Making a twist on a classic with your own hands

Hi all!

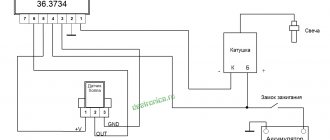

Today we will tell you how to make a twist on the classics yourself. To begin with, we cut the limiters on the levers and on the steering gear. On the levers:

On the steering gear:

To make the required negative camber, there will be few standard bolts; to replace the standard bolts, you will need to buy bolts from a VAZ 2108 generator (4 pcs), use washers to make negative camber so that it looks something like this:

Let's move on to the bipod. The goal is simple, move the steering tip closer to the eversion axis (the upper and lower ball joints facing each other are the rotation axis). And don’t be afraid to weld, the bipod is made of such metal that it won’t fall apart, and the welding site will never fall apart if it’s just welded, most likely all the levers will bend and the spars will go away before the bipod bursts.

Approximate cutting location:

It should look something like this:

Most likely, when you weld it, it will rest against the brake caliper. This can be treated by moving the caliper forward and installing Niva brake hoses. When designing a bipod, try to get as close to the rotation axis as possible. If you look from behind (in the direction of travel of the car) at the steering knuckle, then the location of the attachment to the steering rod should be at the same level. BUT do not get too close, otherwise the steering tip may rest against the lever when turning.

Preparing and removing the caliper . We take the steering knuckle with the hub and bracket that holds the brake caliper. Pay attention to the bend (inward), and simply swap them from left to right. This will give a centimeter of offset without unnecessary “crail”. You can, of course, get perverted and order from a turner... The next step is to remove the edge so that the hub fits inside (for those who didn’t understand, simply make a larger hole, remove the edge of the smaller circle and make it one large one)

In this case, the hub will remain in its place and will not move anywhere; its tapered bearings will fit onto the cone. We take long bolts and washers and glue everything together.

We put on the brake disc and check that everything slows down. We take spacers (regular VAZ ones) in the amount of 8 pieces (4 per side), they are just about 0.5 cm, which will give the brake disc itself a offset.

Taxiing. We make long tie rods. This is the standard tip (this difference in size is the inversion). The bend is very important, it helps to avoid contact with other parts, and most importantly with the side members.

The weakest point in the design! At this point, the bipod gets twisted and tied into a knot even after lightly touching the curb. Be careful.

We install extended hoses from Niva or Gazelle.

After moving the top ball, it started to hit the body, but then a grinder came to our aid, we cut out everything that was in the way.

As a result, you should end up with something like this:

Source

Collective farming with a twist!

Compromise between price and angle. Let's start in order, the stock inversion rests on the limiters on the lower arm, which means we completely remove this limiter, the inversion is quite a bit, but it increases. Now we don’t have enough rack travel, which means we need to increase this travel with spacers like this.

As you can see, one washer (placed on the right (driver’s) side) increases the stroke by 5mm and one spacer (placed on the passenger’s side) increases the rack stroke by 13mm and increases the length of the tie rod! It works like this:

Next you need to move the mounting

steering tip outwards, you can either digest it yourself (as I did) or we order ready-made ones, there are plenty of them on sale)) The picture below perfectly explains why this is necessary:

In practice it looks something like this:

Next is the transfer of the steering rack axis. Why is this necessary: when shortening the bipod, the tie rods become at a very large angle, which leads to the rack biting, that is, the alignment of a straight line: tie rod ball - steering tip ball - lever ball. As soon as such a straight line is built, the rack is not able to turn the wheel back, therefore, the car will continue to drive with the steering wheel turned... There are two solutions:

Spacers with transfer of steering rods, but with such spacers the load on the rack increases. Transfer of the rack, steering rack fastenings are sawed off and moved forward 20mm

Well, then the tension rods (when turning inward) and the langeron (when turning outward) interfere with turning the wheel; this can be solved by lengthening the lower arm, that is, we increase the track, and, as it were, separate the wheels from the tension rods. The lever is simply cut in half and a 30mm spacer is welded in; you can also replace the levers with longer ones, from 34 mm

and install wheels with a good offset.

