How to connect

To understand how to connect a capacitor to an amplifier, it is enough to have a general knowledge of electrical engineering and physics. The electrical circuit for connecting a capacitor to an amplifier is not particularly complicated and can be assembled by any user who is familiar with the basics of electrical safety and has basic skills in handling tools for installing electrical circuits.

The drive is connected in parallel to the audio amplifier and the car battery, strictly observing the polarity: the positive terminal of the capacitor should be connected to the positive terminal of the battery, and the negative terminal to the vehicle ground, i.e. with negative contact.

Before carrying out work, prepare the necessary supplies:

- multimeter;

- assembly knife (“electrician’s knife”);

- a universal spanner for the sizes of the nuts and screws used;

- screwdrivers;

- wires and cables with pre-mounted and crimped lugs;

- 12 V incandescent light bulb;

- toggle switch;

- insulating tape.

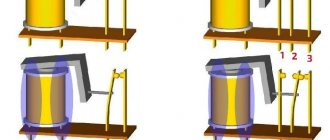

First you need to charge the capacitor, for which you need to assemble a temporary circuit as follows:

- disconnect the battery from the vehicle's electrical circuit;

- connect the negative terminal of the capacitor to the negative terminal of the battery, the positive terminal to the terminal of the light bulb, connect the other terminal of the light bulb to the terminal of the open toggle switch, feed the wire from its other terminal to the positive terminal of the battery;

- close the toggle switch;

- the drive charging current will flow in the circuit and the light will light up;

- the capacitor will be charged when the light bulb goes out.

After charging, disassemble the temporary circuit, save the toggle switch and light bulb for future use, and then begin installing the drive into the system:

- At each electrolyte terminal, secure with screws 2 lugs with wires no more than 50 cm long;

- connect the wire from the negative terminal of the electrolyte to the vehicle ground;

- to connect the amplifier to the drive, connect the wire from the negative terminal of the drive to the negative terminal of the amplifier, and the positive wire to the positive terminal of the amplifier;

- Connect the 2nd wire from the positive terminal of the electrolyte to the fuse, and the 2nd contact of the fuse to the positive terminal of the battery (i.e., the protective device is installed in the gap in the positive circuit between the drive and the battery);

- connect the speaker cable from the radio to the RCA sockets of the amplifier;

- Connect the amplifier remote control terminal with a wire to the control output of the radio.

The tightening force of nuts and bolts must be controlled, according to the calculation table, otherwise undertightened fasteners will cause increased resistance and sparking, and overtightened ones can cause deformation and destruction of electrical circuit elements. Twisting of wires is also prohibited.

The installed drive has a positive effect not only on the quality of low-frequency reproduction by the subwoofer, but also on the entire electrical system of the car:

- serves as a filter for high-frequency voltage harmonics, which are a consequence of the operation of electrical appliances in the machine, and also arise when switching the load;

- stabilizes the operation of the generator during switching off and switching on loads in the electrical circuit;

- is an additional source of charge when starting the car, especially in cold weather and winter, since at low temperatures the battery power decreases, but the capacitor retains its power unchanged.

https://youtube.com/watch?v=OxxWQMkVbYA

It should be noted that simply adding an electrolytic storage device to the electrical system of a car will not necessarily be a panacea if the car’s electrical components do not meet the appropriate requirements: wires and cables must be copper and have a cross-section designed to carry high currents, terminals and lugs must be gold-plated ( where possible) or tinned. A powerful battery should be installed in the car's electrical system.

Connection

Connecting a capacitor to audio equipment is quite easy. It is connected next to the power consumer, the power polarity is straight. That is, the plus must be connected to the plus, and the minus to the minus. Remember that a car is a design solution with its own power supply system and wiring. It is necessary to exclude additional consumers from the circuit, except for audio equipment. To do this you need to install a diode. It is needed to limit the discharge from unnecessary consumers. This electrical element is installed on the positive wire between the power source and the consumer.

Types of capacitors

They are classified by form factors and dielectric material:

Film is the most common type. Polyester, polystyrene, metal paper, Teflon and polypropylene polycarbonate are used. They have a capacity of up to 100 microfarads and an operating voltage of over 500 volts. They have different dimensions and shapes (cylindrical, oval, round or rectangular).

