Briefly about the features and structure of the “six” carburetor unit

Before adjusting the carburetor on a VAZ 2106, it doesn’t hurt to know its design features. After 1980, Ozone and Solex began to be installed on Tolyatti cars. The purpose of the unit’s operation is to prepare a combustible mixture before feeding it into the car’s cylinders. Down to the subtleties, this is not a driving school, we will not disassemble the design, it is enough to familiarize yourself with the main components that ensure optimal operation of a carburetor internal combustion engine:

- Fuel dosing system.

- Mechanisms for controlling throttle valves and enriching the mixture.

- Idle system.

- Accelerator pump and econostat.

- Float chamber.

A chamber with a float and a needle valve is responsible for the stability of the fuel level. Next, gasoline, flowing through the spray tube, enters the chamber, where it mixes with air from the inlet pipe. The amount of mixture is adjusted by the throttle valve, which is connected to the accelerator pedal.

Precise adjustment allows you to prepare the correct mixture of gasoline and air in a ratio of 1:15. During long-term operation of the car, the settings get lost and you have to think about how to adjust the carburetor on a VAZ 2106 on your own. The adjustment technology is the same for both Solex and Ozone.

Carburetor operation on a VAZ

This device, located in the propulsion system, serves to ensure that the movement of fuel is carried out in a certain order. Proper operation of the carburetor helps to obtain the required composition of the combustible mixture. Then the mixture can move horizontally, downward or upward. This parameter depends on the design features of the device, but we will talk about this below.

Basically, the movement of fuel is carried out in the following order: from the fuel tank it enters the float chamber, and then through special nozzles it goes to the atomizer located in the narrowest part of the diffuser. It is at this moment that air enters through the outer tube. The role of throttle valves, through which the dosage of fuel entering directly into the engine cylinders, cannot be underestimated.

When is adjustment needed?

Adjusting the carburetor unit is no more difficult than adjusting the clutch drive on a VAZ 2107 , since it only involves adjusting the jets. In some cases, they need to be cleaned of resins and other contaminants; the presence of contaminants is felt by power dips in the process of accelerating. Many car owners claim that Ozone carburetors are not a very good option and recommend replacing them with Solex.

However, the signs that the device has begun to prepare an enriched mixture and needs to be adjusted are the same for both types of units:

- Increased fuel consumption.

- Frequent overheating of the motor.

- Black smoke from the exhaust pipe and pops.

- Loss of power.

The preparation of a lean mixture is characterized by the following characteristics:

- Popping sounds in the carburetor.

- Loss of power.

- Engine overheating.

Of course, you don’t always need to immediately grab a screwdriver and turn the adjusting screws - perhaps it’s something else. For example, when the idle speed floats, air may leak through the intake manifold gasket, or there may be a breakdown of the brake booster diaphragm. But even the reasons listed are not all the options, so specific recipes for eliminating certain problems cannot be given. The issue should be addressed comprehensively, taking into account the connection between vehicle systems.

Preliminary stage

Before you properly adjust the carburetor on a VAZ 2106 with your own hands , it is important to carry out a number of work steps:

- Adjust the thermal clearances of the gas distribution mechanism.

- Set the optimal ignition timing.

- Open the air damper completely.

All work on setting up the carburetor unit is carried out on a warm engine. Do not forget that during the process you may need new parts and rubber products, so it is better to purchase a repair kit in advance.

Carburetor VAZ 2106

The VAZ “Six” was produced for 30 years, from 1976 to 2006. The car was equipped with a carburetor engine with a capacity of 1.3 liters to 1.6 liters. Various carburetors were used in the fuel system, but the most widely used was ozone.

What is it for?

For each carburetor engine, the integral unit is the carburetor, which is designed to prepare the optimal composition of the fuel-air mixture by mixing air and fuel, as well as to deliver this mixture to the cylinders of the drive unit. For more efficient combustion, the fuel and air mixture must be mixed in a certain ratio, usually 14:1 (air/gasoline). Depending on the engine mode, this ratio may be different.

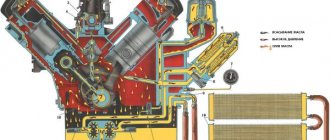

Carburetor design

Regardless of which carburetor is installed in the VAZ 2106 model, the differences between them are minimal. Basic dedicated node layouts:

- Idle speed control system;

- Float chamber;

- economist;

- Support pump;

- Transition system;

- Initial system.

