged. If the positive wire is intact, move one probe of the device to the “+” of the heater filament itself, glued to the glass, and the second to the “-“. It happens that the contacts oxidize or the connection is broken. In this case, there will be a potential difference between them, less than 12 V or completely absent.

- Damage to the heater filaments. In most cases, thread rupture occurs as a result of mechanical stress. This could be a blow, crack, chip, careless installation, or removal of the tint film. It is not difficult to understand where exactly the glass heating breaks; just turn on the heating and look at the glass. After the damaged area, the glass will remain the same as it was. If it was not possible to visually determine the location of the break, we again arm ourselves with a multimeter.

We check the voltage of the glass heating threads:

- Turn on the heated glass, then the multimeter, switch it to DC measurement mode.

- We connect the negative probe to ground, and use the positive probe to measure the voltage of the threads at different points. The heating filament itself is a regular resistor with a tape-type resistance, so the voltage will be different at different points. It is considered normal if at the very beginning of the thread, right next to the negative terminal (ground), the voltage is zero, and closer to the positive terminal it increases to 6-9-12V.

Thus, by moving the probe along the thread, you can easily detect a sharp drop in voltage, which will indicate a break at a given point. The process of restoring glass heating filaments is possible, so do not rush to change the glass because your electric heating does not work.

I recommend a video on how to repair electric heated glass

Text: Question Auto

Source: vopros-avto.ru

Features of problems with imported cars

When the rear window heating malfunctions, you should pay attention to the main points:

- relay;

- wiring;

- circuit breakers;

- threads

You don't need any special skills to replace them. If you study the instructions and know where the heated relay for the car rear window or front structure is located, the wiring diagram, the fuse mechanism, then you can completely do without the help of a specialist.

The element may burn out under certain circumstances, increasing the risk of shorting. As a result, the heating will not turn on because there is no power being supplied to it, because the fuse is a protective mechanism for the heating. To understand the location of the elements, you should refer to the vehicle's owner's manual. Algorithm of actions when the location of the fuse is found:

- Remove the device.

- Inspect for integrity.

- Carry out a performance check separately from the entire device.

- Determine the cause of the malfunction.

- Replace individual spare parts or the entire mechanism.

Wiring

After diagnosing the fuse or replacing it, further searches for the malfunction of the rear window defroster (if it still does not function) must be looked for in the wiring. Cause:

- bummer;

- break on the fastening;

- fracture;

- burnout.

As a result, no current flows to the heating poles and the system does not work. You can perform simple diagnostic steps using a multimeter. To do this, you need to turn on the heating, and then measure the voltage at the heater terminals. They are usually located at the bottom of the glass or on the sides.

It is worth examining the entire length of the wiring for integrity and then, if there is a break anywhere, it will be found. Instructions:

- disconnect the terminals;

- clean connection contacts;

- replace wires.

If one or more thread strips are broken, then no current flows through them. Therefore, ice will appear in some areas, which impairs visibility and reduces driving safety. Complete disassembly of the heating equipment will help verify the break. The solution to the problem is to replace faulty elements with new ones.

Heating relay

The relay is responsible for heating the windshield. If the start key does not turn on the device, you should check the relay. It turns off the heating when the car engine is turned off. The element is located in the mounting block. The exact location is specified in the vehicle manual.

Controls

If the device does not start, the reason may lie not in the relay, but in the dysfunction of the power button itself. It is equipped with an indicator light, and if the sensor does not light up, it means that the device is faulty. The problem must be looked for in the contacts of the toggle switch, to which the threads do not conduct current. Solution: replacing the element.

On domestic cars, only the rear window is predominantly heated. Foreign-made vehicles have heated glass and mirrors. When heating starts in the aft section, other positions are heated in parallel. If pressing the button does not activate the mechanism, the relay and fuse are checked.

