When designing the VAZ Oka 1111 and 11113, the designers tried to simplify and reduce the cost of the design as much as possible. For this purpose, the simplest and most proven solutions were used, the unification of spare parts with other VAZ models, and this concept of building a small car concerns all its components, including the suspension.

The VAZ Oka has a transverse engine and transmission design and is driven by the front wheels. And with this type of drive, the simplest and cheapest suspension option is shock-absorbing struts, also known as MacPherson struts. It is this type of independent suspension that the small car received at the front.

At the rear, they installed a so-called semi-independent beam with a separate design of the main components.

Suspension design

The front suspension design of the Oka largely copies the VAZ-2108, but there are some differences. The main difference is the use of a subframe to fix the arms to the car body in the lower part on the VAZ-1111, while on the Eight they are connected to brackets attached to the body. Naturally, the sizes of spare parts are somewhat different.

Front suspension

The front suspension of the small car includes:

- 2 shock-absorbing struts (each of them consists of a glass, a shock absorber, a spring, an upper support);

- 2 hubs;

- 2 wishbones;

- 2 longitudinal stretch marks;

- 2 ball joints;

- 1 anti-roll bar (with struts);

A paired number of parts indicates that one complete set of them is installed on one side of the car (left, right). As for the stabilizer, there is only one in the suspension design; it is located transversely to the car and connects the suspensions of the two sides.

The suspension scheme on a car is very simple - a cup, a spring, a shock absorber and an upper support form the main component of the suspension - the shock absorber strut. In the upper part, the rack is fixed to the body by means of a support. The bottom of the strut is attached to the hub with a bolt connection (one of them is adjustable).

A transverse lever also fits the hub; it is attached to it through a ball joint. The second end of the lever is fixed in a bracket made on a subframe.

To prevent longitudinal displacement of the wheel during movement, the transverse arm is held by a longitudinal strut. This spacer is inserted into the lever at one end, where it is fixed with nuts, and at the other end it is attached to the subframe bracket.

The stabilizer is installed transversely to the car and its ends fit into the shock absorber struts. The end caps of this part are connected to the wishbones, but not directly, but through special racks. In the central part, the stabilizer is fixed with brackets to the subframe.

Since the suspension is a highly loaded unit, elastic elements made of rubber are used to reduce shock loads between its components at the points of their connection. These include silent blocks, bushings, thrust washers. These rubber elements are classified as consumables and require periodic replacement.

Features and qualities

A feature of the MacPherson suspension is the use of a shock absorber strut as a steering knuckle, which allows it to be installed on the front end. The strut plays the role of a steering knuckle thanks to the ability to rotate around an axis, and this is ensured by the use of a ball joint and a bearing included in the design of the upper support.

In addition to the rubber components, the “weak points” of the front suspension on the Oka are the shock absorbers and the upper supports.

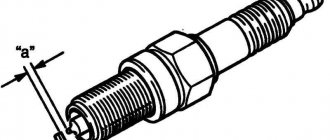

Shock absorbers on VAZ 1111 and 11113 are made in the form of inserts (cartridges) installed in the strut cup and secured in it with a support nut.

Oil shock absorbers are installed, which are not particularly reliable. In addition, they are quite “soft”, which negatively affects the car’s handling.

The upper supports work in very difficult conditions - they bear the main load (the weight of the car, the forces coming to the rack from the wheel while driving). In addition, they take part in driving the car - thanks to the bearings included in the design of this unit, the rack rotates around its axis. All these features of the operation of the supports lead to the fact that over time they wear out and require replacement.

Rear suspension

The rear suspension is semi-independent, presented in the form of a beam consisting of two trailing arms and a spring cross member. These components are connected to each other by a permanent connection (welded).

At one end the trailing arms are attached to the body through brackets, and at the other ends the wheel hubs are attached.

The beam is depreciated by a shock absorber and a coil spring. Moreover, in Oka these elements are installed separately.

