All about the VAZ 2114 fuel pump

The VAZ 2114 has an injection engine with a volume of 1.5 and 1.6 liters.

Such engines are equipped with a large number of sensors, as well as electronic fuel supply under pressure. Quite often it happens that a breakdown occurs in a car and fuel stops flowing to the engine, thereby preventing it from starting. It is quite difficult to find the cause of a fuel pump failure on your own, but after studying our article, you can easily determine the culprit of the breakdown and solve the problem as soon as possible. In this article we will talk about the breakdown of the fuel pump on a VAZ 2114, namely why this part stopped pumping fuel.

Models of fuel pumps for VAZ 2114/2115 cars

VAZ 2114/2115 cars are equipped with 1.5 cm 3 and 1.6 cm 3 gasoline engines with a distributed injection system. A submersible electric fuel pump is used to supply fuel. It is part of the fuel module installed at the top of the gas tank (under the rear seat). In addition to the pump, the module includes a fuel accumulator (cup), a coarse filter and a fuel level sensor with a float.

To supply fuel in VAZ 2114/2115 cars, a submersible electric fuel pump is used

The VAZ 2114/2115 fuel pump is a conventional DC electric motor in a sealed housing with a one-way valve at the outlet. An impeller of a special shape is located on the electric motor shaft. Its rotation ensures the fuel supply.

Design and principle of operation of the fuel pump

In order to find the cause of the breakdown, you must first know the design and operating principle of the fuel pump.

Design

The gasoline pump is made of many parts and resembles an electric DC motor. Its body is made of plastic and metal; inside the body there is a magnet and a rotor, on the shaft of which an impeller is mounted on one side, and a current collector on the other. The fuel pump itself is a brushed motor, which greatly reduces its reliability; many modern cars (foreign cars) have already switched to brushless electric pumps.

One of the important elements of the pump is the check valve, which maintains the built-up pressure in the system and does not allow it to flow back into the tank through the valve.

Principle of operation

When voltage appears on the fuel pump block, it begins to rotate, the impeller pumps fuel into the system, as soon as it reaches the required amount, the fuel pump valve closes, thereby closing the path to the outflow of fuel back into the tank. After which you can start the engine. You can clearly hear the operation of the fuel pump by turning on the ignition and listening to its operation. The fuel pump will make a characteristic squeak and stop after a few seconds - this will mean that the pressure has been pumped into the system.

Fuel pump system

The fuel pump itself does not work; it is part of a special station, the so-called “fuel pump cup”. This part is a bracket for mounting the fuel pump in the tank. Also, a special coarse fuel filter is put on the fuel pump, which allows you to keep the fuel pump from dirt getting into it. A fuel level sensor and a fuel pressure regulator are installed on the glass. Together, all these parts form the fuel pump station, or popularly the “glass”.

Symptoms of a problem

There are many signs of a fuel pump malfunction and they are all similar to each other, and they can also be confused with breakdowns in other elements of the fuel system, such as injectors, filters, RTDs, etc. Signs of malfunction in fuel system elements are always similar, but the fuel pump has its own factor that can clearly indicate its malfunction - the sound of its operation.

Any pump, even the highest quality and new, should make a sound when operating. If there is no sound, then something is definitely wrong with the pump.

Possible symptoms of failure:

All these problems can be caused by other fuel cells. For example, clogged injectors can also affect poor starting and loss of vehicle dynamics.

Checking the fuel pump

To check the fuel pump, you need to measure the fuel pressure in the fuel rail and check the pump itself for pressure “into the wall”.

To check the fuel pressure, you need a special device, a fuel pressure gauge; you can also use a regular pressure gauge with a hose, connecting it to the ramp through clamps.

Then the pressure of the fuel pump is checked, which it presses into the wall; for this it must be dismantled (on 1.5-liter engines you can simply clamp the return line). In this way, the power of the pump is checked when checking the pressure “into the wall”; a good pump presses pressure up to 8 bar.

OPERATING PRINCIPLE AND DESIGN FEATURES

The VAZ 2114 fuel pump is located inside the car’s gas tank, which is why access to it can be problematic if you don’t know which side to approach. To free up access to the fuel pump, you need to remove the rear seat from the fourteenth, under which you will find a rectangular hatch hiding access to the fuel module.

Just recline the back seat and see for yourself

In addition to the pump itself, the VAZ 2114 fuel module includes:

- A float sensor that monitors the fuel level in the gas tank;

- Chamber for fuel intake;

- Mesh filter for coarse cleaning.