1 – headlights; 2 – fog lights; 3 – air temperature sensor; 4 – electric motor of the engine cooling system fan; 5 – blocks connected to the wiring harness of the ignition system; 6 – engine compartment lamp switch; 7 – block for connection to a single-wire type audio signal;

8 – sound signal; 9 – washer fluid level sensor; 10 – front brake pad wear sensors; 11 – oil level sensor; 12 – generator; 13 – engine compartment lamp; 14 – coolant temperature indicator sensor; 15 – starter; 16 – battery; 17 – relay for turning on fog lights;

18 – coolant level sensor; 19 – brake fluid level sensor; 20 – reverse light switch; 21 – windshield wiper gearmotor; 22 – oil pressure warning lamp sensor; 23 – block for connecting to the rear window washer electric motor; 24 – windshield washer electric motor;

How to restore the rear window heating on a car

Modern cars have a heated rear window to maintain good visibility in damp and frosty weather. When it doesn't work well, it's extremely inconvenient to drive, and breakdowns, as a rule, happen completely inappropriately.

Fortunately, you can restore the heating yourself if you have some idea of how it works. Below you will find detailed instructions on how to do this.

Location of Priora fuses under the hood

- F1 (30 A) – power supply fuse for the electronic engine control system (ECM);

- F2 (60 A) – fuse for the power supply circuit of the engine cooling system fan (power circuit), additional relay (ignition relay), rear window heating, electrical package controller;

- F3 (60 A) – fuse for the power supply circuit of the electric fan of the engine cooling system (relay control circuit), sound signal, alarm signal, ignition switch, instrument cluster, interior lighting, brake light, cigarette lighter;

- F4, F6 (60 A) – generator power circuit fuses;

- F5 (50 A) – fuse for the power supply circuit of the electromechanical power steering

Relay and fuse box for Halla air conditioner

- right electric fan power supply fuse (30 A);

- fuse for the power supply circuit of the left electric fan (30 A).

- right electric fan relay;

- additional relay (sequential activation of left and right electric fans);

- left electric fan relay;

- heater fan power supply fuse (40 A);

- compressor power supply fuse (15 A);

- heater fan relay;

- compressor relay.

Panasonic air conditioner relay and fuse box

- Heater fan maximum speed

- Right fan

- Fan sequential relay (low speed)

- Left fan

- Left fan fuse (low speed)

- Right fan

- Heater fan

- Compressor

- Heater fan

- Compressor

Principle of operation

Electricity is used to heat the rear window: threads of thin metal with increased resistance are stretched across the canvas. Under the influence of current, they heat up and dry the water droplets.

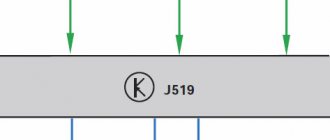

The principle of operation of this system is simple: the positive charge of the battery goes through the ignition switch to one of the switching devices, and the negative charge through the car body to the other. When the heating button is pressed, the devices close an electrical circuit, which includes the threads stretched onto the rear window.

Symptoms of a problem

Typically, motorists do not immediately notice that the rear window heating does not work (or does not work well). This is discovered just at the moment when a good view is needed, but for some reason the glass remains foggy. Based on how the problem manifests itself, you can determine its location and cause:

- The heater activation indicator does not light up. Check that the ignition key is turned to the on position and that the engine is running (in some cars, heating is only possible in this case). If you have taken these points into account, but the glass has not dried, it means that the switching device or the wiring connector may be faulty. You need to look in the machine manual to see where these items are located and replace them with new ones.

- Glass dries slowly. If you notice that in relatively warm weather the process of evaporation of droplets from the surface is delayed, then most likely the voltage in one of the electrical connectors has lost. You need to measure its level with a voltmeter at the input terminals. A difference of even one volt affects the quality of heating. In this case, you need a professional to fix the problem (unless you are one yourself).

- Glass dries unevenly. This happens most often: one of the threads on the rear window breaks, and moisture remains in this place. The fact is that thin metal elements can easily be damaged if, for example, you scratch the surface of the glass with a hard object, carelessly put things on the shelf behind the rear seat, etc.

Troubleshooting in the OZS system

If you find signs that the rear window heating is not working, you must carefully check the entire electrical circuit of the vehicle's EOS system.