Collective farm kit:

Well, something like this, the turn out turned out to be very peasant. It was limited to the fact that the steering tips rested on the lower arms, we will solve with tuned tips.

Well friends, this is the end of the first article. Of course, larger eversion angles can be achieved in other ways, this is just a general idea. Which option to use is up to you! You can see other information about turning in other Nissan Silvia projects.

Thank you for being with us!

Friends,

Subscribe !

It is known that the angle of rotation of the wheels (ejection) on VAZ classic cars can be increased by simply raising money and purchasing a system like wisefab. After a difficult installation, you can increase the rotation angle to 65 degrees. Similar devices are sold for other cars.

Master car enthusiasts have implemented many of their own methods of increasing the turning angle on VAZ cars, ironically calling such methods custom tuning or “ collective farm tuning”

“However, such mechanisms are not inferior in strength and ease of installation to those purchased in a store.

Making a twist on the classics

How to build a cramp | Useful information No comments

Hi all! Today we’ll look at ways to increase the eversion angle on the classics.

And so let's get straight to the point. There are a great many ways to increase the steering angle of the wheels, but there are still two main ones. A system like Wisefab and our favorite style “collective farm tuning” or as the clear guys call it custom tuning. With Wisefab everything is more or less clear, I saved some money, bought it, fitted it, and now the inversion is already 65+ degrees. More details about Wisefab are discussed here: Eversion on a Nissan Silvia.

Let's move on to our favorite topic: do-it-yourself tuning or custom tuning of vases.

To begin with, we cut the limiters on the levers and on the steering gear. On the levers:

On the steering gear:

Go ahead. To create the required negative camber, there were not enough standard bolts; to replace them, buy bolts from a VAZ 2108 generator, 4 pcs., and used washers to make the negative camber. It looks something like this:

The goal is to move the steering tip closer to the eversion axis (the upper and lower ball joints facing each other are the steering axis). And don’t be afraid to weld, the bipod is made of such metal that it will not fall apart, and the welding site will NEVER fall apart if it’s simply welded, most likely all the levers will bend (checked) and the spars will go away before the bipod bursts.

Approximate cutting location:

What happened and what should happen:

Most likely, having welded it, it will rest against the brake caliper. Treatment: the caliper is moved forward, we install Niva brake hoses. When designing the bipod, try to get as close to the rotation axis as possible. This is if you look at the steering knuckle from behind (in the direction of travel of the car), then the location of the attachment to the steering rod should be at the same level. BUT! DO NOT CLOSE TOO MUCH OR THE STEERING END MAY RESTRAINT THE LEVER WHEN TURNING OUT.

Preparing and removing the caliper (to install a shortened bipod).

A steering knuckle with a hub and a bracket that holds the brake caliper. Pay attention to the bend (inward), take it and simply turn it over (or rather, swap them from left to right). This will give you a centimeter of offset without any extra edge. You can, of course, be perverted and order from a turner...

Replacing the steering rack

When cornering at high speed, it is very important to have an instant transfer of the forces of your hands to the wheels. As they say, the efficiency of your actions should be maximum

But with a standard rack you won’t be able to do this quickly. As a result, the maneuver will fail and the car, at best, will roll off the track. This problem is especially relevant in domestic cars with the steering wheel turned all the way to 4 turns. Standing up against a stock foreign car with 3 and 2.4 turns is useless. We install the rail at 2.9 turns and have some changes for the better. Minus the turnover and you can already count on results. Advantages of replacing the rack:

- Acute management;

- Reducing the number of revolutions;

- Smooth and easy rotation of the steering wheel;

Important! In drifting, the most important element is control. All components must be powerful and reliable, there should be no backlash, wear or metal fatigue

Therefore, the mechanisms must be new, the rubber bands and consumables must be changed, and the wheel alignment must be adjusted. A sports rack for VAZ owners will cost about 9-10 thousand rubles, but the effect of its work is much higher. Having changed the rack, we move on to turning the wheels and here you can already practice your engineering abilities. If there are the makings for this, of course. But you can go the beaten path and order sports levers and knuckles.