The gasoline pump has a built-in electric motor, which pumps up the pressure of the pumped fuel. The motor itself is powered from the vehicle's on-board network. The VAZ 2114 gasoline pump is located so that even with a minimum level of fuel in the tank, it is constantly washed with gasoline, as this is necessary for normal cooling of the unit, which gets very hot during operation.

The main working element of a gasoline pump is a membrane, which during operation performs reciprocating movements. During normal operation, when the device is fully operational, the following pressure levels must be maintained in the fuel rail:

- For 1.5 l engine. – from 285 to 326 kPa;

- For 1.6 liter engine. – from 375 to 390 kPa.

As evidenced by reviews from owners of fourteenth VAZs, in practice BOSCH pumps have proven themselves to be the best.

Unlike domestically produced units, they cost almost 20-30% more, but at the same time they have an order of magnitude better build quality and reliability. The estimated cost of the fuel module for a 1.5 liter engine of the fourteenth is 2.5 thousand rubles, for 1.6 liters. – 2.6 thousand

However, rational savings are possible here - in most cases it makes sense to purchase a fuel pump separately, rather than the entire module, since, as a rule, the pump itself “dies”, and the remaining parts of the module remain in working order. Its cost, if taken separately, is 1-1.5 tr.

Why doesn't the fuel pump pump?

If the fuel pump has stopped pumping fuel pressure, then starting the car is out of the question.

Possible reasons:

These three reasons are the main reasons why the fuel pump on a VAZ 2114 stops pumping fuel.

Finding the reason

The first thing you need to do is make sure there is voltage at the fuel pump, and it can go out for several reasons: a blown fuse or relay, burnt-out wiring.

Inspect the fuel pump fuse for integrity. It is located under the center console at the feet of the front passenger. It is necessary to remove the decorative cover of the leg air duct; there you can find three fuses and three relays. All of them must be intact.

You can check the relay using a multimeter by setting the switch to continuity, connect the probes to the relay coil, it should show some resistance. If the multimeter shows an open circuit, then the relay is faulty and requires replacement.

CHANGING THE PETROL PUMP WITH YOUR OWN HANDS

If the fuel pump in the VAZ does not pump, and all of the above system components are normal, it is necessary to clean the filters, and, if necessary, completely replace the unit.

Before starting work, you must completely drain the fuel from the gas tank. To do everything with our own hands, we need a screwdriver and a set of keys. Replacing the VAZ 2114 fuel pump is carried out according to the following algorithm:

- We de-energize the car by removing the “-” terminal from the battery;

- We take out the rear row of passenger seats;

- Unscrew the plastic cap that covers the pump;

- Remove the power wires from the device and disconnect the fuel supply hoses;

- We dismantle the main fastenings of the fuel pump; for this we need the 7th key;

- Now you can remove the fuel pump on the VAZ 2114 and remove the device.

It must be removed carefully, since the float sensor for determining the fuel level is a very delicate structure that is easy to damage . Inspect the fuel pump - if necessary, clean or replace the strainer, however, it may be necessary to completely replace the unit.

VAZ 2114 fuel pump does not turn off

There is a problem, I don’t understand what’s wrong! The engine starts and runs normally, without any complaints. When the engine warms up, after a while the fuel pump turns off and does not respond to the ignition. It sits for 15-20 minutes and starts working again. What is the problem?

It is impossible to say exactly what the problem is that the fuel pump on the VAZ 2114 turns off after the engine warms up due to insufficient description, and yet we will consider options for what could cause this to happen.

The reasons for this can be divided into two parts - mechanical and electrical. Moreover, often one part can become a consequence of the second.

One of the simplest malfunctions that can give this result is a clogged fuel tank ventilation system. The tank lid is not airtight; it has drainage holes through which air passes. Everything is very simple here - air is needed so that a vacuum is not created in the tank as fuel is consumed. If the drainage holes are clogged, as the vacuum in the tank increases due to insufficient air supply, it will be more difficult for the pump to pump fuel into the system. This leads to an increase in the load on it and on the relay for its activation. When the critical load is reached, the relay simply turns off the pump.

And now how everything happens on a car: while the car is standing, air still penetrates the tank and the pressure in it equalizes. After starting the engine, the fuel pump actively pumps fuel, and since air does not flow in the required quantity, a vacuum appears. As the engine warms up, the vacuum increases and the load on the fuel pump and relay increases. To prevent the pump from failing at “one fine moment,” the relay turns off the power to the circuit.

Once you stand for 15-20 minutes, air enters the tank again, equalizing the pressure, and the whole cycle begins again.

