All about silent blocks: description and varieties

The function of the silent block is to connect the rear suspension beam and the car body.

The secondary function is to dampen oscillations and vibrations during movement. The design of this unit element is quite simple. It consists of only two components: a bushing and a rubber gasket. Bushings are divided into external and internal. The external ones are made of plastic, the internal ones are made of metal. The rubber gasket located in the empty space between the bushings does not completely fill it. Rubberized areas alternate with “voids,” which allows this element of the assembly to twist more easily if necessary. The design of the silent block simultaneously performs two options: it resists loads on the beam in motion, and also does not allow the rubber gasket to tear.

While the vehicle is moving, the part is exposed to a number of external influences:

- environmental influences: rain, wind, hail and snow;

- the influence of shaking, impact loads from driving on uneven road surfaces;

- the influence of the torsional load that occurs when the rear beam moves.

These processes are considered to be natural, so the wear factor from them is included in the design of the silent block by design engineers. Under normal conditions, with measured driving on a high-quality road, the connecting element of the suspension will easily cover up to 100 thousand km. In reality, the situation described above happens extremely rarely. More often, the silent block is influenced by a number of external factors:

- incorrect installation of the silent block: non-compliance with technology, etc.;

- driving on a sand-salt road in winter;

- regular driving on bad roads with potholes, potholes, etc.

The less often you expose your vehicle to movement in the situations described above, the longer the silent block and the suspension as a whole will function properly. The silent block of the Renault Logan rear beam is a completely wear-resistant part if you provide it with at least the least gentle conditions.

What is a silent block

A silent block is a special vibration isolator made of two metal bushings inserted into each other and an elastomeric (rubber) insert between them. The main feature of this vibration isolator is the strong permanent connection between the elastomer and the metal obtained during the vulcanization process, due to which there is practically no friction force between them. The block is designed to dampen radial, torsional and axial vibrations. In other words, the silent block connects the car’s suspension parts, in particular the suspension arm and the body, and, due to the rubber insert, reduces vibrations between them.

This part is present on both the front and rear suspension. In the first case, the front arm silent block connects the car body and the front suspension arm, and in the second case, the beam arm with the body. The degree of vibration damping is determined by the quality of the elastomer: elastomers based on natural rubber dampen vibrations best.

About the types of silent blocks and their applicability

These parts exist in the form of rubber and rubber-metal products. The first type can be seen as the lower mounting elements of the rear chassis shock absorbers, and the second type can be seen in other structural suspension components.

Silent blocks have become indispensable components in the suspension of any modern car. The Renault Logan model does not fall out of this list. Its chassis elements are mostly fixed to body and other components using these rubber-metal products.

The suspension points of the subframe to the body are also not devoid of these parts, which helps to reduce vibrations and improves the behavior of the Renault Logan car during maneuvering.

Signs of wear on silent blocks: diagnosis and inspection

Even experienced drivers cannot always determine the true cause of their car's malfunction. For high-quality diagnostics, you will need both a visual inspection and identification of extraneous noise in the car. Use both methods for a thorough diagnosis. Let's look at the main reasons that indicate a silent block failure:

- Complete or partial destruction of beam fasteners. Pay attention to the strength and stability of the structure on which the beam rests. Its complete separation is fraught not only with more complex repairs, but also with the likelihood of an emergency on the road. If you notice a beam coming off while your car is stationary, consider yourself lucky.

- Delamination, extrusion or loss of tightness in the area of the rubber layer. Most often, this situation arises during long-term operation of the silent block, namely, after 60-80 thousand kilometers. When the rubber gasket delaminates, metallic knocking sounds, noise in the area of the rear axle of the suspension, and other sounds that accompany the shock load on the suspension are typical. You can also determine this stage of failure visually: evaluate the skew of the car on the road, its tilt in the front.

- Slight detachment of the rubber gasket from the metal or plastic bushing. It is not difficult to notice this even with an untrained eye. When driving, this is manifested by a slight loss of controllability on turns, a slight but noticeable knocking and other sounds in the rear axle. It would be a good idea to inspect the car's wheels. Uneven tire wear is one of the signs that the hub is not working at full capacity. A slight tilt of the car in a standing position is noticeable.

- Partial destruction of the gasket without affecting the bushings. It’s not for nothing that we put this item at the end of the list. Often this microcrack or tear goes unnoticed until the bushing completely fails. It is very difficult to notice this externally. The only way is to regularly disassemble and inspect the silent block parts. However, the vast majority of drivers do not perform such operations.

Currently reading: Adjusting the clutch drive Renault Logan 1 |

New Logan Remember that the silent blocks of the Renault Logan rear suspension are another part of the car on which traffic safety directly depends. If its destruction has reached the stage described in paragraphs 1-2, it’s time to stop operating the vehicle for safety reasons. If you become a victim of circumstances while driving, call a tow truck.