At the rear, the least reliable suspension components are the same shock absorbers and rubber elements used at the junction of the beam and brackets.

Separately, it is worth noting the springs. The coil springs, installed both front and rear, are made from small diameter rod. This provides high elasticity to the spring, but the rigidity is not enough, which makes the small car “roll” and large body rolls occur when cornering, which worsens the car’s handling.

Malfunctions and their symptoms

The main malfunctions of the suspension of the VAZ Oka car are:

- Wear and damage to rubber elements (silent blocks, bushings, support washers);

- Leakage of working fluid from the shock absorber;

- Wear of the ball joint;

- Spring damage;

- Wear of the upper support;

The front suspension has a direct impact on the car's handling, so any faults in it will negatively affect the car's behavior on the road. The condition of the rear suspension, although it affects handling to a lesser extent, its technical condition is also important.

Symptoms of problems are:

- Knocking in the front suspension, squeaks (when driving through an area with uneven surfaces);

- Incontinence of the rut (when driving on a straight section, it is necessary to steer in order to maintain the trajectory);

- Deterioration in controllability;

- Uneven tire wear;

- Steering wheel vibration when braking;

There are also more specific signs, for example, a clearly noticeable misalignment of the car, which happens in the case of a broken spring.

Note that some symptoms may indicate malfunctions in other components of the chassis - wheel hubs, steering, brake system. Therefore, to more accurately determine the cause, diagnostics of these nodes is necessary. After this, the chassis is repaired, which involves disassembling its components, troubleshooting and installing new spare parts to replace worn ones.

Wear and tear of consumables is the most common reason for the need for suspension repairs. Silent blocks, bushings, washers provide vibration damping during suspension operation. But these parts are made of rubber, which is subject to “aging” and delamination. As a result, their work efficiency decreases. In addition to the environment, the condition of rubber components is also affected by the operating conditions of the vehicle.

Restoring the performance of the suspension is carried out by replacing worn consumables (they cannot be repaired).

The shock absorbers are also not highly reliable, and due to their excessive “softness,” the performance of these components on the Oka leaves much to be desired. Their most common failure is the appearance of a leak of working fluid. Such a malfunction leads to a malfunction of the part. Damage to the shock absorber rod or housing is less common.

Symptoms of problems with the shock absorber are traces of oil on the strut cup, strong knocking (“breakdowns” of the shock absorber) when driving over uneven surfaces.

The ball joint is the lower support point of the suspension, so it does not bear quite heavy loads either. Over time, this joint wears out, which leads to knocking noises (when hitting bumps) and deterioration in handling. This spare part is also non-repairable and must be replaced when critical wear occurs.

Springs do not cause any particular problems for Oka owners. But in rare cases, their destruction is possible. Due to the burst spring, the strut is unable to support the body, causing it to warp. Naturally, the performance of the suspension is completely impaired and it is almost impossible to operate the car with such damage.

The second problem associated with the spring is the loss of its elasticity - it “shrinks”. This type of malfunction manifests itself through vehicle subsidence, often uneven, and “bounces” (strong knocks) of the suspension when driving even over minor uneven surfaces.

Springs cannot be restored and if they lose elasticity or are destroyed, they must be replaced.

The upper support also fails over time. Its “weak points” are the bearing and the rubber layer. The malfunction of this unit manifests itself in the form of creaks, grinding noises when turning, and knocking on potholes. The support cannot be repaired and requires replacement if worn.

see also

Comments 21

Well, I don’t need springs from the Oka... Any springs designed and manufactured for the VAZ-1111(3) OKA car on my trough will constantly burst, because this is not a VAZ-1111(3) OKA.

Doesn’t it seem that given the results obtained (incredible stiffness), sheepskin is not worth the candle?

Significant reduction in roll even without a front stabilizer? It depends on what goals to pursue. At the time of these alterations, I was fighting for tenacity and stability, maneuverability, and not for comfort. The goal has been achieved. Now I don’t need such tenacity, I drive much calmer, so I will rework the suspension to balance between tenacity and softness.

