How to check bicycle chain tension

The use of bicycles entails wear and tear on its main components; in addition, the chain tension weakens over time. To quickly resolve problems and prevent undesirable situations, it is recommended to learn how to adjust the chain tension, either shorten it, or completely replace it with a new one.

Chain tensioner

Normal tension depends on the condition and operation of the entire transmission device. If necessary, it can be adjusted manually, but it is more convenient using a special device. The chain tensioner independently controls the chain stiffness, saving bike owners from unnecessary work.

Varieties

The device is installed on bicycles with open transmissions together with a rear gear shift unit. If necessary, it can be mounted on other types of two-wheeled vehicles. This is mainly required for extreme driving. The following options are most often used:

- ISCG - fastened with bolts with a pitch of 47.77 mm to the frame in three places;

- ISCG 05 is the most popular option, since installation does not require much effort, the distance between fasteners is 55.92 mm;

- BB – installed on the carriage that presses the tensioner to the frame.

The device consists of one or a pair of rollers, a lever, and a spring. The principle of operation is the systematic pulling of the mechanism in the desired direction. A clear fixation of the position of the chain is achieved, eliminating the possibility of it flying off the drive sprocket as a result of strong elongation.

The tensioner is installed parallel to the rear sprocket system: on top without distortions. Otherwise the shift holder will bend. If this happens, you need to pull the device along with the switch to align.

ISCG

ISCG 05

BB

How to make it yourself

If your bike does not have a tensioner, you can purchase one or construct one yourself. There are several ways, the simplest of which is from a bicycle spoke. It needs to be bent into a spiral and then placed in the transmission in such a way that the chain is pulled back. A more complex method is from an aluminum plate 8–11 mm thick. During the work you will also need:

- hacksaw;

- drill with a set of drills;

- file;

- vice;

- hammer;

- sandpaper of different grain sizes;

- tap, holders.

The work sequence consists of the following manipulations:

- outline the old part on the workpiece (rooster), drill the central part;

- using a hacksaw and file, bring the workpiece to the required shape and size;

- make a height difference at the place where the part is attached to the frame (from 4 (in the thinnest place) to 8 mm);

- finally drill the hole to the required diameter;

- cut the threads strictly at an angle of 90° to the axes.

The final stage is sanding and polishing the part. It is advisable not to leave burrs or uneven edges. After this, you can begin installation.

How to install

Before installing the tensioner, you need to remove the chain from the rear sprockets, and after installing it, remove the chain from the front ones. Next, put it on in the following order:

- rear large sprocket;

- tensioner roller;

- outer roller;

- the biggest star is at the front.

In order for the chain to finally take the correct position, it is necessary to actively spin the wheel several times. Next comes adjusting the tensioner to suit your requirements. Usually the angle of its position relative to the frame is changed. It is considered the most suitable - directly at the critical angle, where the strongest tension is formed.

What are the signs that determine the need to adjust the chain tension on a bicycle?

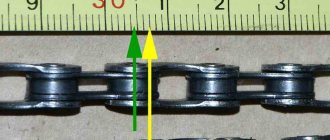

On bicycles equipped with a planetary hub or without a derailleur, it is quite easy to understand that the chain tension needs to be adjusted. You just need to pull it down as much as possible. If it deviates by more than one to one and a half centimeters, it should be adjusted.

But over-tightening is not recommended. Excessive tension will cause increased stress during travel and accelerated wear of the transmission. If after pulling down the stroke does not exceed 0.5 cm, it is necessary to loosen the chain somewhat. But such actions should be performed carefully, because if it is too loose, the chain will fly off the sprocket teeth.

To determine the need to adjust the tension of a bicycle chain, different methods are used:

- speeds are set so that the chain is on the largest sprockets at both points. After this, it is pulled down towards the front fork until the rear-mounted derailleur reaches its limit. When, after such an operation, no more than a couple of freed links remain, the chain length parameter does not need to be adjusted;

- At the front point we set the chain to the maximum size sprocket, at the rear - to the smallest size. At this moment, the guide roller and a similar element of the rear shift tensioner should be located on a common line at right angles to the surface of the ground. The required length on two suspensions is specified as follows: the pendulum is pressed to such a state that the front sprocket cassette goes to its maximum distance in relation to the ratchet. This position is considered the best to determine the length of the chain.

