Forum members who have encountered this issue, please tell me. The upper pipe of the system was torn. cooling. When I removed it, I discovered that the fitting diameters of the pipe were almost 1.5 times smaller than the diameter of the main “body”. Is this a constructive idea, or has it just been torn apart in 10 years? Catalog number 15-186. Yes, does anyone have any ideas on what it can be replaced with (snatched from another car?) New only on order, wait about 2 weeks, and the price tag is around 2000 re, not quite kosher. Take it for disassembly, “pig in a poke” "so to speak.

PS Searching the forum did not give any results.

Alex22

RFD Land Rover Discovery III

RFD Land Rover Discovery III

I'll continue. In general, I went to Automag. “Planet Zhelezyaka” and bought there a pipe leading to the thermostat (2108-1303055), an upper radiator inlet pipe (VAZ-21073-1303025), and an upper radiator pipe 21213 (21213-1303025).

All this was sawed off (iron pipe), cut (rubber pipes), and assembled into one pipe. The diameters of the pipes are like original ones. I connected it all together, tightened it with clamps and filled it with antifreeze, about 8 liters.

In general, as it seemed to me then, everything turned out 5+, cheap and cheerful (the price of 2 rubber and one metal pipes was a little less than 500 rubles, versus almost 2000 rubles for the new original).

But the music didn’t play for long. The car drove like this for almost 3 weeks. But suddenly yesterday, my wife called and said that antifreeze had leaked and one rubber pipe had come off the metal connecting pipe. I got upset, bought more antifreeze, arrived, put everything back in place, filled it with antifreeze, tightened all the clamps properly and was on my way. Today history repeated itself again. The pipe fell off the iron tube again, but only on the other side. Since I tightened everything “dead” yesterday, I was afraid that either the clamp would burst or the pipe, whatever it could be, why the pipes were knocked out. The only thing that comes to mind is that wild pressure is created in the cooling system.

What to blame, the expansion tank plug, the air lock in the system.

I used the search, but did not find a solution for myself.

DAA Ford Maverick

Meatlove Mariner 2.5 2009

❝ Quote(DAA @ Jul 6 2011, 21:26)

The same problem, the pipe burst, only on Maverick 3.0 2001. Now I’m looking for a replacement, the Ford one with number 4,394,835 costs 3,500, the Mazda 15-186 costs an average of 1,900. Can anyone tell me if they are the same, or rather, will the Tribute fit on the Maverick? And one more thing - Mazda has 2 varieties AJ03-15-186J and AJ03-15-186K, does anyone know what their differences are?

DAA Ford Maverick

DAA Ford Maverick

Mr. Pokryshkin Volkswagen Touareg

❝ Quote(RFD @ Jun 17 2011, 19:47)

I'll continue. In general, I went to Automag. “Planet Zhelezyaka” and bought there a pipe leading to the thermostat (2108-1303055), an upper radiator inlet pipe (VAZ-21073-1303025), and an upper radiator pipe 21213 (21213-1303025).

All this was sawed off (iron pipe), cut (rubber pipes), and assembled into one pipe. The diameters of the pipes are like original ones. I connected it all together, tightened it with clamps and filled it with antifreeze, about 8 liters.

In general, as it seemed to me then, everything turned out 5+, cheap and cheerful (the price of 2 rubber and one metal pipes was a little less than 500 rubles, versus almost 2000 rubles for the new original).

But the music didn’t play for long. The car drove like this for almost 3 weeks. But suddenly yesterday, my wife called and said that antifreeze had leaked and one rubber pipe had come off the metal connecting pipe. I got upset, bought more antifreeze, arrived, put everything back in place, filled it with antifreeze, tightened all the clamps properly and was on my way. Today history repeated itself again. The pipe fell off the iron tube again, but only on the other side. Since I tightened everything “dead” yesterday, I was afraid that either the clamp would burst or the pipe, whatever it could be, why the pipes were knocked out. The only thing that comes to mind is that wild pressure is created in the cooling system.

What to blame, the expansion tank plug, the air lock in the system.

I used the search, but did not find a solution for myself.

Replacing the cooling system pipes of a VAZ 2110

In fact, the cooling system pipes on a VAZ 2110 car cannot be called strong, reliable and durable elements. Over time, they can wear out and lose their effectiveness. Therefore, the only thing left for the car owner is to replace them.

