An engine repair stand is a device on which the power unit is mounted after removal from the engine compartment of the car. This solution allows you to significantly simplify the process of cleaning and inspection, as well as disassembling, troubleshooting and repairing the engine. Also, at the engine repair stand, subsequent assembly of the power plant and transportation, if necessary, is carried out. In other words, it is much more convenient to carry out any work on the internal combustion engine when the auto repair shop or garage has a disassembly and assembly stand for engine repair.

We also recommend reading the article on how to repair a cracked cylinder block or cylinder head. In this article, you will learn about various ways to repair a cracked block or cylinder head with your own hands.

One of the main advantages of this device is that the motor, mounted on a multifunctional engine tilting stand, can be rotated at different angles. This feature allows you to improve quality and convenience, and at the same time reduce the time required for repairs and other work. Taking into account the above, such devices are in significant demand. On sale today are both finished products from well-known manufacturers, as well as more affordable offers from small manufacturers. In this article we will talk about what characteristics such a stand should have and what functions it can perform, whether it is possible to make a homemade stand for engine repair, and also what requirements are put forward for such a device.

Materials used:

- Channel - 60 mm.

- Channel - 50 mm.

- Pipes - 36 and 28 mm.

- Metal plates 8 mm - 2 pcs.

- Wheels from a cart.

- A piece of galvanized steel.

The homemade design is shown in the photo.

The axis of rotation of the engine is located at its geometric center.

The frame is made of 60 mm channel, racks with support hinges at the top are screwed to the frame. The hinges are made of pipes and open on hinges. After installing the assembled engine with legs on the stand, the hinges are closed and secured with nuts.

You can secure the engine in the desired position with a removable clamp; just loosen the clamp, turn the engine and tighten it.

On a pair of wheels diagonally, I made a stopper from a curved plate, which is bolted to the frame and clamps the wheel.

A tray made of galvanized roofing sheet is installed under the engine.

Dimensions: frame 600 x 800 mm, height of racks 350 mm.

Requirements for the tilting stand

A tilter, or stand tilter, is a device that can support the weight of a car engine, while the engine does not lie on the stand, but is movably fixed. Thus, in order to gain access, for example, to the crankcase, you do not need to turn it over on a workbench or think about how to strengthen the cylinder block on the surface. The engine mounted on the equipment can rotate freely around its axis and have several fixed positions, depending on the design features. In this case, it is necessary to achieve several indicators:

the device should not take up much space in the garage:

the engine must be fixed firmly and rigidly;

the design must allow a certain force to be applied while maintaining stability;

the structure must be rigid;

The tilter should allow you to easily select the desired position of the engine, holding it securely.

What is needed to make a slipway

The production of slipways is carried out by large world-famous companies and small regional enterprises. The price of such power stands varies greatly, but making such equipment yourself will cost many times less. Depending on the chosen design, drawings should be drawn up, providing for all the features of the future workshop. Then all that remains is to prepare the necessary consumables and tools.

To assemble a homemade slipway you will need a metal profile, which will form the skeleton of the structure. The assembly process is carried out by welding and the appropriate equipment must be available. The fastening system is developed individually and it is important to purchase a power rack mechanism, chains and gripping devices that are difficult to manufacture. Before starting work, you should prepare the metal by cleaning it from rust, degreasing and priming. After which you can begin assembling the structure.

Engine repair equipment

The engine can rightfully be called the “heart” of a modern car. It is this part that bears the greatest number of loads, and the performance of the entire vehicle directly depends on its performance. Owners fix some minor breakdowns on their own, but to fix more serious problems, you should contact specialized auto repair shops equipped with equipment for engine repair. A signal for the need to visit a car service center may be an increase in fuel consumption or difficulty starting the car.

The technology for repairing any engine is built in several stages. First, the attached equipment is removed from it, then the assembled engine is washed.

After this, the motor is placed on a stand to disassemble the engines. This equipment for engine repair allows you to securely fix the part in a position convenient for work. Paradoxical as it may seem, often the cause of damage to car engines is dirt getting into them. Therefore, after disassembly, all its components are thoroughly cleaned.