If you inspect your car even infrequently, then problems of this kind cannot arise while driving. Fortunately, the silent block will notify you of failure in advance.

Diagnostics

Naturally, in order for the operation of a car to be safe, it is important to systematically check all its components, and the suspension is no exception. The normal “working” life of silent blocks in Renault-Logan does not exceed 100,000 km, but given the current state of the roads, this figure may be significantly lower.

Before making a replacement, it is important to diagnose the suspension. The main signs of worn silent blocks are such phenomena in the behavior of the machine as:

- management became sluggish;

- the car constantly pulls to the side, especially at high speed;

- When hitting bumps, “dull” impacts are heard.

Of course, the above symptoms may also appear in the event of breakdowns in other suspension components, but it would also be useful to inspect the silent blocks.

To fully diagnose the cause of the machine’s abnormal behavior, it is necessary to conduct a visual inspection. To do this, you can put the car in a “pit” or lift it with a lift to a service station. Having carefully examined each part and determined whether there are defects in them (cracks, scuffs, etc.), you can answer the question: do you need to replace the silent blocks with Renault Logan or not.

Step-by-step replacement of silent blocks on Renault Logan

A high-quality part is the key to reliable and durable operation of the entire suspension as a whole. To make a choice in favor of the best silent block, you should pay attention to two key points:

- brand of the silent block manufacturing company;

- its quality characteristics and reliability indicator.

It offers the highest quality products for rubber-metal structures on the market. Despite the fact that this brand positions itself as the best analogue of the original silent block, it significantly benefits in cost. Moreover, the Renault brand itself uses Lemforeder products when assembling new Logan cars.

To select the correct silent blocks, use the article numbers that are imprinted on the parts themselves. If for any reason this cannot be done, use the Renault original spare parts catalogue. Searching for spare parts by article number from the manufacturer is a good thing. You should use this method when purchasing both silent blocks and other car parts. Still, we recommend, if possible, replacing the rear silent blocks of Renault Logan with original parts.

The modern online and offline auto parts market is a huge field in which you can easily get lost and stumble upon low-quality or Chinese parts. We recommend using the following methods in your search:

- By given car make, year of manufacture and generation. This will, at a minimum, narrow the search to the required number of parts that match the brand.

- By VIN code - the universal vehicle body number.

- By article. If you know the article number of the required part, then we consider this method the most suitable. If you have an article, Internet scammers are almost completely deprived of the opportunity to deceive you.

As you can see, when selecting spare parts, it is important to know exactly what you are choosing among silent blocks for Renault Logan. Filters configured with the parameters from the list above will help you with this.

Working with a car suspension or its individual parts cannot be called difficult. We are confident that even an inexperienced car owner can handle this type of repair. Follow the steps described below, and replacing the silent block will be successful:

- Place the car over the inspection hole and raise the rear of the car using a jack. After securing the car in a raised position, remove both rear wheels.

- The next stage is cleaning the beam and suspension from dirt and dust. After the site is prepared, you can begin to dismantle the handbrake cables, pipe and power regulator. The holes formed as a result of dismantling must be plugged with something soft. Previously prepared rags are suitable for this.

- At this point, the preparatory work is considered completed. Remove the shock absorbers and all fasteners that hold the beam in place. Make sure you remember which torsion bar is left and which is right. It wouldn’t hurt to leave some kind of marking on them.

- Lubricate the seating groove, after which you can replace the silent block.

- Follow all steps in reverse order.

Currently reading: Replacing the front suspension arm of Renault Logan

As you can see, replacing the silent blocks of the Renault Logan rear beam is a terribly simple type of repair. Follow the tips given above and you will easily master the automotive business at the entry level. Moreover, each subsequent repair will be better than the previous one, so self-repair is a so-called investment in your future ownership of the vehicle.

In order to accurately select silent blocks for front levers and more, two aspects should be taken into account:

- quality indicators of the product;

- the reputation of the manufacturer and reviews of its products.

Among the most well-known and trusted manufacturers based on the production of rubber-metal products for chassis and capable of reaching the level of the original product in terms of quality is the well-known brand “Lemforder”. The range of spare parts of this company involves the use of some products by the Renault plant as original elements.

To correctly search for the required analogue, it is recommended to use the data of article numbers belonging to a specific manufacturing company. This code is mainly contained on the part itself. If for various reasons it is damaged and reading it is not possible, you should refer to the original Renault catalog, which displays the spare part numbers for the unit you are interested in.

What tools to prepare?

To ensure an effective process for replacing silent blocks in the front arms and in the rear beam structure, you should acquire the following tool kit:

- a car lift that allows you to carry out work with convenience;

- puller of a suitable type;

- a set of keys, the standard size of which varies from “10” to “32”;

- socket heads, in the “company” of which we involve an elongated wrench and a ratchet;

- sufficient amount of rags and appropriate lubricant;

- hammers of different sizes (depending on the situation).