The first thing to check is the serviceability of the fuses. So, for example, on a VAZ-2110 these are rear window heating fuses F4 and F7, which are located in the mounting block. Their malfunction may occur due to a factory defect, short circuit or voltage surge in the on-board network. The faulty fuse needs to be replaced, for which it must be removed from the mounting block.

Next, you need to check the terminal connections in the OZS system. When operating a vehicle, all equipment is subject to strong vibrations. As a result, the contacts may be damaged or a terminal may become disconnected or loose.

The heated rear window relay must also be checked. Breakdown of the relay is possible when the wire in the working coil of this part breaks or due to burnt contacts, due to a manufacturing defect or short circuit. To check it, the relay must be removed and checked using a tester. If this part malfunctions, it needs to be replaced with a working spare part.

You should also check the rear window heating contact. A conductive element is attached to the rear window using glue, which is a contact to which an electric current is supplied through a wire, which is transmitted through this contact to the heating filaments.

In this place, the wiring may break or, due to the fact that the glue was of poor quality, the contact element may peel off from the glass.

Quite often, the failure of the rear window heating is caused by a break or damage to the threads in the heating element on the rear window. This is detected by visual inspection or instrumental analysis. Visually, only obvious damage to the thread can be detected by identifying a gap between the damaged ends.

It is possible that during some repair work on the car, mechanical damage was caused to the surface of the glass on which the heating element is attached using glue.

However, the main tool for diagnosing this malfunction is a voltmeter or ohmmeter.

They allow you to accurately identify an area with faulty threads, even if this break cannot be visually detected.

How to find the location of a broken glass heating filament

Now let's talk about how to check where the rear window heating thread has broken. To do this, you will need a voltmeter or ohmmeter of your choice. Do the following:

- Inspect the rear window - sometimes the break is visible to the naked eye: the thread is interrupted and resumes after a few millimeters.

- Turn on the heating and see where the water drops have not dried. Take a magnifying glass and look at this area more closely.

- Let the heating function remain active. One metal rod of the voltmeter needs to be connected to the positive heating terminal, and the second should be drawn along the thread from the side of the clamp with the “-” sign. Keep an eye on the indicators: the break will be where 0 volts is displayed.

- Take an ohmmeter and attach one probe to the common wire (the negative of the battery is connected to it), and carefully lean the other one against the center of each thread in turn. The break is where the resistance jumps to 4-6 ohms.

Repair materials

To fix problems with the rear window defroster, you will need:

- paste or glue capable of passing current (special ones, sold in automotive supply stores);

- or copper-brass powder and paint;

- or zinc chloride, material for joining workpieces POS-18, soldering iron;

- as well as a repair kit for heating filaments (if the gap is very large, several centimeters).

How to fix a heated rear window with your own hands

Now let’s figure out how to repair the heated rear window of a car with your own hands. There are several ways:

- Using paste (glue). Apply the paste to the break site, extending two centimeters beyond the intact thread. Dry with a special hairdryer (not for hair, but for various materials) or let it dry naturally for a day.

- Using a repair kit. If the break in the rear window heating threads is several centimeters, then this is the best method. Unpack the stencil and stick it on the desired area. Carefully place the new thread into the empty space. Apply a layer of the resin included in the kit on top. Once it dries, apply another coat. There should be 4-5 of them in total.

- Using paint and copper-brass powder. This can already be called restoration using improvised means. Take a copper-brass alloy ingot and file it. Mix the resulting fine powder with paint in a 1:1 ratio until it becomes pasty. Glue the electrical tape as a stencil and apply the resulting composition to the tear site.

- Using a soldering iron. Apply zinc chloride to the desired area, apply solder to the soldering area and touch the wire with a soldering iron. This way you can also repair a large tear.

There are other tips on how to restore heating, but to use them in practice you need unsafe reagents: sulfuric acid, copper sulfate, etc. It is best, especially for motorists without experience in self-repair, to use a paste or a special repair kit.

Source: drivertip.ru

DIY heating repair

The most common reason for heating not working is damage to thin conductive threads. Modern technologies make it possible to restore broken areas of these threads with your own hands without the involvement of specialists.

Finding the location of the thread break

First you need to find the damaged areas of the threads. The process will not take long, since the cliffs are clearly visible to the naked eye. It is extremely rare to see minor damage that is difficult to see, in which case you need to use a voltmeter.