The MBGG capacitor (metal-paper sealed frequency) has the following technical characteristics:

- Ambient temperature indicators – from -60 to + 70 degrees;

- MTBF – at least ten thousand hours;

- Shelf life – 12 years;

- Insulation resistance – 6 kOhm.

Electrolytic - have an impressive capacity. They are made from a metal film and a thick electrolytic solution. They have limitations in polarization and rated voltage, which require special operating conditions, since incorrect installation leads not only to their physical destruction, but also to damage to other units.

Ceramic - made of connected conductors on a ceramic plate. They are distinguished by a large capacity and small dimensions. They are not polarized.

Other types - in addition to the above types, there are others, the use of which is more specialized.

Installation and charging

This procedure is not something very complicated.

Note

An interesting and noteworthy fact is that the battery is rarely the owner's attention while the car is starting. As soon as problems begin, the owner begins to sound the alarm

Read more: ZIC X5 10W40 oil: characteristics, analogues, articles, reviews

The condition of the battery, of course, especially with the onset of cold weather, deserves more careful attention, but still, even if it is new and fully operational, it will definitely need the help of a capacitor (see Why is a capacitor needed for car audio today) in a car where there is a powerful subwoofer.

Detailed and step-by-step instructions on how to do this are provided here:

First, you should prepare: find a DC source (battery in this case), a resistor (it comes with the capacitor) or a 12 V light bulb (if you couldn’t find a resistor) and wires for connecting the capacitor (they should be of the same cross-section, as well as power cables).

Note. As for the negative terminal of the capacitor, it must be connected to the “ground” of the car (body).

- Carefully turn off the fuse for the speaker system;

- Remove the wire from the positive terminal of the capacitor;

- We connect the battery to the network (you can learn how to do this from thematic articles);

- We take a resistor or a light bulb, connect one contact to the positive terminal of the drive, and the other to the power wire (charging time is determined by the manual, instructions included in the kit);

Capacitor for subwoofer

- put back the fuse for the speaker system;

- wait as long as necessary (at least 2 minutes), then turn off the resistor;

- We connect the drive's power cable to the positive terminal directly.

Advice. It is not recommended to tighten the terminals too much, as this will lead to undesirable consequences.

Why do you need a capacitor for a subwoofer?

Thus, we explained why this component is needed in a car. Now let's move on to the useful topic of how to install and connect a capacitor.

Installation

The installation process itself has the following features:

- The capacitor is installed no further than half a meter from the amplifier to avoid a decrease in the amplitude of the current due to the resistance of the connecting wires;

- In no case should you skimp on a capacitor, and if you decide to install it, it must be a high-quality one, and not some Chinese one, so that it will be of any use.

- If there is still no electronic circuit in the capacitor, then it is recommended to initially recharge the element with a 12-volt light bulb;

- Interestingly, you can install a capacitor in a system of any power, regardless of the number of amplifiers.

Charger

As for charging the capacitor (see How to charge a capacitor for a subwoofer yourself), then, as mentioned above, it is useful to charge with a 12 V light bulb, which will let the user understand how the process goes. It itself implies the following:

- A light bulb or resistor (preferably a 12 V light bulb) is connected to the battery positive on the wire;

- The other end of the wire is connected to the positive terminal of the capacitor;

- During the charging process, if the capacitor has a display with a light indication, it will light up. The voltmeter value on the capacitor will also increase, but as soon as it stops, charging must also be completed;

- Remove the light bulb or resistor.

Capacitor in a car generator

A capacitor is installed in the generator to eliminate interference in the general power supply system of the vehicle during generator operation. It protects the car from voltage surges in the ignition system, and also reduces the level of interference in the radio.

This is a privilege of modern vehicles, the equipment of which necessarily includes such a capacitor, which ensures clean operation of the radio, regardless of passing cars. The same cannot be said about old car brands, whose radios made unbearable noise from every passing vehicle.

The capacitor ensures clean operation of the radio, regardless of passing cars

Recommendations for choosing capacitors

Never purchase or install capacitors of questionable manufacture. Always pay attention to the method of installation of the product and the presence of protection against accidental short circuit. In case of self-installation, choose products that have visual sensors for monitoring its condition and on-board network. This will make it easier for you to install, as well as further operate it.. A car capacitor is connected to a circuit of any power, even if one amplifier is operating

Many motorists prefer to install capacitors in a car sound system that is equipped with an external amplifier

A car capacitor is connected to a circuit of any power, even if only one amplifier is operating. Many motorists prefer to install capacitors in a car sound system that is equipped with an external amplifier.

