VESKO-TRANS.RU

How to turn your car on its side for repairs |

Enable JavaScript to improve site performance

How to turn a car

For repairs

sometimes you need to put the car on its side. To ensure that this operation does not cause harm to the body, it should be carried out using special tools and in compliance with all safety rules.

- - tilt device

- - spare wheel

- - several assistants

Before tilting the car, consider whether such an operation is necessary. It may be enough to jack up the sides of the car one at a time and hang it on supports, use a repair hole or a span. Do not forget that any careless action when turning the car can cause serious damage to the body.

If you decide to somersault

Car, you will need a special tip suitable for your car. Because this device requires money, but is self-organizing. Not an easy task, rent it for a few days. Use the factory device. The only reliable and safe way to tilt your car.

There is a simple version of an inverted car, which is usually used for a “classic” VAZ. Suitable for other vehicles of similar design. Please note that you will need the help of several people. Don't lean against the machine

You risk injury or injury.

Lower the front side window, insert it vertically into the window opening, closer to the door pillar. After this, assistants should carefully tilt the machine to the side, maintaining a margin. Touching the ground, the wheel reliably holds the car in an inverted position. When turning the machine, make sure the wheel is in a vertical position.

You can make a dump truck using diagrams online. Do not use wood or other unstable materials when using the device. When working with a homemade device, think about breaking it, so always have some form of fall insurance on your car.

Video can be closed in 20 seconds

How to turn a car

Didn't get an answer to your question? to our specialist:

All experts in this field

published December 25, 2012

Want to know how to push it back down with just a few hands?

to art

New tips for living

Expert advice: how to prepare your car for sale

Almost all car companies and dealers only sell new cars, which is sometimes expensive. So.

With this article it also looks

How to save money

The only way to save on auto body work is to do it yourself. You cannot skimp on either anti-corrosion treatment material or metal. If you are not an experienced welder and doubt the quality of the repair, it will be cheaper to invite a specialist than to redo broken seams a year later.

The cost of underbody repair in a specialized car service starts from 22-25,000 rubles. And this price is justified. Included in the price:

- interior dismantling;

- full body diagnostics;

- use of spot and electric welding;

- bottom treatment with anticorrosive agent;

- interior installation, electrical equipment connection.

Drivers prefer to do their own repairs because the stereotype is that service stations increase prices and invent defects that do not exist. To avoid deception, it is recommended to tap the bottom of the car yourself on an overpass; if there is minor damage that does not require complete overcooking of the bottom, then opt for independent repairs.

Is it possible to manually move a car without its owner?

Given: Ford Focus is standing half a meter from the curb, parallel to it. The wheels are flat. The owner cannot be found.

Is it really possible to move it by hand close to the curb? How many people will be needed? Maybe there are some subtleties of the rearrangement technique?

I see two options: - Just “bad force”: gather men (how many?) and jerkily lift and rearrange his backside, and then his front. — “Resonance”: one (two? three?) people swing the rear of the car in a vertical plane so that the resonance increases the vibrations to such an extent that the adhesion of the wheels to the asphalt decreases to such an extent that another (two? three?) person, pressing on the car horizontally, towards the curb, would gradually move it. Then they do the same with the face of the car.

A Lada can easily hold 5-6 people behind the wheel arches. Because they moved it at one time.. it was necessary..

And now cars are made of foil, why bother...

There are 14 messages in this topic

Zver 78

- Evil philologist

- Site administrator

- 78

- 2,587 messages

- City:South-West

- I drive a

VAZ-21013, 1986.

Sam 2

- A right-hander to the core

- Club member

- 2

- 2,465 messages

- City: Ave. Testers

- I drive a

VAZ-21011

Zver 78

- Evil philologist

- Site administrator

- 78

- 2,587 messages

- City:South-West

- I drive a

VAZ-21013, 1986.

metrolog 1 094

- SparcoRacer-VoronGlass

- Moderator

- 1 094

- 6,758 messages

- City:North of the city

- I drive a

VAZ 2102, ShNG

Zver 78

- Evil philologist

- Site administrator

- 78

- 2,587 messages

- City:South-West

- I drive a

VAZ-21013, 1986.