A slightly more advanced model of a disassembly stand is an engine repair stand. It can be equipped with additional accessories, such as trays for collecting technical fluids.

After disassembling and washing the engine, it is necessary to inspect it, repair or replace damaged parts. For these purposes, specialized equipment for engine repair is also used.

Installations for honing cylinders of automobile engines are designed for honing cylinder mirrors. The operation is carried out in order to achieve proper seating of the piston rings. After all, only in this way can the required tightness of the fuel combustion chambers be achieved. The bushings of the upper and lower connecting rod heads, valve mechanism drives, and engine cylinders are honed. There are two types of honing stands on the market with different types of hone: a “bottle brush” and a surface hone, made in the form of an attachment with sharpening stones.

After all structural elements have been restored, the engines are assembled, tested and run-in at a stand for assembling and adjusting engine clutches.

Engine break-in stands are one of the most important types of equipment for engine repair. Many models allow for both cold and hot running, while others are designed for only one operation.

Cold running can significantly reduce the breakthrough of gases into the crankcase from the combustion chamber and the penetration of oil into it. The engine is connected to the stand and begins to run in, first at low speeds, then their frequency constantly increases.

Hot running does not eliminate the influence of temperature on engine parts, and, as a result, uneven heating of the elements, leading to uneven thermal clearances.

The further operation of this important unit largely depends on the quality of the equipment used to repair the engine. After all, careless disassembly or honing with a low-quality machine can lead to engine damage that is not noticeable at first glance, but can greatly affect its performance after a certain period of time.

Dear site visitors and potential clients. The management of the website www.ural-ks.ru brings to your attention that all information posted on our website is of an advertising nature and does not contain an offer with all the essential terms of the agreement, from which the will of the person making the offer is seen to conclude an agreement on the terms specified in offer conditions (public offer), but is an invitation to make an offer provided for in paragraph 1 of Art. 437 of the Civil Code of the Russian Federation.

All essential conditions for the purchase of advertised products will be specified in the purchase and sale agreement.

You can get all the necessary information on the configuration, prices, purchase and delivery of products advertised on the website from our specialists by phone.

Prices for goods are calculated in rubles at the dollar and euro exchange rates; at the time of placing the products on the website, the final price of the products is calculated at the current foreign exchange rate. To clarify this information, you can call our managers or make a request by email.

In case of delay in issuing an invoice and commercial proposal, as well as if there are any complaints about the work of the sales department, contact a senior manager.

Attention! All prices on the website are excluding VAT

Source

Why does the engine break down?

Of course, we all want our vehicle to serve us for a long time and at the same time be in excellent working condition all the time. However, this only happens in fairy tales, and in practice, even new cars taken from branded showrooms need repairs after just a few years. And what can we say when the owner does not spare his “iron horse”? In general, many factors contribute to the failure or incorrect operation of one of the main parts of a car - the engine.

So, let's look at the main mistakes that lead to such disastrous consequences. As already mentioned, the most negative impact is the incorrect operation of the vehicle, for example, the use of unsuitable fuel or low-quality technical fluids. Untimely replacement of the oil and timing belt and constant overload of the vehicle will also have a negative impact. Neglecting the engine’s need to warm up in the cold season will be even more destructive. And what can we say about malfunctions after mechanical impact due to an accident?

Features of the engine stand design

Of course, you can do without any tilters and disassemble the Zhiguli engine on a box or on a workbench, if you have one. But there will always be a risk that the motor will slip out and fall on your feet or on the floor; you always need to call someone for help, it’s always inconvenient. Some of the drawings shown on the page are designed specifically for VAZ engines, and some are universal. But they all work for their owners and make engine repair easier.

The main thing that needs to be achieved is stability and rigidity. Not everyone graduated from a university with an “A” in strength of strength materials and technical mechanics, so we will give some main points as a basis for building with your own hands or changing the dimensions indicated in the drawings. There are also many options for tilters that attach the engine to only one console. This causes increased stress on one rack. This design also has the right to exist, but subject to certain conditions.