Expensive capacitors are used in modern cars, in which several amplifiers can be installed at once

Today there are many capacitors for cars on the market: from simple and inexpensive to the most elite. The latter are usually used in modern cars, in which several amplifiers can be installed at once.

A capacitor (from the Latin word “condensare” - “compact”, “thicken”) is a two-pole device with a certain value or variable value of capacitance and low conductivity, which is capable of concentrating, accumulating and releasing an electric current charge to other elements of the electrical circuit.

A capacitor, or as it is also called simply “conder” for short, is an element of an electrical circuit, consisting in the simplest version of two electrodes in the form of plates (or plates), which accumulate opposite discharges and therefore they are separated from each other by a dielectric of small thickness compared to their size the electrically conductive plates themselves. In practice, all manufactured capacitors are multilayer rolls of electrode strips in the shape of a cylinder or parallelepiped, separated from each other by layers of dielectric.

How to eliminate additional load on car wiring

Autocapacitors have one serious drawback: the ability to self-discharge. This type of electrical devices is bad for your car battery. Especially if there are a lot of them and it’s cold winter outside. To solve this problem, there are many devices on the market that are connected only when voltage appears at one terminal.

Capacitors from popular companies are equipped with a very convenient function, for example, installing a voltmeter. This is necessary for visual instrumental monitoring of voltage sags.

When connecting to the starting system, be sure to check that there is no voltage on the starting wire when parked. If there is no potential on it, then the car's network will be blocked from the capacitor. It is very easy to perform manual switching yourself. To implement this, you just need to use a relay. The switch can be placed in any place where it is convenient.

Selecting a starting capacitor for an electric motor

A modern approach to this issue involves the use of special calculators on the Internet that perform quick and accurate calculations.

To carry out the calculation, you should know and enter the following indicators:

- Motor winding connection type: delta or star. The capacitance also depends on the type of connection.

- Engine power is one of the determining factors. This indicator is measured in Watts.

- Mains voltage is taken into account in calculations. As a rule, it can be 220 or 380 Volts.

- Power factor is a constant value that is often 0.9. However, it is possible to change this indicator during calculation.

- The efficiency of the electric motor also affects the calculations performed. This information, as well as others, can be found by studying the information printed by the manufacturer. If it is not there, you should enter the engine model on the Internet to search for information about what the efficiency is. You can also enter an approximate value, which is typical for such models. It is worth remembering that efficiency may vary depending on the condition of the electric motor.

Such information is entered into the appropriate fields and an automatic calculation is carried out. At the same time, we obtain the capacity of the working condensate, and the starting condensate should have an indicator 2.5 times greater.

You can carry out such a calculation yourself.

To do this, you can use the following formulas:

- For the star winding connection type, the capacitance is determined using the following formula: Cр=2800*I/U. In the case of a triangle connection of the windings, the formula Cр=4800*I/U is used. As you can see from the information above, the type of connection is the determining factor.

- The above formulas determine the need to calculate the amount of current that passes through the system. For this, the formula is used: I=P/1.73U?cos?. For the calculation you will need engine performance indicators.

- After calculating the current, you can find the capacitance indicator of the working capacitor.

- The starting one, as previously noted, should be 2 or 3 times higher in capacity than the working one.

When choosing, you should also consider the following nuances:

- Operating temperature range.

- Possible deviation from the calculated capacity.

- Insulation resistance.

- Loss tangent.

Usually, the above parameters are not paid much attention. However, they can be taken into account to create an ideal electric motor power system.

Overall dimensions can also be a determining factor. In this case, the following dependence can be distinguished:

- Increasing the capacitance leads to an increase in the diametrical size and outlet distance.

- The most common maximum diameter is 50 millimeters with a capacitance of 400 µF. At the same time, the height is 100 millimeters.

In addition, it is worth considering that on the market you can find models from foreign and domestic manufacturers. As a rule, foreign ones are more expensive, but also more reliable. Russian versions are also often used when creating an electric motor connection network.