Sam 2

- A right-hander to the core

- Club member

- 2

- 2,465 messages

- City: Ave. Testers

- I drive a

VAZ-21011

metrolog 1 094

- SparcoRacer-VoronGlass

- Moderator

- 1 094

- 6,758 messages

- City:North of the city

- I drive a

VAZ 2102, ShNG

Pavlik 647

- no status

- Moderator

- 647

- 4,398 messages

- City: Kupchino, Sofiyskaya street...

- I drive

21011 1980, 2123 2005...

Zver 78

- Evil philologist

- Site administrator

- 78

- 2,587 messages

- City:South-West

- I drive a

VAZ-21013, 1986.

Sam 2

- A right-hander to the core

- Club member

- 2

- 2,465 messages

- City: Ave. Testers

- I drive a

VAZ-21011

metrolog 1 094

- SparcoRacer-VoronGlass

- Moderator

- 1 094

- 6,758 messages

- City:North of the city

- I drive a

VAZ 2102, ShNG

Pavlik 647

- no status

- Moderator

- 647

- 4,398 messages

- City: Kupchino, Sofiyskaya street...

- I drive

21011 1980, 2123 2005...

Zver 78

- Evil philologist

- Site administrator

- 78

- 2,587 messages

- City:South-West

- I drive a

VAZ-21013, 1986.

pavlo 0

- Master

- Club member

- 0

- 260 messages

- City: Vaska…..

- I drive a

VW Golf III

Communities › GAZ Volga › Blog › Question for those who tipped the car on its side to treat the bottom

If you tip the Volga on its side, right on its wheels (not on tippers), then how long can it stand like that without much harm to the suspension and steering components? if for a month for example

Comments 30

I had it for about 2 weeks, and everything was fine, only a little oil fell out of the bridge.

the axle seal may leak

At least a year. Just remove the battery and drain all the fluids - oil, gasoline... washer fluid... And keep an eye on the pressure in the tires.

...once my Jetta (Volkswagen) sat on its side for two weeks. Well, I stood there and stood there. Two weeks have passed, the planned work has been completed, it’s time to finish it. Dropped it. Let's start it up. But it won't start. So that even the starter does not turn over. At first we thought the battery was dead. They put another one. Same song. The starter does not pull. Is it really covered? Somehow unexpectedly... Okay, let's pull it in tow and start it. They pulled. We put it in gear to start the engine... and the front wheels, the ones that are driven, “become a stake” in gear, well, they simply refuse to rotate, as if they were tightly stopped with a handbrake. What nonsense? The car drove to the garage under its own power two weeks ago, everything was fine, no problems, not even hints... and here it is! They pulled several times - all to no avail. We were exhausted from bewilderment :)) We left the car alone for a while. Then they tried again, what should we do?! Eventually it started. True, it smoked blue smoke mercilessly for some time :)) It turned out that after two weeks of sitting on its side, oil from the crankcase slowly flowed through the rings into the cylinders... When they tried to start it, the pistons couldn’t squeeze it out :)) and The starter was locked and the wheels were being towed... When it had sat on the wheels for several hours, almost all of the oil flowed back into the crankcase, and then it started up. Well, of course, while the remaining oil in the cylinders was burning out, it smoked terribly... such an experience :)) please take it into account.

Holy shit) I've already drained the oil) I hope the cylinders with the elbow don't rust inside)

:)) if for a month, for example, ? should not ?

...once my Jetta (Volkswagen) sat on its side for two weeks. Well, I stood there and stood there. Two weeks have passed, the planned work has been completed, it’s time to finish it. Dropped it. Let's start it up. But it won't start. So that even the starter does not turn over. At first we thought the battery was dead. They put another one. Same song. The starter does not pull. Is it really covered? Somehow unexpectedly... Okay, let's pull it in tow and start it. They pulled. We put it in gear to start the engine... and the front wheels, the ones that are driven, “become a stake” in gear, well, they simply refuse to rotate, as if they were tightly stopped with a handbrake. What nonsense? The car drove to the garage under its own power two weeks ago, everything was fine, no problems, not even hints... and here it is! They pulled several times - all to no avail. We were exhausted from bewilderment :)) We left the car alone for a while. Then they tried again, what should we do?! Eventually it started. True, it smoked blue smoke mercilessly for some time :)) It turned out that after two weeks of sitting on its side, oil from the crankcase slowly flowed through the rings into the cylinders... When they tried to start it, the pistons couldn’t squeeze it out :)) and The starter was locked and the wheels were being towed... When it had sat on the wheels for several hours, almost all of the oil flowed back into the crankcase, and then it started up. Well, of course, while the remaining oil in the cylinders was burning out, it smoked terribly... such an experience :)) please take it into account.