In any case, the stand will be made of profiles, it does not matter whether it will be a square pipe, a powerful angle or an I-beam. At the junction of two profiles, a certain amount of movement cannot be avoided.

In this case, an ordinary triangle will come to the rescue, which is the most rigid and indestructible figure. Consequently, it is necessary to unload the central post as much as possible, and this can only be done with the help of slopes, so that the maximum load falls on the support triangle.

It is very important to correctly position the center of gravity and relieve the lower frame from bending loads. Here, too, several braces will have to be included in the design.

The center of gravity must be located so that it is possible to rotate the engine without problems, but at the same time the entire structure remains stable. You need to take into account both the weight of one cylinder block and its weight together with the cylinder head, flywheel and crankshaft.

Connecting (checking) the motor

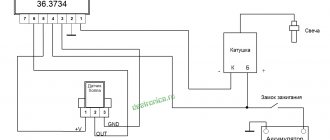

Naturally, before you start assembling something, the electric motor must first be connected and tested. In old washing machines, there are two versions of motors: an older and high-quality one, which has a closed housing with an impeller, with two supply terminals, and a newer one - four terminals, no impeller, cooling occurs through holes in the front and rear, through which the windings are visible.

The old version does not require any capacitors for starting - the starting winding is cleverly connected and disconnected inside the engine using a special mechanism. Thanks to this, no connection difficulties should arise: both outputs are connected to a 220 volt network. The disadvantage of such a motor is that the direction of rotation of the shaft is preset by an internal connection and cannot be changed. Typically the direction is clockwise and therefore it will be necessary to use a left hand thread to attach the stone.

The newer version has four terminals of two windings: working and starting. You can distinguish them using a multimeter: the resistance of the working winding is about 10 Ohms, the starting winding is about 40 Ohms. Perhaps the resistances will differ from those indicated, but only slightly. The starting winding must be connected through a 4-5 µF capacitor for a voltage of at least 400 V. I have come across composite capacitors for similar motors: two connected in series, 10 µF each at 300 V. That is, in this way the maximum permissible operating voltage of the finished capacitor was raised. Using a composite capacitor of two with low voltages (at least 300 V) is possible, but not advisable. Capacitors should be non-polar!

You can check the engine without capacitors and starting winding at all: voltage 220 V. supplied directly to the working winding. With this connection, the motor will start without load in any direction. To set the direction of shaft rotation, you need to connect the starting winding and capacitor. For emery, you need to set the direction counterclockwise

. The connection diagram is shown below, if the shaft rotates clockwise, you need to change the connection of the starting winding.

In many publications on the network I have seen a statement that the starting windings do not need to be connected at all, and the direction of rotation must be set manually when starting. Allegedly, if the starting circuit is used, the engine will burn out. I can only explain these speculations in one way - one wrote nonsense, and the rest were copied from the first. I can say with confidence: the starting winding can and should be connected through a 4-5 uF capacitor, the starting circuit should always be connected, without any additional buttons. And if the motor is working properly, such a connection is safe and completely harmless for it.

Features of the engine stand design

Of course, you can do without any tilters and disassemble the Zhiguli engine on a box or on a workbench, if you have one. But there will always be a risk that the motor will slip out and fall on your feet or on the floor; you always need to call someone for help, it’s always inconvenient. Some of the drawings shown on the page are designed specifically for VAZ engines, and some are universal. But they all work for their owners and make engine repair easier.

Read more: Universal low and high beam headlights

The main thing that needs to be achieved is stability and rigidity. Not everyone graduated from a university with an “A” in strength of strength materials and technical mechanics, so we will give some main points as a basis for building with your own hands or changing the dimensions indicated in the drawings. There are also many options for tilters that attach the engine to only one console. This causes increased stress on one rack. This design also has the right to exist, but subject to certain conditions.