A clogged fuel inlet grid of the fuel pump can give approximately the same result. But here everything happens not because of a lack of air, but because the pump needs to supply a certain amount of fuel, and it is very difficult to do this through a clogged mesh. It starts to work under load and the relay turns off the power after a while. This can also happen due to a clogged fuel filter.

There may also be problems with the fuel pump itself. Burnt wires connecting to it, insufficient weight, wear or damage to the electric motor creates an increased load on the fuel pump relay, which causes it to operate after a certain time.

Before you start searching for the cause of this malfunction, you must first check the power supply circuit of the fuel pump.

After the engine stalls, you must immediately find its relay and check its temperature with your hand. If the element is very hot, then this is a signal that the entire circuit is working under heavy load. But what causes the heating still needs to be determined.

It is located on the VAZ 2114 on the passenger side, under the side decorative panel of the center console. There are three relays and fuses for them. The fuel pump relay is installed in the middle.

When checking the temperature, you should immediately evaluate the condition of the fuse, as well as the contact of the relay itself in the seat. By the way, this element can also fail, causing its operation to be incorrect. It’s easy to check its functionality; just close its contacts immediately after the engine stops. If the fuel pump starts to work, the relay must be replaced.

If everything is in order with this element, and a malfunction appears, then the cause should be sought in the components of the fuel system. The pump performance and filter throughput are checked. Indeed, due to excessive load on the pump due to a malfunction, clogged filter, fuel inlet mesh or tank ventilation system, the relay will turn off the pump after a certain time to prevent burnout.

Another item to check is the crankshaft position sensor. Initially, it may seem that the DPKV has nothing to do with the fuel supply system, but this is not so. Indeed, based on the readings of this element, the electronic unit controls the power system and the fuel supply circuit too. If the wiring to the sensor is not operating correctly or is damaged, the unit may turn off the power to the pump at certain moments.

In general, when searching for the cause, you should start from the relay and fuse, and then check both the mechanical and electrical components of the circuit of the fuel supply elements.

Fuel pump malfunction in VAZ 2114 and VAZ 2115 cars is a fairly common phenomenon. You can solve this problem yourself, without resorting to the services of a car service. The pump replacement procedure is quite simple. It will require only a few hours of free time and a standard set of tools.

PRESSURE LEVEL

In order to get most of the picture of what is happening, it is enough to measure the pressure in the fuel rail. For this, it is necessary to use a pressure gauge that has a small measurement range (preferably up to 7 atmospheres), since devices with a large range can produce significant inaccuracies.

Rail pressure measurement

Under the hood of the fourteenth there is a pressure fitting; unscrew its cap and connect the pressure gauge to it. Normal indicators should be as follows:

- When the engine is idling – 2.5 kPa;

- At the moment of ignition - 3 kPa;

- With a pinched drain hose – 7 kPa;

- When gaining speed - 2.5-3 kPa.

If the pressure gauge needle does not move when the ignition is turned on, then the gasoline pressure regulator is most likely broken. When there is no change as the speed increases, the fuel pump itself has failed, but if the needle moves very slowly, which indicates that the pump is pumping, but poorly, the fuel pump screen is clogged.

Diagnostics

A malfunction of the VAZ 2114/2115 fuel pump can be caused by:

Checking the electrical circuit

At the beginning of the diagnosis, you should check the electrical circuit of the fuel pump. To do this you will need:

Checking the electrical circuit is carried out in the following order:

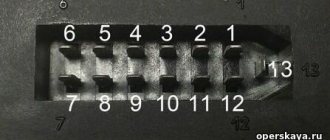

The relay and fuse for the fuel pump on the VAZ 2114/2115 are located in the mounting block under the glove compartment.

Set your multimeter to voltmeter mode. Connect one probe of the device to the relay terminal to which the pink wire fits, and the second to the car body. Turn on the ignition. The device should show the on-board network voltage in the range of 11.7–12.4 V. If there is no voltage, the problem may be a broken wiring or a malfunction of the ignition contact group. In this case, it is better to contact an auto electrician. If power is supplied, check that the relay is working. With the ignition on, use a screwdriver or a piece of wire to close the contacts to which the pink and gray wires go. This closes the circuit bypassing the relay. If the fuel pump works, replace the relay.

The ground wires of the fuel pump are attached to the body with a self-tapping screw

Pressure check

If the pump is working properly, but the engine begins to operate intermittently, you should check the fuel pressure in the system. For this you will need:

In addition, the presence of an assistant is desirable.