Rubber tubes for CO

Today we will tell you how to remove and replace these elements. You must act strictly in accordance with the operating instructions and observe all safety precautions. This will allow you to protect yourself and your car from unnecessary troubles.

Radiator

The product in question is very often used in trucks, buses and tractors. It is efficient in medium and severe operating conditions. They are also made in different lengths and can be easily cut.

| L | d1 | d2 |

| 80 | 55 | 60 |

| 100 | 65 | 70 |

| 100 | 60 | 65 |

| 100 | 55 | 60 |

| 100 | 50 | 55 |

| 100 | 35 | 40 |

| 100 | 25 | 30 |

| 120 | 65 | 70 |

| 120 | 60 | 65 |

| 120 | 55 | 50 |

| 125 | 65 | 70 |

| 125 | 60 | 65 |

| 125 | 55 | 60 |

| 125 | 50 | 55 |

| 125 | 45 | 50 |

| 125 | 35 | 40 |

| 125 | 25 | 30 |

| 125 | 20 | 25 |

| 135 | 65 | 70 |

| 135 | 60 | 65 |

| 135 | 58 | 70 |

| 135 | 55 | 60 |

| 135 | 50 | 55 |

| 135 | 35 | 40 |

| 135 | 25 | 30 |

| 135 | 20 | 25 |

| 150 | 65 | 70 |

| 150 | 60 | 65 |

| 150 | 55 | 50 |

Preparation

It is necessary to remove the pipes only when the car engine has completely cooled down. Therefore, if you have just stopped by your garage for procedures, do not rush. It is better to leave the car overnight and return to work tomorrow morning.

- Make sure that the pipes are actually damaged and need to be replaced.

- Be sure to drain the coolant from the system. If you recently changed it, there is no need to dispose of the liquid. Just use a clean container to drain so you can refill it later.

- The order in which you perform the work depends on what hoses are used on your vehicle.

Worm

You've probably wondered why “wormy”? But because this device is based on a worm gear, which can transform the rotational movements of the screw. It is used to fix pipes to the surface. The part itself includes: tape, bolt and lock. This material can evenly distribute the load if the hoses are tightened. The mount itself is suitable for repeated use. These products are highly resistant to rust and are also very durable and airtight.

Standard pipes with union connector

If such hoses are present, dismantling them is carried out as follows:

- Elements of this type are usually mounted using clamps. Just check what kind of clamps they are - disposable twist type or standard worm clamps. If they are disposable, we highly recommend replacing them with worm driven items. They are more practical and reliable;

- Armed with a screwdriver, loosen the clamp slightly and move it along the pipe. This way you can completely release the fitting;

- The hose is carefully, without unnecessary or sudden movements, removed from the receiver, that is, the fitting. Quite new pipes that have not yet worn out are easy to remove, but old ones can “stick”;

- If the element does not want to be removed just like that, twist it on the receiver, pry it with some sharp object, and pull it. You just can’t put in a lot of effort, because the pipes are very fragile. If the situation is really sad, just cut the hose with a knife. It is simpler, easier, although it will require large financial costs;

- When installing new hoses, clamps are first put on and then pulled onto the cooling system receivers;

- If you previously used a twist-type clamp, be sure to remove it. As an alternative, both a screw clamp and a worm clamp are suitable. There is no big difference in price, but the level of reliability is significantly higher;

- If you have difficulty fitting the elastic pipe onto the fitting, slightly wet the latter with soapy water. Another option is to warm the ends of the hoses in warm water;

- To facilitate installation, never use lubricants containing oils;

- Pull the ends of the hoses onto the fitting, check the correct installation and laying in the engine compartment;

- Now move the clamp to the required position and tighten, thereby ensuring a strong fastening of the new element of the cooling system;

- Follow the procedure to fill the system with coolant;

- Turn on the power unit and watch for signs of coolant leakage. It is quite possible that the clamp was not tensioned tightly enough, or there is a defect on the pipe itself. Although such things should be checked before purchasing.

Heater heat exchanger hoses

The other hoses in the VAZ 2110 cooling system are those connected to the heat exchanger of the heater.

, the O-rings must be replaced . Therefore, we advise you to purchase them in advance. The dismantling procedure itself is as follows.

- Two heater hoses are connected to the heat exchanger using a single connector. Some modifications of the VAZ 2110 may require dismantling the camshaft cover.