In any case, the stand will be made of profiles, it does not matter whether it will be a square pipe, a powerful angle or an I-beam. At the junction of two profiles, a certain amount of movement cannot be avoided. In this case, an ordinary triangle will come to the rescue, which is the most rigid and indestructible figure

Therefore, it is necessary to unload the central post as much as possible, and this can only be done with the help of slopes, so that the maximum load falls on the support triangle

In this case, an ordinary triangle will come to the rescue, which is the most rigid and indestructible figure. Consequently, it is necessary to unload the central post as much as possible, and this can only be done with the help of slopes, so that the maximum load falls on the support triangle.

It is very important to correctly position the center of gravity and relieve the lower frame from bending loads. Here, too, several braces will have to be included in the design. The center of gravity should be located so that it is possible to rotate the engine without problems, but at the same time the entire structure maintains stable stability

You need to take into account both the weight of one cylinder block and its weight together with the cylinder head, flywheel and crankshaft

The center of gravity must be located so that it is possible to rotate the engine without problems, but at the same time the entire structure remains stable. You need to take into account both the weight of one cylinder block and its weight together with the cylinder head, flywheel and crankshaft.

Purpose of the engine repair stand and its care

It is not so important why the unit failed; in any case, the result is the same - the need for diagnostics and further repair work. In this case, a special stand used specifically for such purposes will be indispensable.

The motor is mounted on it in a suspended state, and then diagnosing, transporting and repairing the unit becomes many times easier. In addition, most of these mechanisms are equipped with a special unit, thanks to which the angle of rotation of the engine can be changed in any range, which greatly facilitates the work carried out.

But, like all devices, such a stand also needs good care. Therefore, be sure to carry out visual inspection to look for defects, and if there are any, then you should postpone operation. Before each use, check whether all fasteners are securely fixed; if not, retighten them. And of course, keep it only in a dry and clean place, remove all debris after each use, and regularly lubricate all moving parts. Only with proper use, a stand, even a homemade one, will last quite a long time, reliably and will pay off if you are going to become a motor mechanic.

Operation of the power stand

A slipway can be made of any design; frame or platform are most suitable for such purposes. The main thing is to approach your work responsibly and show your own ingenuity. Understanding how to make a slipway is quite simple, and choosing the right material will help reduce the cost of its creation. To implement your own ideas, you should take the best of existing models. The operation of the slipway is designed for many years and such equipment will prove its practical usefulness more than once.

Even in minor accidents, the geometry of the power structure of the car body is sometimes disrupted, which greatly complicates the process of high-quality restoration. Without qualified editing, it is unlikely that you will be able to set even gaps between the outer panels and correct wheel alignment angles. And if the angles are not set, the car will begin to pull away on the road, the tires will wear out faster and more unevenly.

Technological features

How to make a car tipper with your own hands? This question is quite interesting. There are many different ways to make such a lift. But almost all of them are based on a jack. This lifting mechanism is supplemented with extensions, resulting in a design that is no different from the factory one. Only it costs several orders of magnitude cheaper. The following indicators must be taken into account:

- Safety;

- Load capacity;

- Climbing angle.

What will you need?

To work, you will need a durable channel, as well as a steel sheet. A jack will be used as a working tool. You can use not only the mechanical, but also the hydraulic option. In addition to the usual set of accessories, you will need a grinder and a welding machine.

Features of the engine stand design

Of course, you can do without any tilters and disassemble the Zhiguli engine on a box or on a workbench, if you have one. But there will always be a risk that the motor will slip out and fall on your feet or on the floor; you always need to call someone for help, it’s always inconvenient. Some of the drawings shown on the page are designed specifically for VAZ engines, and some are universal. But they all work for their owners and make engine repair easier.

The main thing that needs to be achieved is stability and rigidity. Not everyone graduated from a university with an “A” in strength of strength materials and technical mechanics, so we will give some main points as a basis for building with your own hands or changing the dimensions indicated in the drawings. There are also many options for tilters that attach the engine to only one console. This causes increased stress on one rack. This design also has the right to exist, but subject to certain conditions.

In any case, the stand will be made of profiles, it does not matter whether it will be a square pipe, a powerful angle or an I-beam. At the junction of two profiles, a certain amount of movement cannot be avoided.