The perfect combination

As mentioned above, car speakers have the right to be called that if they involve a trio (sub, amplifier and capacitor). Let's try to figure out which combination can be called ideal.

Woofer Mystery MJB 12, amplifier Sony XM-504Z and capacitor Stinger SPC111

A powerful trio that delivers perfect sound. At the same time, everything is in a budget option and you don’t have to pay extra.

Selection of amplifier, subwoofer and capacitor

Woofer Specifications

| Mystery Corps MJB 12 | High quality MDF |

| Diffuser | High quality chrome plated injection molding |

| Suspension | Butyl rubber |

| Magnet/magnetic system - weight | 40 oz/80 oz |

| Voice coil | 2" aluminum, covered with cardboard |

| Case dimensions, mm | 450/418/367 |

| Peak power, W | 250-500 |

| approximate cost | 4-5 thousand rubles |

Specifications of the Sony XM 504Z amplifier

| Dimensions, mm | 350/233/55 |

| Peak power, Ohm/W | 4/100 – 2/125 – 1/250 |

| Channels, number | 4/3 |

| Power supply | MOSFET transistors |

| approximate price | 3-4 thousand rubles |

Technical characteristics of the Stinger 111 capacitor

| Capacitance, farad | 1 |

| Voltage range, V | 16-20 |

| Internal resistance, mOhm/Hz | 1,5/120 |

| Voltmeter | Has digital/LED display red/3 segments/auto power off and on |

| Diameter, mm | 75 |

| Height, mm | 250 |

| Case color | grey |

Review of capacitors for a snack

Brax IPC

What kind of capacitor is needed for a subwoofer

Capacitor costing 300 US dollars. The model name IPC stands for “intelligent power capacitor.” It has the following features:

- The user will find in this model a luxurious, superbly finished, clearly thought out device with the highest electrical performance;

- The length of the capacitor body is 280 mm, and the diameter is 75 mm;

- The operating principle is based on automation, which will provide charging with a normalized current and protect the acoustics from overvoltage;

- The Brax capacitor operates at 17.5 V, if connected incorrectly, automatically connected to the power network and disconnected;

- Provides a continuous indication of the voltage at the amplifier terminals (see How to connect an amplifier and subwoofer to a car radio: you are your own master);

- The capacitor is made in a stylish, beautiful case with a transparent head, in the center of which a 3-charge digital indicator is displayed. This indicator becomes active as soon as it senses the slightest voltage ripple on the amplifier and shows a voltage of up to 0.1 V;

- The capacitor readings are not carried out by continuous blinking, as on some cheap models, but are averaged with a time constant of about 1.5 s;

- For rapid fluctuations, the answer is another indicator, operating on 2 LEDs. If one of them or two blinks at once, this indicates short-term voltage ripples;

- There is also a third indicator called CPS. It is needed to report danger: if it lights up red, the polarity is reversed; if it lights up yellow, the overvoltage protection has tripped.

In a word, this is a gorgeous device that we recommend everyone buy. In addition to purely intellectual capabilities, this capacitor has virtually no internal resistance and it passes through at a record low.

Power Ampere SPV 100D

An excellent electronic capacitor with declared internal resistance characteristics. The approximate price of the device is $250. It has the following features:

- Stated internal resistance characteristics: 1.8 mOhm/120 Hz and 1 mOhm/20 kHz;

- The advantages of this capacitor will be fully manifested in conjunction with a high-quality amplifier (where power supplies, as a rule, operate at a higher frequency);

- The head of the device is filled with electronics, which ensures smooth charging in 10 seconds;

- You can know that charging is in progress by the blinking indicators;

- If the voltage in the network crosses the value limit of 15.5 V, the protection is triggered immediately. If the voltage drops (11 V), the capacitor turns off and goes into hibernation.

Power Ampere Capacitor Operation Chart

Signat ECC1

Automotive capacitor for $230. Extremely compact, despite its record performance. Features:

- The model is made in a traditional dark blue case, with a diameter of 70 mm (the usual size of capacitors in other models is 75 mm);

- The top or head of the device, as is commonly seen on high-end capacitors, houses the electronics. It is able to provide a fully automated charging procedure in just 1 minute. We are talking about a current of 500 mA;

- You can find out about the charging process by the LEDs that light up. There are 5 of them of different colors, from red to green, and they glow alternately. You should know that when the last fifth indicator lights up, this indicates that the capacitor is fully charged.