To better understand the operation of the device, the listed systems must be analyzed in more detail.

Idle system

The idle speed system (idle throttle system) was designed to maintain a stable engine speed with the throttle valve closed. In this mode, the engine is driven without assistance. The fuel is extracted by the system from the float chamber and mixed with air in the emulsion pipe.

Float chamber

The structure of each carburetor contains a float chamber in which a float is located that controls the fuel level. Despite the simplicity of this system, there are situations in which the fuel level does not reach the optimal value. This is due to the valve needle leaking. This is due to the use of low quality fuel. The problem may be resolved by cleaning or replacing the valve. The float itself requires adjustment from time to time.

Econostat

ECO statistics provide high-speed fuel and provide a fuel-air mixture in proportions adapted to the rotation. The fuel and air mixer consists of a pipe with different sections and emulsion channels at the top of the mixing chamber. At maximum engine load there is a vacuum in this area.

Acceleration pump

To prevent the gas pedal from falling off, the carburetor has an overdrive pump that provides additional fuel. The need for this mechanism means that the carburetor cannot provide the required amount of fuel to the cylinders during rapid acceleration.

Transition system

Transition systems in the carburetor enrich the fuel mixture during idling to operate the main metering systems when the gas pedal is pressed freely. The fact is that after opening the throttle valve, the amount of air flowing through the diffuser of the main dosing system increases. Despite the appearance of the speed risk, there is not enough fuel flowing out from the main metering chamber. The combustion mixture is lean due to the large amount of air contained in it. As a result, the engine may be turned off. In the case of the second chamber, the situation is similar - after opening the throttle, it is necessary to enrich the fuel mixture to eliminate hangers.

Starting system

When starting a cold engine with a carburetor, it is not always possible to deliver the right amount of fuel and air. To achieve this, the carburetor has a starting system that allows you to regulate the air supply using an air damper. This part is located on the first compartment and is adjusted by a cable from inside the cabin. When the engine warms up, the throttle valve opens.

A choke is a device that prevents air from entering the carburetor during a cold engine start.

When you press the choke knob, the mixture is richer, but there is a gap of 0.7 mm so as not to flood the spark plugs.

What carburetors are installed on the VAZ 2106

Although the VAZ “Six” has long been out of production, a large number of these cars can be found on the roads. Their owners often wonder which carburetor can be installed instead of a conventional one, keeping in mind the following goals: reducing fuel consumption, improving vehicle dynamics and generally achieving optimal performance. The embodiment of these desires is quite possible today, which requires replacing a conventional carburetor. Let's consider what modifications of the devices in question can be installed on the VAZ 2106.

At the beginning of the production of cars of the VAZ family, the power units were paired with carburetors of the Dmitrov Automotive Aggregate Plant (DAAZ). A license was purchased from Weber for the production of these devices. Many sixes are equipped with just such carburetors. They are distinguished by good dynamics, simple design and high fuel consumption, usually at least 10 liters per 100 kilometers. Getting a carburetor in good condition is very problematic. To assemble a properly functioning unit, you will need to purchase several devices.

Float adjustment

One of the main stages in setting up a carburetor unit. A high level will produce a “rich” mixture, and more of it will be supplied to the cylinders, but there will be no expected dynamics. Only fuel consumption will increase, as well as its toxicity.

The float tongue must be installed so that its stroke is no more than 8 mm. In some cases, the problem may be the needle valve. Then you need to remove the float, pull out the needle and check the patency of the holes.

Adjusting the carburetor VAZ 2106

Set of screwdrivers (flat, cross, cross);

- Impact wrench set;

- A set of round bayonets or drills with different diameters;

- rubber bulb;

- toothpicks;

- Flushing mechanism;

- stopping support

- tweezers;

- Mister;

- rag

- Idle speed adjustment is carried out using qualitative and quantitative bolts. The procedure consists of the following steps:

XX adjustment

Start the engine and warm it up to operating temperature of 90˚C, and then turn it off.

- One of the main procedures when setting up a carburetor is adjusting the float chamber. If the gasoline level in the chamber is high, the fuel mixture will be rich, which is not normal. As a result, toxicity and fuel consumption increase. If the level is lower than it should be, there will be insufficient gasoline in various engine operating modes. In this case, set the float tongue so that its jump is 8 mm. It is worth lifting the float, removing the needle and checking whether it is damaged. If the carburetor is flooded, it is better to replace the needle.