In such cases, it is better to unscrew the spark plugs and drive them away... Water hammer could easily occur.

“in hindsight” :)) we also realized this... but it turned out okay

But how to put a barge on its side - it’s heavy. How many people need to be attracted to help tip it over?

A couple of jacks or a hi-jack with an extended arm.

But how to put a barge on its side - it’s heavy. How many people need to be attracted to help tip it over?

My 5 people lifted and the same 5 people lowered (it turned out quite brilliantly), I’ll throw the recording in the on-board vehicle later

was the car without an engine?

IMHO, just don’t overcook the spars in this position!

Find a hole and do everything on the hole or overpass. This is not the first car I have treated measles this way.

www.drive2.ru/b/2553884/ Look at me! On one side until it stops, the wheel is under the roof. I survived for a week, but I could have done more. The bodybuilder checked it later, nothing happened.

It is still advisable to support the rear axle, otherwise if the springs are old, it may be damaged

Yeah, that’s exactly what the guys wrote, I didn’t quite put mine on its side, I lifted one side half a meter to unscrew the pulley from the box. I don’t think anything can be damaged in a static position on the side.

tip it over on the left side so the gasoline and oil won’t be stolen;) and without them, your car is useless to anyone and it won’t make any noise.

Yes, I’ll be tumbling in the garage anyway, so it’s not a problem)

I overturned the 2106, it was definitely standing for a couple of months (I changed the box and treated the bottom), but I didn’t rest it with the tires, but rested it on the B-pillar under the roof (through a soft pad)

Source

So, how should you preserve your outboard motor?

All the steps below are the same for both types of engines (2 and 4 stroke)!

1. It is necessary to drain the transmission oil from the gearbox and replace it with new one.

We do this in order to eliminate the presence of water in the gearbox. Otherwise, in winter, water will freeze in the gearbox and tear its walls.

If water is found in the gearbox, it is necessary to determine the cause of its appearance and eliminate it. The most common cause is leaky seals.

2. Check the presence of lubricant on the splines where the propeller fits onto the shaft. If necessary, apply a special waterproof lubricant.

This way we will protect the steel shaft from corrosion during downtime.

3. We check the lubrication in all moving, rubbing elements of the engine (gear shift drive cams, accelerator handle drives, etc.). If necessary, remove the old grease and lubricate with a small amount of new waterproof grease.

This will protect metal elements from corrosion, and also eliminate the presence of dirt in the rubbing mechanisms that has adhered to the old lubricant.

4. The next important step will be to inject all engine grease fittings.

This procedure must be carried out for several reasons. Firstly, moisture can also accumulate in the mechanisms to be extruded, which will freeze in winter with all the ensuing consequences. Secondly, dust and dirt accumulate in these places, which sticks to the lubricant, then this dirty, greasy mixture turns sour and leads to poor operation of the mechanism.

You need to syringe the mechanism until clean lubricant comes out of the cracks. All excess grease and dirt must be thoroughly wiped off.

5. We check the fuel system, removing all remaining fuel from it. Drain the fuel from the filter, hoses and carburetor float chamber.

This is necessary because the fuel may often contain excess impurities, as well as water from condensation in the fuel tank. In addition, for a two-stroke fuel mixture, oil may precipitate and be deposited on the walls of the fuel system. These impurities can cause the carburetor needle to stick or become clogged. Accordingly, in the spring, fuel will not flow correctly into the combustion chamber and the engine will not start or will not work correctly.

6. Lubricate all rubber and PVC elements with silicone grease (hoses, high-voltage wires of the ignition coil, etc.).

This procedure will protect these elements from drying out and cracking.