What kind of capacitor is needed for a subwoofer?

- Voltage fluctuations are controlled by the same LEDs that monitor the charging of the device. When the voltage fluctuates, they go out one by one;

- There are two more separate LEDs. One of them is designed to indicate whether the connection to the power circuit has occurred, and the other reacts if there is an error in the polarity connection.

- The ECC1 signal is designed so that the operation of the device can be observed from two positions: either through a transparent wall or from above, where there are translucent windows;

- The statistical capacity of the device is 1.07 farads.

We recommend. Quite a decent capacitor and the price is not too high.

What kind of capacitor does a subwoofer need?

Installing the capacitor is easy to do with your own hands and calling a specialist for help will be superfluous. Just watch the video and study a few photos. And of course, step-by-step instructions should be at hand.

Operating principle and purpose

The operation of a capacitor for acoustic systems is based on the law of conservation and accumulation of energy of the simplest element found in many electrical circuits. The simplest capacitor consists of two conductors with a dielectric between them. The length of these conductors, depending on the capacity, can reach from one meter to several tens, as well as the dielectric located between them. This entire design is very compact, so even with such a huge capacitance for electronic devices as one Farad, the dimensions of the capacitor for the subwoofer allow it to be placed in a car.

The principle of operation of a car capacitor connected to the power circuit of an amplifier or subwoofer is that in normal mode, when the supply voltage is at least 12 Volts, it is capable of accumulating an electrical charge. When a fan of loud music turns up the regulator and increases the power of the audio system, the current in the power circuit increases greatly and can reach up to 100 Amps, and a voltage drop occurs, since neither the generator, nor, especially, the battery is designed to work with such a large constant load. Moreover, in the car circuit, especially at night, there is already a load caused by the switched on lighting devices, wiper motor, air conditioning and other devices, depending on the configuration of the car’s electrical equipment. When listening to powerful bass, the acoustic capacitor for the subwoofer will compensate for the decrease in the supply voltage, that is, its drawdown. Without this device, the voltage at some points will drop to 8-9 Volts, which is unacceptable both for installed stereo systems and for the entire on-board circuit of the car.

Thus, we can identify several obvious signs that will be noticeable to the driver due to the absence of a high-capacity capacitor in the subwoofer power circuit:

- Flashing headlights in time with the music;

- Increased fuel consumption associated with increased load on the generator;

- Disabling or significantly reducing the sound quality of the audio system with increasing power and especially with strong low frequencies emitted by the subwoofer.

Methods for selecting a capacitor for powerful speaker systems

In order to choose the right acoustic capacitor for a subwoofer

you need to take into account the maximum and operating power of the sound amplifier. For 1000 W of stereo system power, a capacitance in its power supply circuit is required equal to 1 Farad. This is a very large capacitance that can compensate for the voltage drop; mainly in electronics you can find capacitors whose capacitance is measured in microfarads.

Also required for stable operation of the system is an electronic circuit built into the device body, designed for:

- voltage indication in the amplifier power circuit;

- supplying energy from a backup energy source (capacitor) at the desired peak moment of drawdown;

- adjusting the amount of energy to protect against blown fuses.

An acoustic capacitor for the subwoofer is connected in parallel to the power circuit, being sure to observe polarity and minimize its distance from the amplifier terminals.

Review of the most common acoustic capacitors

Brax IPC

- from connection with incorrect polarity;

- from overvoltage, that is, if the voltage rises above 17.5 Volts.

It is equipped with a bright three-digit indication of the voltage value of the amplifier supply circuit, which displays the average value for a time of 1.5 seconds, which is very pleasant and distinguishes this model from cheaper ones. There is also an indication that the protections described above are enabled.

Power Ampere SPV 100D

Signat ECC1

. Listed market price $230. It is compact, since its diameter is 7 cm. The process of fully charging the acoustic capacitor is notified by 5 LEDs of different colors. Charging time and ability to work in normal mode is about 1.5 minutes. An emergency shutdown occurs when the supply voltage on the subwoofer increases to 16.5 V.

Thus, lovers of creating powerful car audio will have to fork out for another necessary tool to obtain high-quality sound and maintain the car’s on-board voltage system in normal mode.