- Remove the metal clip that is located on top of the connector.

- Push the plastic tab towards the left side of the connector to release it.

- Remove the heat exchanger connector, remove the old O-rings. It is strongly not recommended to return the same ones to their place.

- An alternative to such connectors can be hoses with a spring clamp made of metal.

Now all that remains is to install a new set of pipes and complete the job. For this:

- Carry out installation by following the reverse sequence of disassembly and dismantling;

- Be sure to put new O-rings in place;

- Fill the cooling system with coolant;

- Start the engine and make sure there are no coolant leaks.

As you can see, replacing the cooling system pipes can easily be done with your own hands. This will require accuracy, consistency of your actions, as well as the use of new, high-quality parts to replace the old ones.

If you cannot or do not want to deal with such issues yourself, contact a good car service center, where they can quickly and efficiently bring your cooling system to normal condition.

Cooling system pipes for VAZ 2110, 2111, 2112 (video)

Cooling system hoses VAZ 2110, 2111, 2112…

Hello dear readers of the blog RtiIvaz.ru. Today I want to continue the conversation about the auto radiator pipes of the cooling system of the VAZ Lada 2110 “ten”, Lada 2111 “eleventh” and 2112 Lada “twelfth”.

In the previous auto article, we looked at the radiator hoses of the cooling system of the VAZ 2108, 2109, 21099, 2113, 2114, 2115. We looked at the video and photos and found out what the sets of pipes of the “eight”, “nine”, “ninety-nine”, “thirteenth” are , the “fourteenth” and “fifteenth” Lada models differ from each other.

We determined the “upper” supply and also found out which “lower” coolant outlet was a thick rubber hose. You have found out where which rubber tubes fit, today we will continue to look at the video of the Lada 2110, 2111, 2112 pipes.

The cooling system pipes are such a thing that they always seem to be in good condition, but they make themselves felt when you don’t expect them.

You've probably seen cars on the road more than once with their hoods open in a cloud of steam.

So the coolant floats, falling on the burning engine parts (exhaust manifold), escaping in a fountain through a burst rubber pipe.

Therefore, guys, be vigilant if you haven’t changed rubber hoses for a long time. Don’t tempt fate—guessing whether you’ll be lucky or not will be unlucky—but replace all the rubber hoses of your car in advance.

What kind of outlet and inlet rubber hoses of the VAZ 2110, 2111, 2112 radiator are they, look at the video and photo, friends...

Look at the photo on the left, numbered -1, the rubber tube supplying coolant is the “upper” one, and numbered -2, the rubber tube is taking out the “lower” coolant. Numbered -3; -4 “shorts”, one of which is a bypass from the block head to the water pump, and the other “short” is a connecting coupling.

The considered pipes on the left are suitable for VAZ cars of the “tenth” family with carburetor and injection engines.

- 2110-1303025 radiator supply hose, number -1 (see photo)

- 2110-1303010 radiator outlet hose, number -2 (see photo)

- 2108 -1303092Р coupling connecting the thermostat and water pump, as well as the bypass “short”, numbers -3; -4 (see photo)

Next, look at the photo on the right under number -5 for the coolant supply pipe on the “top”, and at number -6 for the outlet pipe. cool liquid "bottom". You see number -7, the so-called “long corner” bypass pipe. cool liquids.

These pipes on the right are for Lada VAZ-2111 and Lada VAZ-2112 cars with an injection engine. There are also the longest “upper inlet” and “lower outlet” pipes on the VAZ-2112 with a 16-valve engine.

- 2112-1303025 radiator supply hose, number -5 (see photo)

- 2112-1303010 radiator outlet hose, number -6 (see photo)

- 2108 -1303092Р coupling connecting thermostat and water pump “shorty”, number -8 (see photo)

- 2109-1303093-01 connecting hose for thermostat and water pump bypass “long angle”, number -7 (see photo)

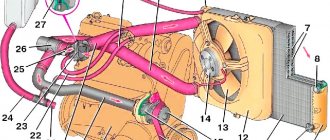

Cooling system for carburetor engines.

This cooling system consists of:

- Radiator for the stove.

- Heater radiator hose (steam removal)

- A pipe from the heater radiator to drain antifreeze.

- The pipe supplying antifreeze to the heater.

- Coolant temperature sensor (DTOZH)

- Pipe for supplying the pump pipe (water).