7. We treat electrical terminals with special terminal sprays.

This procedure will protect the terminals from souring and corrosion.

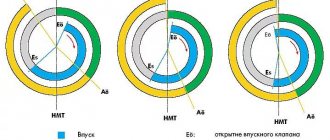

8. After the above procedures, we move on to the most important thing - preservation of the cylinder block.

For this purpose, there are various aerosol mixtures for preservation.

There is no need to pour engine oil and oil-fuel mixture into the cylinder block, this will only make the engine worse and you will have difficulty starting it in the spring.

It is necessary to spray the aerosol mixture through the air intake hole of the carburetor and at the same time crank the engine starter with the ignition off. Thus, the additives included in the mixture form a protective film in the intake channels, and in the cylinder block, and on the valves, as well as in the exhaust channels

It is important, after this procedure, not to turn the starter again until spring, otherwise the protective film formed in the cylinder block will be broken

This procedure is necessary to protect the internal parts of the engine from moisture and protect them from corrosion.

It is important to spray the aerosol directly through the carburetor into the air inlet. Thus, the preservative gets onto all internal components of the engine, and not just into the combustion chamber, when adding the preservative through the spark plug wells! This procedure applies to both types of engines

This procedure applies to both types of engines.

Additionally, for a 4-stroke engine, before performing the above procedure with an aerosol, you need to change the engine oil in the crankcase.

This is done because the oil used during the season contains various impurities from products of combustion and oil breakdown, fuel additives, etc.

All this precipitates and settles on the walls of the crankcase, which is not very good for the engine. Therefore, it is better to change engine oil at the end of the season, and not in the spring!

How to make a car tipper with your own hands?

The safest and most correct way is to tip the car on its side using a special device that you can build with your own hands. A tipper is a very expensive purchase, so if you need it once or twice, it would be most rational to simply rent it.

Well, now I will offer you a plan on how to build a homemade tipper for a car.

Homemade car tipper - drawings to help

I will provide the drawings themselves at the end of this section, and we will start with a list of the necessary materials for assembling a tipper jack with your own hands.

1. A rectangular pipe with parameters 40×80×3 mm will be needed by a craftsman to make a beam located horizontally and a vertical post.

2. Cross beam: pipe 40×20×2 mm.

3. Supports: a regular pipe with a diameter of five centimeters.

4. Pipe to which the wheels of the car are connected: approximate diameter - five centimeters, length - three meters. It should fit easily into the supporting elements.

5. The length of the lever was chosen to be one meter.

How does the device work?

Holes are drilled in the vertical stand into which a pair of bolts are inserted. The first bolt is located under the crossbar on which the car rests, and the second is responsible for fixing the lever. There is no need to secure them with nuts!

To jack up the car ten centimeters, which is the gap between the holes in the vertical pillar, you need to remove the locking lever bolt, move the latter to the next position and lock the handle by inserting the bolt into a new hole located above the previous one.

Now we begin manipulating the lever: lifting it, the beam with the machine will also stretch, and when it is above the next hole, without letting go of the shoulder, insert a bolt there. With these simple manipulations, we will gradually raise one side of the car to the desired height. This process will take you just a few minutes.

Here are some simple drawings of a passenger car tipper, which you can easily make with your own hands:

Higher, and higher, and higher: how and why to raise the car body with spacers

What is clearance?

If you think that the ground clearance of a car, also known as ground clearance, is the distance from the lowest point on the bottom of the car to the supporting surface (road surface), then you are mistaken... This lowest point is sought for measurement not over the entire area of the bottom of the car, but only on its so-called “central part”. The concept seems vague, but there are simple formulas for calculating it. There is no point in delving into them. For ease of understanding, the “central part” of the average sedan, used to determine ground clearance, looks something like this (marked in red):

Articles / Popular questions What is the geometric cross-country ability of a car? Owners of serious SUVs criticize modern crossovers for their low cross-country ability - including geometric cross-country ability. And often, I must say, quite deservedly. What is geometric... 8926 0 0 10/09/2017

As we can see, many points of the lower part of the body (suspension elements in the wheel area, marked with arrows, mudguards, sill plates, muffler tips and some others) are not taken into account when determining ground clearance and can (and do turn out to be!) noticeably closer to the asphalt than that point , which is taken as a reference when determining the official value of ground clearance. And if you consider that the factory clearance figures for foreign cars are most often valid only for an empty car, without cargo or passengers, then you shouldn’t be surprised when a city car scrapes its bottom on a completely harmless dirt road on the way to the country.