Turning out wheels for drifting on a classic with your own hands - work process

The sequence of work to increase the angle of rotation of the wheels of VAZ cars is as follows. It is not difficult to perform it, understanding why each action is performed.

The eversion axis is a straight line passing through the ball joints. The steering tip must be moved to this axis as much as possible.

To do this, carry out welding work on the bipod. You should know that the bipod is made of good metal that can be welded using any welding method.

When marking the bipod for trimming, it is necessary to align the rotation axis with the steering knuckle as much as possible, while the attachment point on the rod should be at the same level. Try to create a gap between the steering tip and the bipod lever at maximum eversion.

In the event that the shortened bipod that has been manufactured does come into contact with the brake caliper, it can always be moved forward.

Drift Suspension Features

The main feature of drift suspension is its rigidity. All elements of the system must be sufficiently stable due to the fact that the load on the car during drifts is very large.

It is best to strengthen the body itself with spacers. Springs should also be chosen stiff. These can be replaced with coilover sets. They represent a single mechanism of shock absorber and spring, which can be adjusted both in height and stiffness.

An increase in the skid angle can be achieved by changing the steering system

It is very important to increase the wheel turnout. It is also worth widening the tracks

In this case, the front track should be the same as the rear, or slightly smaller. Experts recommend reducing the Ackermann angle to zero. This will increase the stability of the vehicle when cornering.

Reviews (0)

The A-arm is installed in place of the stock upper and transverse reaction rods.

Advantages over the standard suspension system:

The A-shaped arm is installed instead of the longitudinal reaction rods, the connection to the axle is carried out through the upper ball joint 2101 (not included in the kit), the ball joint mounting bracket is welded to the rear axle housing.

To install the lever, you need to weld a bracket for fastening the ball joint onto the housing of the rear axle stocking gearbox!

A-shaped lever, welded bracket for attaching the lever to the rear axle stocking. Applicability:

Almost every owner of a Niva SUV periodically has a desire to test its functional potential in severe off-road conditions, for which it undergoes full-scale tuning. However, many car owners, behind external styling and equipping with all kinds of accessories, often forget about upgrading the body component. In particular, in order not to bend the rear axle under difficult operating conditions, it must be strengthened, for which it is necessary to integrate an A-shaped lever on the Niva, which can, in principle, be made on its own.

Turning wheels with your own hands on a VAZ classic photo

The easiest way is to swap the brake caliper mounting brackets from the left side to the right. This way you can save a few centimeters of distance and leave the turner alone.

To install the hub, remove the edge, otherwise the hub will not fit into its seat. The tapered hub bearings remain in place, a cone sits on them and is secured with long bolts and washers.

All that remains is to install new extended brake hoses; for this it is best to simply buy Nivov brake hoses. The GAZelle has even longer brake hoses; they can also be used on the VAZ.

Buy regular spacers for the VAZ, you need 4 of them on each side - 8 pieces in total. Spacers need to be used to move the brake disc. Removal must be done, since the caliper is shifted by a centimeter by moving the brackets and installing spacer washers.

All that remains is to fit the spacers in place, inside the brake disc, and secure the spacers. The total height of the spacers, each equal to 5 mm, should compensate for the distance of the caliper displacement.

It is possible that the new mechanism will touch the internal parts of the body. They can be cut with a grinder, as they will not damage the outer surface of the body. Most often, body trimming cannot be avoided in the area of the upper ball joint.

Testing the operation of the entire mechanism may end in deformation of the overcooked bipod, so try to carry out “hard” tests, for example, do not go around the curb at full angle of rotation. A durable bipod is a guarantee of safety. Technical modification of the car is tuning the VAZ 2108 on your own.

Since you are reading this article, it means that you have finally decided to strengthen the body on your VAZ 2101. It doesn’t matter what prompted you to undertake this responsible and time-consuming process: deformation from an impact, car tuning, or just your hands itching, one thing is for sure - the price of repairs will pleasantly surprise you if you do all the repairs yourself.

Lada 2107 VAZmezdie Altezy › Logbook › How to prepare the suspension of a Zhiguli for winter drifting?