Video: how to make idle stable

Adjusting the float chamber

After adjusting the float chamber, check the performance of the auxiliary pump. To do this, remove the carburetor from the engine and remove the top cover from it. Check the pump in the following order:

Adjusting the accelerator pump

Prepare a bottle of clean gasoline, replace the empty carburetor container, and fill the float halfway with fuel.

- When checking the accelerator, pay attention to the direction, shape and quality of the flow. In the case of normal flow, it should be uniform, without deviations or spraying of gasoline. In case of any irregularities, replace the accelerator spray for a new one. Structuring in the carburetor there is an adjusting screw in the form of a conical bolt, the wing of which causes the plug to overflow. With this screw you can change the fuel flow through the support pump, but only to a lesser extent.

The carburetor, as used, must be cleaned and air-bleeded every 10,000 km. Nowadays there are many cleaning tools without removing the unit from the machine. As a rule, however, they only help in cases of minor contamination. With more serious embodiments, it is necessary to remove the device. After removing and disassembling the carburetor, unscrew and clean the filter screen and injectors. Gasoline can be used as a cleaning agent, and if that doesn’t work, as a solvent.

Cleaning or replacing jets

To avoid damaging the diameter of the nozzles, do not use metal objects such as a needle or wire for cleaning. A toothpick or plastic stick of a suitable diameter is best. After cleaning, the nozzles are blown with compressed air to ensure that no dirt remains.

At the end of the entire procedure, we check the compatibility of the injectors with the installed carburetor. Each part is marked with a series of numbers that indicate the performance of the injectors.

Video: how to clean the carburetor

Carburetor markings

Table: numbers and sizes of jets for VAZ 2106 carburetors

| Main system fuel injector | Air nozzle in the main system | Idle injector | Air nozzle for idle speed adjustment | Pressure pump nozzle | 1 stone. | |||||

| 2 cat. | 1 stone | 2 stones | 1 stone | 2 stones. | 1 stone. | 2 stones. | fuel | bypass | 2101-1107010 | |

| 135 | 135 | 170 | 190 | 45 | 60 | 180 | 70 | 40 | 40 | 2101-1107010-02 |

| 130 | 130 | 150 | 190 | 50 | 45 | 170 | 170 | 50 | 40 | 2101-1107010-03; |

| 2101-1107010-30 130 | 130 | 150 | 200 | 45 | 60 | 170 | 70 | 40 | 40 | 2103-1107010 |

| 135 | 140 | 170 | 190 | 50 | 80 | 170 | 70 | 40 | 40 | 2103-1107010-01; |

| 2106-1107010 130 | 140 | 150 | 150 | 45 | 60 | 170 | 70 | 40 | 40 | 2105-1107010-10 |

| 109 | 162 | 170 | 170 | 50 | 60 | 170 | 70 | 40 | 40 | 2105-110711010; |

| 2105-1107010; 2105-1107010-20 107 | 162 | 170 | 170 | 50 | 60 | 170 | 70 | 40 | 40 | 21053 |

| 100 | 115 | 150 | 135 | 35–45 | 50 | 140 | 150 | 45 | 40 | 2107-1107010; |

| 2107-1107010-20 112 | 150 | 150 | 150 | 50 | 60 | 170 | 70 | 40 | 40 | 2107-1107010-10 |

| 125 | 150 | 190 | 150 | 50 | 60 | 170 | 70 | 40 | 40 | 2108-1107010 |

| 97,5 | 97,5 | 165 | 125 | 42 ± 3 | 50 | 170 | 120 | 30/40 | — | The reasons for dismantling an assembly can be different: replacement with a product of a different modification, repair, cleaning. In any case, remove the air filter first. To replace, you will need the following tools: |

Setting idle speed

The process involves two screws that set the quantity and quality of the mixture. For high-quality settings, having a gas analyzer will not hurt. Before adjusting the carburetor on a VAZ 2106, you need to know about the restrictive plastic bushings that are pressed onto the adjusting screws. These plugs do not allow you to violate the factory settings. If this factor prevents you from setting XX normally, then you should break them out with a slotted screwdriver.

Idle speed control technology:

- With the air damper open, set the crankshaft speed screw to 800-900 rpm.

- Rotate the quality screw to set the maximum engine speed.