What is a car capacitor and why is it needed?

Today, a car capacitor is usually understood as an electrolytic capacitor connected to a car audio amplifier (or directly to a radio) in parallel with the supply wires. But why is it needed?

Capacitors are often used to protect against network interference.

1. Filtering of power supply interference. Capacitors have been used for a long time as the simplest, but at the same time, quite effective filter of power supply interference - they have probably been noticed by everyone who has happened to look inside electronic devices. The capacitor is charged by the supply voltage and, in the event of a sharp drop in voltage, compensates for the drawdown, returning the accumulated charge to the network. Usually, high-quality car amplifiers have their own protection against voltage sags, but if you hear extraneous sounds from the speakers when you turn on auto electrical components (fan, wipers, headlights, etc.), a capacitor can help. And one more thing - regardless of where the capacitor is installed in the car network, it will maintain the voltage of the entire network, and not just the amplifier. Therefore, if your headlights flicker when the audio system is running, then after installing the capacitor they will stop flickering (they will burn at full intensity). Another thing is that strong (until the headlights flicker) drawdowns during operation of the audio system clearly signal a lack of power from the generator and battery. Installing a capacitor will not solve this problem - it is not a source, but a consumer of energy, and in the event of a power shortage, it will likely worsen the problem.

2. Supports power supply to the radio during peak loads, for example, when playing bass. There are two options here:

2.1. There is not enough power going to the audio system. The reasons may be different: a dead battery, a weak generator, power wires of insufficient thickness, etc.

What does it look like in theory?

In this case, when installing a capacitor (close to the amplifier), theoretically, it is possible to obtain a certain increase in sound volume without distortion - provided that the excessive loads are short-term (no more than a fraction of a second) and are interspersed with periods of reduced load of no less duration (so that the capacitor can restore charge).

And as most often happens in practice.

But real music cannot meet such requirements - the bass in compositions rarely sounds for less than a few seconds. Therefore, there will be practically no noticeable effect - it can hardly be called an improvement in sound quality if the speaker starts wheezing a third of a second later than usual.

2.2. There is enough power, but the battery does not have time to “give” the required current. As you know, when a consumer appears, the battery discharge current does not set instantly; and the installation time depends on the characteristics of the battery - primarily on the internal resistance (more precisely, on the reactive component of the internal resistance). And if the internal resistance of the battery is high, then when the load sharply increases, it will provide the required current with some delay, small, but sound distortion at this moment can already be noticeable.

Connection diagram of a capacitor to the amplifier power circuit.

Indeed, in this case, installing a capacitor may be an acceptable alternative to replacing the battery. This will not completely solve the problem, but it can smooth out the bass fronts, for example.

Recently, “capacitors” have appeared on the shelves of car dealerships, characterized by a huge (up to hundreds and even thousands of Farads) capacity, but at the same time having a modest size and a very attractive price. These are not capacitors, these are ionistors. There is little point in connecting them to an amplifier - yes, they have the declared capacitance, but ionistors differ from capacitors in their high internal resistance (ESR), low maximum discharge current and low rate of installation of the supplied current. There are ionistors with low ESR, similar in characteristics to capacitors, but they are much more expensive.

general information

The best capacitors for acoustics

So why do you need a capacitor? As you know, the price for it is not small and not all motorists, even lovers of good sound, want to cut their budget once again. On the other hand, every music lover sooner or later acquires a powerful speaker system or brings it to perfection. This is very good, but the more powerful the system, the more energy you give it.

A capacitor in acoustics (see) is a component that serves as an additional power source for an amplifier. This element is very important and

Read more: Changing the oil in an automatic transmission with your own hands, video instructions

So, the capacitor is able to solve the problem with dips, since it is a high-capacity electrolytic device, the connection of which occurs in parallel with the power supply circuit of the amplifier. The capacitor has practically no resistance, or rather, it is so small that the current is given to the amplifier instantly, thereby eliminating the occurrence of dips. Then, with the same speed, the capacitor is charged again and is ready to give out the next portion of beneficial current for the amplifier.

Top 5 devices of 2021

Based on consumer reviews, the 5 best capacitors for a subwoofer have been selected, showing good results and a long service life. These include products from well-known brands, suitable for use by both novice and experienced car audio engineers.