It would be useful to involve an assistant, since some operations require their convenient implementation, acting in pairs.

Preparing for replacement: what you need

High-quality and measured preparation for repairs is already half the battle when it comes to replacing a component such as a silent block. If you personally participate in the replacement, you will need a number of tools and devices. We have compiled a complete set of necessary equipment for you below:

- The jack is the most important part of the repair, without which no work on the suspension can be done. Even if you install the car above the inspection hole, you will still have to raise the rear wheel row.

- Puller of the required type. Depends on the generation your car belongs to.

- A set of open-end or bolt wrenches ranging from 10 to 32.

- A driver, ratchet and sockets - this set will be needed to remove hard-to-reach fasteners.

- Use a rag to remove grease and released oils.

- A new bottle of lubricant, which is needed to moisten the unit after reassembly.

- Small impact hammer (may be needed to remove rusted fasteners).

If possible, call a friend for help. A number of replacement works, as you can later see for yourself, are more convenient and faster to do together. For example, this concerns the removal of a beam. You need to unscrew all the fasteners, and a friend will help keep the beam suspended. Of course, you can do it alone, but as they say, “one pair of hands is good, but two are better.”

Create an account or sign in to comment

The beam still does not fall and hangs on the jack and stop, which will be in the area of the brake disc. We place a stop in the area of the brake disc, I used 2 bricks.

One lies flat, the second on the edge. We take a jack and jack up the beam a little to slightly relieve the pressure of the bolt on the silent block.

Then we take it out and knock out the bolt. Everyone writes correctly that it is easier to change on the left, i.e.

And on the right it’s not difficult, everything is quite easy. The bolt has been removed, now we lower the jack on which our beam lies.

Let's start with the front suspension

In order for the replacement of the silent blocks of the front levers to be successful, there is no alternative to dismantling the front levers and then removing them.

The order of manipulations.

- Loosen the wheel rims and hang the car on a lift.

- We remove both wheels from the Renault Logan.

- Using suitable wrenches, unscrew the bolt that holds the ball pin of the lever support of the same name in the steering knuckle.

- The lever is fixed to the subframe of the Renault Logan using two bolts. Unscrew them and take the part out.

- To remove used elements, we use a puller, ensuring its correct position in relation to the lever (special grooves).

- We clean the lever cage, where we subsequently add lubricant.

- We install new products into our mounting clips.

Currently reading: Changing the oil in a manual transmission in a Renault Logan

When replacing the silent blocks of the front arms, we take into account the distance formed between the brackets for fixing the part being serviced. If this indicator is neglected, then subsequent installation of the lever in place will be impossible. To be on the safe side, it is recommended to carry out the required measurements in advance, which will allow you to determine the amount of tolerance to ensure the clearance.8. After making sure that the dimensions are correct, we mount the unit in place.

Replacement of the front control arm silent blocks is complete.

A successful “operation” presupposes that the person performing it has little experience in this work.

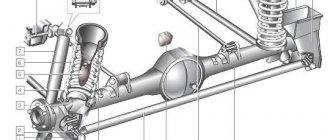

How to service the rear beam?

Replacing the silent blocks of the rear beam involves dismantling this assembly. If you happen to have a special tool, then this procedure can actually be performed without removing the beam, which is rare.

Let's get started.

So, replacing the silent blocks of the rear beam is not a complicated procedure, but it is a responsible one. Let's do it step by step.

- We hang the car using a lift and then remove the wheels of the stern axle.

- We loosen the fasteners of the rear shock absorbers on the Renault Logan and subsequently remove the springs.

- After removing the springs, we screw the bolts into the fastening points of the lower shock absorber brackets on the beam.

- This ensures a “suspended” position of the entire structure, allowing further actions to be carried out conveniently.

- We install a supporting element under the central sector of the beam and unscrew the bolts at the front points of its attachment.

- Using a tool, we remove each worn-out rear beam silent block from its mounting sockets.

- We clean the cavities and press new products until they are completely seated (a mini-press will do).

- We return the beam fixing elements to their places, but do not tighten them.

- We unscrew the shock absorber fasteners, set the beam level with the bottom, and then tighten the attachment points to the Renault Logan body. This is a necessary measure to ensure the correct location of a device such as the silent block of the rear beam in the socket of the beam placed under the load and to prevent premature wear of the new rubber-metal elements.

- We install the springs and secure the shock absorbers.

Replacement of the rear beam silent blocks has been completed.

Parts selection

An important factor influencing service life is the selection of replacement components. It is best to purchase them at large retail outlets. Be sure to ask the seller for product certificates. This will guarantee that the spare part is not “left-handed”. People often prefer to buy parts from the manufacturer, but in practice, contract parts turn out to be of no worse quality, but much cheaper. Polyurethane parts are considered to be of higher quality. Always buy a complete set of silent blocks. They should be replaced at the same time, even if only one of them is faulty.