As a result, many car owners, who are not ready to buy an SUV or at least a crossover, seek to “raise” their sedan in order to make it more versatile. By installing tires with a larger diameter from the list of sizes allowed by the manufacturer, an honest centimeter and a half height is gained, however, purchasing new wheels is expensive, and some sizes are even rare. Therefore, the method of raising the body with spacers has gained significant popularity. Let's look at its features, pros and cons.

Spacer design

Spacers are divided into front and rear, differing in design. For a full “lift”, necessary to increase the vehicle’s cross-country ability off asphalt, all four are installed. But sometimes they make do with a pair of rear ones for partial lifting, which is usually required when there are frequent suspension breakdowns and the bottom touches uneven roads from carrying heavy loads in the trunk or three passengers on the back seat.

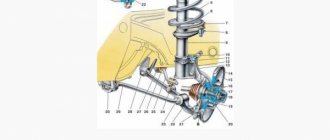

Front spacers (we are talking about MacPherson suspension) are installed between the shock absorber strut support and the body. They are rings made of hard plastic or aluminum. Rear spacers are installed between the body and the spring of the rear axle or beam. They look like “steering wheels” made of dense rubber or polyurethane with a diameter corresponding to the diameter of the spring.

What does a spacer change?

A spacer mounted above the A-pillar mount raises the body above the A-pillar, thereby increasing the angle of the lower A-arm. As a result, the body and those “clinging” parts that were actually lower than the official ground clearance figures (sills, bumper edges, mudguards, etc.) “rise” above the road by the size of the spacer (value “B” in the picture). It is important to note that the position of point “A”, located on the lever in the area of the ball joint, does not change. Where you would have caught a stump or cobblestone under the lever on a non-lifted car, you will catch it on a lifted one. The lift of point “A” can only be increased by installing wheels of larger diameter.

The picture above is of the front axle of the car. In the case of the rear axle, everything is not so clear. No, if the rear axle also has an independent suspension - the same MacPherson strut or multi-link - then the effect of increasing the ground clearance will be exactly the same as in the first case. However, if the rear of the car has a “cart design” (a U-shaped torsion beam or a continuous drive axle), then the effect of increasing ground clearance does not occur even in the central part. The body is raised above the bridge, and the gap between the bridge and the road remains unchanged.

Car body? Of course it is important!

As long as the car lasts, accidents will continue to happen. And in all this flow of cars and their transfer from one owner to another, the issue of the condition of the purchased car will always be relevant. Most cars that have been in minor accidents do not particularly bother their owners with their old flaws. But the damage that the car received as a result of a rollover can affect not only the quality of driving the car, but also the safety of the driver and his passengers.

In essence, the car body is considered a rigid supporting structure. It is capable of carrying not only the loads of transported luggage, but also withstanding all kinds of loads that arise while driving on uneven roads. In particular, for twisting. Similar loads arise when driving on country roads with large differences between axles.

Who is right in the dispute - the dealer or the owner?

Regarding dents and scratches, you can get the following answer from the dealer: “They were on the car before it came to us.” Regarding the dirty interior that requires dry cleaning: “You brought the dirt there yourself.” Regarding the car rolling spontaneously: “This happened due to a malfunction, the presence of which the master was not informed.”

At the same time, the owner of the car is sure: the dents, scratches and dirt are “new”, and the accident occurred due to the fault of the receptionist, who was not convinced that he parked the car safely! By the way, in the latter case, you should remember about the law “On the Protection of Consumer Rights”. It states that the owner is completely under no obligation to know about hidden defects in his car, and therefore cannot warn the dealer about something he himself does not know.

How to prepare a washing machine?