In this case, an ordinary triangle will come to the rescue, which is the most rigid and indestructible figure. Consequently, it is necessary to unload the central post as much as possible, and this can only be done with the help of slopes, so that the maximum load falls on the support triangle.

It is very important to correctly position the center of gravity and relieve the lower frame from bending loads. Here, too, several braces will have to be included in the design.

The center of gravity must be located so that it is possible to rotate the engine without problems, but at the same time the entire structure remains stable. You need to take into account both the weight of one cylinder block and its weight together with the cylinder head, flywheel and crankshaft.

Assembly

If the installation will need to serve various types of engines or simply be for all occasions, then it should be made universal. It should be taken into account that VAZ car engines differ significantly from BMW mechanisms in fastening methods. It may be necessary to create a stand for disassembling and assembling the KamAZ-740 engine or other large-sized engines.

A pair of channels with 10 mm holes is welded to the rotation plate. The pitch is 50 mm. Places for channels are marked in the area of the motor mounts. The center of gravity is precisely directed along the axis of rotation of the plate. This will make it possible to simply rotate the stand around its axis.

Using a manual hoist makes it possible to install the structure on wheels (they must be strong enough). This will make it easier to move the faulty part around the room. If necessary, it can be easily moved to the far corner. You should also attach a tray at the bottom, thanks to which the dirty waste from the engine will not spill on the floor. The existing pan below will make it possible to flush the engine.

Working with the stand

Before starting operation, be sure to carry out a visual inspection of the system. If any defects are discovered that could damage the equipment during maintenance, they must be corrected. If upon inspection there are no such defects, you can begin work.

For a good and long service life of the structure, it is necessary to monitor its condition. It is necessary to check the reliability of the fixing fasteners each time you use it, regularly lubricate all moving parts and store the unit in a dry place. The possibility of direct contact with precipitation and moisture should be excluded.

You should not load the stand above the actual calculated weight, so as not to drop the engine due to breakdown. During operation, the structure must be placed on a stable surface. It is also worth using a locking pin for the rotating mechanism. You should work carefully and carefully.

Materials for production

Due to the fact that the engine tilter will have to work under severe conditions of physical stress associated with the weight of the engine, high demands are placed on materials.

The following materials are used for manufacturing:

- steel square profile 70 x 70 with a wall thickness of 3 mm, length 3 m;

- steel pipe with outer diameter 60 mm, inner diameter 53 mm, length 245 mm;

- steel pipe with outer diameter 47 mm, length 480 mm;

- steel channel with internal side width 70 mm, wall thickness 3-4 mm, length 280 mm;

- flange for bolted connection to the engine - 1 pc.

Purpose of the engine repair stand and its care

It is not so important why the unit failed; in any case, the result is the same - the need for diagnostics and further repair work. In this case, a special stand used specifically for such purposes will be indispensable.

The motor is mounted on it in a suspended state, and then diagnosing, transporting and repairing the unit becomes many times easier. In addition, most of these mechanisms are equipped with a special unit, thanks to which the angle of rotation of the engine can be changed in any range, which greatly facilitates the work carried out.

But, like all devices, such a stand also needs good care. Therefore, be sure to carry out visual inspection to look for defects, and if there are any, then you should postpone operation. Before each use, check whether all fasteners are securely fixed; if not, retighten them. And of course, keep it only in a dry and clean place, remove all debris after each use, and regularly lubricate all moving parts. Only with proper use, a stand, even a homemade one, will last quite a long time, reliably and will pay off if you are going to become a motor mechanic.

Types of slipways and their main differences

There are 4 types of design:

- Floor-standing. Standard rail mounted design.

- Roll-on. Small in size. Such structures are stored in a garage or workshop.

- Frame. Structures on chains designed for complete repairs and lifting the machine to a height.

- Platform. Designed for professional repairs. Suitable for large machines.

Floor structures

The floor slipway is also called stationary. Its difference is that there are rails on the floor that allow you to move the mechanisms. With their help it is easy to carry out body work.

The stationary slipway is convenient thanks to retractable mechanisms.