- Using the quantity screw, set the speed on the tachometer to 950-1030 rpm.

- Use the quality screw to set the maximum speed again.

- Repeat these operations until the speed of 950-1030 rpm does not coincide with the maximum speed set using the quality screw.

- After the moment of coincidence, return the quality screw to the position where the engine speed was 800-900 rpm.

If you have a gas analyzer, use a quality screw to achieve a CO concentration in the exhaust gases of 0.5-1.2%. The final position of the screws must be secured with plastic sealant to prevent spontaneous unscrewing.

Adjusting the idle speed on a VAZ 2106

First you need to prepare the car. We warm up the engine to a temperature of 900 degrees. We ensure that the engine operates stably at idle speed.

Let's watch a video in which everything is shown in an accessible and understandable way:

The text instructions are as follows:

- Using the quantity screw, we achieve a crankshaft speed of 820 to 900 rpm.

- Using the quality screw, we bring the unit into stable and uniform operation. Then, by tightening the screw, we destabilize the operation of the motor and unscrew it again to restore it. Our task is thus to achieve the most stable engine operation with the leanest possible mixture.

- Using the quantity screw, we again bring the speed to the desired value.

- It is best to carry out the operation two or three times.

Adjusting the rods

An equally important stage in the process of adjusting the “six” carburetor is performed through the transitions:

- Remove the air filter and its housing.

- Measure the distance between the central points of the tips, it should be 80 mm .

- To change the length of the rod, release the tip with a screwdriver and unscrew the lock nut with an “8” wrench, and then perform the adjustment by rotating the tip.

- Tighten the fasteners and install the rod in its original place, start the engine and press the gas pedal all the way. If the throttle does not open completely, the damper has a travel reserve.

When asked how to further adjust the carburetor on a VAZ 2106, experts recommend performing a few more simple steps:

- Remove the end of the longitudinal linkage and unscrew the locknut.

- Reduce the length of the rod, secure it and again check the degree of opening of the damper by pressing the gas pedal to the floor. The damper must be completely closed.

- If it is necessary to increase the rod length, you need to loosen the throttle cable.

Operating principle and maintenance

One of the main adjustments of the Ozone carburetor is the adjustment of the fuel level in the float chamber. The level affects both the economic performance of the engine and the acceleration dynamics, starting and operation at high speeds. If the fuel level in the float chamber is insufficient, the engine will run on a lean mixture, which will affect the stability of speed in transient conditions, and the engine will not be able to develop its rated power, and there will not be enough fuel.

To determine the correct level in the float chamber, it is necessary to remove the air filter with housing and the top carburetor cover. The clearance gap between the float and the plane of the carburetor cover gasket should be no more than 6.5 mm. The gap is adjusted by bending the float tongue (A), which during measurement should barely touch the needle valve ball.

In this case, it is necessary to check the tightness of the valve. To do this, it is enough to create a vacuum in the tube placed on the fitting, either with your mouth or with a bulb. If the tightness of the valve seat is broken, the valve needle itself must be replaced along with the seat. They are sold both as a repair kit and separately. If the valve tightness is good, all that remains is to check the free movement of the float. It must be at least 8.5 mm.

Having mastered the basic methods of adjusting the VAZ 2106 carburetor and its design, you can achieve optimal fuel consumption, satisfactory acceleration dynamics and optimal engine power. And when working with Ozone carburetors, it is enough to study the diagram and structure of the unit, then adjusting, cleaning and replacing jets, gaskets and diaphragms will not be particularly difficult. Good luck to everyone on the roads, stable engine operation and high-quality fuel!

What do we have after proper adjustment of the carburetor unit of the “six”?

Checking the adjustments of the fuel mixture preparation unit is the same important maintenance step as monitoring the condition of the car battery . An integrated approach to setting up the carburetor guarantees not only a comfortable mode of movement, but also a lot of useful points:

- An increase in power and a confident increase in speed.

- No failures in the operation of the internal combustion engine in the low and medium speed sector.

- Improved dynamic characteristics - the car picks up speed faster and accelerates in a short time.

- Optimal engine response, which is expressed in the responsiveness of the gas pedal.

The listed qualities make it possible to effectively use the combustible mixture, which is necessary both in urban traffic jams and on country roads. Therefore, proper adjustment of the carburetor unit will help the car gain speed in a timely manner and complete the planned maneuver.