Kicx flc 1.5

pros

- good equipment

- contacts for ring terminals

- reverse polarity protection

- charge level indication

Minuses

- weight, dimensions

- capacity is only 1.5F

- low operating voltage margin

The main advantage of this capacitor is its complete ease of installation. Convenient complete brackets and a reliable contact group are provided. The product shows excellent service life thanks to electronic protection and a special mesh.

MD.Lab PC-E1.0

pros

- 1F capacity with small measurement error

- compact aluminum housing

- built-in voltmeter

Minuses

- no reverse polarity protection

- small margin for maximum voltage

- poor equipment (only capacitor)

This drive can only provide 18 V pulse voltage. If this is enough, the device will appeal to experienced audio system designers. The capacitor can operate at temperatures from -40 to 60 degrees Celsius and has low leakage currents.

ACV CAP-5.0F

pros

- overload protection

- protection against incorrect activation

- amplifier integration option

- possibility of connecting several series-connected load units

- advanced electronic parameter control system

- indicator light and built-in voltmeter

Minuses

- dimensions

- low pulse voltage value

- own connection diagram

- awkward terminal blocks

The most complete control of voltage and operating parameters available today, as well as the possibility of direct control from the amplifier are two striking features that distinguish this capacitor model. It will appeal to users who want to create a truly powerful system. A capacity of 5F is enough for acoustics of 5 kW.

Kicx DPC 2.0F

pros

- excellent power to size ratio

- built-in charge indicator

- Built-in shutdown relay in standby mode

- good surge voltage reserve

Minuses

- small area terminals

- poor equipment (only capacitor)

- low operating voltage 12V

This capacitor is very unpretentious. With some drawbacks, it allows overheating up to 95 degrees Celsius and will retain the charge when parked without the use of special connection circuits. The device will appeal to beginners; it is capable of delivering a 24V pulse.

What to look for when purchasing?

The main thing that a car owner who wants to buy an electrolytic capacitor for a subwoofer should take into account is the ratio of its capacity and the power of the system. The rule is quite simple. The minimum limit is 650 to 850 µF per kilowatt. To simplify calculations, it is recommended to take 1F per 1 kW of sound system power.

It is ideal if a capacitor with a capacity exceeding the nominal values is installed in the car. Other features of a good element are as follows:

- The delivery kit should include everything you need to install the electrolytic capacitor in the machine. These include the wires that connect the amplifier, and special protected brackets that prevent damage to the element shell and the occurrence of other emergency situations;

- The pulse voltage of the capacitor should be 24 V. This is a sufficient reserve (the corresponding operating parameter of the on-board network is from 12 to 18 V) so that the drive does not overheat during charging;

- for a sharp release of high power and the formation of large currents, the capacitor must have powerful connectors with thick leads and a large area. Responsible companies offer products with gold-plated contacts;

- Charge indicators are a huge help, including for the convenience of monitoring the status of the drive during operation. This could be a simple circuit with a row of LEDs or a digital display;

- If you need a drive that you can simply connect and count on long-term stable operation, it is recommended to buy products equipped with a charge and condition monitoring system. Such models must be equipped with an indicator.

The last, but one of the main, remark: you should not save on buying an electrolytic capacitor for a subwoofer. On specialized forums you can find many examples, videos and photos of disassembling cheap products. They clearly and accurately show the discrepancy between the actual characteristics and the declared ones, and also describe the dangers of using this type of drive.

Sub

Which amplifier to choose for a subwoofer

The most difficult speaker to artificially amplify is the sub. It is for this reason that so many large-sized subwoofer amplifiers are produced today. They are designed specifically for amplification of low frequencies. Here is what is recommended to know for those who are thinking about improving the sound of a subwoofer:

- 1-channel or mono amplifiers are capable of operating with a wide range of impedances. Such devices have a special tone setting, separate filters that help thunderous bass erupt at full power;

- 2 and 4-channel “amplifiers” are also capable of subwoofer amplifiers, but they are not able to cope with the effect of low impedance. They quickly overheat as soon as the sub starts playing at full power.

How to choose an amplifier for a subwoofer

The ideal amplifier option for a low-frequency driver, which will enable the subwoofer to produce an excellently balanced sound, is a device characterized by the following parameters: 50-200 watts.

https://youtube.com/watch?v=x2hMrOoDY_s