Floor structures have 3 advantages:

- They take up little space.

- They cost less than other slipways.

- Fast installation of transport.

The disadvantage is the complexity of installation of the structure.

Roll-up

A rolling slipway is a slipway that is used for light repair work if there is no full-fledged slipway or its use is impossible for some reason. The difference is that the rolling slipway is small in size - it is not necessary to roll the car up to it. You can bring the rolling slipway to the car.

This design has advantages:

- It is customizable for different types of cars.

- Possibility of equipping the device with hydraulics.

- The clamp fastening design has no analogues.

- Can be used with most types of machines.

- Compact size.

The disadvantage is that it is impossible to carry out complex work involving large distortions.

Frame

A distinctive feature of frame structures is the use of the frame as a base. The car is secured with chains. Most often this design is used for minor repairs. But, at the same time, the structure of frame stocks is more complex than others. They are equipped with grippers that allow you to fix the car body in the required position or even lift it to a certain height.

Platform models

The platform model is very similar to the trestle structure. It allows you to pull the car body in any direction. A lot of different equipment can be installed on the slipway platform. Pulling on a platform is very convenient, and the functionality is enough to make professional repairs right in the garage.

Safety precautions at work

When cutting rolled metal with a grinding machine, you should wear safety glasses, a respirator, and work gloves. This is due to the risk of sparks and glass dust coming into contact with the skin, eyes and respiratory tract.

When electric welding, you must wear a protective mask to protect your eyes from bright flashes. For what? When welding, ultraviolet radiation occurs, which without a mask can lead to a kind of tanning of the skin of the face and open surfaces, and damage to the eyes. Due to the danger of electric shock, when welding it is also necessary to wear protective gloves, and it is advisable to ground the device. In practice, canvas mittens are used; they also protect against thermal burns.

Be sure to have an OU-2 or OU-5 carbon dioxide fire extinguisher on hand. Any spark in the garage can lead to unpredictable consequences.

But in general, a homemade tilting stand should not create safety problems if it is assembled without any hackwork. On the contrary, it makes it possible to significantly ease the work of a mechanic, reduce injuries, and forget about crushed or pinched fingers or torn lower backs. In general, this is a useful unit on the farm, not inferior in quality to the industrial tilter for the AE engine.

Review and cost

To transport motors, water-motor boats use carts, both individually produced to suit their needs, the design and weight of the motor, and industrially produced (for universal use), which can be purchased in stores selling water-motor equipment and boats.

Trolley for transporting outboard motor TM-2

The trolley is designed to carry a fuel tank with the engine; it has a collapsible design. The support for a stable position, the mount for a standard fuel tank, the handle with wheels are easily detachable. To install the motor on a boat, it must be removed from the cart and moved to the transom of the boat. The weight of the aluminum trolley is 8.7 kg, which is two times lighter than a trolley made of structural steel. Cost 6500 rubles.

Price - 6500 rubles.

Morlab trolley

This is a transformable trolley. The design is patented. The stand, support, and handle for transportation are folded, the assembled cart is very compact and allows you to take it with you to the boat. The weight of the trolley is 6 kg, which is ensured by the frame being made of a square aluminum profile. The special design and shape of the false transom allows you to transfer the motor from the cart to the transom of the boat without lifting the motor. Cost 7500 rubles.

Price - 7500 rubles.

What is needed to make a machine

There is nothing complicated about assembling the equipment yourself. It is possible to make the simplest model of a lathe, the basis of which is a tool rest, a tailstock and an electric motor from an automatic washing machine.

To make a machine capable of processing wood material, you will have to prepare everything you need. The list of source materials includes:

- a motor from an old washing machine that has retained its functionality;

- the board from which the base of the device is prepared. As an option, the lathe can be mounted on a workbench;

- metal corners, the length of which is 19.5 cm, and the size is 2 by 2 cm. You will also need a pipe with a square cross-section. Steel blanks will be used to make tool rests;

- corner 6.2 by 6.2 cm, length 16.5 cm - you need to make a tailstock from it;

- the tool rest must be secured to the base with a bolt, the length of which must be at least 7 cm;

- a piece of steel pipe, the diameter of which is slightly larger than the size of the electric motor shaft;

- a bolt with a pointed tip that can be used to make a rotating headstock assembly.