The thread has a resistance of 10 ohms, each section has its own voltage. On the first - the voltage is twelve volts, on the third - already six, and on the fifth - zero. To search for a break, measure the voltage at the center of each element. If there is damage, the multimeter will output 12 or 0 volts, which makes it clear that there is a break on the left or right side of the thread.

Troubleshooting a heater using a copper solution

To work you will need:

- sulfuric acid;

- copper rod, diameter up to 10 mm;

- copper sulfate;

- strip of fabric 50x30 cm;

- scotch;

- scissors;

- glass cleaner.

To repair damage to a conductive thread, do the following:

- At the first stage, it is important to prepare the damaged surface for restoration work. To do this, use a rag soaked in alcohol and wipe the glass with it. When the dirt is completely removed, degrease the surface.

- Place tape on both sides of the conductive thread at the break point. We attach the adhesive tape so that the width between the strips corresponds to the heating filament.

- The copper rod is wrapped with fabric at one end. We secure the so-called tassel with threads.

- A copper solution is being prepared. Half a glass of water is thoroughly mixed with two teaspoons of copper sulfate. A little highly concentrated sulfuric acid or electrolyte from car batteries is added to the resulting liquid.

- The terminals from the heating device are connected to ground. The wire from the positive terminal of the battery is connected to a previously made brush made of a metal rod.

- The resulting electrode, soaked in the solution, carefully rubs the areas of broken threads. The ends of serious breaks are pre-processed using an electric soldering iron. He also installs a connecting jumper made of the thinnest wire. As a result, slightly damaged areas are covered with copper.

What should I do if the rear window defogger does not work?

In winter, on cars in which the air conditioning does not work well, the rear window defroster is a real salvation. Driving a car without being able to assess the situation behind you is extremely irresponsible, and it is not recommended to go to parking areas with ice on the rear window. Some drivers use a scraper to remove ice, but most car models have a rear window defogger that can eliminate the ice problem.

The rear window defroster is a very simple device that consists of a series of horizontal lines of electrically conductive material applied directly to the glass. Near the side edges of the glass, vertical conductor lines approach the threads, through which the current flows to the electrically conductive material. The simple design of the rear window heater suggests that there are not many reasons that can lead to its failure. Below we present the main reasons why the device may not work, as well as methods for repairing the rear window defroster.

Broken rear window defroster threads

One of the most common malfunctions of this car component is a broken thread. Thin electrically conductive threads only need to be slightly touched for a rupture to occur, and this will lead to the rear window defroster no longer performing its intended functions. Most often, problem areas are diagnosed visually.

If you cannot detect visible breaks in the rear window defroster filaments, you can use diagnostic tools to troubleshoot the problem. Get a multimeter and use it to measure the voltage in all sections of each thread. For example, 5 conditional control points are taken on each thread. The negative probe of the multimeter is connected to ground, and the positive probe is connected to the test points of each thread. Moving the measuring probe from one end of the thread to the other, a voltage drop from 12 to 0 Volts should be observed on the device. If at one of the control points the voltage is higher or lower than normal, then you should take a closer look at this area, since there is an open circuit there.

Attention: Apply a sharp probe to the heater filaments carefully so as not to cause further damage.

Repair. A car enthusiast can easily fix such a malfunction on his own. Automotive stores sell a special kit designed to restore the rear window defogger pattern. The kit includes a stencil, conductive glue and a brush. The stencil is glued to both sides of the damaged area, after which conductive glue is applied to the problem area. Next, you need to wait until the composition dries (about 30 minutes) and remove the stencil.

Rear window defroster fuse blown

If any electrical device on your car stops working, the first thing you need to do is check the fuses. Fuse failure can be caused by a temporary surge in current in the vehicle's on-board circuit or a more serious malfunction.

Repair. First, try simply changing the fuse and using the device normally. If the problem persists and the element fails again, determine the cause of the blown fuse and repair it.

Where are the fuses on the Priora?

- The main mounting block of the Priora is closed with a lid and located at the driver’s left foot. To open it, you need to turn three latches 90° and unclip the lid.