Before transportation, it would be correct to place the washing machine in the original packaging, and put polystyrene or foam rubber in the wall, but this is the ideal option. Most often, a washing machine that has worked for more than a year does not have any intact packaging, but also no components or fasteners at all. Therefore, during transportation you will have to improvise. In the process of preparing the washing machine for transportation, first of all, you need to do the following.

- Disconnect the washing machine from electrical and water supplies. At first glance, this seems funny, but there are a huge number of cases when the machine begins to be moved without disconnecting the hoses or one of the hoses. And often simply by not disconnecting the power cord. What happens after this can be easily guessed.

- Remove any remaining water from the machine. Water stagnates in hoses, pipes, and drain pump and can cause trouble when transporting a household appliance.

- Secure the hoses, wires, hatch, so that all this does not dangle and does not interfere with moving the washing machine.

- Cover all sharp corners and protruding sharp parts of the washing machine with tape to avoid injury when carrying the machine.

After this, you need to take measures to fix the washing machine tank. The best fixation option is transportation bolts, which are screwed through holes in the back wall of the washing machine. Read more about installing and removing shipping bolts in this article.

If the transport bolts have not been preserved, then you need to open the upper wall of the washing machine by unscrewing several bolts, and then put foam rubber, polystyrene foam, clean rags, etc. in the space between the tank and the walls. Then you need to return the upper wall back along with the fasteners.

After you have secured the tank, wrap the body of the washing machine in fabric and tie it with twine. If you carry out all the above steps, you can successfully transport the machine without the original packaging, you just need to be careful.

How to park with your back to the curb.

Reverse, unlike forward, is unpleasant because you can only control the movement using the mirrors. Reverse parking takes practice and experience. But, if you know some subtleties, you can quickly learn how to park in reverse without special assistants.

To perform the maneuver perfectly, use the left mirror again to orient yourself.

How to tip a car on its side to repair the underbody without special tools?

And this variation is for those who are used to doing everything with their bare hands. This mainly concerns VAZ classics. It’s dangerous, of course, but I’ll briefly state the point. We immediately gather either a crowd of friends or people ready to help you, for example, for a symbolic monetary reward. Then we do the following: we lower the window on the front door on the side on which we will tip the car and insert the wheel into the open opening! The spare wheel should be installed in a vertical position and located closer to the door pillar.

Further, the action develops according to the following rule: several people, on the one hand, will lift the car, keeping it from turning over sharply, in parallel, on the other hand, someone must hold the spare wheel until it touches the ground and the car is in a stable vertical position . The spare tire should also be kept in a strictly vertical position at all times.

For those who do not understand how this event is carried out correctly, I suggest watching the video material, which should clarify the situation for many:

In custody

There are a great many designs of self-made tippers posted on the Internet. However, you must remember that all the parts from which the device will be assembled must be of the highest quality; no wooden or plastic inclusions are allowed, only metal! The homemade product can fail at any time, damaging both the car itself and the technician who lifts it. So, we protect ourselves, and also protect our car from falling by building special mechanisms for this, which will have a different design in each individual case.

And yet, before putting the car in an “interesting position” for repair, it’s worth thinking several times, maybe safer and more simple ones will do - a traditional pit, an overpass, a lift, or the same ubiquitous jack?

Last edited: Aug 20, 2018

Maria Famous

Messages: 8,351 Likes: 615 Gender: Female

“Real boys” overturn cars on stumps and prop them up with crowbars.

These garage “masters” are damned. Don’t be afraid to boil tanks without draining the gasoline or disconnecting the battery. Before such work, it is advisable to drain all fluids from the car, from washer fluid to gasoline. If you don’t turn it over for a long time, then you don’t have to drain the oil, but then you can’t drive right away, and you have to let the car sit for at least an hour so that everything “settles down.”What am I getting at, all these tippers and gangways like those in the video are intended exclusively for rubbish that you wouldn’t mind smashing with a sledgehammer, let alone carelessly repairing.

These are usually VAZs, Muscovites and others like them. It’s a pity to even spend time on building special devices for such carts, which is why they are thrown so unceremoniously! To lift an expensive foreign car, you don’t even need such dashing guys, everything is tied to normal, expensive equipment! Imagine that they will throw Lexus like that!Maria and Andrew like this.