The verification procedure is as follows:

Find the pressure fitting and remove the cap from it

When unscrewing the spool valve, fuel may spray out of the fitting.

Connect the pressure gauge to the fitting using a hose and clamps

GROUND AND FUEL PUMP RELAY

In the fourteenth, the mass of the fuel pump is fixed under the dashboard, next to the handbrake lever, during use of which the mass can be touched and shifted from its normal position. To fix this, remove the plastic around the handbrake, clean the ground contacts and reattach it.

Next to the ground there is a VAZ 2114 fuel pump relay. The relay is necessary so that during ignition the required pressure level is immediately created in the system.

A few words about where the fuel pump relay is located: after removing the plastic around the handbrake, you will immediately find 3 different relays - one of them is from the fuel pump.

It is better to immediately replace a broken relay with a new one; it is not expensive.

The fuel pump whistles and hums

Let's start with the fact that the proper operation of the fuel pump involves a certain noise or soft humming sound after turning the ignition key. In other words, the fuel pump hums while it creates operating pressure in the line. This process lasts 2-3 seconds, after which the driver can hear a slight click. This click is produced by the fuel pump relay.

Note that many drivers of cars with mileage of 100 thousand km or more. and more note a slightly increased noise level from the fuel pump. The fuel pump may hum or whistle louder when you turn the ignition key. At the same time, there are no problems with engine starting, fuel consumption and smooth reactions to pressing the gas pedal while driving. The car practically does not lose any dynamics, allowing you to drive with a humming gas pump for tens of thousands of kilometers.

The fuel pump is very noisy: troubleshooting

In most cases, an increase in noise level occurs due to an increasing load on the gas pump, which becomes more difficult to pump the required amount of fuel. Overheating or failure of the pump itself is less common.

At the initial stage, it should be understood that if the gas pump makes a sound (albeit different from normal), then power is supplied to the device and the pump itself reacts to the supply of electricity. Based on this, the problem can be localized faster. Before diagnostics, it is recommended to replace the fuel filter to eliminate the possibility of a decrease in throughput in this area.

There is also a simple solution that allows you to quickly check the status of your device. The method involves removing the return hose and inserting it into a separate container suitable for pouring gasoline. Next, you need to measure how much fuel is drained back into the tank. The norm for many gas pumps is a minimum value of 1.5 liters per minute or more. The disadvantage of such measurements can be considered very approximate readings, which do not allow obtaining accurate data.

If the check shows that the pump does not produce the required pressure or constantly works to maintain it, then you need to change or clean the fuel pump strainer. To do this, you will need to remove the fuel pump, which is usually located in the rear of the car under the seat. Please note that on cars that have been in use for a long time, in parallel with replacing the mesh, it is necessary to wash the gas tank itself. The fact is that dirt and deposits will quickly damage the new filter.

After replacing or cleaning the pump filter, you should also check the pressure regulator in the fuel rail and clean the injection nozzles. In most cases, these procedures can reduce the noise level or almost completely eliminate the whistling and hum of the fuel pump. If the pump continues to make noise, then there is a high probability that the pump motor needs to be replaced.

Independent troubleshooting of alarm systems

- It is often possible to fix the malfunction and remove the engine lock yourself if you can detect blown fuses. This problem often leads to malfunctions of the alarm system. The fuses must be checked; if a problematic element is detected, the blown fuse must be replaced with a known good one.

- Malfunctions in the operation of the alarm can also be associated with insufficient battery charge or loose terminals on the battery contacts. In this case, the battery is still able to sluggishly crank the starter, but the engine blocking may already work and further prevent the engine from starting.

Another step is to check the limit switches (limit switches), which are located under the hood and trunk lid. Moisture ingress or oxidation of the limit switch often causes an incorrect signal to the alarm control unit, which leads to engine blocking

Please note that unprofessional installation of alarms and limit switches, as well as improper engine washing can lead to malfunctions of electrical equipment

Replacing the fuel pump motor

The reason for replacing the fuel pump module motor is low gasoline pressure or sudden changes in pressure, which is recorded by a pressure gauge during the diagnostic process. Also, the imminent failure of the motor is indicated by the fact that the fuel pump is humming or whistling.

In this case, it is often possible not to change the pump assembly, which will save money. The device must be removed (similar to the situation with cleaning or replacing the mesh filter), after which it is disassembled. The motor itself is replaced and can be purchased separately. The housing and fuel level sensor can be left from the old fuel pump. At the same time, it is recommended to replace the gas pump gasket and other rubber seals, which are not designed for re-installation after removal, that is, they are disposable.