I decided to reveal a topic that is not described in detail anywhere - installation and adjustment of Clubturbo sport levers (in common parlance “red levers”). As when installing any other levers on a classic, you will need a complete set of new lever fasteners, namely:

1. Lower arm axle - 2 pcs.2. Upper arm axle - 2 pcs.3. Nut m12x1.25 - 4 pcs.4. Self-locking nut m14x1.25 - 10 pcs.5. Nut m8x1.25 - 16 pcs.6. Bolt m8x1.25x25 - 12 pcs.7. Washer 15.0x40.0x2.08. Washer 17.0x32.0x2.5 - 4 pcs.9. Washer 14.0x45.0x2.0 - 4 pcs. 10. Grover m12 - 4 pcs. 11. Grover 8.2x2.0 - 16 pcs.

Also, in addition to the levers and fasteners themselves, you will need the following parts:

12. Ball joints - 4 pcs. (strictly the top ones!) 13. Lower shock absorber mount - 2 pcs. 14. Copper washer d10 - 4 pcs. 15. Bungee bolt m10 - 2 pcs. 16. Niva brake pipes - 2 pcs.

17. Bolt m10x1.25x66 - 4 pcs. 18. Bolt m10x1.25x32 - 4 pcs. 19. Caliper locking plate - 4 pcs. 20. Extended Clubturbo bends (needs modification using an angle grinder and welding)21. Steering bipod (can be used; requires modification using an angle grinder and welding)

Brakes remain standard, but a 14″ system can be installed if desired.

So, when everything is purchased, you can start disassembling/assembling. I won’t write how to disassemble the suspension on a Zhiguli; a lot has already been written about this on the Internet, except that not everything can be unscrewed. I advise you not to waste time on WD-40, burners, brushes and other devices - immediately take a grinder and saw off what won’t come off!

Regarding the assembly, there are several points to pay attention to:

1. The first and main thing is the correct installation of the upper arms. They should be placed with the bent side forward and the protrusion on the platform under the ball joint facing down. Many people, due to inexperience, incorrectly install ball joints in the arms, and then lose their wheels on the road or cannot adjust the wheel alignment. The correct option involves installing ball arms at the bottom and nothing else.

2. It should also be remembered that the fastenings of the levers to the body should be tightened with the car lowered on the wheels, otherwise the silent blocks will be in the wrong position, similarly with shock absorbers.

3. Before assembling the brake hoses, copper washers must be heated well with a torch and cooled sharply, then they will become soft and there will be less chance of leakage from under the bungee bolt.

4. If you need a stabilizer, then it must be shortened by approximately 7-10 cm so that its end is opposite the mount on the lower arm (with a margin of about 5 cm) and screwed to it using the original rubber band and a 45 mm muffler clamp. or using a proprietary stabilizer mount from Clubturbo.

After assembling the suspension, it is necessary to adjust the wheel alignment. Optimal values for “red levers”: - camber 1.5° - 2° - total toe 15′ - caster (longitudinal inclination of the king pin) 6° - 8°

As an addition, I will describe my version of modifying the steering system. The bipod is shortened longitudinally, but practically not shortened transversely. The steering arms are shortened by 10 cm. This configuration allows for a sharper steering response, greater turnout and, unlike the option with straight bipods, does not have a zero Ackermann angle at maximum turnout (the car does not tend to fall into a corner and has the ability to accelerate in a skid ). Also, at maximum eversion, the steering rods do not break, since they rest against the lever, which almost completely eliminates the wheel swinging in different directions.

ps In the title photo are wheels with an offset of +50 and spacers of 15 mm.

Information prepared by my mechanic barnybrown

Question answer

In response to all of the above, I personally have a reasonable question: what exactly prevented the designers from initially achieving maximum values of torsional rigidity* of the VAZ 2101 body?

Firstly, this is the mass of the car. That is, here is the principle of the “golden mean”: either we reduce the weight of the car or increase its strength. Of course, we can suggest using more modern materials as the amplifier material, for example, carbon and titanium, but here another pitfall awaits us - the price.