- The fuse box is under the hood, which is located near the expansion tank.

- Another mounting block, which is located near the left foot of the front passenger. To gain access to the fuses and relays, unscrew several screws with a Phillips screwdriver.

Below is a description of each fuse and relay block in order.

Oxidation of contacts on heater connectors

The rear window defroster may stop working properly due to oxidation of the contact directly bonded to the glass. To detect this malfunction, you need to measure the voltage of the supply wire and make sure that it exceeds 11 Volts.

Repair. If the measurement results in a value less than 11 Volts, it is necessary to clean the contact from any oxidation that has formed. To clean the contact, you can use fine-grain sandpaper or a special rust remover.

Other malfunctions of the rear window defroster

If all the diagnostic procedures described above have been carried out, but the problem is not found, it means that the rear window defroster is not working due to a broken wiring or failure of the power button. It is recommended to first look into possible problems in the button, and if they are not found, you will have to diagnose broken wires.

Source: okeydrive.ru

Methods for repairing heated rear window

Driving safety is largely determined by a good view from the driver's seat. During periods of temperature changes, problems with car windows often arise. In autumn, winter, and spring they often fog up and condensation forms on them. The problems are especially aggravated at night. To prevent such situations, a heating system for the front and rear windows is provided.

During operation, problems often arise with the rear glass: for various reasons, certain zones stop working. It is important to control such processes, since safety while driving depends on it.

How to connect the heated rear window

Cars are used throughout the year. The windshield is heated using warm air flows, and the rear - thanks to electrical energy. Thin strips of conductive tracks are applied to the inner surface of the glass behind the rear row of seats.

They are made from different elements, among which are copper, nickel, chromium, granite, and tungsten. When electricity is supplied, they release heat, which heats the glass surface, freeing it from excess moisture.

The total heating current is approximately 10 Amps. Since the resistance of each filament is about 12 ohms, a current of 1 A passes through each filament.

Depending on the manufacturer, heating filaments are glued, applied by vacuum spraying or electrochemically. Each technology provides its own way to restore the functionality of the system.

Most often, the heating filaments are powered by battery voltage, which is supplied to them through a system of fuses, relays and switches. However, in some cars the system works only after the engine is started. In such cases, the circuit contains an additional blocking relay. In addition, a fuse rated at least 15 Amps is used.

The diagram helps to understand the operation of the rear window heating system:

- Electricity is supplied to the switch from the “+” terminal of the battery through the ignition switch and fuses.

- The negative pole of the battery and one of the glass heater wires are led out to the car body.

- When the toggle switch is pressed, electric current is output to the relay coil, which closes the power contacts.

- As a result, the electric flow is directed to the heater filaments, and after passing through them to the negative pole of the battery.

Priora fuse box diagram

| Fuse no. | Current strength, A | "Standard" and "Norm" | “Norma” with air conditioning and “luxury” |

| F1 | 25 | Engine cooling radiator fan | Reserve |

| F2 | 25 | Heated rear window | Mounting block, rear window heating relay (contacts). Electrical package controller, contact “10” of XP2 block. Rear window heating element. |

| F3 | 10 | Right headlight, high beam | Right headlight, high beam lamp. Instrument cluster, headlight high beam indicator. |

| F4 | 10 | Left headlight, high beam | |

| F5 | 10 | Sound signal | Mounting block, horn relay. Sound signal. |

| F6 | 7.5 | Left headlight, low beam | |

| F7 | 7.5 | Right headlight, low beam | |

| F8 | 10 | Alarm signal | Mounting block, alarm relay. Alarm sound. |

| F9 | 25 | Priora heater fuse | Reserve |

| F10 | 7.5/10* | Interior lighting, instrument panels, brake light | Instrument cluster, pin “20”. Brake light switch. Brake light bulbs. Interior lighting unit. Interior lighting. The door sill light on the right front door. Additional brake signal. |