The main operating parts of a lathe are the tool rest and the headstock, between which a piece of wood is inserted. Rotational motion from an electric motor is transmitted from the tool rest to the product. With the help of the tailstock, the product is held while maintaining its static position. The headstock is moved using a manual drive.

For ease of use, you will need certain tools and fasteners:

- electric drill with a set of drills;

- grinder with cutting discs;

- bolts and nuts with which the entire main structure will be assembled.

Once everything you need is prepared, you can move on to the main task. You just need to figure out how to properly make a lathe using an old motor from a washing machine.

Tools and materials for creating a structure

We will need the following materials and tools:

- Metal profiles.

- Extended profiles (needed for racks).

- Metal corners.

- Welding machine.

- Bolts and nuts.

- Fastening mechanisms.

- Paint and primer.

- Chains and hooks.

- Hydraulic equipment.

- Spray gun.

- Power rack.

Homemade engine tilter

Many car enthusiasts repair their car engines on the garage floor or on a workbench. This is always inconvenient, associated with constant lifting of weights, tilting a bulky cylinder block or cylinder head. All these factors lead to excessive fatigue of the car mechanic and a decrease in the quality of engine assembly. To make their work easier, craftsmen have developed many homemade tilter designs for the engine.

Options for homemade tilter designs

There really aren't many options. In the West, complex and bulky home-made structures are known, like a crane beam, almost with hydraulic drives.

In domestic conditions, car enthusiasts assemble the simplest structures from what is at hand. Of the homemade tilters for the engine, two-support and cantilever versions are known. The last design is the easiest to manufacture. Its characteristics are sufficient to carry out major repairs of almost any passenger car engine weighing from 150 to 250 kg.

Before starting to manufacture the unit, it is necessary to study in detail the existing samples of stands for engine repair. The sample is selected to suit the immediate needs of an amateur car mechanic. The availability of materials and dimensions for ease of work in a small garage are assessed. The permissible load weight is calculated in accordance with the type of engine that is to be repaired.

Based on the results of a study of existing structures, a sketch drawing of the most optimal version of a cantilever-type tilter was developed. Overall dimensions in the diagram are given in millimeters.

In the sketch, the designations D 60 and D 52 correspond to diameters of 60 and 52 mm.

Materials for production

Due to the fact that the engine tilter will have to work under severe conditions of physical stress associated with the weight of the engine, high demands are placed on materials.

The following materials are used for manufacturing:

- steel square profile 70 x 70 with a wall thickness of 3 mm, length 3 m;

- steel pipe with outer diameter 60 mm, inner diameter 53 mm, length 245 mm;

- steel pipe with outer diameter 47 mm, length 480 mm;

- steel channel with internal side width 70 mm, wall thickness 3-4 mm, length 280 mm;

- flange for bolted connection to the engine - 1 pc.

Tools and hardware for stand assembly

To connect the nodes of a metal structure made of a steel channel and a square profile, you will definitely need a welding machine that allows you to work with an electrode with a cross-section of at least 3-4 mm. In addition, for cutting you will need a grinding machine with a metal cutting disc with a diameter of 115-125 mm. To ensure bolted connections of prefabricated parts, you will need a drill with the ability to work with a drill with a diameter of up to 14-20 mm. M12 bolts are also required to assemble the structure.

You will also need a set of files to cut off burrs and uneven edges, and remove flaws in metal cutting. It wouldn't hurt to purchase some sandpaper to remove rust from the surface before painting.

Assembly of the engine tilter

The first step is to cut out the channel and square profile in accordance with the sketch. Next, a vertical post is made from the profile and welded to the square from the channel. Then the structure is reinforced with metal slopes, which can be made from scrap parts.

After this, a base is welded from a cut square profile - a tilter stand for engine repair. At the site of the bolted connection to the base of the vertical post, preparatory work is carried out, steel bushings are inserted and welded to strengthen the structure.