Secondly, safety. There is such a thing as active and passive safety, and so, the engine compartment of a car plays an important role in passive safety. It should be as less rigid as possible so that its deformation has time to absorb the main force of the impact.

So designers have to look for compromises and come up with ideal balances for calculating torsional stiffness indicators.

Torsional stiffness* is the ratio of newton meters to degrees (Nm/deg.). The more force we apply (newton - meter), the greater the angle (degree) through which the car body is deformed. For the VAZ 2101 this value is 7300 Nm/deg, and after we strengthen the body of the VAZ with our own hands, this figure will increase by about 20-25%.

Two attempts to make three: tuning VAZ-2103

Classics for drifting, classics for rallying - that's all, you say, we've already seen it. Yes, we note that we didn’t treat you like this, but we haven’t served “troika” in this sauce yet.

In reality, creating even such a “standard” project turned out to be more difficult than composing a simple poem like the one above. The mistakes, however, also turned out to be “typical”, but that’s what tuning is famous for: everyone who works on their project themselves often walks on a rake that just fell after the previous enthusiast.

Concept

The beginning of the project dates back to November 2014, when the VAZ-2103 found a new owner in the person of Oleg. There were quite “classic” plans for the “classic” car: buy it in order to inexpensively understand what drifting is and whether it’s worth pursuing it further. Immediately after the purchase, it was slightly modified for targeted trips: steering bipods shortened by 30 mm were installed to increase the wheel turnout and the differential was welded, and a basic set of a “bucket” and a sports steering wheel appeared in the cabin. And - let's go.

From December to March, the “troika” was mercilessly exploited in the field of studying the basics of controlled skidding on all possible routes near Moscow, and by the end of winter it turned into a hill of crumpled metal. But Oleg understood that winter skiing is not only interesting, but also quite affordable. Therefore, having assessed the condition of the load-bearing body elements of his Lada, such as the floor and side members, he was convinced that they were “still usable”, and decided not to scrap the car, but to restore it to continue amateur competitions.

FakeHeader

Comments 15

This beauty is also in the plans

As I know from personal experience... the icon is placed to increase the suspension travel (in the field)! I also know that you won’t turn your heels with him! You'll be tortured to change the ball joints! and look what happens if this ball screws up! a bug for the highway and not for off-road!

I read from one guy who races in rallies. So he installed such a lever and wrote that it was of no use. I can’t find it so I can send you the link.

I rode this for two years - put it on, everything is on fire) only positive emotions)

(281/366) On September 9, serial production of the penny began

The first “Kopeyka” was produced at the new plant on April 19, 1970, and today mass production of this legendary and iconic Pepelats began, which gave rise to a whole series of cars, the so-called “classics”, produced in Tolyatti until 2012. Yes, the development is not entirely ours, all units and production technologies were purchased from Fiat, but in the process of localizing the Fiat 124 model to our roads and realities, the original has changed a lot and has become more reliable. It seems that it is believed that VAZ was never able to assemble anything more reliable than Kopeika. Well, and a special congratulations to the entire movement of the Battle Classics, happy holiday!

Tuning and strengthening the body of the VAZ 2101

There is a large amount of body tuning that can be done on the VAZ 2101; the choice is based on only two factors: the further purpose of the car and the thickness of its owner’s wallet.

We will not delve into all the intricacies of the technological process, since when strengthening the body, a classic VAZ requires only imaginative thinking and hands growing from one place, we will discuss only some of the main, so to speak, basic options.

Front suspension strut

The universal front strut brace is designed to maintain the initial positions of the front suspension points during dynamic vehicle movement.

Strengthens the mudguard struts, which deform over time when the front suspension breaks down, thereby preventing and stopping the extrusion of the side members that has already begun, and increases the lateral rigidity of the body.

Installation of the spacer does not require any additional work; it is installed in the standard holes of the horizontal upper suspension mounts. At the same time, you additionally receive from 10 to 25% of the stiffness of the front glasses.

When tuning the body of a VAZ 2101, with the help of struts of this type (including in the rear), your car significantly reduces the risk of lateral skidding, which is very important when sliding sideways.