Diagnostics

Any malfunction of suspension components affects the geometric parameters of this component (changes in toe, camber, and longitudinal inclination of the steering axis). The consequence of geometry violation is deterioration in car handling and uneven tire wear.

Diagnostics of the suspension is a simple operation. At service stations it is performed on special stands, but it can be done with your own hands.

Self-checking the condition of the diagnostics comes down to a visual inspection and applying force to certain points.

When inspecting, pay attention to all rubber elements. Cracks or delaminations on them will indicate wear of the consumable and the need to replace it.

After examination, the diagnosis is performed as follows:

- We put the car on the inspection hole;

- We climb under the car and take the tire iron;

- We insert a pry bar between the wishbone and the subframe. Swing the lever;

- In the same way, we check the condition of the stabilizer link;

- We hang up the front of the car;

- Holding the wheel, swing it in the transverse direction (pull “from yourself to yourself”);

By applying force, play is checked at the joints (in a working suspension there should not be any). If there are backlashes, they will appear in the form of knocks. This way, the key connection points are checked - the arms to the brackets and the hub, the upper support to the body, as well as the condition of the ball joint.

The rear suspension is checked in the same way - but in it, force should be applied to the cross members of the beam to check the condition of the silent blocks.

If the diagnostics reveals backlashes, the suspension is repaired, which consists of disassembling it, defacing it and installing new spare parts.

Tuning and improvements

As already, the front suspension on the Oka leaves much to be desired, so many small car owners are interested in how to strengthen the suspension and improve its performance. Suspension tuning helps a lot in this matter.

Conventionally, tuning of this component on the VAZ-1111 can be divided into two categories - with minimal impact on geometric parameters and serious alteration.

In the first case, reworking the suspension comes down to replacing the shock absorber and installing rubber elements with improved characteristics. The front suspension spring does not change in this case.

On the Oka, in addition to factory shock absorbers, you can install similar parts from other cars, but here it is important to take into account their dimensional parameters, in particular the length.

The front shock absorbers of the VAZ-1111, for example, are similar to the front shock absorbers from the Chevrolet Niva, VW Jetta/Golf 2. But the former, when fully extended, are 1 cm shorter than the “original” ones from Oka, and the shock absorbers from VW, on the contrary, are longer by 3 cm. Therefore, their installation will entail a change in ground clearance. But as an option, the rod on the Jetta 2 parts can be ground down by 3 cm and a thread can be cut on it, thereby adjusting the part to the required dimensions.

In both cases, replacing the shock absorber with a stiffer one will have a positive effect on the car’s handling and will reduce the “rolliness” of the car, and at the same time, the alteration will have virtually no effect on the geometry of the entire unit.

As for the serious modification of the suspension, everything here depends on what the owner wants to get as a result. For example, some “Okovody” make a kind of crossover out of a small car. And for this, a suspension lift is performed, which boils down to adding spacers to the strut design, while the shock absorbers are also replaced with higher ones. As a result, the car is significantly “lifted” - its ground clearance increases.

In general, there are many modification options and they are, by and large, limited only by the imagination of the car owner. Some only strengthen the suspension, others modify it using components from other cars, and others practically develop it from scratch, adapting it to certain operating conditions of the car.

How to choose rear suspension springs

When buying rear springs, their quality can be checked in this way: examine the shape of the spring, and if it turns out that any turn of the plane cannot touch, then it is better to buy another spring.

No matter how much you protect your own car, the springs of the Oka still begin to sag, no matter how hard the manufacturers try to make every detail with high quality and for a long service life. When replacing them, the main thing is not to buy from dubious sellers.

There are many good products, for example “Phobos” - suspension spring 1111, the dimensions fit perfectly. It has such a progressive characteristic that the car is provided with sporty dynamics, the car is stable in all modes due to the fact that the ground clearance is lowered from 5 to 10 mm.