Maria Famous

Messages: 8,351 Likes: 615 Gender: Female

Imagine that they will throw Lexus like that!

Click to expand...And I would like to see this. Especially if Lexus crushed this chair into dust and completely collapsed on its side. This is a dangerous undertaking, and I am terribly afraid of these rollovers. Dad has a chief engineer at work, so his head is twisted to the side. The car fell off the jack, and he lay under it for several hours. They barely saved him, but they never fixed his neck, and he still walks with his head on his side.

And I thought, in the picture they knocked over the Niva and decided to cook it. But the car is not designed to lie on its side like that. Therefore, my question is, how will such a rollover affect the geometry of the body? They cooked it, and then the body turned sideways.

Maria Famous

Messages: 8,351 Likes: 615 Gender: Female

Sergey Vasilievich

, I thought about this too. The body can easily move, and it is advisable to lighten it as much as possible before cooking. Ideally, it’s better to just have a lift, or a pit/overpass, but what about turning over? It's too dangerous, hard, and it seems to me that it's more of a show-off. Even take the video that I posted. Couldn't these places be cooked on the overpass? There is such a place that it is quite possible to crawl up, and there was no need to turn anything over.Mariya

, and yet for some reason many welders repair a car in exactly this position. They cooked a nine for me, and they turned it over too. It was then that I became acquainted with this procedure for the first time. Honestly, I was a little shocked. By the way, my car was cooked badly.Andrew Moderator Forum Team

Messages: 3,559 Likes: 478 Gender: Male

It seems to me that those who repair scrap metal that has already rotted and rolled away are thinking about the question of how to tip a car on its side. They won’t mock a fresh car like that.

Andrew

, that’s right, only for scrap metal. Since normal service stations have special stands for restoring body geometry, where normal cars are repaired. True, it still costs more than simply overturning the car somewhere in the garage.

Page 1 of 2 1 2 Forward >

Operating principle and theory of semi-automatic electric welding

Welding with a semi-automatic inverter using carbon dioxide is today the most common type for self-repair of the bottom. Using gas welding is quite problematic, since it is difficult to make a high-quality seam.

The carbon dioxide semi-automatic machine allows you to weld metal with a thickness of 0.8 to 6 mm, has compact dimensions, and is convenient for welding difficult areas. The machine uses carbon dioxide; it enters the welding zone under pressure and displaces air, preventing oxidation of the metal, which does not burn, but melts. The welded sections are connected, forming an even, narrow seam.

Preparation of the welding machine takes place in the following stages:

- Check the garage electrical system for the required voltage.

- Remove all flammable materials from the vehicle and within a radius of 1 meter from the work site, remove the battery, and drain the fuel.

- Insert welding wire into the inverter.

- Set the required polarity for ordinary wire used for welding metal. The minus is placed on the clamp and the plus on the burner.

- Connect the carbon dioxide cylinder.

- Check the inverter for functionality. First, the gas is supplied, then the wire is turned on and the welding current is supplied.

It is recommended to use technical carbon dioxide for welding; the chemical has less water vapor than food-grade carbon dioxide.

What seam to weld the underbody of a car

There are several techniques for cooking the bottom of a car. Professional tinsmiths recommend using step welding, welding in stitches: 2 cm of welded metal, 5 cm gap. This type of welding increases the rigidity of the body and enhances the tensile safety of the structure. During vibration during movement, the bottom does not deform, as with welding with a continuous seam, and does not tear, as with spot welding.

Damage level

The upside-down can be obtained by carefully tipping it onto the roof or received by numerous blows.

Therefore, buying a shifter car is dangerous. During the inspection, you may not be able to determine that the car is pulling to the side. And, if the power unit or automatic transmission was also damaged. It will be difficult to ride it correctly.

Since there is a lot of restoration work to bring an overturned car back to factory shape, and all of it is visible, a closer inspection can reveal some shortcomings.

How to identify a shifter?

This can be determined by carefully inspecting the following parts:

- Loin part of a car roof.

- Roof pillars.

- Other body elements. You need to look not only at the condition of the body paint, but at the gaps between the parts, they must be the same. If, for example, the trunk lid has a gap of more than a centimeter on one side, and almost flush on the other, then the geometry is clearly broken.