“Serious” guys have “richer” struts (see photo)

Rear suspension extension

Next we will talk about improving the rear suspension of the car, namely the Parnar rod.

As you remember, the purpose of this element is to prevent the rear axle from moving in a transverse direction to the body, while at the same time, without limiting its vertical movement in any way, it is a transverse rod fixed at one end to the body and the other to the bridge.

It is precisely from these lateral forces that the so-called “house” of the Parnar thrust is gradually deformed, which we will strengthen by welding a patch of 3 mm sheet iron.

Also, when actually performing body tuning on a VAZ 2101, the Watt mechanism can be considered an alternative to Parnar traction.

As can be seen in the photo, regardless of the suspension travel, the suspension with the Watt mechanism installed does not, unlike the Parnar rod, “pull” towards the rear suspension axle.

I would also like to offer another option for tuning the rear suspension of the VAZ 2101, namely installing an anti-roll bar and an A-arm.

This “upgrade” will allow us to reduce the car’s roll when cornering and make the rear suspension more rigid and predictable.

When installing a stabilizer bar, you do not need to have any special skills; the work is carried out in two stages:

It is also advisable to install an additional couple of longitudinal rods, for which we will need to make additional fastenings to the body and axle for each rod.

Setup and installation

The camber of the front wheels must be made negative. The ideal parameter is considered to be 2.8 degrees of negative camber. This is done to more accurately control the car in a skid. It is best to reduce the camber and toe of the rear wheels to zero.

Caster is the angle between the steering axis of the wheel and the vertical in a side view

If it is enlarged, the car is easier to control, which is quite important at high speeds. If the caster is too high, the steering becomes heavier

This is due to the fact that the negative camber of the wheel that is external when turning the car increases. To begin with, you should use 1-2 degrees to normal.

In order to drift, you need to take into account all the features of setting up the car's suspension, choose the vehicle itself and learn how to perform stunts correctly.

Only after this can you achieve truly high results in this type of driving and gain a certain status among other motorists

It is important to remember that any little thing in this matter can significantly affect the final result, so you should not ignore the advice of specialists

Steering knuckles NIVA

Installation of steering knuckle levers from Shnivy

I think many people know about the “sluggishness” of the long-wheelbase Niva 2131 (not M). At first it didn’t seem so problematic to me, but the more I drove, the more I realized: “But the car is not as maneuverable as I would like!” Then, quite by accident, I found information on the steering knuckle levers

Pulleys: they are shorter and from a control point of view, they are much better suited to the 31st Niva (unlike the standard levers 21213). This year I decided to install them, combining them with a suspension upgrade. For installing Shnivy levers that are 2.5 cm shorter than the original ones

you need to buy two right side tie rods (the left one is even longer) from the same Shniva, or, saving money, take only the long parts of the rods (the short ones are no different):

Comparison of long parts

You can leave the original rods, but in this case there are few threads of the screwed-in rods left in the adjusting couplings:

This is what it looks like assembled

As a result, we get a turning radius reduced by 2 meters.

Impressions from installing steering knuckles for the Niva: 1) On the highway you have to steer less, the control has become a little sharper (it’s easier to avoid obstacles); 2) Leaving the garage ahead, I think everything is clear from the tracks:

3) Reversal is now no problem:

At the spring, turn 180 degrees (marked in yellow the tracks where they previously ran into a cliff)

Uncoupling the front axle and replacing the knuckles in NIVU

Over the past few days, my hands have grown accustomed to the welding machine and grinder. Although when installing the engine I made some clever brackets that would allow me to mount the standard Niv axle, I still decided to untie it. Having studied the market of ideas and ready-made solutions, I decided to make the brackets for fastening to the beam myself (otherwise ready-made ones from shnivy for 1200 apiece are too fat). I cut everything out of 8 mm steel sheet, now I have learned the true zen of figure cutting with a grinder. I welded a jet rod cut in half to one of the sides, it turned out something like this

on the car it now looks like this:

Since the fists with Iveco bearings arrived the day before, I decided to change them too. And once we take everything apart, we can at the same time change the silent blocks in the upper and lower control arms, they have been asking for this for a long time. Anyone who has encountered this operation knows that in 90% of cases it is almost impossible to pull out the axis of the lower arms. So we boldly buy a new one, and after trying to turn the old one, we cut it off with a grinder and knock out the rest with a sledgehammer to such and such a mother. If we can’t knock it out, then we drill it out (this is very long and labor-intensive). My neighbor even had a device for drilling it. To avoid the hassle of knocking out old silent blocks and hammering in new ones, I assembled my press in the evening. I used what was lying around in the garage, under the fence, and God knows where else. It didn't seem to turn out bad

True, then it had to be modernized a little. I initially made the table on which the part is placed from the 50th corner (in the photo), but it was pushed through almost immediately, and the M10 bolts with which it was secured were cut off. The table is now made from 16 gauge, as is the entire press. I think the assembly process is already clear to everyone, so I won’t describe it.

Regrinding the steering knuckle for the Iveco NIVA bearing

regrinding the steering knuckle for the Iveco bearing, the bearing can also be used 1. SKF BTH1024C, VKBA3551 2. FIAT 93 82 4579 3. HK 90/83 4. RUVILLE 4013 5. TIMKEN K 80758 6. OPTIMAL 681 923 7. MAGNETI MARELLI KKR1 122 8. KYK BTH 1024 9. SNR R140.13 10 RBF PN 70028 11 NK 752341

regrinding the steering knuckle for Iveco bearings

regrinding the steering knuckle for Iveco bearings

Set of reinforced, balanced axle shafts NIVA

https://www.drive2.ru/l/3988935/, https://www.drive2.ru/l/8278081/, https://www.drive2.ru/l/3523536/

Wheel alignment adjustment in NIVA-VAZ-2121-21213-21214-2131

After repairing the suspension and replacing numerous components of the VAZ-2121, the time has come to adjust the wheel alignment

Rating 0.00 [0 Vote(s)]

Lada 2107 Project 3.0 › Logbook › About the inversion. Levers. Varieties of eversion. Drift. 36

Hello everyone, in this post I would like to express my opinion about different eversion bars as briefly as possible. So, there are many manufacturers that produce levers, such as: Club turboTurbo temaStinger sportST auto

Well, these are the largest of the manufacturers, I’m not talking about fakes, analogues, etc. And I’m not talking about separately upper arms, lower arms, etc.

Well, then let's start with the most common and, as many consider, the best levers! Club turbo!

The next most popular levers are Turbo Tema!

The turbo theme has varieties of drift levers, well, the turbo club also has them, but I won’t talk about them, I’m talking about the most popular ones! What can I say about the green ones, they’re not even bad levers. Minimum camber is 2 degrees, castor is 8 degrees. I really liked the quality of workmanship, good welded seams, neat bends, etc. But many people say that they bend like a full name. This is not true, all levers bend equally! Absolutely the same as the turbo club if you go to the curb!

I’ll say about the red levers that they don’t even look very good. Of course, they will have less inversion than on green ones, and this is a simpler option, since green ones are supposedly wild.

Now Stinger Sport

I personally don’t trust Stinger levers at all, as there have been situations with their product. In the photo these are not drift levers, but just sports, for castor, camber, well, you understand. So I won’t praise or describe them too much.

All I can say about this is that it’s the same as the turbo club, turbo theme, etc. It’s just a different color and may have different parameters, such as Castor, camber, Ackermann. There have been a lot of negative reviews about them lately, like they cheat people, don’t send levers, and people wait for months!

The conclusion is: Club turbos are not bad, but expensive. Green turbo theme is not expensive and very good for drifting! Stinger... I don’t even want to write St., everything is clear too.

The only difference between the green TT and the blue CT is that on the green it is a little more difficult to turn the steering wheel and the minimum camber values. Everything else is the same, the completeness is the same. But the price is another matter. Blue ones cost 9000+ and green ones cost 6000, so think for yourself,

My choice is the green turbo theme! They performed very well!