| F11 | 10/20* | Wiper | Mounting block, high speed windshield wiper relay. Switch for cleaners and washers, contact “53a”. Wiper and washer switch, contact “53ah”. Heated rear window switch. Mounting block, rear window heating relay (winding). Windshield wiper motor. Rear window wiper motor (2171,2172). Windshield washer motor. Rear window washer motor (2171,2172). Airbag control unit, pin “25”. |

| F12 | 20/10* | Terminal 15 devices | Instrument cluster, pin “21”. Electrical package controller, contact “9” of block X2. Electromechanical power steering control unit, contact “1” of block X2. Reversing light switch. Reversing lamps. Parking system control unit, contacts “11” and “14”. |

| F13 | 15 | Cigarette lighter fuse Priora | |

| F14 | 5 | Left headlight, parking light, license plate light, trunk light | Side light lamps (left side) Instrument cluster, main light indicator License plate lights Trunk light Electrical package controller, pin “12” of block X2 |

| F15 | 5 | Right headlight, parking light | Side light lamps (right side) Glove compartment lamp |

| F16 | 10 | Terminal 15 ABS | Hydraulic unit, contact "18" |

| F17 | 10 | Left fog lamp | |

| F18 | 10 | Right fog lamp | |

| F19 | 15 | Seat heating | Seat heating switch, contact "1" Front seat heaters |

| F20 | 5/10* | Immobilizer control unit | Recirculation switch (switch on) Mounting block, relay for low beam headlights and parking lights (automatic lighting control system) Heater electric fan relay Automatic lighting control switch Windshield wiper and external lighting control unit, contacts “3”, “11” Automatic climate control system controller installation, pin “1” Automatic window cleaning system sensor (rain sensor), pin “1” |

| F21 | 7.5/5* | Rear fog lights | Light switch, contact "30" Diagnostic block, contact "16" Clock Automatic climate control system controller, contact "14" |

| F22 | -/20* | Reserve | Windshield wiper motor (automatic) Mounting block, windshield wiper relay and windshield wiper high speed relay, (contacts) |

| F23 | -/7.5* | Reserve | Windshield wipers and external lighting control unit, pin “20” |

| F24-F30 | Reserve | ||

| F31 | 30 | Electrical package control unit | Electrical package controller, terminal “2” of block X1 Electrical package controller, terminal “3” of block X1 Driver’s door module, pin “6” Threshold light of the left front door |

| F32 | Reserve | ||

* - for the “Norma” configuration with air conditioning and “luxury”

| Relay | "Norm" | "Norma" with air conditioning | "Lux" |

| K1 | relay for turning on the electric radiator fan of the engine cooling system | Reserve | Relay for turning on the low beam and side lights of the headlights (automatic lighting control system) |

| K2 | rear window heating relay | ||

| K3 | starter activation relay Priora | ||

| K4 | additional relay (ignition relay) | ||

| K5 | space for backup relay | ||

| K6 | windshield washer and wiper relay | ||

| K7 | headlight high beam relay | ||

| K8 | horn relay | ||

| K9 | alarm relay | ||

| K10 | Reserve | Fog light relay | |

| K11 | Reserve | Front seat heating relay | |

| K12 | Reserve | ||

Causes and troubleshooting of the heater

If the heating system does not turn on or operates intermittently, then you need to find out the reasons and take timely measures. In different situations the problem is solved in different ways.

Blown fuse

At the first sign of a breakdown, you need to check the fuse. Only after this, if necessary, the switch itself, relays, contacts, and electrical wiring are examined.

First you need to find the fuse itself and determine its integrity. If it is difficult to diagnose based on external signs, then it is better to replace it.

Faulty wiring

Failure of the wiring system in the absence of external damage is determined using a voltmeter or multifunction tester.

After turning on the heating, there should be a voltage at the terminals of at least 11 Volts.

Instead of special devices, you can use a car light bulb by connecting the wire and ground to the “+”. If it does not light up, then repair is required.

Contact fastenings are broken

Often, during operation, the terminals on the connectors become oxidized and do not conduct electricity. For diagnostics, it is necessary to measure the voltage directly at the contact glued to the glass.

If the voltage is below 11 Volts, you need to clean it with sandpaper or a special rust remover. In addition, the terminal connection contacts can be restored by soldering.