Then you should begin the final assembly of the engine tilter. The stand is connected to the stand by welding and M12 bolts.

A horizontal pipe with an outer diameter of 60 mm and an inner diameter of 52 mm is welded to the vertical stand. A horizontal axis is inserted into this part. It can be made of a steel pipe with a diameter of 47 mm with a welded flange for bolting the cylinder block or cylinder head.

In the horizontal axis, you can drill through holes every 45° along the radius, to be able to fix the position in space with pins after rotating the attached motor to the required angle.

Step-by-step construction instructions

The construction of any home-made structures begins with the design stage. You need to make a slipway that is convenient to use. It is important that it does not take up too much space, blocking free movement.

The second point is always the creation of the structure's frame. The last point is to install fasteners and tightening devices yourself.

Drawings and dimensions

First you need to make suitable drawings. Ready-made options can be found below. The markings are made according to the dimensions of the vehicle. Afterwards the stage of preparation and selection of tools and materials begins. We will also need to make a mounting system large enough to fit our vehicle. It would be nice to cook it with the ability to change the height.

- Once all the drawings are ready and the materials have been selected, you can start working. First you will have to remove moisture from the materials and coat them with a primer. You can paint them right away, or you can leave this step for last.

- Now weld the metal corners to the base profile.

- Weld the profile (this will be the stand). It is secured with bolts.

- Now the chains, hooks and retractable devices are welded.

Frame making

The frame is responsible for fixing the car. Therefore, you need to be careful when creating it.

- Before creating the frame, you need to create the outer frame. It is to this that the frame will be mounted.

- A metal profile is suitable as a material. A stand and grips are attached to it (they are needed to fix the car threshold).

- Now the thresholds are being made. They are created from metal corners.

- Thresholds are installed on beams and secured with bolts.

- After installation, all elements will have to be secured by welding.

Fastening the body to the slipway

Clamps are required for fastening. If you can't buy them, make your own. You will need railway platforms (what the rails are attached to the sleepers). Each of the platforms is cut in half, and metal is welded onto the inside. It is cut into diamonds using a grinder.

You don't need to do anything to the outside. A plate 4 millimeters thick is also welded to the inside. It is important that the clamping device fixes the threshold and does not bend during use.

Installation of rack and pulling devices

Factory hydraulic attachments are suitable for racks and devices. If they cannot be purchased, a homemade mechanism will do. The power of the device should be from 1 to 2 tons. To attach the pulling devices, you need a pad. It is made from a channel and installed in the frame of the slipway. To place the tightening mechanism and chains in any place, it is necessary to make holes in the frame along the entire slipway.

If the stand is made independently, it is recommended to use a tower device. It is heavy, but the restoration of the car will be uniform.

Making a slipway is not that difficult. If you have basic knowledge of construction, you can easily do everything yourself. The main thing is to choose the right material and make the right drawings.

Selection of slipway design

The application of multidirectional forces is the most important feature of a power stand. Such work is difficult to do manually. You can make a slipway with your own hands of various designs. Such devices are made of durable metal, and their features depend on the type of repair being performed. When choosing a suitable slipway model, you should take into account the parameters of the transport for which it is being manufactured. The dimensions of the stand, characteristics of devices and mechanisms can be selected based on the most successful models from Trommelberg, Nordberg BAS or Autorobot.

Purpose and advantages of self-manufacturing a slipway

A slipway is mechanical equipment whose task is to restore the original state of the car frame and body geometry. Straightening of deformation bends, dents and other irregularities is carried out using local loads. In most major changes in body geometry, a slipway is the only possible solution to restore the shape of the car frame. The presence of such equipment is mandatory for every workshop and guarantees high-quality body repairs.

To decide to make a slipway with your own hands, you need to understand not only the purpose of such a mechanism. Manufacturers offer different functionality of this equipment. Some models are only suitable for use in large service centers. There are also more mobile options that can be installed in a garage or similar space. When purchasing such devices for personal use, their price will be high and making them yourself is most advisable.