- Thermostat.

- Filling pipe

- Expansion barrel plugs

- A sensor indicating the coolant level.

- Expansion tank.

- Outlet hose.

- Exhaust manifold liquid heating chambers.

- Outlet pipe (from the radiator).

- Pipe for supplying fluid to the radiator.

- Steam exhaust pipe (from the radiator).

- Left radiator tank.

- Sensor for turning on the electric fan.

- Cooling fan drive electric motor.

- Fan impellers.

- Right radiator barrel.

- Radiator coolant drain plugs.

- Electric fan housings.

- Timing belt.

- Cooling pump impellers.

- Inlet pipe (to the water pump)

- Antifreeze supply hose to the liquid chamber of the carburetor starter.

- Outlet pipe.

Description of design

The cooling system is liquid, closed type, with forced circulation. The tightness of the system is ensured by the inlet and outlet valves in the expansion tank plug. The exhaust valve maintains pressure in the system when the engine is hot (due to this, the boiling point of the liquid increases and steam losses are reduced), it opens at a pressure of about 1.1 kgf/cm2. The intake valve opens when the pressure in the system decreases relative to atmospheric pressure by 0.03–0.13 kgf/cm2 (on a cooling engine). The thermal operating conditions of the engine are maintained by a thermostat and an electric radiator fan.

The coolant pump is a vane, centrifugal type, driven from the crankshaft pulley by a camshaft drive timing belt. The pump housing is aluminum. The roller rotates in a double-row bearing with a “lifetime” supply of lubricant. The outer ring of the bearing is locked with a screw. A toothed pulley is pressed onto the front end of the roller, and an impeller is pressed onto the rear end. The distance from the mating surface of the pump cover to the outer end of the pulley should be 52±0.5 mm, and to the outer (facing the block) end of the impeller - 39.8±0.1 mm. A thrust ring made of a graphite-containing composition is pressed to the opposite end of the impeller, under which there is an oil seal. If the pump fails, it is recommended to replace it as an assembly.

The redistribution of liquid flows is controlled by a thermostat with a solid heat-sensitive element. On a cold engine, the thermostat valve closes the pipe leading to the radiator, and the liquid circulates only in a small circle (through the thermostat bypass pipe), bypassing the radiator. On VAZ-2108, -21081, -21083 engines, the small circle includes the heater radiator, intake manifold, carburetor throttle assembly heating unit (on engines with semi-automatic starting - and the liquid chamber of the semi-automatic starting device). On the -2111 engine, fluid is supplied to the heater and the throttle assembly heating unit.

At a temperature of 87±2 °C, the thermostat valve begins to move, opening the main pipe, while part of the liquid circulates in a large circle through the radiator. At a temperature of about 102 ° C, the main valve opens completely, and the bypass valve closes, and all the liquid circulates through the engine radiator. The stroke of the main valve must be at least 8 mm.

The radiator consists of two vertical plastic tanks (the left one has a baffle) and two horizontal rows of round aluminum tubes with pressed-on cooling plates. To increase cooling efficiency, the plates are stamped with a notch. The tubes are connected to the tanks through a rubber gasket. The liquid is supplied through the upper pipe and discharged through the lower. Next to the inlet pipe there is a thin pipe for the steam pipe.

The electric radiator fan on VAZ-2108, -21081, -21083 engines is switched on by a sensor-switch screwed into the right radiator tank. Its contacts close at a temperature of 99±3 °C and open at 94±3 °C. On cars manufactured before 1998 (with an old fuse box), another sensor (TM-108) was installed that controls the fan motor through relay 113.3747 in the mounting block. On the -2111 engine, the fan is turned on by a signal from the electronic engine control unit (via a relay).

Cooling system for injection engines.

Points 1 to 26 are the same for the cooling system of carburetor engines.

Unlike the system described above, this system also consists of:

- The pipe supplying antifreeze to the throttle pipe.

- A pipe that drains fluid to the throttle pipe.

- DTOZH.

- Inside the radiator tube.

- Radiator cores.

What does damage cause?

The most common cause is engine overheating; failure will occur in a very short period of time. As a result of overheating, the cylinder block becomes deformed, cracks may appear and the piston may become deformed.

But it is much worse when the piston is completely deformed and makes a hole in the cylinder block. Such a breakdown usually leads to a complete replacement of the damaged engine with a new unit.