Step-by-step instruction

The transmission elements of bicycles from most manufacturers, with rare exceptions, are compatible with each other. You just need to select the same number of transmission and chain speeds. For example, for a transmission with nine gears you will need a chain designed for the same number of speeds.

Removing the old chain

Using a chain squeezer, press out one of the pins (the pin that connects the chain links) in the bottom passage of the chain. If there is a locking link, remove it. After removing the roller, carefully remove the chain from the bike.

Best articles: Which bike is better - mountain or road?

If you use one chain for a long time without replacement, you may need to replace the cassette.

Installing a new chain

Shift reverse and forward gears to the largest sprockets. If your bike has a clutch, loosen it.

Throw the chain over the guide roller, pull it through the mechanism's legs, and wrap it around the tensioner roller. Carefully release the gearshift mechanism.

Chain measurement

You need to make sure that the chain will behave properly when shifting into any gear without damaging other parts of the bike. To check, the chain must be installed on the two largest sprockets, front and rear. Even if you never drive in such a gear.

Align the two ends of the chain and identify the extra links that need to be removed. To fix the chain in this position, use part of a bicycle spoke.

Once the required chain length has been determined, remove unnecessary links. Throw the chain back over the smallest sprockets.

Attention ! On full suspension mountain bikes you need to make sure there is enough chain length when the suspension is compressed

Circuit connection

For Shimano chains, you need to connect both ends with a roller. After installation, the excess part of the roller is broken off with pliers.

Rotate the pedals until the locking link is in the middle of the upper passage. Then hold the rear wheel to prevent it from spinning. Press down on the pedals and the locking link will finally slide into place. Make sure the chain is installed correctly. Pedal the bike using all gears.

How to tension a bicycle chain

The correct position of the chain is the main condition for the smooth operation of bicycle transport. If the chain tension on a bicycle is higher than the maximum value, the pedals will turn quite difficult. In addition, chain links wear out much faster. If the element sag excessively, the likelihood of it coming off while driving increases.

You will be interested in How to remove a chain without squeezing: algorithm of actions

Bicycle without speeds

When tensioning the chain on a simple bicycle, keep in mind that its position should not be too tight. An indicator of up to 0.5 cm is considered optimal.

To begin with, the bike is turned over, something soft is placed under the seat to protect the leather trim from damage. A pair of nuts securing the rear wheel are loosened. To adjust the required level of sag, the wheel rim is carefully moved along the inclined grooves. Once the specified level of adjustment has been reached, the wheel nuts are tightened again, tightening firmly, but without undue force, so as not to damage anything.

The operation of bicycle transport must ensure free movement of the pedals. After completing the adjustment, be sure to check how the bicycle behaves in motion, check the wheel axle, which should be parallel to the carriage.

On a vehicle with multiple speed limits

The tension of the chain on a bicycle at speeds is carried out due to the stiffness of the switch spring. But when its length is large enough, using a tensioner will not get rid of the sagging. In such situations, while moving, the chain hits the frame structure.

When the length is less than the permissible value, difficulties arise with turning on speed modes. In addition, all elements of the shift mechanism and the gears themselves wear out faster.

To make the chain shorter, first place it on the largest sprockets at the front and rear, and pull it back, moving the derailleur all the way forward. To determine the optimal length, it is recommended to add a couple of links.

There is another option: the chain is placed on a large front sprocket and a small rear one, tightened so that the roller axles occupy a common vertical.

We adjust the length of the chain on a two-suspension vehicle. We fix the pendulum mounted at the rear so that the distance from the rear ratchet to the front cassette is maximum. Once the optimal length is determined, the excess links will have to be removed.

Bicycle chain problems

One of the most common problems is chain slack.