- I can also suggest plastic, seals, interior trim.

- Also, it’s a good idea to take or buy a thickness gauge and measure the thickness of the body metal, for example, every 20-30 cm. Look on the Internet what the thickness of the car body metal of the make and model inspected should be, and compare.

( 2 ratings, average 5 out of 5 )

Repair tools and materials

In half of the cases, the need for a full underbody repair is discovered by technicians at a service station during routine vehicle diagnostics. When the car is lifted onto an overpass, it is easier for a mechanic to see corrosion plaques on the metal, dents from impacts, etc. The cost of repairs depends on the degree of damage; in a workshop this is a justifiably high price of 10,000 rubles. only for overcooking the thresholds.

But in the case of a body, the degree of damage to the metal may be excessive and it will not be necessary to repair the bottom with patches, but to completely or partially replace the load-bearing elements. Many drivers choose garage repairs; it is 10-15 times cheaper; if the technician has skills in gas or electric welding, the cost of the work is minimal.

Before welding the underbody of a car with your own hands, you need to prepare the following tools and materials:

- calcium carbide, oxygen cylinder if gas welding is used;

- copper wire, carbon dioxide, if welding is performed semi-automatically;

- metal for patches;

- replacement wheels for a grinding machine;

- bitumen mastic, paraffin anticorrosive for treating the external and internal surface of the bottom;

- putty.

Equipment and tools that will be required for repairs:

- grinder (angle grinder);

- chisel with a wide blade;

- welding machine;

- metal scissors;

- straightening hammers;

- electric drill.

During the work, you may need a degreaser, a spot welding machine for tack, and R-80 sandpaper.

Recommendations

How can you determine if the car you are buying has a “bad history”?

If there are no special devices that can determine the difference in the thickness of the paintwork, then an ordinary magnet will come to the rescue. You can take the most standard magnet that was left over from audio speakers. We hide it in a thin woven fabric and, so that the rag does not unwind and allows you to work comfortably, we wrap this “sandwich” once with tape. The home flaw detector is ready, let's start inspecting the car.

By passing such a magnet over the entire body of the car, if there are separate areas where the body was repaired, a significant decrease in the attraction of the magnet to the car body will be felt. This is how a magnet will show itself on any problem area of the car, be it a thick layer of putty or internal corrosion that has formed under the car’s paintwork. And special attention should be paid to this procedure when examining the roof of the car, because this is the most painful place of the car if it gets into an accident and tips over onto the roof. High-quality “stretching” the roof of a car is not a simple process that requires a lot of experience and knowledge.

In addition to the above method, it is worth paying attention to the condition of the tires, because improperly performed repairs to a car shifter can affect the tires. Due to incorrect geometry of the car body, tires may wear unevenly. Although this also happens due to poor balancing.

Car glass is one of the most eloquent factors in the history of a car. All factory glass of the car has a single stamp. And if, when examining the car, there is a noticeable difference between the side windows and the windshield, then with a high probability we can say that this car could have had a frontal impact or “sunbathed” on the roof.

The most accurate way to check a car is the VIN code. Thanks to this identification combination, you can recognize the entire life of the car, since if it is involved in an accident, it is necessarily registered in this incident under its personal code. Of course, this procedure is not free, but a car also costs money.

Also, today at the service station there is a special package of services for auto mechanics who, for a fee, will carry out a complete diagnosis of the client’s car, including defects in the body, engine, electrical parts and chassis. This method can also be considered almost 100% reliable.

Of course, it is worth noting that modern specialists are able to restore a car so elegantly and efficiently that to identify the pitfalls of such a car requires an equally distinguished craftsman. After all, when a car rolls over, there is almost a 99% probability that the airbags will deploy, and not every owner will install them again, much less resellers. But a high-quality repair of the shifter can give such a car a good service life. Use these tips and you will be at least somewhat insured against a bad purchase.

I decided to do body work, namely to weld the bottom of the nine, and for this I need to turn the car over. Before starting to tip over, I removed the battery, I turned it over on the right side, and otherwise it would have imparted a greater load. This tipping option is convenient for those who don’t have 8-10 bros nearby who could help put the car on its side.