. This process is due to the fact that the axles gradually wear out during movement, which leads to sagging of the chain. This process actually cannot be prevented, so it is simply necessary to remove excess links as it lengthens.

In order to shorten the chain you will need a chain and pliers:

- Disconnect the chain and remove the squeezer.

- We determine the number of extra links (the optimal way is to pass the chain through large sprockets).

- We remove unnecessary links according to the principle of disconnecting the chain.

- We connect the chain and check its mobility.

Another difficulty is the chain slipping

: Depending on the severity of the problem, the cyclist may experience either minor inconvenience while riding or serious difficulties leading to possible loss of parts, injuries and accidents. Among the reasons for chain slippage are the following:

- Caliper adjustment. In middle positions this can lead to the chain jumping over the sprockets, and in extreme positions it can get jammed between the frame and the sprocket. To avoid such difficulties, it is necessary to adjust the calipers in a timely manner: in this case, do not forget about those gears that are not often used (for example, 1-1 or 3-9).

- Wear of the chain or its components. The critical mileage of a bicycle can be from 2 to 8 thousand km: when these indicators are reached, the chain begins to jump off under increased load, then more and more often. In this case, you can notice a certain looseness of the chain, as well as an uncharacteristic sharpness of the sprockets. This problem can only be solved by completely or partially replacing the damaged element.

- Presence of dirt or dirt in the chain. Particles of dirt, ice, grass or soil can cause problems with the circuit. In this case, it is easy to eliminate slippage: you just need to clean and lubricate the chain.

- The chain is twisted or broken. Twisting is an easily solvable problem that occurs when the weave fails or a jammed chain is removed. To eliminate it, you need to find the damaged link, carefully bend the chain and straighten the defect. A rupture, of course, requires more serious efforts: replacing a damaged pair of links or the entire chain.

Removing chain links

We have decided how to check the chain tension. Now let's talk about how unnecessary links are removed.

It turns out that a new chain is not installed on bicycles right away. And first of all, this requirement applies to high-speed modifications. Often, before installation, the chain has to be adjusted in length, removing excess links.

You might be interested in: Chain lock for a bicycle: how to choose a lock

For simple bicycles, simple models of chains are provided, each individual link of which is an independent lock. For bicycles with speed derailleurs, a non-separable type of flail is used. Before disassembling them and removing excess links, the pin heads on the link are ground with emery, after which the rivets are separated with a squeezer - a special device. With its help, links are not only quickly separated, but also separated, removed and reassembled. The tool has two grooves, with the help of one of which the pin is pressed out, and on the second, reverse pressing is performed.

A tool such as a squeezer does not cause any difficulties in operation. Having determined the number of chain links that need to be removed, the chain must be disconnected and removed from the bicycle. It is clamped in a squeeze, fixed, and the knob is slowly turned in the direction of movement of the clock hand. The position of the release rod is constantly monitored so that it is positioned exactly along the chain pin, which does not need to be completely pressed out.

During operation, the force applied to perform the rotation is also monitored. Initially, the move will seem a little heavy, after which it will become much easier, and at the final stage resistance will begin to be felt again. The chain is disconnected and removed from the vehicle, the pin remains on the outer edge of the plate.

To ensure that the bicycle chain tension setting is correct, the extra links are counted from the end of the chain where the pin is removed. Then the links are removed, the chain is connected again - the pin is pressed into place using a squeezer. The alignment point must be carefully examined. The pin should be distributed evenly on each side of the plate, and the links at the connection point should move easily and smoothly.

What types of bicycle chains are there?

All types of bicycles, regardless of their purpose, use the same chain design. This product is a single-row roller chain with a clearly marked pitch of 12.7 millimeters. In this case, a separate link includes:

- external plates;

- internal elements;

- pins;

- rollers;

- rollers.

The main difference between the chains is based on whether the speed is high or not. The number of speed modes determines the availability of suitable sprockets. And this in turn affects the width of the bicycle chain. Also a characteristic variety will be the presence of a specific lock or its absence. It serves to make it easy to dismantle the chain and reinstall it.

The last classification applies to the manufacturers of the goods, but this is a matter of preference.